- |<

- <

- 1

- >

- >|

-

谷ノ内 勇樹, 岡部 徹2017 年 81 巻 4 号 p. 151

発行日: 2017/04/01

公開日: 2017/03/25

ジャーナル フリーPDF形式でダウンロード (447K) -

萱沼 義弘, 水橋 正英, 新藤 裕一朗原稿種別: オーバービュー

2017 年 81 巻 4 号 p. 152-156

発行日: 2017/04/01

公開日: 2017/03/25

[早期公開] 公開日: 2017/01/16ジャーナル フリーRecycling of precious metals from scraps generated from manufacturing process have been widely done. The recycling process calls for maintenance of confidentiality of the scrap, use of isolated lots for the recycling operation, high recovery rates, short operation time and low treatment costs. In recent years, the recycling process has been facing three additional problems. The first is the reduction in the precious metal content in the scraps because of their substitution by other non-ferrous metals. The second is the contamination of metals that are never contained in natural ores. They have been used for upgrading the product performance, but those contaminations make it difficult to extract and purify precious metals. The third is the enforcement of stringent environmental regulations in Japan, which prohibits the continuous use of certain chemicals such as nitric acid. This paper describes the work carried out by a precious metals recycling company to solve the aforementioned problems.

抄録全体を表示PDF形式でダウンロード (791K) -

成田 弘一, 鈴木 智也, 元川 竜平原稿種別: レビュー

2017 年 81 巻 4 号 p. 157-167

発行日: 2017/04/01

公開日: 2017/03/25

[早期公開] 公開日: 2017/02/17ジャーナル フリーMost of the refineries for platinum group metals (PGMs) in Japan have adopted solvent extraction methods for mutual separation of PGMs. Few effective extractants for industrial use have been found although some industrial processes were established in 1970's. Recently, some compounds have been reported as candidates for practical PGM extractants in addition to new concepts for PGM extraction mechanisms. In this review article, we present well-known PGM recovery processes based on solvent extraction, industrial extractants and their properties, and conventional extraction mechanism for PGMs. Additionally, we discuss recent interesting extraction systems (amide-type compounds and ionic liquid) and then introduce new extraction concepts based on the specific interactions at the outer-sphere of a metal complex in the organic phase.

抄録全体を表示PDF形式でダウンロード (1324K) -

藤間 研也, 森本 太郎, 糸魚川 博之, 別役 大2017 年 81 巻 4 号 p. 168-177

発行日: 2017/04/01

公開日: 2017/03/25

ジャーナル フリーThe platinum group metals (PGM: platinum, palladium, rhodium, ruthenium, iridium, and osmium) are widely used in electrical devices and in catalysts. It is important that sustainable methods of recycling PGMs in waste electrical devices and catalysts are developed because PGMs are expensive and new sources in the Earth's crust are limited. In this work, processes for recycling ruthenium, platinum, palladium, and rhodium based on chlorination in molten chloride flux are investigated. Scrap containing ruthenium was chlorinated using Cl2 at 873 K in molten LiCl-NaCl, then the ruthenium was reduced using flowing H2 in molten salt. As a result 99.96 mass% Ru powder was obtained. Platinum, palladium, or rhodium was chlorinated using Cl2 at 973 K in molten NaCl-CsCl. The chloride complex containing Pt, Pd, and Rh at the desired composition was then treated using one of two processes. In one, the complex was oxidized using Na2CO3 and then reduced on granular CaCO3 in flowing H2 at 1473 K. In the other, the complex in the solid state was directly reduced using flowing H2. Both processes gave PGM-alloy powder products with the desired compositions. The morphologies of the PGM powders could be controlled in recycling process.

抄録全体を表示PDF形式でダウンロード (1386K) -

永井 燈文, 柴田 悦郎, 中村 崇2017 年 81 巻 4 号 p. 178-185

発行日: 2017/04/01

公開日: 2017/03/25

ジャーナル フリーThe oxidation–distillation method was used to separate ruthenium (Ru) from a solution containing platinum group metals. In this method, Ru was oxidized to ruthenium tetraoxide (RuO4). The RuO4 was then distilled and recovered from a hydrochloric acid (HCl) solution. In this study, sodium bromate (NaBrO3) was used as the oxidizer, and the amount of NaBrO3 needed to convert Ru to RuO4 was investigated. The Ru in the HCl solution was precipitated as an ammonium ruthenium complex salt by addition of ammonium chloride (NH4Cl) under various conditions and temperatures. The relationship between the precipitation conditions and the properties of the precipitated salts was investigated. The purity of the Ru powder, obtained by pyrolysis of the precipitated salt, was also analyzed.

