- |<

- <

- 1

- >

- >|

-

柳瀬 裕太, 宮内 創, 松本 洋明, 横田 耕三原稿種別: 論文

2020 年 84 巻 12 号 p. 365-373

発行日: 2020/12/01

公開日: 2020/11/25

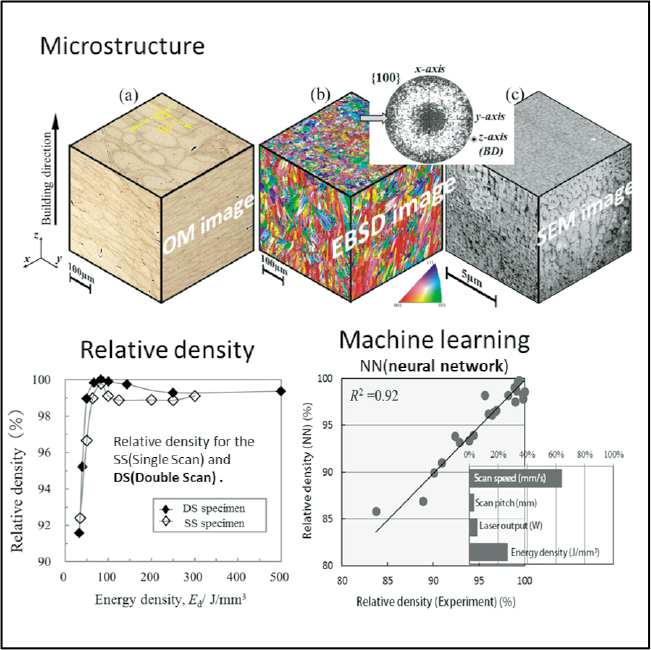

ジャーナル フリー HTMLThis work examined the behaviors of densification and microstructural formation of the Al-10 mass% Si- 0.35 mass% Mg alloy fabricated by Selective Laser Melting (SLM) method on the basis of experimental work and machine learning. Additionally, the effect of scanning repeated twice in each layer (double scanning) in the SLM process was also investigated. The SLM- Al-10 mass% Si- 0.35 mass% Mg alloy exhibited the columnar grained microstructure with an (α-Al-Si) eutectic cell structure. Refined microstructures were produced at an increasing scanning speed with a decreasing the energy density (J/mm3). Relative density tended to increase with an increasing of energy density for scan pitch conditions of 0.1 mm and 0.05 mm. And a scattering was obviously exhibited at a higher relative density more than 95%. The analysis based on machine learning revealed that a scanning pitch of 0.2 mm was just a condition to achieve a high relative density. Except for the condition at a scanning pitch of 0.2 mm, a scan speed was the most important factor in affecting the relative density. Thus, a machine learning approach enabled to identify the important processing factor for affecting the behavior quantitatively. Additionally, compared to a conventional single scanning process, it was found in this work that the double scanning resulted in a higher relative density with keeping the fine microstructural formation.

Graphical Abstract Fullsize Image抄録全体を表示PDF形式でダウンロード (3323K) HTML形式で全画面表示

Graphical Abstract Fullsize Image抄録全体を表示PDF形式でダウンロード (3323K) HTML形式で全画面表示 -

中川 康太朗, 林 桃希, 高野(佐藤) こずえ, 松永 裕隆, 森 広行, 北原 周, 小貫 祐介, 鈴木 茂, 佐藤 成男原稿種別: 論文

2020 年 84 巻 12 号 p. 374-381

発行日: 2020/12/01

公開日: 2020/11/25

[早期公開] 公開日: 2020/10/23ジャーナル フリー HTMLRelationship between dislocation multiplication and work hardening of tensile-deformed Cu-Zn alloys with different grain sizes was investigated. X-ray diffraction line-profile analysis was employed to evaluate dislocation parameters. It was confirmed that dislocation multiplication was enhanced with a decrease in the grain sizes. This was mainly caused by GN (Geometrically Necessary) dislocation, which was characterized by KAM (Kernel Average Misorientation) in EBSD (Electron Back Scatter Diffraction). The strength of dislocation hardening was evaluated from the α value in the Bailey-Hirsch equation: σ=σ0+MTαGb√ρ. The α values were estimated by plotting the flow stress against square root of dislocation density. The α values became smaller with the decrease in the grain sizes, suggesting that the strength of dislocations hardening for unit length of dislocation became smaller. In order to elucidate the origin of the relationship between the grain size and the α values, the influence of grain size on the fraction of GN dislocation density as well as the outer radius of dislocation strain field. Whereas the effect of the fraction of the GN dislocation on the α values was small, the outer radius of dislocation strain field strongly affected the α values.

