2016 Volume 22 Issue 5 Pages 605-609

2016 Volume 22 Issue 5 Pages 605-609

In recent years, food consumption trends in Japan have been changed greatly by the “westernization of the meal”. In particular, the increased consumption of dairy products and decreased consumption of rice are remarkable. Thus, we investigated the possibility of producing a cheese-like food from rice milk. Rice milk was pasteurized, fermented by lactic acid bacteria (LAB), and coagulated with various coagulation agents. Several heating conditions were applied for pasteurization of the rice milk, and the most rapid and efficient condition was achieved when the rice milk was heated at 65°C for 30 min. After fermentation, the population of LAB and pH of the fermented rice milk were found to be similar to those of fermented dairy milk. Some samples went through a dehydration step before coagulation with gelatin, xanthan gum, or agar. The dehydrated samples containing gelatin were similar in breaking strength to standard dairy cheese, and thus were used in sensory evaluation. In the sensory test, the sample containing 2.5 wt% gelatin received the highest overall acceptance of 41.6%.

Food consumption trends in Japan have changed greatly during the last half century due to the “westernization of the meal”. The consumption of dairy products, particularly cheese consumption, has increased significantly, from 153,325 tons in 1990 to 295,333 tons in 2013. Currently, imported cheese constitutes approximately 80% of this consumptioni).

On the other hand, the consumption of rice was at its highest level in 1963 at 118.3 kg per person, but by 2010 had decreased to 59.5 kgii). This decrease can be attributed not only to the westernization of the meal but also to food diversification due to high economic growth, which has made it possible to import a variety of foods from overseas. The decrease in rice consumption has caused a variety of problems, such as an increased abandonment of cultivated land and a decreased food self-sufficiency rate. The Ministry of Agriculture, Forestry and Fisheries (MAFF) of Japan announced that the decrease in the food self-sufficiency rate is a serious problem, and Japan is obligated to ensure future reliability of the food supplyiii). Rice has been cultivated since ancient times as a staple food of Japan. Ideas for the development of new consumption styles for rice are essential for the effective promotion of Japan's paddy agriculture.

Here, we propose the development of “rice cheese”, a cheese-like food made from rice. Cheese-like food is defined as a product with properties similar to those of standard cheese, and which is made from raw materials other than fresh milk. Matsuoka et al. (1968) reported the manufacturing of a cheese-like product from soybean milk. After completion of the cheese-like product, aging was not successful due to the high moisture content. However, they succeeded in creating a product similar to Camembert cheese. Ofuya et al. (1991) reported that it is possible to produce a cheese-like curd (Akede cheese) with acceptable organoleptic properties from African yam bean (Sphenostylis stenocarpa) milk. Homma et al. (2009) reported that cheese-like foods can be produced from six types of nut milk (hemp nut, coconut, almond, pine nut, cashew nut and macadamia nut). Thus, cheese-like foods have been made from various milk alternatives.

The most important process in making cheese-like food is the lactic acid fermentation of the raw materials. There are several reports concerning lactic acid fermentation of rice. Dong-Hwa (1989) reported a yogurt-like product made from rice with lactic acid bacteria (LAB). Komano et al. (2010) also developed a yogurt-like product from rice. In these two studies, the rice was fermented after autoclave treatment. From these reports, it was considered that lactic acid fermentation of rice is possible. However, there is no information of a cheese-like food made from lactic acid-fermented rice milk.

In this study, the possibility of producing a cheese-like food from rice milk was investigated. The rice milk was made from brown rice using a micro wet milling (MWM) system (Koyama and Kitamura, 2014). As the first step in making rice cheese, the characteristics of pasteurization, lactic acid fermentation, and coagulation of the processed rice milk were investigated and compared to those of processed dairy cheese.

