2019 Volume 44 Issue 3 Pages 186-191

2019 Volume 44 Issue 3 Pages 186-191

A micro liquid–liquid extraction has been applied to sample preparation in the current authorized method for clopyralid in compost. The method rendered matrix effects practically negligible during determination with ultraperformance liquid chromatography-electrospray ionization tandem mass spectrometry with an improved limit of quantification of 0.7 µg/kg dry weight. Moreover, it had good accuracy and reproducibility. Therefore, the method is proposed as a highly effective routine analytical technique for investigating the actual status of clopyralid residue in compost.

Clopyralid (3,6-dichloropyridine-2-carboxylic acid) is known as a selective and systemic herbicide showing an auxin-like action. This herbicide, which is mainly used to control various annual and perennial broadleaf weeds in areas with cultivated crops such as sugar beets, fodder beets, and maize, is also used for weeding in pastures and non-crop land.1) Physiological disorders of horticultural crops such as vegetables and flowers suspected to result from clopyralid in cattle manure compost have been confirmed in Japan.2) The following are regarded as factors contributing to physiological disorders caused by clopyralid: (1) Degradation is slow, depending on the soil type; thus clopyralid persists for long periods in the soil. (2) Clopyralid remains to a greater or lesser degree in crops, including forage cultivated in soil with herbicide residue. (3) Most clopyralid is excreted promptly in manure without being metabolized in livestock that have consumed feed crops with clopyralid residue.1) (4) By application to soil of clopyralid-contaminated compost that includes excrement as a raw material, damage to horticultural crop production has been particularly great. Namiki et al.3) report that physiological disorders might arise, depending on highly susceptible crops, even at low clopyralid concentrations in soil of around 1 µg/kg, although the degree to which the physiological disorder appears depends on the crop.4)

Given this background, Japan, which is approximately 75% dependent on imported feed, is conducting a survey of clopyralid residue concentrations in imported feed and compost produced from livestock excrement.5,6) In Japan, the authorized Testing Methods for Fertilizers (2017)7) have been used for monitoring surveys as an analytical method for clopyralid residue in compost. However, the detection of remaining clopyralid in the low concentration range described above is impossible as a practical matter because the limit of quantification (LOQ) of the analytical method is about 10 µg/kg. Therefore, the establishment of an analytical method with 10 times higher LOQ sensitivity than the current method is urgently needed.

Analysis of clopyralid using high-performance liquid chromatography (HPLC) is the mainstream method.8–15) For analytical methods of clopyralid using gas chromatography (GC), derivatization before determination is necessary.16–19) Therefore, the analytical operation is generally complicated. Today, liquid chromatography or ultraperformance liquid chromatography equipped with tandem mass spectrometry (LC-MS/MS8,9,11,13) or UPLC-MS/MS10,12,14,15)) is the prominent method for analyzing pesticide residues in various matrices. It is being applied routinely to analyze clopyralid, as described above. When establishing a residual analytical method for clopyralid, investigating the sample-preparation method (extraction method and cleanup method of crude sample extracts) appropriately before chromatographic determination is important to achieve outstanding analytical performance of LC-MS/MS. The most problematic issue in determination with LC-MS/MS is the influence on ionization caused by matrix components coexisting with target pesticides derived from a sample, i.e., matrix effect.20–23) To reduce the matrix effect, it is necessary to clean up the sample extracts thoroughly.21) However, as the complexity of the sample-preparation procedure increases, the possibility of losing the target pesticides during the procedure might also increase. A means is adopted to correct the matrix effect using an external or internal matrix-matched calibration method.20–23) Because clopyralid shows changes in the physicochemical properties as a result of its pH dependence (pKa=2.0) and high water solubility (7,850 mg/L (in distilled water), log Kow=–2.63 (at pH 7)),1) establishing a residual analytical method for complicated matrices such as compost will probably be difficult. Clopyralid is therefore regarded as a problematic pesticide.13)

This study examined a sample-preparation method with a new concentration process based on extraction using methanol under alkaline and a cleanup method using solid-phase extraction (SPE) cartridges pre-packed with a copolymer of N-vinylpyrrolidone (hydrophilic) and divinylbenzene (lipophilic) adopted in the Testing Methods for Fertilizers (2017).7) The method is expected to increase the analytical sensitivity of a residual analytical method for clopyralid in compost, a complicated matrix.

