2019 Volume 59 Issue 10 Pages 1929-1931

2019 Volume 59 Issue 10 Pages 1929-1931

The effects of individual substitutional element addition (Si, Al, Mn, Cu, Ni and Cr) on Hall-Petch relationship in interstitial free ferritic steels were systematically investigated by employing experimental examinations, the pie-up models and grain boundary segregation theory. Chemistry-dependent Hall-Petch coefficients were observed, which was principally interpreted based on the established correlations between the critical grain boundary shear stress and the grain boundary segregation depending on the kind of elements. Exceeded grain boundary segregation levels were found to be the predominant contributions of enhanced grain refinement strengthening abilities.

Grain refinement strengthening is one of the most attractive methods to increase the strength of polycrystalline materials. The yield strength (σy) measured by tensile tests is usually expressed by the well-known Hall-Petch relationship as a function of average grain size (d), as shown below:1,2,3)

| (1) |

| (2) |

On the other hand, the effects of substitutional element additions on ky have not been widely studied and well understood yet, though there are a few reports on the effects of Ni, Cr and P.8,9,10,11,12) In this work, the effects of individual addition of substitutional elements (Si, Al, Mn, Ni and Cr) on Hall-Petch relationship were investigated in IF ferritic steel to evaluate their effects systematically by combining experimental examinations, the dislocation pile-up model and the GB segregation theory by McLean.13) The quantitative correlation between critical GB shear stress (τ*) and GB segregation magnitude was then established to interpret the mechanisms of ky increment due to alloying elements.

The nominal chemical compositions of employed IF steel specimens with various substitutional element additions (Si, Al and Mn) are summarized in Table 1. The preparation processes of above specimens for determining the Hall-Petch relationship were given in previous works.8,9) The results on the effects of Ni and Cr could be found in previous works.8,9) Small amounts of C and N (<0.002 wt.%) were designed to be fixed as Ti(C,N) by sufficient Ti addition.8,9) Tensile tests were carried out on standard specimens according to JIS13B with strain rate of 1.0×10−3 s−1. The microstructure was observed by optical microscopy and electron backscatter diffraction (EBSD) to quantify (nominal) average grain size. Detailed instructions on X-ray diffraction (XRD) and Young’s modulus measurement experiments were given in the recent publication.14)

| Specimens | Si | Al | Mn | Ni | Cu | C | N | S+P | Ti | Xi, (at.%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1% Si steel | 0.93 | 0.051 | 0.001 | 0.002 | 0.001 | 0.0012 | 0.0005 | <0.0005 | 0.028 | 1.84 |

| 2% Si steel | 1.97 | 0.053 | 0.002 | 0.002 | 0.002 | 0.0012 | 0.0003 | <0.0005 | 0.025 | 3.86 |

| 3% Si steel | 3.14 | 0.066 | 0.002 | 0.003 | 0.005 | 0.001 | 0.0005 | <0.0005 | 0.028 | 6.09 |

| 1% Al steel | 0.027 | 1.080 | 0.001 | – | 0.001 | 0.001 | 0.0005 | <0.0005 | 0.021 | 2.05 |

| 4% Al steel | 0.022 | 3.97 | 0.0049 | – | 0.002 | 0.0008 | 0.0006 | <0.0005 | 0.019 | 7.95 |

| 0.5% Mn steel | 0.020 | 0.050 | 0.520 | 0.002 | 0.002 | 0.0012 | 0.0004 | <0.0005 | 0.025 | 0.53 |

| 1% Mn steel | 0.016 | 0.053 | 1.07 | 0.003 | 0.003 | 0.001 | 0.0009 | <0.005 | 0.0278 | 1.09 |

| 2% Mn steel | 0.011 | 0.066 | 2.090 | 0.002 | 0.003 | 0.0008 | 0.0006 | <0.0005 | 0.025 | 2.13 |