Materials Hokuriku 193 brown rice (harvested at the National Agricultural and Food Research Organization, Hokuriku research center in 2011) was used in this study. Table 1 shows the components of Hokuriku 193 brown rice. This variety shows high yield, and contains more protein and fatty acids than regular riceiv). Petri film EC (Escherichia coli) plates and AC (Aerobic Plate Count) plates were purchased from 3M Japan (Tokyo, Osaka). Lactococcus lactis subsp. cremoris powder, FD-DVS CHN-11, was purchased from Chr Hansen (Hoersholm, Denmark). D-/L-lactic acid assay kit was purchased from Megazyme International Ireland (Wicklow, Ireland). BCP (Bromocresol Purple) added plate count agar medium was purchased from Merck (Darmstadt, Germany). Glucose C2 test kit was purchased from Wako Pure Chemical Industries (Osaka, Japan). Gelatin, agar, processed cheese (Baby Cheese, QBB, Hyogo, Japan), and natural cheese (Cream Cheese, MEGMILK SNOW BRAND Co., Ltd, Tokyo, Japan) were purchased from a local market.

| Protein (%) | Moisture (%) | Amylose (%) | fatty acid (mg/100g) |

|---|---|---|---|

| 7.4 | 14.0 | 19.1 | 19.9 |

Rice milk Rice milk was made from brown rice using a MWM system. The brown rice was soaked for 300 min at 2°C before milling. Figure 1 shows the layout of the MWM system used in this experiment. The rice feeding equipment feeds the rice samples, and the tubing pump simultaneously feeds water to the stone mill. The electric motor only rotates the lower stone mill. The rice milk can be obtained by milling rice and water simultaneously. The feeding rate of water was set to 40 mL/min, the sample feeding rate was set to 18 g/min, and the rotational speed of the mill was set to 50 rpm.

The electric stone mill system

➀ Rotary rice feeding equipment ➁ Motor ➂ Stone mill ➃ Tubing pump ➄ Water tank ➅ Rubber spatula ➆ Sample bottle

Pasteurization Ten milliliters of rice milk was sterilized at constant temperature in a test tube heated in a water bath. The water temperature of the bath was set to 65°C or 75°C, and the heating time was set to 15, 30, 45, or 60 min. After sterilization, 1 mL of sterilized rice milk was applied to a Petri film EC plate, which was cultured at 35°C for 24 h. After cultivation, the existence of coliforms was checked. Another drop (1 mL) of sterilized rice milk was applied to a Petri film AC plate. This was cultured at 35°C for 48 h. After cultivation, the number of colonies was counted (aerobic plate count, APC).

Lactic acid fermentation Lactic acid bacteria solution (0.5 wt%) was added to the sterilized rice milk, and was cultured at 30°C for 16 h. The pH of rice milk was measured with a pH meter (Horiba Corporation, Kyoto, Japan). After centrifuging (1000 g × 10 min) the rice milk, the concentration of lactic acid and glucose in the supernatant was measured with a D-/L- lactic acid assay kit and glucose C2 test kit, respectively. To count the LAB population, the rice milk was cultured on agar culture medium with BCP at 37°C for 72 ± 2 h. These parameters ware measured at 0, 1, 2, 3, 4, 6, 8, 10, 12, 14, and 16 h from the start of lactic acid fermentation.

Coagulation of lactic acid fermented rice milk In this experiment, rice milk was prepared under the following conditions: 10 mL rice slurry was sterilized at 65°C for 30 min, then LAB solution (0.5 wt%) was added to the sterilized rice milk and cultured at 30°C for 12 h. Lactic acid fermented rice milk was dehydrated with a sieve and kitchen paper for 24 h at room temperature. Non-dehydrated and dehydrated rice milk samples were coagulated with the following agents: gelatin, agar, and xanthan gum.

Gelatin (1.5, 2.5, 3.5, 4.5, 7.0 wt%) was added to the rice milk (dehydrated and non-dehydrated) and the mixture was left to stand for 15 minutes. The mixture was heated to 60°C in a microwave oven and blended with a hand mixer for 1 min. After blending, the mixture was coagulated at 4°C for 3 h.

Agar (1.5, 2.5, 5.0, 7.0 wt%) was added to the fermented rice milk (dehydrated and non-dehydrated) and the mixture was heated, blended, and coagulated using the same method as for the gelatin mixture.

Xanthan gum (5, 10 wt%) was added to rice milk (dehydrated and non-dehydrated) and the mixture was blended with a hand mixer for 1 min. The xanthan gum mixture was coagulated at 4°C for 24 h.

Measurement of breaking strength After coagulation, the breaking strengths of the rice cheese samples coagulated with gelatin, agar and xanthan gum, processed cheese, and natural cheese were measured using a rheometer (Sun Scientific Co., Ltd., Tokyo Japan). All samples were subjected to measurement immediately after their removal from the refrigerator. A spherical plunger with a diameter of 1.5 cm was used. Each sample was cut into a 3-cm cube. The sample stage speed was 60 mm/min.