Pesticide residue analysis-grade clopyralid with purity of 99.3% (by HPLC) was purchased from Wako Pure Chemical Industries Ltd. (Osaka, Japan). All other chemicals were of LC-MS grade, HPLC grade, pesticide residue analysis grade, or analytical grade. Water used to prepare a mobile phase for UPLC-MS/MS was prepared directly in the laboratory using a Milli-Q water purification system (Millipore Corp., Bedford, MA, USA).

The stock solution (1 mg/mL) of clopyralid was prepared by dissolving 10 mg of the standard in 10 mL of HPLC-grade acetonitrile. It was stored in the dark at 4°C. A working standard solution (20 µg/mL) was prepared daily, diluting the primary stock solution with 0.1% formic acid to obtain calibration standards with concentrations of 1–100 ng/mL. These standard solutions were used to prepare UPLC-MS/MS calibration curves.

2. SampleAir-dried, commercially available cattle manure compost samples were crushed with a variable-speed rotor mill (Pulverisette 14; Fritsch GmbH, Idar-Oberstein, Germany) equipped with a sieve ring (500 µm).

3. Sample-preparation procedure3.1. Proposed method3.1.1. ExtractionFive grams of a spiked or clopyralid-contaminated sample was weighed into a 100 mL Erlenmeyer flask with a screw cap. After methanol–1 M NaOH (99 : 1) (50 mL) was added to the sample, the sample mixture was shaken vigorously for 30 min using a reciprocating shaker. The sample mixture was transpired to a 50 mL glass centrifuge tube. Then it was centrifuged for 5 min at 1,700×g using a low-speed centrifuge. The solid residue was shaken again with 40 mL of methanol–1 M NaOH (99 : 1). The two sample extracts were filtered through a glass fiber filter under suction and were then made up to 100 mL with methanol–1 M NaOH (99 : 1).

3.1.2. Cleanup with solid-phase extraction (SPE) cartridgeA 10 mL aliquot of the sample extract (equivalent to 0.5 g of the sample) was loaded into an SPE cartridge that had been pre-packed with a hydrophilic–lipophilic balanced sorbent (225 mg, Oasis HLB; Waters Corp., Milford, MA, USA) preconditioned with 5 mL of methanol and 5 mL of Milli-Q water. The retained clopyralid was eluted with 10 mL of methanol–0.01 M NaOH (1 : 1). Methanol (5 mL) was added to the eluate. Then the solution was concentrated to about 5 mL under reduced pressure at a water bath temperature of 40°C. To the concentrated solution, 3 mL of 1 M HCl was added. Then the solution was loaded into another new Oasis HLB SPE cartridge that had been preconditioned with 5 mL of acetonitrile and 5 mL of 0.1 M HCl. The cartridge was washed with 10 mL of 0.1 M HCl, 5 mL of acetonitrile–0.1 M HCl (1 : 9), and 5 mL of water. The retained clopyralid was eluted into a 10 mL glass conical centrifuge tube with a screw cap, along with 4 mL of acetonitrile–0.0028% NH3 solution (1 : 9).

3.1.3. Micro liquid–liquid extraction (micro LLE)The pH of the eluate was adjusted to approximately 14 by adding 100 µL of 1 M NaOH. After 2 mL of dichloromethane was added to the solution, the mixture was vortexed for 0.5 min and was centrifuged for 3 min at 1,700×g. The organic phase was extracted carefully using a microsyringe (Hamilton Co., Reno, NV, USA) and discarded. This washing step was repeated twice. To the aqueous phase, 150 µL of 12 M H2SO4 was added; then the pH was adjusted to approximately 1. After 2 mL of dichloromethane was added to the acidified solution, the mixture was vortexed for 0.5 min and was centrifuged for 3 min at 1,700×g. The organic phase was collected carefully using a microsyringe. This extraction step was repeated three times. After the organic phase was concentrated under reduced pressure, it was evaporated to dryness using a gentle stream of nitrogen at 40°C. The residue was reconstituted in 200 µL of 0.1% formic acid. The final solution was filtered for 5 min at 8,000×g using a centrifugal filter (0.22 µm PVDF filter; Merck Millipore Ltd., Tullagreen Carrigtwohill, Cork, Ireland) (matrix equivalent to 2.5 g of sample/mL).

3.2. Reference methodThe authorized method for analysis of clopyralid residue in compost samples listed in the Testing Methods for Fertilizers (2017)7) was used as a reference method to verify the performance of the proposed method.

