All issues

Volume 80, Issue 10

Displaying 1-9 of 9 articles from this issue

- |<

- <

- 1

- >

- >|

Overview

-

Michiko Yoshitake2016 Volume 80 Issue 10 Pages 603-611

Published: 2016

Released on J-STAGE: September 25, 2016

Advance online publication: September 09, 2016JOURNAL FREE ACCESSA method of materials design through multi-disciplinary use of materials information, “materials curation”, is presented. Examples of materials design or prediction of material behavior, such as work function tuning in binary alloy systems and a guideline of thermoelectric material search, by utilizing already existing various information on materials are demonstrated. The method utilizes materials information in different fields, for example, device physic+surface physics+metallurgy, or growth kinetics+crystallography+phase diagram. To make such multi-disciplinary use of materials information easier, a tool that enables anyone to connect various physical quantities in different fields has been under development.

View full abstractDownload PDF (5985K)

Regular Article

-

Hyung-Gyun Park, Kwon-Hoo Kim, Kazuto Okayasu, Makoto Hasegawa, Hirosh ...2016 Volume 80 Issue 10 Pages 612-619

Published: 2016

Released on J-STAGE: September 25, 2016

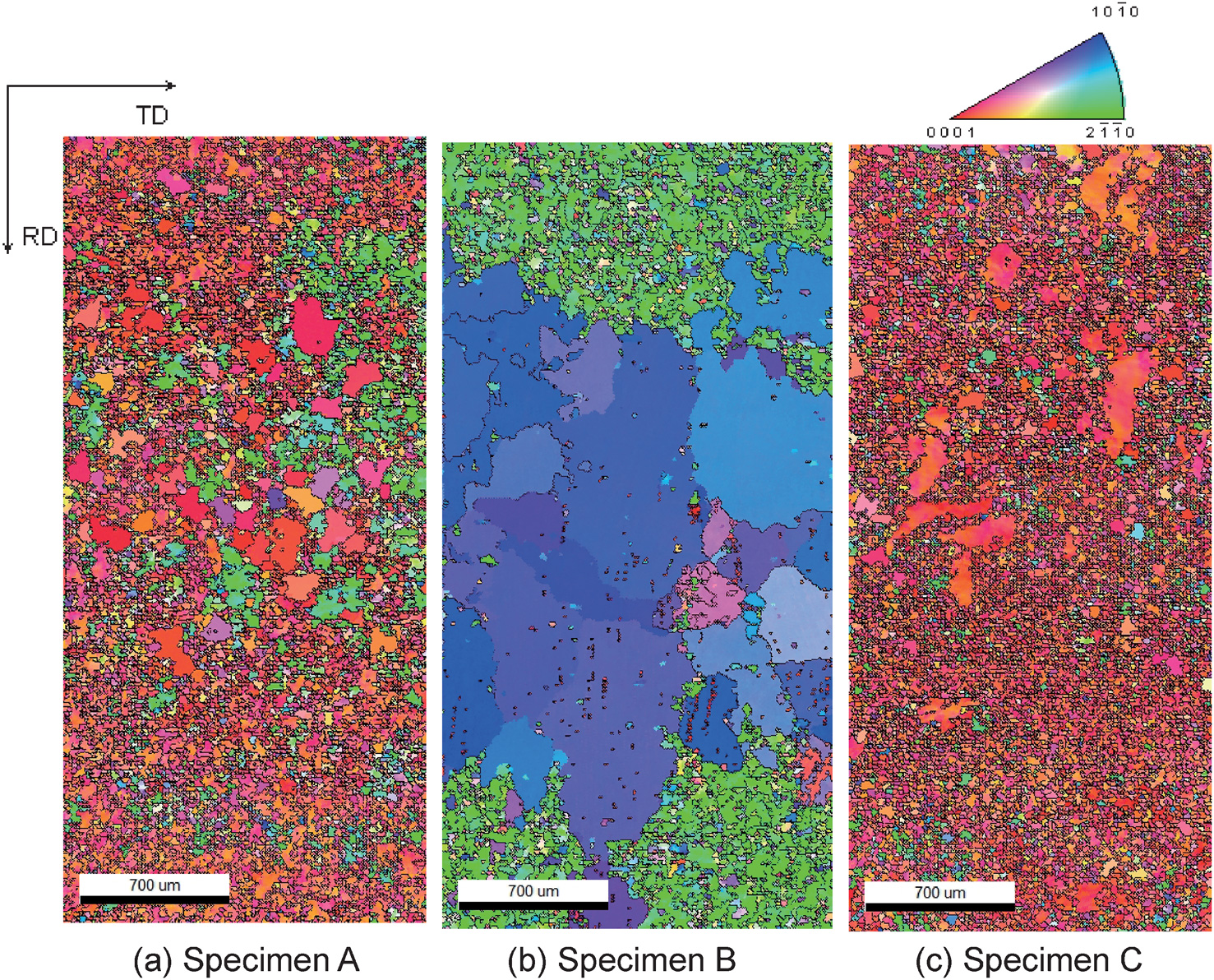

Advance online publication: July 29, 2016JOURNAL FREE ACCESSAZ31 magnesium alloy specimens are deformed at 723 K with a strain rate of 5.0×10−2 s−1 in the plane strain compression mode and the effects of deformation on the texture and microstructure evolution are studied. The specimens feature three different textures unsuitable for the activation of a basal slip system. It is found that the areas of high pole density appear at 20° away from the compression plane in the (0001) pole figures when the activation of both basal and prismatic slip systems are suppressed. When the plane strain compression deformation can be achieved only by the prismatic slip systems or the first order pyramidal slip systems, a heretofore unreported phenomenon manifests: alternating changes in crystal grain structure and texture with increasing strain. It is concluded that this change can be attributed to orientation stability for the deformation and preferential growth of grains such that {1010}〈1120〉 orientation consumes {1120}〈1010〉 grains.

Fig. 4 Fullsize ImageGrain structure maps derived from EBSD measurement of specimens A, B and C deformed at 723 K with a strain rate of 5.0×10−2s−1 up to a strain of −1.0.View full abstractDownload PDF (10462K)

Fig. 4 Fullsize ImageGrain structure maps derived from EBSD measurement of specimens A, B and C deformed at 723 K with a strain rate of 5.0×10−2s−1 up to a strain of −1.0.View full abstractDownload PDF (10462K) -

Manabu Kubota, Yukiko Kobayashi, Kohsaku Ushioda, Jun Takahashi2016 Volume 80 Issue 10 Pages 620-629

Published: 2016

Released on J-STAGE: September 25, 2016

Advance online publication: August 05, 2016JOURNAL FREE ACCESSMany studies have investigated the effect of alloying elements on the recrystallization behavior of work hardened austenite. However, the recrystallization behavior of high carbon low alloy steel has not been systematically investigated yet. In this study, the effects of alloying elements (Al, Nb, V, Ti and B) are examined by means of double hit compression test, TEM and 3DAP (Three-dimensional atom probe) analyses. The following conclusions were obtained:

(1) When alloying elements are in solid solution, Nb and Ti has equally strong effects on inhibiting recrystallization, followed by V.

(2) When deformation and holding temperature becomes low, the recrystallization is remarkably inhibited by adding 0.1%V.

(3) Fine particles were not observed by 3DAP observation in the 0.1%V steel which shows the strong inhibition effect on recrystallization. The solute V content measured by 3DAP decreased as the holding time increased and, recrystallization commenced at the time when relatively coarse precipitates formed.

View full abstractDownload PDF (7190K) -

Manabu Kubota, Yukiko Kobayashi, Kohsaku Ushioda, Jun Takahashi2016 Volume 80 Issue 10 Pages 630-639

Published: 2016

Released on J-STAGE: September 25, 2016

Advance online publication: August 05, 2016JOURNAL FREE ACCESSMany studies have investigated the effect of alloying elements on the recrystallization behavior of work hardened austenite. However, the recrystallization behavior of high carbon low alloy steel has not been systematically investigated yet. In this study, the effects of alloying elements, focusing on the carbon content, are examined by means of double hit compression test. The following conclusions were obtained:

(1) The independent effect of carbon content on recrystallization behavior is not observed.

(2) The effects of Nb, Ti and V addition on inhibiting recrystallization are promoted when carbon content is increased from 0.1% to 0.55%.

(3) The carbon content dependency of the effects of Nb and Ti addition on recrystallization becomes weaker when deformation and holding temperature become lower.

(4) C-V complexes or very fine VC clusters are postulated to be responsible for retarding recovery and recrystallization of 0.55%C-0.1%V steel, which shows the very strong inhibition effect.

View full abstractDownload PDF (9220K) -

Toko Tokunaga, Koichi Takahashi, Munekazu Ohno, Katsuhiko Sasaki, Teru ...2016 Volume 80 Issue 10 Pages 640-645

Published: 2016

Released on J-STAGE: September 25, 2016

Advance online publication: August 12, 2016JOURNAL FREE ACCESSNew heatsink materials having higher thermal conductivities have recently been required due to the recent rapid improvements in performance of the central processing unit, CPU, with increasing heat generation from computer devices. As an alternative material to conventional heatsink materials such as Al and Cu, composites containing carbon fibers have recently been gaining much attentions because of their extremely high thermal conductivity. However, the carbon fiber exhibits high thermal conductivity only in its longitudinal direction. Therefore, it is essential to control the orientation of the carbon fibers in the composite materials. In the present study, hot extrusion of a powder-fiber mixture is applied to realization of unidirectional array of carbon fibers in Al matrix, and the effects of volume fraction of carbon fiber on the thermal conductivity of the carbon fiber oriented Al-based composite have been investigated. It has been demonstrated that the carbon fibers are unidirectionally oriented in the extrusion direction, and consequently, the thermal conductivity in this direction increases with the increase in volume fraction of the carbon fiber. For the composites with more than 30 vol% carbon fiber, the addition of Al-Si alloy powder or the application of the spark plasma sintering, SPS, before extrusion was found to be effective for improving the sinterability of the powder-fiber mixture.