Sensory test In this experiment, rice cheese samples were prepared under the same condition as the coagulation test. Three rice cheese samples containing 1.5, 2.5, and 3.5 wt% gelatin and made with dehydrated rice milk were evaluated. Each sample was cut into an approximately 1-cm cube. All samples were put in the refrigerator until just before evaluation. The panel consisted of 24 people, 10 men and 14 women, with an average age of 24.7 years. A 7-point scaling method was used to evaluate the gelatin-containing rice cheese. The samples were given out randomly to the panelists. The rice cheese containing 2.5 wt% gelatin was used as a standard (4 points). Five evaluation criteria were used: roughness (rough:1, smooth:7), sourness (sour:1, not sour:7), hardness (hard:1, soft:7), smell (good:1, bad:7), and stickiness (sticky:1, not sticky:7). Moreover, evaluators chose their favorite sample among the three samples and the favorability rate was calculated as the percentage of evaluators who chose the sample. Significant differences between samples containing 2.5% and 1.5% gelatin, 2.5% and 3.5%, and 1.5% and 3.5% were determined by a t-test using Microsoft Excel 2010 (Microsoft Corporation).

Sterilization test The sample was positive for the Escherichia coli group when rice milk was sterilized at 75°C for 15 min, suggesting that this condition was not sufficient for rice milk pasteurization. The other conditions were negative for the E. coli group, and APC was under 5.5 × 103 CFU/g (Table 2). Health standards state that APC in foods should be under 1 × 105 if other criteria are not setv). Sterilization at 65°C for 30 min was the most rapid and efficient condition where the resulting sample met this standard.

| Temperature (°C) | 65 | 75 | |||||

|---|---|---|---|---|---|---|---|

| Time (min) | 30 | 45 | 60 | 15 | 30 | 45 | 60 |

| Escherichia coli group | − | − | − | + | − | − | − |

| the number of general live germs (CFU/g) | 5.5×103 | 1.2×103 | 9.7×102 | <107 | 1.1×103 | 7.9×102 | 7.8×102 |

In result of Escherichia coli group, (−) E.coli was not detected. (+) E.coli was detected.

