- |<

- <

- 1

- >

- >|

-

2017 Volume 34 Pages Cover34_1

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (485K) Full view HTML -

2017 Volume 34 Pages EdBrd34_1

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (3458K) Full view HTML

-

2017 Volume 34 Pages 1-2

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (1732K) Full view HTML

-

2017 Volume 34 Pages 3-23

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: January 30, 2016Download PDF (18065K) Full view HTML -

2017 Volume 34 Pages 24-43

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: January 30, 2016Download PDF (17800K) Full view HTML -

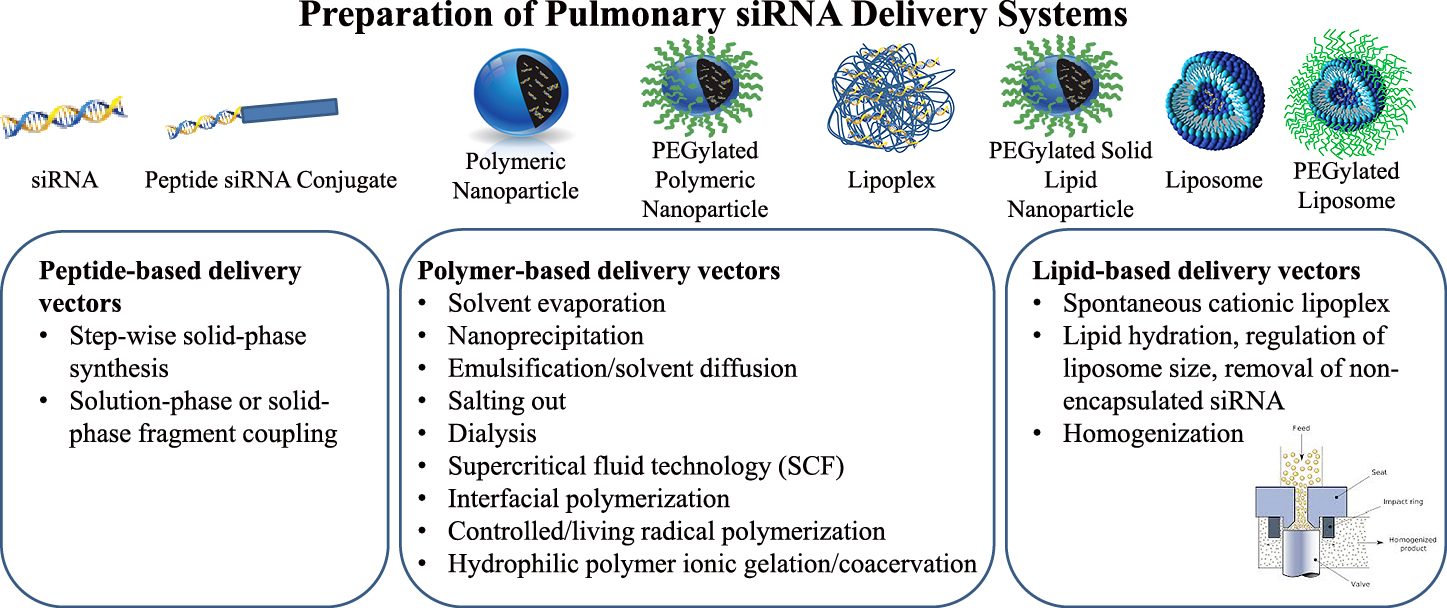

2017 Volume 34 Pages 44-69

2017 Volume 34 Pages 44-69

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: April 30, 2016Editor's pickIn the continually growing realm of therapeutic siRNA research, inhaled delivery of siRNA has been an attention-grabbing route of administration due to its potential as a targeted approach for protein synthesis inhibition through RNA interference. Evident hurdles to effective siRNA delivery include overcoming the natural defenses of the lungs as well as intracellular internalization and release of siRNA. This valuable article discusses different preparation methods for multiple types of nanoparticulate delivery systems of siRNA that have been composed of lipids, polymers, peptides, and inorganic materials. Additionally, the authors discuss examples of these cutting-edge nanoparticle siRNA delivery systems to the lungs via various inhalation delivery devices.

Download PDF (8326K) Full view HTML -

2017 Volume 34 Pages 70-79

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: April 30, 2016Download PDF (4152K) Full view HTML -