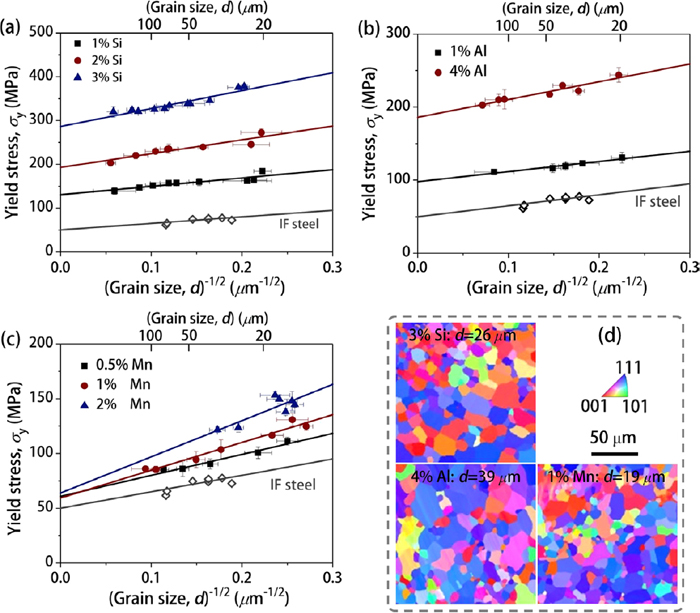

Figures 1(a)–1(c) show the Hall-Petch plots of IF ferritic steels with various Si, Al and Mn contents. It is observed that the addition of alloying elements significantly varies both the intercept with vertical axis (σ0) and the slope of the lines (ky). In Fig. 1(d), EBSD micrographs of selected samples with different substitutional element additions indicate full recrystallization grains and little difference on texture. Figures 2(a) and 2(b) summarize the plots of σ0 and ky values with various Si, Al, Mn, Ni8) and Cr9) contents (at.%). The obtained values of σ0 are the combined contributions of friction stress of pure iron and solid solution strengthening of each element, in which the GB strengthening function is not included.8) Hence, the solid solution strengthening ability of various substitutional elements exhibits the following sequence: Si > Al ≈ Ni > Mn > Cr. The present results generally coincide with previous works in IF steels.12,15,16,17,18) The slight differences could be the included GB strengthening in some works,9,15,18) the presences of different impurities,17) few interstitial elements12) and experimental factors.8,9,17) As shown in Fig. 2(b), complicated effects of various substitutional elements on the values of ky are observed. Mn, Si and Ni additions significantly increase ky, while 4% Al steel gives a slight increase of ky. In addition, Cr has little influence on ky.

The Hall-Petch plots of IF ferritic steels with various substitutional element additions: (a) Si, (b) Al and (c) Mn. The plot of IF steel3) is presented as reference. (d) Selected EBSD micrographs showing the recrystallized grains of various steels. (Online version in color.)

Summarized plots of (a) σ0 and (b) ky values with various Si, Al, Mn, Ni8) and Cr9) contents. The results from other references on the effect of various alloy elements on σ012,15,16,17,18) and (b) ky12) are also compared. Experimental results of the effect of substitutional element additions on (c) lattice parameter (a) and (d) Young’s modulus (E). (Online version in color.)

By utilizing the Nelson-Riley refinement from XRD results,19) the estimated lattice parameter, a, of the present steels are summarized in Fig. 2(c). Si is found to decrease lattice parameter while other substitutional elements increase it. The change of lattice parameter with Al additions is the most remarkable. In Fig. 2(d), the measured Young’s modulus (E) values of the present steels are exhibited. Si and Al additions significantly decrease Young’s modulus, while the additions of Ni, Mn and Cr display little effect on it. The obtained values of a and E will also be used to calculate τ* (Eq. (2)) subsequently.