Fig. 13 Flow stress of the Cu-Zn alloys versus (a) √ρ, and (b) ln(Re/r0)√ρ. Fullsize Image抄録全体を表示PDF形式でダウンロード (2096K) HTML形式で全画面表示

Fig. 13 Flow stress of the Cu-Zn alloys versus (a) √ρ, and (b) ln(Re/r0)√ρ. Fullsize Image抄録全体を表示PDF形式でダウンロード (2096K) HTML形式で全画面表示 -

島内 優, 池本 祥, 大森 滋和, 糸井 貴臣原稿種別: 論文

2020 年 84 巻 12 号 p. 382-390

発行日: 2020/12/01

公開日: 2020/11/25

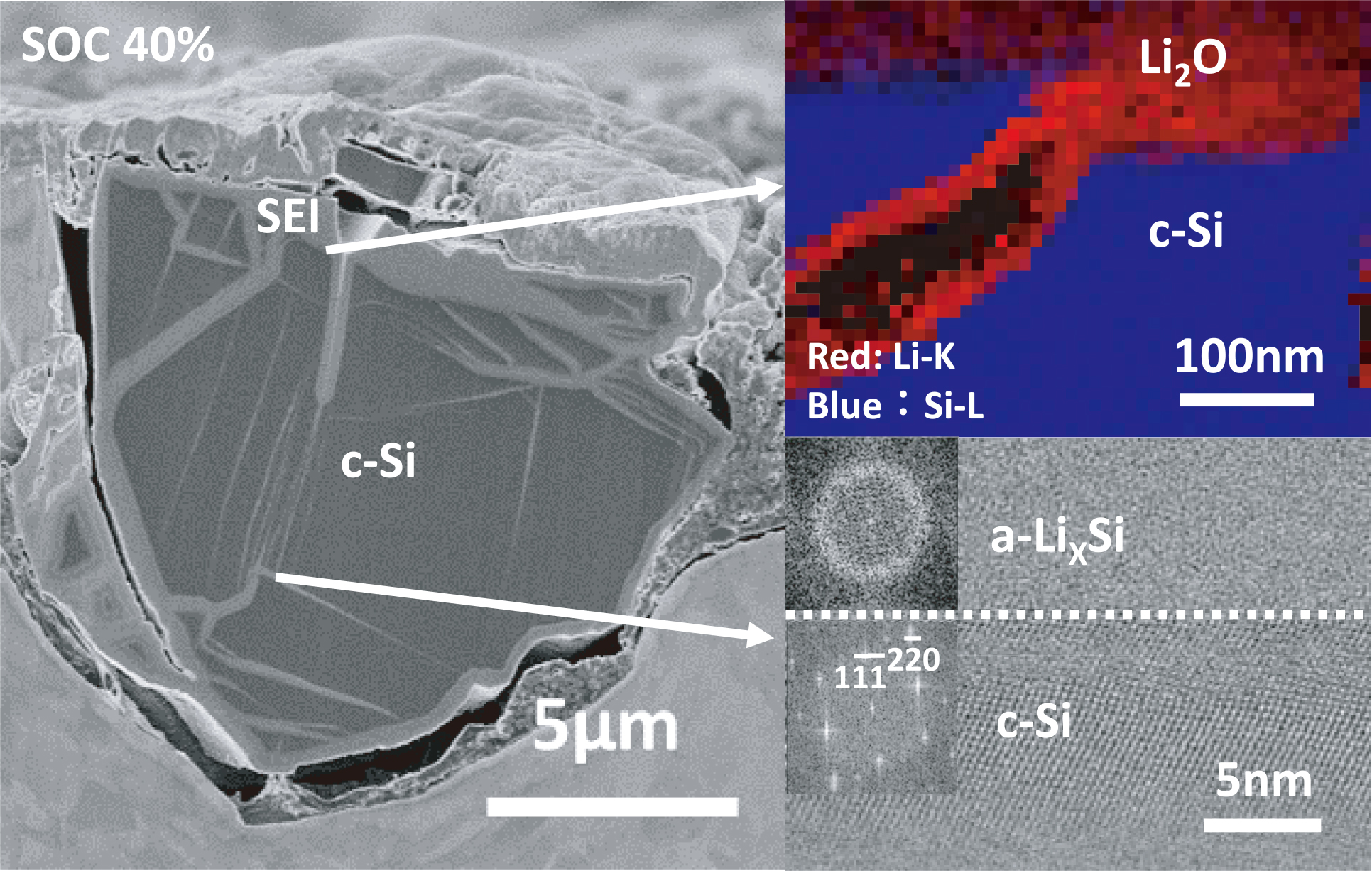

ジャーナル フリー HTMLA SEI (Solid Electrolyte Interphase) is formed on the surface layer of the negative electrode active material of a lithium ion secondary battery (LIB) during the initial charging process, and its morphology and structure significantly affect performance and safety. In this study, by conducting ex-situ experiments, SEM, TEM and STEM-EELS observations were performed on Si negative electrodes under charge state within an actual battery and Si negative electrodes directly charged on a TEM thin film, revealed morphology and structure of the SEI. All of the processes from specimen preparation for electron microscopy observation to specimen transport were performed under non-atmospheric exposure conditions.

The SEI on the surface of the Si negative electrode grew thicker as the charge depth increased. On the other hands, LixSi amorphous phase due to the lithiation by solid-state reaction was confirmed inside the Si negative electrode. It was found that Li2O was formed on the most surface of the Si negative electrode at the initial stage of charging, and the SEI was mainly composed of Li2O. The SEI of about 1 µm was observed on the Si negative electrode after 40% charge, and the thickness of the SEI decreased to less than 1/5 after discharge.

Graphical Abstract Fullsize Image抄録全体を表示PDF形式でダウンロード (4625K) HTML形式で全画面表示

Graphical Abstract Fullsize Image抄録全体を表示PDF形式でダウンロード (4625K) HTML形式で全画面表示 -

斎藤 尚文, 鈴木 一孝, 福田 裕太, 伊藤 友美, 野田 雅史, 権田 善夫, 千野 靖正原稿種別: 論文

2020 年 84 巻 12 号 p. 391-398

発行日: 2020/12/01

公開日: 2020/11/25