抄録全体を表示PDF形式でダウンロード (1059K) -

木下 武彦, 石垣 友三2017 年 81 巻 4 号 p. 186-191

発行日: 2017/04/01

公開日: 2017/03/25

ジャーナル フリーContinuous counter-current foam separation (CCFS), which features simultaneous injections of metal/surfactant solutions into the rising foam bed, was applied to the recovery of Pd(II) from hydrochloric acid solutions containing several other metals. In aqueous solutions a nonionic surfactant, poly(oxyethylene) monooleyl ether (POOPE), was added along with a series of thiodiglycolamide (TDGA) extractant as metal collector. Using tetrabutyl-TDGA, selective separation of Pd(II) was attained over the other metals, though the total amount of metal recovered in the foamate was small. This low recovery results from decreasing foam stability, which was ascertained by cavities in the foam bed, caused by the addition of organic extractant. Moreover, tetra-2-ethylhexyl-TDGA was tried and satisfactory separation could be attained; the percent recovery of Pd(II) was 95% with the enrichment 1.8 while the separation factors of Pd(II)/Pt(IV), Pd(II)/Fe(III), Pd(II)/Cu(II) and Pd(II)/Zn(II) were 518, 162, 635 and 209, respectively.

抄録全体を表示PDF形式でダウンロード (1112K) -

松野 泰也, 小此木 江里, 吉村 彰大, 佐藤 真理, 佐藤 主税2017 年 81 巻 4 号 p. 192-195

発行日: 2017/04/01

公開日: 2017/03/25

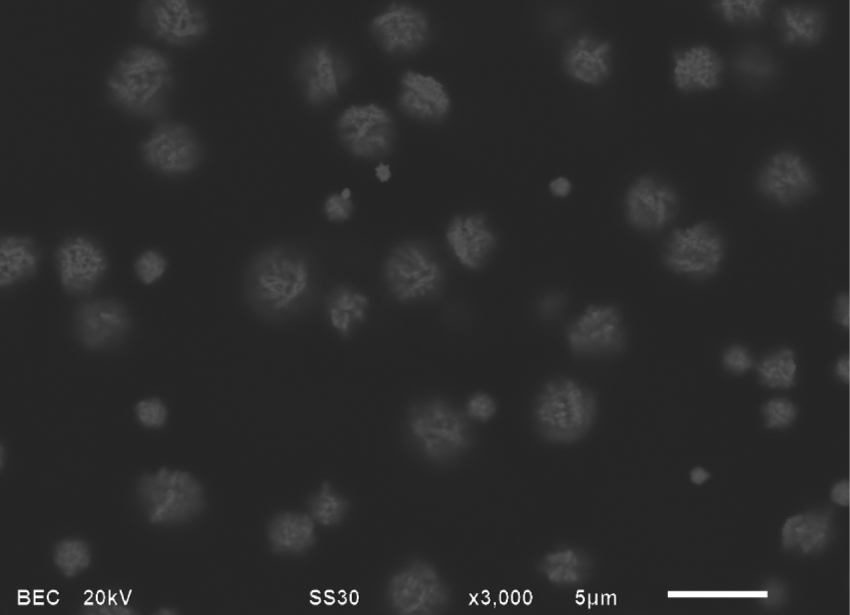

[早期公開] 公開日: 2017/02/10ジャーナル フリーWe have presented a novel method for the production of gold micrometer-sized particles by dissolving and recovering gold with DMSO/HCl containing CuCl2 and NaCl. It was reported that spherical or confeito-like particles could be formed depending on the concentrations of dissolved gold and Cl- ion in the liquid. In this paper, in-situ observation for the formations of gold particles in the liquid phase was conducted using atmospheric scanning electron microscopy (ASEM). An electron-permeable window made of pressure-resistant 100 nm-thick silicon nitride (SiN) film, set into the bottom of the open ASEM sample dish, allows an electron beam to be projected from underneath the sample. This structure of ASEM enable us to observe dynamic phenomena in liquid or gas under atmospheric pressure in real time. It was found that all of the particles formed during in-situ observation were confeito-like in shape, which was different from what had been expected.

