- |<

- <

- 1

- >

- >|

-

Yasutaka Hashimoto, Tsuyoshi Nishi, Hiromichi OhtaArticle type: Review

2017 Volume 81 Issue 5 Pages 221-225

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

Advance online publication: March 27, 2017JOURNAL FREE ACCESSThe viscosities of the lead-free solders are important to simulate the process of the manufacturing process. In this article, current status of the viscosity measurements for the lead-free solders are reviewed. In addition, we introduced the current work of the viscosity measurements for the lead-free solders by using the rotational viscometer with concentric cylinder spindle geometry.

View full abstractDownload PDF (960K)

-

Yoshinori Sakamoto, Sayuri Takemura, Wataru Yamazaki, Masaomi Shimura, ...2017 Volume 81 Issue 5 Pages 226-233

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

Advance online publication: February 24, 2017JOURNAL FREE ACCESSMany research studies have been conducted so far about the occurrence of the whiskers in Sn-plating.

However, most of them have paid attention to the generation mechanism of the whiskers, and to the time variations of both the number and lengths of the whiskers. Very few research studies have been conducted on the correlation between the generation of the intermetallic compound and the occurrence of the whiskers.

In the present study, double-layer plating(Sn/Cu thin films)was electrodeposited on the 7-3 brass substrate to investigate quantitatively the time variation of the amount of the intermetallic compound generated in the Sn plating film. It was clarified that the relation between the amount of the intermetallic compound and the elapsed time can be expressed by the two different straight lines on the log-log graph. In the early stage until the first seven days after the plating processing, the rate of the generation amount of the intermetallic compound was faster than that in the next stage. When the amount of the intermetallic compound per area is less than 5%, the whisker density increased with an increase in the amount of the intermetallic compound per area. On the other hand, in more than 5% of domains of the intermetallic compound per area, a clear correlation between them was not observed.

It is considered that the internal compressive stresses increase in the inside of the Sn plating with an increase in the amount of the intermetallic compound. It is inferred that the whiskers arise on the Sn-plating film to release the above internal compressive stress. Seven days later after the plating processing, the generation rate of the amount of the intermetallic compound decreased because of the change in the diffusion mechanism, i.e. from the grain boundary diffusion to the volume one. Corresponding to the rate of the amount of the intermetallic compound, the rate of the whiskers formation was also suppressed.

View full abstractDownload PDF (1433K) -

Mami Kasakura, Yoshisato Kimura2017 Volume 81 Issue 5 Pages 234-243

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

Advance online publication: February 17, 2017JOURNAL FREE ACCESSTwo-phase microstructure consisting of the E21 type (Co, Ni)3AlC, κ phase, and (Co, Ni) primary solid solution, α phase, forms having three different characteristic morphologies in the same alloy according to their thermal history. Two of them are observed in the as-cast microstructure; the primary α phase dendrite with fine cuboidal κ precipitates, and the eutectic lamellar consisting of α and κ phases. During heat treatments of the alloys at high temperatures, the nodular type discontinuous precipitation (DCP) lamellar, consisting of α and κ phases, forms locally in the primary α dendrite regions as the third morphology. The inter-lamellar spacing and nodule size of the DCP lamellar becomes larger with increasing heat treatment temperature. Micro-Vickers hardness numbers of the α primary dendrites having κ precipitates and the eutectic lamellar are comparable, and higher than those of the DCP lamellar. The alloy annealed at 1173 K for 96 h exhibits high yield strength, the 0.2% proof stress, exceeding about 800 MPa in compression, and the excellent ductility of 13.6% plastic strain at room temperature in tension. On the other hand, the DCP lamellar formation lowers the strength of the alloys, however high strength about 750 MPa can be maintained in the alloy heat treated at the highest temperature of 1373 K as the lowest yield stress of all. Elevated temperature strength measured at 1123 K for the alloy heat treated at 1173 K is 486 MPa of yield stress in compression. The DCP lamellar formation can be suppressed by the two-step heat treatments and by the unidirectional solidification. The former has more homogeneous distribution of fine DCP lamellar than single-step heat treated alloys. The latter is very effective to improve the homogeneity and thermal stability of α and κ two-phase aligned microstructure and to maintain high temperature strength of 452 MPa at 1123 K.