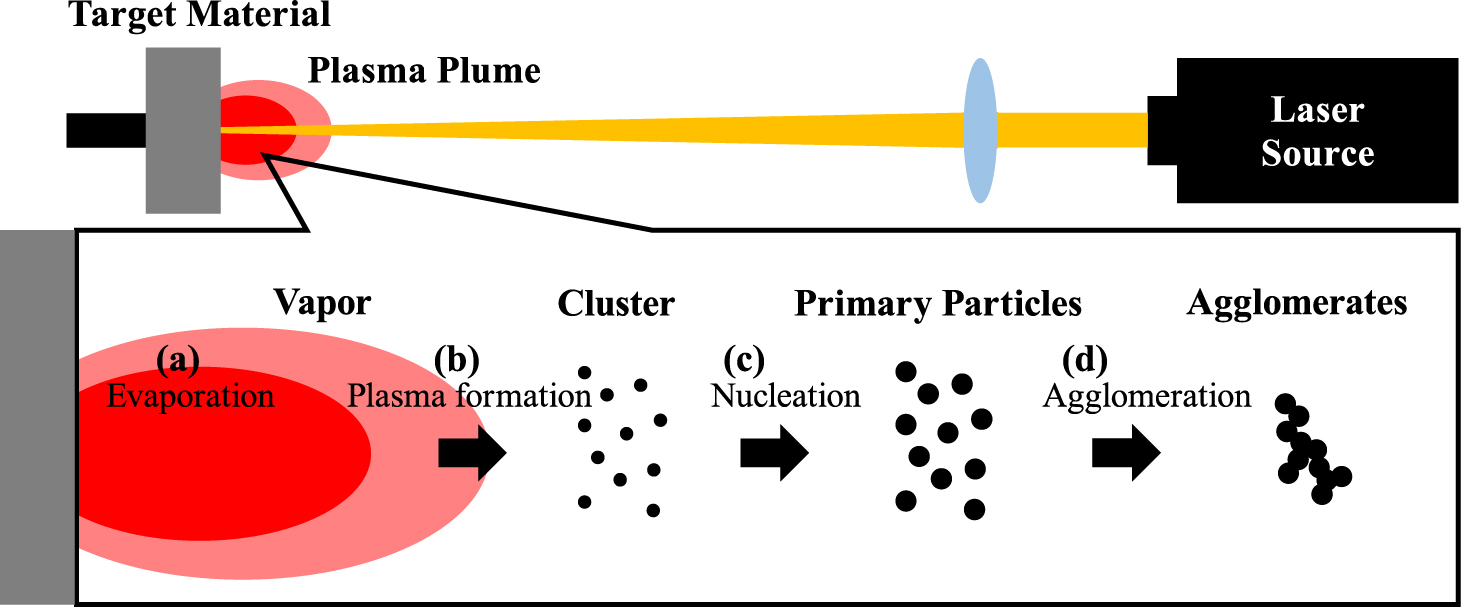

2017 Volume 34 Pages 80-90

2017 Volume 34 Pages 80-90

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: April 30, 2016Editor's pickRecent progresses in laser ablation technology enables to generate various kind of nanoparticles with unique functionalities and superior performance. This review discusses the formation mechanism and techniques for synthesizing the functional nanostructures such as size-controlled semiconductor quantum dots, carbon nanotubes, nanowires, and core shell nanoparticles.

Download PDF (7106K) Full view HTML -

2017 Volume 34 Pages 91-105

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: July 30, 2016Download PDF (4508K) Full view HTML -