3.2.1. ExtractionFive grams of compost sample was weighed into a 200 mL Erlenmeyer flask with a screw cap. After methanol–1 M NaOH (99 : 1) (100 mL) was added to the sample, the sample mixture was shaken vigorously for 30 min with a reciprocating shaker. After standing, the supernatant was centrifuged for 5 min at 1,700×g.

3.2.2. CleanupA 5 mL aliquot of the sample extract (equivalent to 0.25 g of the sample) was cleaned up according to the method described in Section 3.1.2. The volume of the eluate from the second cartridge was accurately adjusted to 5 mL with 0.1% formic acid. Then the solution was centrifuged for 5 min at 8,000×g. The supernatant was analyzed as a final solution (matrix equivalent to 0.05 g of the sample/mL).

4. Analytical condition of UPLC-MS/MSLC-MS/MS analyses were conducted using a UPLC system (Acquity Ultra Performance LC; Waters Corp.) equipped with a degasser, a pump, an autosampler, and a column oven. An analytical column was a UPLC HSS T3 (50 mm×2.1 mm, 1.8 µm particle size; Waters Corp.). A guard column (5 mm×2.1 mm, 1.8 µm particle size; Waters Corp.) was used as a pre-column. The column was maintained at 40°C. A gradient program was used with mobile phase, consisting of methanol and 0.1% formic acid with the following methanol contents: 0–2 min, 5%; 2–7 min, 5–60%; 7–8 min, 60–95%; 8–8.5 min, 95–5%; 8.5–10 min, 5%. The flow rate was 0.4 mL/min. The injection volume was 2 µL.

The MS/MS system (Quattro Micro API; Waters Corp.) was a triple quadrupole mass spectrometer equipped with an electrospray ionization (ESI) interface. The parameters used for MS under ESI positive-ion mode were as follows: capillary voltage 1.0 kV, cone voltage 20 V, desolvation temperature 400°C, source temperature 120°C, cone gas (nitrogen gas) 50 L/hr, desolvation gas (nitrogen gas) 800 L/hr, and collision gas (argon gas). Mass spectrometric detection was performed in multiple reaction monitoring (MRM) mode with the following parameters: precursor ion m/z=192, product ion for quantification m/z=146 (collision energy=20 eV), and product ion for confirmation m/z=110 (collision energy=30 eV) (Fig. S1).

To establish a highly sensitive analytical method for clopyralid in cattle manure compost, we studied (1) the adequacy of extraction times and (2) the addition of a concentration process while referring to the authorized method listed in Testing Methods for Fertilizers (2017).7)

First, the validity of the repetition number of extraction times was examined using clopyralid-contaminated cattle manure compost samples. From repeating the extraction twice with methanol–1 M NaOH (99 : 1), a maximum 1.3-fold difference was found compared with the concentration of clopyralid detected with the reference method using single-time extraction (Table 1). Therefore, it is necessary to repeat extraction at least twice to achieve more accurate analytical values.

| Sample No. | Extraction by repeated extraction (2 times) (proposed method) | Extraction by single extraction (reference method) | ||

|---|---|---|---|---|

| Detected concentration (µg/kg dw, n=5) | RSD (%) | Detected concentration (µg/kg dw, n=5) | RSD (%) | |

| 1 | 21.2±0.4 | 2.0 | 18.5±0.3 | 1.6 |

| 2 | 93.0±4.2 | 4.5 | 73.2±3.1 | 4.2 |

| 3 | 228.9±0.4 | 0.2 | 177.0±5.0 | 2.8 |

According to the reference method, 5 mL of the sample extract, corresponding to 0.25 g of the cattle manure compost sample, is cleaned up using Oasis HLB SPE cartridges. The final solution volume is set as 5 mL (matrix equivalent to 0.05 g of the sample/mL). Therefore, the concentration of clopyralid in the final solution is lower than that in the compost sample. As a result, this might contribute to a reduction in the matrix effect during determination with LC-MS/MS since interfering substances coexist in the final solution. However, because the LOQ is invariably low while avoiding matrix effects caused by sample dilution, a concentration process must be applied after the cleanup procedure with SPE to lower the LOQ. Therefore, the micro liquid–liquid extraction (micro LLE) method invented by Schaner et al.9) has been applied to the process. The concentration process was made easier by applying of the following operation using the proposed micro LLE method: (1) washing of the interfering substances coexisting in the eluate from the SPE cartridge with 1 M NaOH and (2) quantitative re-extraction of clopyralid into the organic (dichloromethane) phase by shifting the pH of the aqueous phase strongly to the acidic side (pH <1.5) with 12 M H2SO4. The micro LLE method separates the organic phase and aqueous phase by centrifugation, unlike the classical LLE method. Therefore, this method offers the benefit that the organic phase can be easily isolated without forming an emulsion at the liquid–liquid interface. As a result, it was possible to concentrate the volume of the final solution to 0.2 mL by the application of micro LLE (matrix equivalent to 2.5 g of the sample/mL).