View full abstractDownload PDF (2412K) -

Hiromu Hisazawa, Yoshihiro Terada2017 Volume 81 Issue 5 Pages 244-250

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

Advance online publication: February 24, 2017JOURNAL FREE ACCESSThe effect of the content of Ti and Al on the morphology of γ′ precipitates is examined for 13 kinds of Ni-based model alloys aged at 1073 K/100 h. The morphology of γ′ precipitates was evaluated using the absolute moment invariants technique. The magnitude of cuboidal for γ′ particles clearly depends on the lattice misfit, but does not depend on the volume fraction of the particles. More γ′ particles tend to form a flat and parallel interface pair or elongated shape when the Ti and Al content is increased. These results suggest that the lattice misfit makes γ′ particles cuboidal and volume fraction strengthens their interaction, leading to a unique morphology.

View full abstractDownload PDF (1081K) -

Akira Kobayashi, Katsuhisa Nagayama2017 Volume 81 Issue 5 Pages 251-256

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

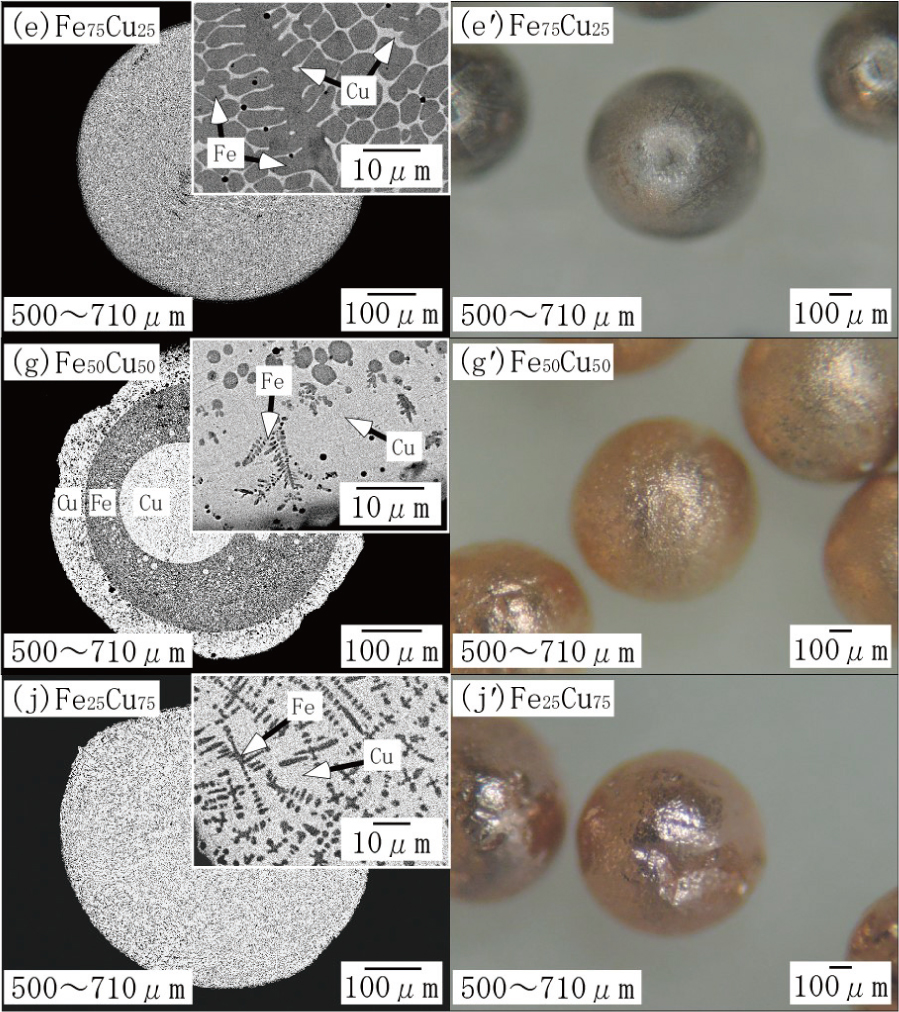

Advance online publication: March 10, 2017JOURNAL FREE ACCESSLiquid phase separation usually occurs in immiscible alloys under gravity. The drop tube and electromagnetic levitation processes, which are types of containerless processes, enable solidification melt without using a container. This would avoid heterogeneous nucleation induced by the container walls, thus obtaining undercooling conditions. The abovementioned processes have been used to study the undercooling solidification and metastable phase formation of the melt. Metastable miscibility gap is observed in the Fe-Cu binary alloy; however, metastable phase formation in the wide composition range used by the drop tube process has never been reported. In this study, we obtained samples of Fe-Cu binary alloy using a drop tube apparatus with a free fall length of 2.5 m and an electromagnetic levitation apparatus. In addition, we aimed to examine the effectiveness of the containerless process for microstructure formation of the Fe-Cu binary alloy based on undercooling solidification. The results of the SEM and EDS analyses showed that the minor liquid phase, Fe or Cu, finely dispersed in the matrix of the major liquid phase of Fe75Cu25 and Fe25Cu75 particle samples, and the two or three layer structure of Fe50Cu50 particle samples. In particular, all the samples exhibited a phase separation caused by the metastable miscibility gap and the dendrite growth of Fe phase with the decrease of the cooling rate.