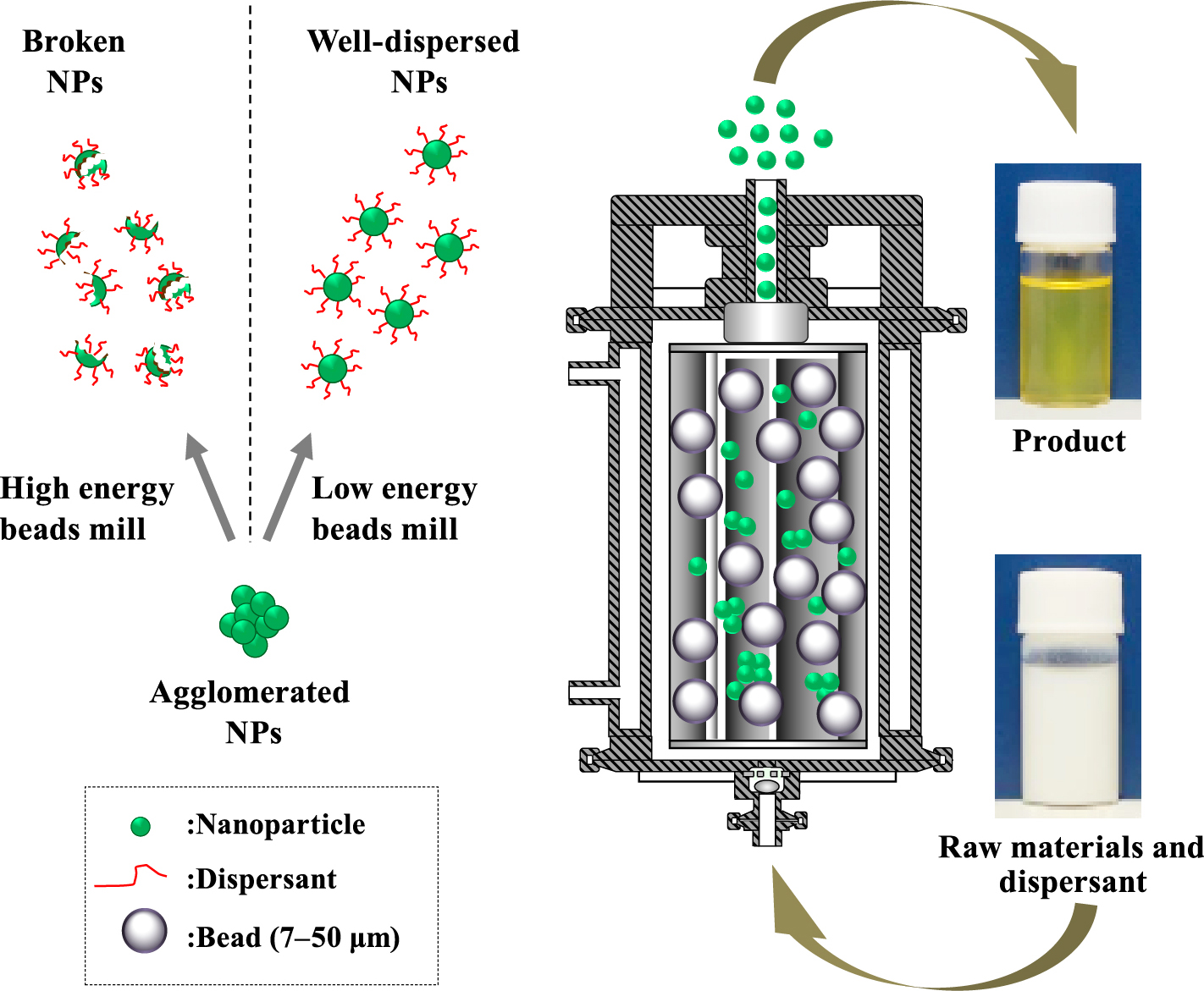

2017 Volume 34 Pages 106-124

2017 Volume 34 Pages 106-124

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: August 30, 2016Editor's pickWidely used in the minerals, cement, ceramics and chemical industries for 150 years, ball mills have attracted the attention of engineers in describing size reduction quantitatively for over 70 years. However, this last quarter of a century has been particularly active, given the widespread use of the discrete element method, which has triggered the development of novel modeling approaches to describe size reduction in them. The work reviews the various hurdles that have been faced by researchers and the solutions proposed to overcome them in describing size reduction in ball mills using the so-called advanced models, with emphasis on the work by the author and his co-workers at the University of Rio de Janeiro.

Download PDF (2394K) Full view HTML -

2017 Volume 34 Pages 125-140

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: August 30, 2016Download PDF (3716K) Full view HTML -

2017 Volume 34 Pages 141-154

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (7433K) Full view HTML -

2017 Volume 34 Pages 155-167

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (15528K) Full view HTML -

2017 Volume 34 Pages 168-182

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (4273K) Full view HTML

-

2017 Volume 34 Pages 183-196

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: January 30, 2016Download PDF (12163K) Full view HTML -

2017 Volume 34 Pages 197-206

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: January 30, 2016Download PDF (5337K) Full view HTML -

2017 Volume 34 Pages 207-212

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: April 30, 2016Download PDF (5631K) Full view HTML -

2017 Volume 34 Pages 213-223

2017 Volume 34 Pages 213-223

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: April 30, 2016Editor's pickThe present study through batch kinetic experiments with the use of quartz as test material aims to assess the effect of ball filling volume on the specific rate of breakage and identify the cumulative breakage function by keeping the powder filling volume constant. A new methodology is proposed by combining two software packages for the reliable description of the grinding process that enables the scale-up of laboratory results to larger scale mills.

Download PDF (3116K) Full view HTML -

2017 Volume 34 Pages 224-233

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: May 20, 2016Download PDF (4814K) Full view HTML -

2017 Volume 34 Pages 234-240

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: July 09, 2016Download PDF (5132K) Full view HTML -

2017 Volume 34 Pages 241-247

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: July 09, 2016Download PDF (13501K) Full view HTML -

2017 Volume 34 Pages 248-257

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: July 30, 2016Download PDF (6964K) Full view HTML -

2017 Volume 34 Pages 258-274

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: August 30, 2016Download PDF (7792K) Full view HTML -

2017 Volume 34 Pages 275-281

Published: 2017

Released on J-STAGE: February 28, 2017

Advance online publication: August 30, 2016Download PDF (2586K) Full view HTML -

2017 Volume 34 Pages 282-289

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (6712K) Full view HTML

-

2017 Volume 34 Pages 290-291

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (9481K) Full view HTML -

2017 Volume 34 Pages 292

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (3129K) Full view HTML -

2017 Volume 34 Pages 293

Published: 2017

Released on J-STAGE: February 28, 2017

Download PDF (564K) Full view HTML

- |<

- <

- 1

- >

- >|