View full abstractDownload PDF (2453K) -

Ryosuke Yamagata, Kyosuke Yoshimi2016 Volume 80 Issue 10 Pages 646-654

Published: 2016

Released on J-STAGE: September 25, 2016

Advance online publication: August 12, 2016JOURNAL FREE ACCESSLaves phases may be one of effective reinforcements at higher temperature for creep-resistant ferritic steels. In this study, the effect of Nb/W ratio on crystallization and precipitation behavior of Fe2 (Nb, W) Laves phase was investigated for Fe-Cr-Al-Nb-W ferritic alloys. Fe-9Cr-6.5Al-10 (Nb, W) (at%) alloys were prepared by a conventional arc-melting technique. In the As-cast condition, the 10 at% Nb alloy was entirely composed of a eutectic phase of ferrite and Fe2Nb. By substituting W for a part of Nb, the microstructure was changed to the combination of the primary ferrite and the eutectic of ferrite and Fe2 (Nb, W). The microstructural change indicates that the composition shifted from eutectic to hypo-eutectic with increasing the W/(Nb+W) ratio in the alloy. For the 10 at% W alloy, there was no Laves phase in the as-cast microstructure. However, a number of Laves phase precipitates were observed inside grains after heat-treatment at 1000℃. The volume fraction of Laves phases decreased with increasing the W/(Nb+W) ratio in the alloy since the solubility limit of W in the ferritic matrix is higher than that of Nb at 1000℃. Therefore, the volume fraction and morphology are controllable by the Nb/W ratio in the Fe-Cr-Al-Nb-W alloy.

View full abstractDownload PDF (6584K) -

Eisaku Sakurada, Shunji Hiwatashi, Kohsaku Ushioda2016 Volume 80 Issue 10 Pages 655-662

Published: 2016

Released on J-STAGE: September 25, 2016

Advance online publication: September 16, 2016JOURNAL FREE ACCESSThe precipitation hardening with fine carbides of nm size has already been applied to various advanced high-strength steels. In the present study, the role of fine TiC precipitates in the ferrite phase on cyclic deformation behavior was investigated for a Ti-added dual-phase steel with a strength of 780 MPa. In particular, the cyclic hardening and softening behavior characterized by the changes in cyclic plastic strain during stress-controlled fatigue testing was discussed from the viewpoints of the evolution of dislocation substructures. The fatigue life of the precipitation-hardened steel with 2 to 5-nm TiC precipitates is remarkably long as compared with that of a Si-added solution-hardened steel with a comparable ultimate tensile strength. For a specimen which eventually fractures before 2×106 cycles at least, the cyclic plastic strain gradually decreases, i.e., the cyclic hardening takes place, at the beginning of cyclic loading. After a certain number of cycles, the cyclic softening starts, i.e., the cyclic plastic strain reaches a minimum and, then, continuously increases, up to fracture. It was confirmed that the cyclic hardening is accompanied by an increase in dislocation density, while cyclic softening is caused by the dislocation rearrangement. The commencement of cyclic softening is remarkably delayed in the steel with fine TiC precipitates. The strong pinning effect by the precipitates, probably due to the Orowan mechanism, not due to the cutting mechanism, was observed by transmission electron microscopy (TEM). Therefore, it is considered that the long fatigue life of the precipitation-hardened steel is led by the fine TiC precipitates which play a role of the obstacles against mobile dislocations.

View full abstractDownload PDF (5164K) -

Maki Hashimoto, Ryoichi Toyoda, Yoshihito Matsumura2016 Volume 80 Issue 10 Pages 663-666

Published: 2016

Released on J-STAGE: September 25, 2016

JOURNAL FREE ACCESSIn our recent research, it was found that the effects of ion bombardment for thin films can be estimated using the ion bombardment parameter Pi. Internal stress in sputtered thin films can be classified into thermal stress and true stress. In this study, the internal stress in thin films was evaluated by the changes in evaporant sources (Ni or Al), substrate (Si or glass), and substrate temperature during the deposition. Internal stress in thin films with ion bombardment as a part of true stress was controlled by plasma diagnostics. Thermal stress in the thin films was evaluated from the thermal expansion coefficient of the films and the substrate with the changing substrate temperature during thin film deposition. It was found that internal stress of the films was strongly dependent on thermal stress. Despite the control of ion bombardment by plasma diagnostics, the values of true stress for the films were not continuous. This suggests that in addition to ion bombardment, true stress is also governed by microstructural changes with changing substrate temperature.

View full abstractDownload PDF (1102K)

-

Hiroki Yoshida, Takaaki Yamazaki, Takayoshi Adachi, Naoki Fukumuro, Sh ...2016 Volume 80 Issue 10 Pages 667

Published: 2016

Released on J-STAGE: September 25, 2016

JOURNAL FREE ACCESSJournal of the Japan Institute of Metals and Materials Vol. 79, No. 3 (2015) 78–81

p.80, Fig. 2(f)

View full abstractDownload PDF (504K)

- |<

- <

- 1

- >

- >|