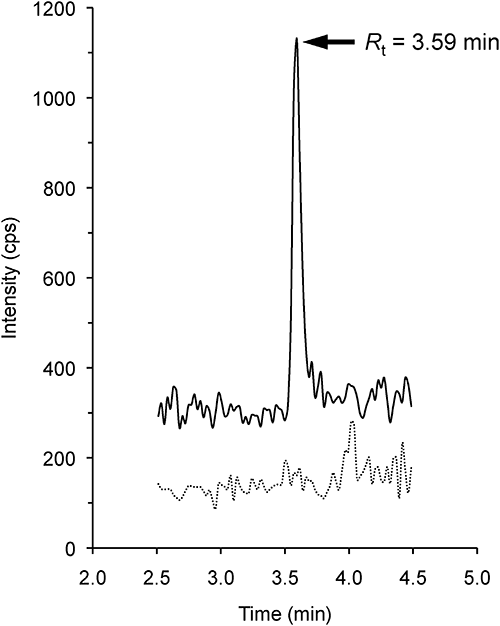

As portrayed in the MRM chromatograms obtained by treating the cattle manure compost samples (blank sample and spiked sample at 2 µg/kg dry weight (dw)) according to the proposed sample-preparation method, no interfering peak was observed near the elution time (Rt=3.59 min) of clopyralid (Fig. 1). Furthermore, confirmation of the potential matrix effect when determining LC-MS/MS revealed that, although weak ionization suppression (−3%) was observed in the sample extract, it was not to be regarded as a disturbance that substantially hinders quantitative determination.23) In other words, results suggest that the proposed sample-preparation method is capable of removing the interfering substances suitable for LC-MS/MS. As a result, the proposed analytical method requires no internal calibration method or matrix-matched calibration method for correction of the matrix effect. Quantification using the simplest external calibration method can be done using the proposed method.

The LOQ and limit of detection (LOD) of the proposed method using the cattle manure compost samples spiked with clopyralid at 2 µg/kg dw were estimated, respectively,24) to be 0.7 µg/kg dw and 0.3 µg/kg dw. On the other hand, the LOQ and LOD of the reference method were 7.7 µg/kg dw and 3.0 µg/kg dw, respectively. Because the analytical sensitivity improved approximately 10 times when comparing the LOQ with the reference method, results suggest that the proposed method has analytical sensitivity sufficient to prevent physiological crop disorders that can occur at concentrations lower than the LOQ of the reference method in cattle manure compost. Incidentally, considering that the LOQ depends on (1) the analytical performance of the LC-MS/MS owned by each laboratory, (2) the proficiency of the analytical chemist in pesticide residue analysis, (3) the amount of compost input to cropland, and (4) the concentration in soil where physiological disorder might occur, 2 µg/kg dw is expected to be the target LOQ.

2. Analytical validation (accuracy, precision and collaborative study)The accuracy of the proposed method was confirmed using the cattle manure compost samples spiked with clopyralid at 2, 10, and 50 µg/kg dw. As shown in Table 2, the average recovery was 71–79%. The relative standard deviation (RSD) was 5% or less. Confirmation of the precision of the proposed method (within-day precision, n=3/day; between-day precision, n=3/day×5 days) using cattle manure compost samples contaminated with low and high concentrations revealed that both variations were 3.3% or less (Table 2).