[早期公開] 公開日: 2020/10/09ジャーナル フリー HTMLThe mechanical properties and microstructure of rolled and annealed Mg–8 mass%Al–1 mass%Zn–1 mass%Ca (AZX811) alloy plates were investigated. To investigate the effect of rolling temperature, samples were prepared by rolling at 623 K and 723 K, following which annealing was performed at 473 K. The size of the Al–Ca compound was finer in the 723 K rolled sample than in the 623 K rolled sample. The higher tensile strength and elongation of the 723 K rolled sample compared to the 623 K rolled sample were attributed to the finer Al–Ca compounds in the former. In addition, the effect of annealing temperature on the mechanical properties and microstructure of the 723 K rolled AZX811 alloys were investigated. As a result of these investigations, a decrease in proof stress and an increase in failure elongation were observed when the annealing temperature was set to 573 K. This was mainly ascribed to a decrease in the fraction of grains below 10 µm in size, a decrease in the basal texture intensity, and a solid solution of fine Mg17Al12 precipitates.

Graphical Abstract Fullsize Image抄録全体を表示PDF形式でダウンロード (1577K) HTML形式で全画面表示

Graphical Abstract Fullsize Image抄録全体を表示PDF形式でダウンロード (1577K) HTML形式で全画面表示 -

阿部 俊太郎, 大石 航司, 寺田 芳弘原稿種別: 論文

阿部 俊太郎, 大石 航司, 寺田 芳弘原稿種別: 論文

2020 年 84 巻 12 号 p. 399-405

発行日: 2020/12/01

公開日: 2020/11/25

ジャーナル フリー HTMLTo evaluate the stability of the α-Mg/C14–Mg2Ca lamellar microstructure, the aging treatment was carried out for the Mg–14.8 mass%Ca near-eutectic alloy at 573-723 K for 1-150 h. The spacing of the lamellar structure obtained by the eutectic reaction L → α-Mg+C14–Mg2Ca after casting is approximately 250 nm. It was found by the HRTEM observation that the α/C14 interface is composed of terraces and steps, and the terrace is parallel to the (1101)α pyramidal plane of the α-Mg lamellae. The lamellar microstructure is stable below 573 K. By contrast, the lamellar spacing (λ) continuously increases with the increasing aging time (t) above 573 K, and the increase of λ can be described as λ2−λ02 = kT t, where λ0 is the lamellar spacing for the as cast specimen and kT is a constant depending on aging temperature. The activation energy for the coarsening of the α/C14 lamellar microstructure was evaluated as 112 kJ/mol, which is close to the activation energy for the inter-diffusion of Ca in Mg. The hardness of the lamellar region decreases with the increasing λ, which is indicative that the α/C14 interface acts as an obstacle to the basal slip of dislocations in the α-Mg lamellae.