Fig. 5 Fullsize ImageView full abstractDownload PDF (1539K)

Fig. 5 Fullsize ImageView full abstractDownload PDF (1539K) -

R. Yoshimura, H. Esaka, K. Shinozuka2017 Volume 81 Issue 5 Pages 257-263

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

JOURNAL FREE ACCESSIn order to investigate the effect of the addition of a small amount of Zn to a Sn-based eutectic alloy, the thermal histories during solidification were measured and the solidified structures of the Sn-2Ag-xZn alloys were characterized. The Zn content, x, was varied from 0 to 0.6 mass%. Five grams of the alloy were melted and cooled at a constant cooling rate of 0.05 K/s. The temperature of the alloy was measured using a fine, K-type thermocouple and recorded using a data recorder. The undercooling for the nucleation of primary(β-Sn), ΔTexp, was defined as the temperature difference between the minimum temperature before nucleation and the maximum after recalescence. It was found that ΔTexp decreased with increasing x. When x was between 0 and 0.15 mass%, the slope of this decrease was large. On the other hand, when x exceeded 0.15 mass%, the slope became small. The solidified structures of these alloys consisted of the primary(β-Sn)phase and the eutectic structure, which were typical for hypoeutectic alloys. The volume fraction of primary(β-Sn), f β-Sn, was larger than the equilibrium value and decreased slightly with increasing x. This indicated that the undercooling for the nucleation of the primary(β-Sn)phase is linked to the volume of the primary phase; however, this relation is weak.

View full abstractDownload PDF (1383K) -

R. Yoshimura, H. Esaka, K. Shinozuka2017 Volume 81 Issue 5 Pages 264-269

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

JOURNAL FREE ACCESSIn order to assess the effect of Zn addition in Sn-2Ag alloy on the undercooling of the primary (β-Sn) phase, tip radii of the columnar dendrites of primary (β-Sn) have been systematically investigated. Sn-2Ag-x Zn alloys were prepared for the experiments, where x=0, 0.05 and 0.6 mass%. These alloys were unidirectionally solidified at growth velocities of 4, 10, 20, 30 and 40 μm/s. The tip radii of columnar dendrites of primary (β-Sn) on the longitudinal cross section of quenched samples were characterized. It was found that the tip radius decreased with increasing growth velocity and with increasing amounts of Zn. The effect of Zn addition on the solid/liquid interfacial energy was analyzed by assuming that the addition of Zn to Sn-2Ag alloy will not change the physical parameters such as the diffusion coefficient of the solute, solidification temperature range, and entropy of fusion. The addition of small amounts of Zn may considerably decrease the solid/liquid interfacial energy of primary (β-Sn). This may possibly decrease the undercooling for nucleation of the primary (β-Sn) phase in Sn-2Ag-x Zn alloy.

View full abstractDownload PDF (1094K) -

Yuta Suzuki, Yuji Sutou, Daisuke Ando, Junichi Koike2017 Volume 81 Issue 5 Pages 270-275

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

Advance online publication: March 27, 2017JOURNAL FREE ACCESSEffects of Cu addition on hardness and wear properties of (Cr, Mo)N films were investigated by nanoindentation and ball-on-disk measurements. (Cr100-x-yMoxCuy)N films were deposited onto a stainless steel substrate by a reactive DC magnetron sputtering of Cr50Mo50 and Cu targets under the mixture of argon (45 ccm) and nitrogen (5 ccm) gases. The hardness of the film increased from 21.9 to 23.5 GPa by Cu addition of y=3.4 of Cu addition and then drastically decreased with further increasing Cu addition. The drastic decrease in hardness is caused by the formation of amorphous structure. In crystalline films, it was found that the change of hardness obeys the inverse Hall-Petch relationship. The wear mechanism of the film was changed by increasing Cu addition, adhesive wear (y=0), lubricated wear (3.4 ≤ y≤ 12.6) and abrasive wear (y≥ 20.4). It was also found from wear track observation that the lubricated wear in the Cu content region of 3.4 ≤ y≤ 12.6 was obtained by the formation of the oxide debris resulted from the film with as small amount of Cu (3.4 ≤ y ≤ 12.6). With further increase in Cu content (y≥ 20.4), the film was severely worn because of its low hardness of the amorphous film.