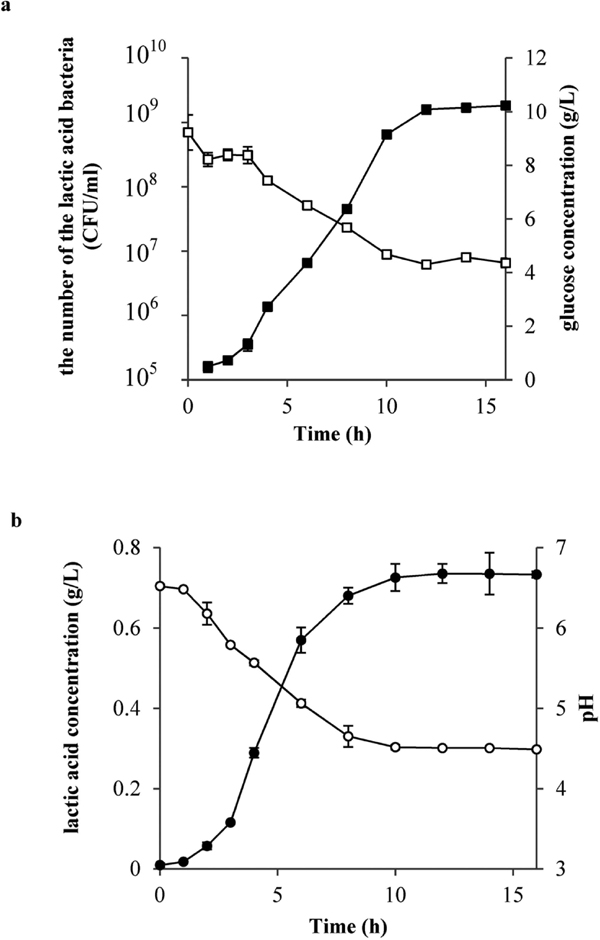

Lactic acid fermentation test As fermentation progressed, the number of LAB increased and glucose concentration decreased. At the same time, the lactic acid concentration increased and pH decreased (Fig. 2). LAB generate lactic acid from lactose, thereby decreasing the pH valuevii). This result indicates the successful lactic acid fermentation of rice milk. All parameters became constant after 12 h, where the number of LAB was 1.8 × 109 CFU/mL, pH value was 4.5, glucose concentration was 4.3 g/L, and lactic acid concentration was 0.74 mg/g. The number of LAB in fermented milk is over 108 CFU/mLvi). Matsuoka and Fuke (1977) reported that the pH value of lactic acid fermented soy bean milk was between 5 and 6. Nishiya et al. (1990) reported the pH of cheese made from skim milk before ripening is between 5.4 and 5.8. The pH value of fermented rice milk is lower than other cheese.

Result of lactic fermentation

a: Time course of the number of the lactic acid bacteria and glucose concentration. ■ the number of the lactic acid bacteria □ glucose concentration

b: Time course of the lactic acid concentration and value of pH. ● lactic acid concentration ○ pH

Coagulation test Figure 3 shows the result of the breaking test. The average water content of dehydrated samples changed from 82.1 to 65.5%. The breaking strengths of the processed cheese and natural cheese used as standards were 20.0 N and 8.3 N, respectively. The dehydrated agar samples and dehydrated 4.5, 7.0 wt% gelatin samples were too hard to measure with the equipment used, showing values over the measurement limit of the rheometer. The viscosity of the dehydrated samples with xanthan gum were higher than that of the original rice milk, but the samples did not become solid; thus, their breaking strengths could not be measured. Meanwhile, the breaking strengths of non-dehydrated samples with xanthan gum could be measured; however, they were the lowest of all samples. The 7 wt% agar sample was the hardest among the non-dehydrated samples, with a breaking strength of 6.9 N. Inoue et al. (2009) reported that ager gel was harder than gelatin gel. The breaking strengths of the 1.5 wt% and 3.5 wt% gelatin samples (dehydrated) were 8.3 N and 20.0 N, respectively. Yang and Taranto (1982) reported the production of mozzarella cheese analogs from soybeans or soy protein products, gelatin, gum arabic and other ingredients. The breaking strengths of all non-dehydrated samples were under 8.3 N. From these results, we found that the breaking strengths of dehydrated gelatin samples were similar to that of the standard dairy cheese, thus these were used in the sensory evaluation.

The result of coagulation test

● dehydrated sample with gelatin. ○ non-dehydrated sample with gelatin. □ non-hydrated sample with agar-agar. △ non-dehydrated sample with xanthan gum.

Sensory test Table 3 shows the results of the sensory evaluation and the overall acceptance. There were no significant differences in roughness, sourness, and smell. The sample containing 3.5 wt% gelatin achieved the highest ranking in hardness and lowest ranking in stickiness. On the other hand, the sample containing 1.5 wt% gelatin achieved the lowest hardness ranking and highest stickiness ranking.

| Amount of gelatine (%) | Sensory evaluation (pt.) | Favorable evaluation (%) | ||||

|---|---|---|---|---|---|---|

| roughness | Sourness | Hardness | Smell | Stickiness | ||

| 1.5 | 4.22a ± 1.41 | 3.92a ± 1.64 | 6.38a ± 0.70 | 3.82a ± 0.57 | 2.39a ± 1.31 | 29.2 |

| 2.5 | 4ab | 4a | 4b | 4a | 4b | 41.7 |

| 3.5 | 3.58b ± 1.41 | 3.83a ± 1.49 | 3.71b ± 1.42 | 3.83a ± 0.92 | 4.25b ± 1.30 | 29.2 |

Each value of the sensory evaluation is shown as the mean ± SD. Values with the same letter (a or b) are not significantly (p > 0.05) different.

In the evaluation of overall acceptance, the sample containing 2.5 wt% gelatin received a higher grade than the other samples, with a favorability rating of 41.6%. The two remaining samples received a 29.2% favorability rating each. Many panelists indicated that the 2.5 wt% gelatin was favorable because “the texture was most similar to cheese”. However, many panelists indicated that all samples were “too sticky and sour”.

Based on these results, the sample containing 2.5 wt% gelatin was judged most suitable for use as rice cheese, but the improvement of stickiness and sourness was necessary for all samples. Although this study succeeded in determining the optimal texture of the cheese-type food, further work is needed to adjust its flavor so that it resembles dairy cheese.