Fig. 3 FE-SEM image of the α-Mg/C14–Mg2Ca lamellar microstructure observed in the Mg–14.8 mass%Ca alloy, where the bright phase is α-Mg and the dark one is C14–Mg2Ca, respectively. Fullsize Image抄録全体を表示Editor's pick

Fig. 3 FE-SEM image of the α-Mg/C14–Mg2Ca lamellar microstructure observed in the Mg–14.8 mass%Ca alloy, where the bright phase is α-Mg and the dark one is C14–Mg2Ca, respectively. Fullsize Image抄録全体を表示Editor's pick2021年新進論文賞

PDF形式でダウンロード (7903K) HTML形式で全画面表示 -

原 聡宏, 江草 大佑, 三原 麻未, 田中 宏樹, 大沼 郁雄, 阿部 英司原稿種別: 論文

2020 年 84 巻 12 号 p. 406-412

発行日: 2020/12/01

公開日: 2020/11/25

[早期公開] 公開日: 2020/11/02ジャーナル フリー HTMLWe have investigated the work softening (WS) phenomena during a cold-roll process of an Al-Fe alloy, based on hardness measurements, electron microscopy observations, and thermodynamic calculations. The WS behavior was confirmed in the Al-Fe alloy when the rolling rate was larger than 80%, which contained fine grains with severe deformation. In contrast, the behavior and microstructural features were hardly observed in the A1050 alloy. Composition analyses showed that almost all Fe in the present Al-Fe alloy form the θ-Al13Fe4 phase, in which a trace impurity element, Si, is found to be significantly segregated. This Si partitioning behavior is confirmed by the thermodynamic calculations and consequently leads to a higher purification of the relevant Al matrix as being almost close to the 4N (99.99 mol%) level, known as a “scavenging effect” of the impurities. It can be concluded that the highly purified aluminum matrix provides an intrinsic origin of the WS of the present Al-Fe alloy. Significant reductions of the impurities may lead to an extended mean-free path of dislocation motions and related grain boundary effects, which promote the occurrence of dynamic recovery and/or recrystallizations at severe deformation ranges even during the cold-roll process.

Fig. 3 (a)-(d) SEM-BSE images and Fe-EDS maps of Al050 alloy and Al-Fe alloy, respectively, each of which was independently obtained from representative areas of the samples. (e) TEM bright field image and selected area diffraction pattern obtained from the Al-Fe compound in Al-Fe alloy. (f) Fe and Si compositions of the θ phase in Al-Fe alloy obtained by SEM-EDS point analyses. A black line represents a regression line of the Si/Fe ratio estimated by the least-squares method. A gray region represents a prediction interval of the regression line with one sigma. (g) HAADF-STEM image of the θ phase in Al-Fe alloy and a line profile of Si k-edge photon counts of the relevant EDS spectra taken across the Al matrix to the θ phase. Fullsize Image抄録全体を表示PDF形式でダウンロード (6323K) HTML形式で全画面表示

Fig. 3 (a)-(d) SEM-BSE images and Fe-EDS maps of Al050 alloy and Al-Fe alloy, respectively, each of which was independently obtained from representative areas of the samples. (e) TEM bright field image and selected area diffraction pattern obtained from the Al-Fe compound in Al-Fe alloy. (f) Fe and Si compositions of the θ phase in Al-Fe alloy obtained by SEM-EDS point analyses. A black line represents a regression line of the Si/Fe ratio estimated by the least-squares method. A gray region represents a prediction interval of the regression line with one sigma. (g) HAADF-STEM image of the θ phase in Al-Fe alloy and a line profile of Si k-edge photon counts of the relevant EDS spectra taken across the Al matrix to the θ phase. Fullsize Image抄録全体を表示PDF形式でダウンロード (6323K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|