Fig. 7 Fullsize ImageASEM images of gold particle formation in the liquid after 46 minutes at a magnification of ×3000, Experiment 2.抄録全体を表示PDF形式でダウンロード (898K)

Fig. 7 Fullsize ImageASEM images of gold particle formation in the liquid after 46 minutes at a magnification of ×3000, Experiment 2.抄録全体を表示PDF形式でダウンロード (898K)

-

峯田才寛 , 三浦誠司 , 岡 和彦, 宮島達也2017 年 81 巻 4 号 p. 196-205

発行日: 2017/04/01

公開日: 2017/03/25

ジャーナル フリーIn order to understand a plastic deformation behavior of pure Mg and Mg-Y alloy single-crystals under a complex stress condition, newly established in-situ Brinell indentation was conducted. The deformation morphology on the upper surfaces of the specimen around the indent could not been sufficiently observed by the previously reported in-situ indentation methods using an optically transparent indenter due to refraction of rays at a surface of the indenter. In this study, the space between the indenter and the specimen surface are filled with immersion liquids such as silicone oil and kerosene. This technique enables to observe the specimen surface during indentation. Using in-situ Brinell indentation on pure Mg and Mg-Y alloy single-crystals, it is found that the shape of the indents on them are not circle but elliptic even during the loading. The aspect ratio of the indents decreases with increasing Y content. Moreover, occurrences of plastic deformation mechanisms around and beneath the indent could be observed during loading and unloading process by using the in-situ Brinell indentation method.

Fig. 2 Fullsize ImageThe in-situ images of (a) pure Mg, (b) Mg-1.3 at.%Y and (c) Mg-2.3 at.%Y single-crystals during loading process with nr/ni=0.85. (d) An in-situ image processed to measure the major and the minor diameters of the indent on pure Mg single-crystal at 9.8 N.抄録全体を表示PDF形式でダウンロード (1592K)

Fig. 2 Fullsize ImageThe in-situ images of (a) pure Mg, (b) Mg-1.3 at.%Y and (c) Mg-2.3 at.%Y single-crystals during loading process with nr/ni=0.85. (d) An in-situ image processed to measure the major and the minor diameters of the indent on pure Mg single-crystal at 9.8 N.抄録全体を表示PDF形式でダウンロード (1592K) -

山田 遥平, 中久保 昌平, 武田 実佳子2017 年 81 巻 4 号 p. 206-210

発行日: 2017/04/01

公開日: 2017/03/25

[早期公開] 公開日: 2017/02/03ジャーナル フリーIn the hot rolling process, the external appearance of steel can deteriorate due to spalling of oxide scales. We used a tensile test in order to evaluate and quantify the adhesion of the scales in the hot rolling process. When loaded with tensile stress, the behavior of the scales goes through the following three stages:

①The scales have only residual stress

②The scales and the steel are both elastically deformed

③The scales are elastically deformed but the steel is plastically deformed.

For these three stages, the strain energy accumulated in the scales before spalling was calculated and then the adhesion energy was derived. For about 4 μm thick scales on 99.9% Fe and Fe-1.0%C the adhesion energies were 1.70 J/m2 and 36.2 J/m2, respectively. The adhesion energies determined by a scratch test were 2.90 J/m2, and 31.6 J/m2 each. Thus, the results of the two tests are approximately in agreement.

抄録全体を表示PDF形式でダウンロード (849K) -

中佐 啓治郎, 山本 旭宏, 久保 隆, 王 栄光, 李木 経孝2017 年 81 巻 4 号 p. 211-220

発行日: 2017/04/01

公開日: 2017/03/25

[早期公開] 公開日: 2017/02/10ジャーナル フリーArgon ion sputter etching was applied to commercially pure titanium at a radio frequency power of 100, 200 or 250 W for 1.8 to 9 ks. Cone-shaped protrusions with base diameters of 2-5 μm were formed when the specimens were put on a stainless steel disk as well as on a copper disk. On the other hand, no protrusion was formed on a 3N-purity titanium specimen put on the copper disk. These facts mean that the origin of protrusions formed on the commercially pure titanium is not Fe, Ni, Cr and Cu particles arrived from these disks. The origin is considered to be fine titanium oxides precipitated near the surface area, i.e., the collision of argon ions with titanium atoms of specimen surface have brought about high temperature, high temperature-gradient and high vacancy-density gradient, and have promoted quick formation of oxides due to a large amount of oxygen diffusion from interior to surface of the specimen. It is probable that the oxide grow to a pillar perpendicular to the surface under the high temperature and vacancy-density gradient. The pillar acts as a mask and the protrusion begins to form at the root of the pillar. According to an EBSD analysis, the protrusions were densely formed preferentially on the grains with

crystal plane but not with closed-packed {0001} plane and

crystal plane but not with closed-packed {0001} plane and  plane. This corresponds that the oxide pillar can grow stably perpendicular to the

plane. This corresponds that the oxide pillar can grow stably perpendicular to the  plane without being sputtered out.抄録全体を表示PDF形式でダウンロード (2237K)

plane without being sputtered out.抄録全体を表示PDF形式でダウンロード (2237K)

- |<

- <

- 1

- >

- >|