According to Langmuir-McLean approach,13,20) equilibrium GB segregation level (

| (3) |

| (4) |

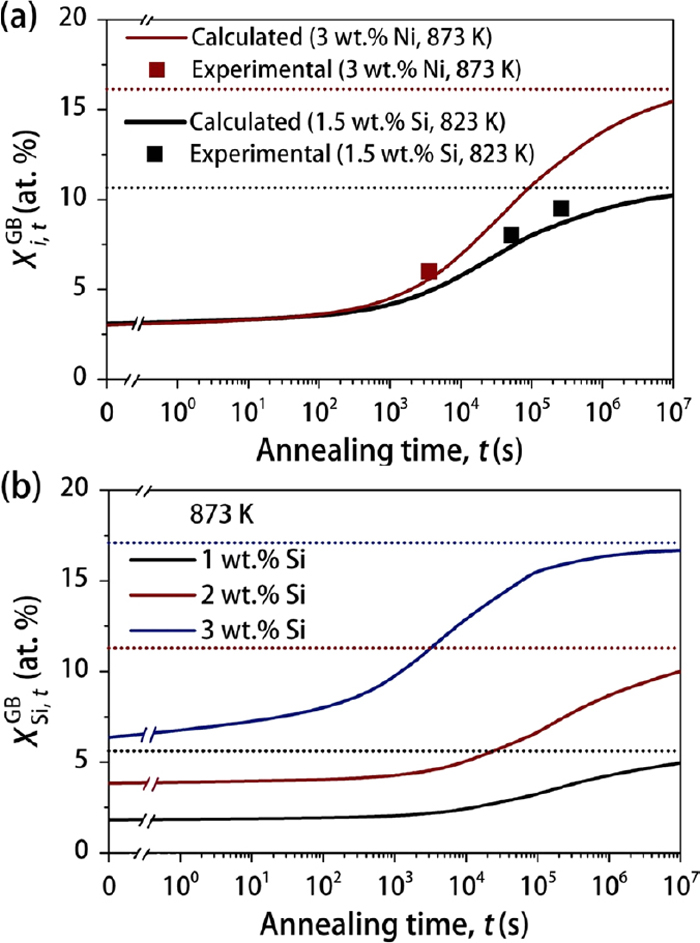

To calculate the practical GB segregation magnitude, the following assumptions were made first: (a) There is little effect from impurities and the present specimens were treated as Fe-i binary alloys; (b) Little segregation during recrystallization treatment is formed (i.e.,

| β | δ (nm) | ΔG0 (kJ/mol) | ΔGi,T (kJ/mol) | D0 (cm2/s) | Q (kJ/mol) | |

|---|---|---|---|---|---|---|

| Si | 3×104 | 1 | −9 | ΔG0+0.012ΔT | 1.47 | 233 |

| Al | 3×104 | 1 | −12 | ΔG0+0.008ΔT | 5.31 | 196.5 |

| Mn | 3×104 | 1 | −11 | ΔG0+0.025ΔT | 1.49 | 233.6 |

| Ni | 3×104 | 1 | −14.4 | ΔG0+0.016ΔT | 1.4 | 245.8 |

| Cr | 3×104 | 1 | −4.9 | ΔG0+0.009ΔT | 0.44 | 253.3 |

(a) A comparison of calculated GB segregation kinetics and experimental measurements8,23) on GB segregation levels to demonstrate the reliability of current calculations; (b) Influences of Si contents on GB segregation kinetics at 873 K. The dashed lines indicate equilibrium GB segregation level. The parameters for the present calculations are listed in Table 2. (Online version in color.)

Figure 4(a) summarizes the calculated GB segregation levels under the experimental conditions in which Hall-Petch relationship is determined (Fig. 1). The deviations from the initial alloy contents (

(a) Summarized results on the calculated GB segregation levels corresponding to the experimental conditions in which Hall-Petch relationship is determined (Fig. 1). The experimental examination on Ni added steel is also presented.8) (b) Quantitative correlations between τ* values and exceeded levels of GB segregation (ΔX). (Online version in color.)

To sum up, on the basis of experimental examinations, the dislocation pile-up models and GB segregation theory, the influences of substitutional element additions (i.e., Si, Al, Mn, Ni and Cr) on Hall-Petch relationship were systematically studied in IF ferritic steel. The substitutional elements had particular effects on the values of σ0 and ky. Exceeded GB segregation levels (ΔX) were found to dominate the critical grain boundary shear stress (τ*), and this leads to the enhanced grain refinement strengthening abilities resulted from the increment of ky.

This work was supported by JSPS KAKENHI Grant Number JP15H05768.