| Accuracy | |||||

|---|---|---|---|---|---|

| Spiked level (µg/kg dw) | Average recovery (%, n=5) | RSD (%) | |||

| 2 | 71.5±2.7 | 3.7 | |||

| 10 | 78.3±2.9 | 3.8 | |||

| 50 | 78.9±4.0 | 5.0 | |||

| Precision | |||||

| Sample | Within-day precision (%, n=3/day) | Between-day precision (%, n=3/day×5 days) | |||

| Cattle manure compost contaminated with low concentration of clopyralid | 0.4–3.0 | 3.3 | |||

| Cattle manure compost contaminated with high concentration of clopyralid | 0.1–2.0 | 2.5 | |||

| Collaborative study | |||||

| Sample No. | NARO | FAMIC | Ratio of concentration (FAMIC/NARO) | ||

| Detected concentration (µg/kg dw, n=5) | RSD (%) | Detected concentration (µg/kg dw, n=5) | RSD (%) | ||

| 1 | 4.5±0.2 | 4.1 | 5.0±0.4 | 7.2 | 1.1 |

| 2 | 15.6±0.1 | 0.9 | 14.5±1.4 | 9.6 | 0.93 |

| 3 | 42.1±1.6 | 3.8 | 40.0±2.3 | 5.8 | 0.95 |

| 4 | 49.7±0.8 | 1.7 | 49.5±1.3 | 2.6 | 1.0 |

| 5 | 100.7±3.7 | 3.7 | 96.4±7.0 | 7.3 | 0.96 |

| 6 | 186.8±5.0 | 2.7 | 170.0±13.2 | 7.7 | 0.91 |

To confirm reproducibility among laboratories, the National Agriculture and Food Research Organization (NARO) and the Food and Agricultural Materials Inspection Center (FAMIC) shared clopyralid-contaminated cattle manure compost samples of six kinds. Then a collaborative study was conducted. In the FAMIC, the quantification of clopyralid was carried out according to analytical conditions previously reported.14) Table 2 shows that the ratio of the average detected concentrations of clopyralid obtained at two laboratories was 0.91–1.11. No statistically significant difference was found between their analytical values (Student t test, p=0.196). These results suggest that the proposed method has sufficient accuracy and precision for the analysis of clopyralid residue in cattle manure compost samples.

3. Application of the proposed method to clopyralid-contaminated cattle manure compost samplesThe proposed method and the reference method were applied to nine commercially available clopyralid-contaminated cattle manure compost samples. Comparison of both analytical values (Table 3) revealed that, although almost equal values were obtained for the two samples, differences of 1.1–1.2 times were found in the values of the five samples. Because the micro LLE is given to the proposed method, the probability of clopyralid loss during the sample-preparation procedures is regarded as higher than that in the reference method. However, contrary to this hypothesis, higher analytical values than those for the reference method are probably achieved because of the different numbers of extraction repetitions described above. Furthermore, the results demonstrate that clopyralid can be detected even from cattle manure compost samples contaminated at very low concentrations, for which detection is difficult using the reference method.

| Sample No. | Proposed method | Reference method | ||

|---|---|---|---|---|

| Detected concentration (µg/kg dw, n=5) | RSD (%) | Detected concentration (µg/kg dw, n=5) | RSD (%) | |

| 1 | 0.94±0.1 | 5.6 | Not analyzed | — |

| 2 | 3.3±0.3 | 8.1 | Not analyzed | — |

| 3 | 81.0±1.7 | 2.0 | 68.8±3.9 | 5.7 |

| 4 | 93.0±4.2 | 4.5 | 88.1±1.8 | 2.0 |

| 5 | 106.1±5.4 | 5.1 | 89.4±2.5 | 2.8 |

| 6 | 114.9±5.7 | 5.0 | 99.8±7.4 | 7.4 |

| 7 | 115.1±6.6 | 5.7 | 115.8±3.5 | 3.0 |

| 8 | 121.5±9.7 | 8.0 | 119.9±4.5 | 3.7 |

| 9 | 143.3±6.9 | 4.8 | 131.3±5.5 | 4.2 |

In conclusion, we improved extraction methods and used a concentration process with micro LLE based on the reference method. Thereby, we established a highly sensitive analytical method able to detect clopyralid residues in cattle manure compost samples contaminated at extremely low concentrations without matrix effects. The analytical method for clopyralid residues in cattle manure compost samples established in this study fulfills analytical requirements such as accuracy and precision for utilization as a practical routine analytical method. Therefore, its application to clopyralid residue monitoring surveys of cattle manure compost samples is anticipated.

This work was supported by a grant from the Ministry of Agriculture, Forestry, and Fisheries of Japan (28045C). We appreciate Dr. Yuji Shirai (Fertilizer and Feed Inspection Department, FAMIC), who cooperated in the collaborative study, and Dr. Koji Ito (Institute for Agro-Environmental Sciences, NARO) for giving excellent technical assistance. The authors thank Fastek, Ltd. (Miyagi, Japan, http://www.fastekjapan.com/) for English-language review of this report.