View full abstractDownload PDF (1436K) -

Yuta Takeuchi, Yukiko Ogawa, Daisuke Ando, Yuji Sutou, Junichi Koike2017 Volume 81 Issue 5 Pages 276-281

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

Advance online publication: March 31, 2017JOURNAL FREE ACCESSMg-Sc-Zn based alloy was investigated to understand the effects of introducing bcc structure on mechanical properties. The alloy ingot was prepared by induction melting of ZK60 and pure Sc in Ar atmosphere, and then hot rolled at 550°C into a sheet. The rolled sheets were finally annealed at 500 (designated as α-type) and 680°C (designated as α+β-type) for 30 minutes. From XRD patterns and SEM observation, the existence of ScZn compound was confirmed in both samples. The volume fraction ratio of bcc/(hcp+bcc) were 0 and 73% on samples annealed at 500 and 680°C, respectively. The ultimate tensile strength (UTS) and elongation of the α(hcp)-type sample were 280 MPa and 20.5%, respectively, while those of α(hcp)+β(bcc)-type sample were 373 MPa and 5.9%, respectively. It was found that c/a ratio of α-type sample was small indicating that non-basal slip systems were activated during tensile test. On the other hand, it was suggested that, in β phase, the stress induced phase transformation from bcc to hcp occurred during tensile test which causes higher strength and lower elongation.

View full abstractDownload PDF (2153K) -

Hiroshi Kobayashi, Hirofumi Shoji, Satoshi Asano, Masaki Imamura2017 Volume 81 Issue 5 Pages 282-287

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

JOURNAL FREE ACCESSThe matte chlorine leach and electro-winning (MCLE) process, developed by Sumitomo Metal Mining Co., Ltd. (SMM) is well known as a unique commercial nickel refining process with a high nickel recovery ratio. SMM has gradually increased the ratio of mixed sulfide (MS: mixture of nickel and cobalt sulfides) that can be used as a raw material in the MCLE process over the past decade. However, the reactivity of MS in chlorine leaching remains insufficient and further improvements are needed.

We performed bench scale chlorine leaching tests with iron chloride, instead of the currently used copper chloride, as an oxidant medium for chlorine gas. However the reactivity of MS was not improved despite the higher oxidation-reduction potential (ORP) of iron chloride than that of copper chloride. Though stability studies of iron chloride complexes based on an E-pCl (potential, -log aCl-) diagram, the chlorine leaching potential that is suitable for copper chloride was found to be too low for iron chloride. Reactivity of MS was improved at a higher leaching potentials; however this did not represent a significant improvement over copper chloride based methods. We elucidated the reaction mechanism and showed that chlorine leaching with iron chloride is not suitable for industrial application to MS.

View full abstractDownload PDF (1078K) -

Shogo Takesue, Shoichi Kikuchi, Hiroyuki Akebono, Jun Komotori, Kengo ...2017 Volume 81 Issue 5 Pages 288-293

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

Advance online publication: April 07, 2017JOURNAL FREE ACCESSIn this study, the effects of gas blow velocity on the surface properties of a Ti-6Al-4V alloy treated by a gas blow induction heating (IH) nitriding system were investigated. The surface microstructure of the treated specimens was characterized using scanning electron microscope and X-ray diffraction. In addition, micro-Vickers hardness and nanohardness were measured and reciprocating wear tests were conducted to evaluate the modified surface layers. The results showed that the nitriding of a specimen was facilitated by using a smaller gas blow nozzle. Incorporating the smaller nozzle resulted in an increase in gas blow velocity, which in turn increased the IH power and the temperature inside a specimen, thus accelerating the nitrogen diffusion. Moreover, nitriding at a lower treatment temperature (973 K) was achieved by increasing gas blow velocity. The specimen nitrided at a lower temperature with a high gas blow velocity exhibited better wear resistance than the untreated specimen. This process also inhibited transformation to an acicular α phase, which involves apparent grain coarsening.

View full abstractDownload PDF (1098K)

-

Akira Kobayashi, Katsuhisa Nagayama2017 Volume 81 Issue 5 Pages 294

Published: May 01, 2017

Released on J-STAGE: April 25, 2017

JOURNAL FREE ACCESSJournal of the Japan Institute of Metals and Materials Vol. 80, No. 5 (2017) 251–256

Figure CaptionsView full abstractDownload PDF (1803K)

- |<

- <

- 1

- >

- >|