2013 Volume 53 Issue 9 Pages 1538-1544

2013 Volume 53 Issue 9 Pages 1538-1544

In order to increase the permeability of the sintering bed for sinter ore productivity, RF-MEBIOS (Return Fine - Mosaic Embedding Iron Ore Sintering) process, in which return fine as dry particle is added to granulated raw materials and then they are charged into a sintering machine, is proposed.

In this paper, the pot suction tests and the direct shear tests were carried out to confirm the reason of increasing permeability of the sintering bed by addition of dry particle. As a result, it is proven that the increasing of permeability is caused by two major phenomena. One is by increasing the pseudo-particle size at granulation and the other is by decreasing the bulk density of the sintering bed after charging. The former is achieved by higher moisture content in the raw materials at granulation. The latter is achieved by higher friction in the packed bed composed of dry and wet particle compounds. Therefore, the voids are easy to remain in the sintering bed when the materials are charged into the sinter machine. The influence of the dry particle brand on permeability is not so strong, but larger dry particles make the permeability higher. Also, when the wet particles are added after granulation, the permeability decreased at the same moisture content condition of the packed bed.

The recent increase in the amount of fine ore, such as Brazilian concentrated ultra fine, in the raw material of sinter ore lowers the permeability of the sintering bed and the yield of the sinter ore. The collapse of voids in the sintering bed will cause problems although the bed has a porous structure. A pre-granulation technique has been developed and applied to such fine ore.1) Recently, controlling the bed structure by including loosely packed parts and densely packed parts in the same packed bed has been discussed.2,3,4) This idea is named MEBIOS (Mosaic Embedding Iron Ore Sintering).5)

The schematic view of the sintering bed structure of the MEBIOS method is shown in Fig. 1. The purpose of the MEBIOS method is making a high density but high permeability packed bed by setting denser parts and looser ones in the same packed bed. For example, high-density large green balls, with a diameter of 5 to 15 mm, are placed in the packed bed to make lower density parts around the balls by a “wall effect” so that the permeability of the packed bed increases. It was confirmed that MEBIOS had also role of keeping high void ratio at sintering because during sintering large dense particles maintain the shape but partially aggregate with surrounded loose packed parts in sintering bed.6,7)

Concept of MEBIOS process.

The application of MEBIOS with a low price capital investment has to be developed for product competitiveness. Finally, from the view point of controlling moisture location at the sintering bed, it is confirmed that even small dry particles charged into the sintering bed has a similar effect on controlling the bed structure due to friction between dry particles and wet particles. In addition, the moisture content can be controlled at granulation and at charge into the sintering bed individually, which has the effect of improving granulation. For a commercial sinter plant, return fine is used as the dry particle by bypassing the mixing and granulating route. So, this process is named RF-MEBIOS (Return Fine - MEBIOS). The RF-MEBIOS has been applied to three sinter plants and productivity has been improved.8)

In this report, the influence factors to increase permeability of sintering bed by adding dry particles to granulated raw materials was basically investigated by pot suction tests. And the friction change by making composition of dry and wet particles is confirmed by direct shear tests.

In this paper, RF-MEBIOS process (or just RF-MEBIOS) means the sinter materials handling procedures in which dry particles are added on granulated other materials. It makes mosaic structure composed of a combination of dry particles and wet particles.

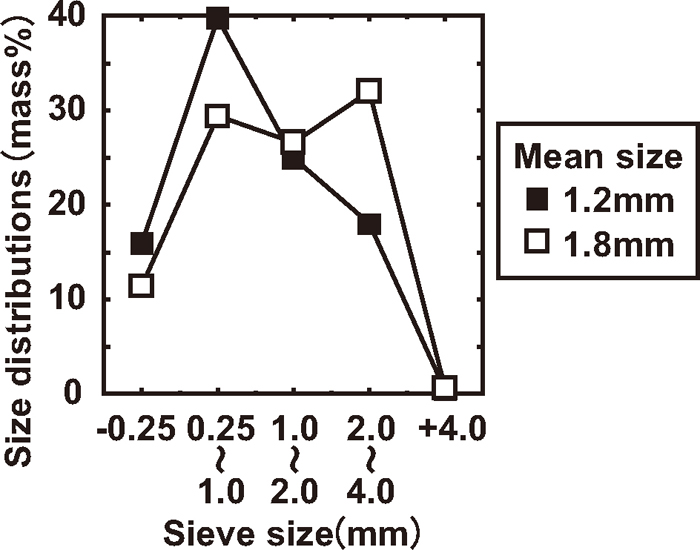

The effect of RF-MEBIOS process on permeability of a sintering bed was investigated by suction test using 105 mm diameter pot. At first, 12.0 dry-kg sinter raw materials consist of hematite ore, limestone, coke breeze, and “dry particles” were prepared and dried to 0% moisture content. Dry particles were return fine, hematite ore, and pisolite ore which were fixed to given size distribution shown in Fig. 2, respectively. Blending conditions of materials are shown in Table 1.

Size distribution of dry particles.

| Base | RF-MEBIOS | |

|---|---|---|

| Iron ore (hematite) | 70.0 | 70.0 |

| Limestone | 10.5 | 10.5 |

| coke breeze | 4.5 | 4.5 |

| Dry particles | 15.0 | 0.0 |

| Sub total | 100.0 | 85.0 |

| Dry particles (add) | 0.0 | 15.0 |

| Total | 100.0 | 100.0 |

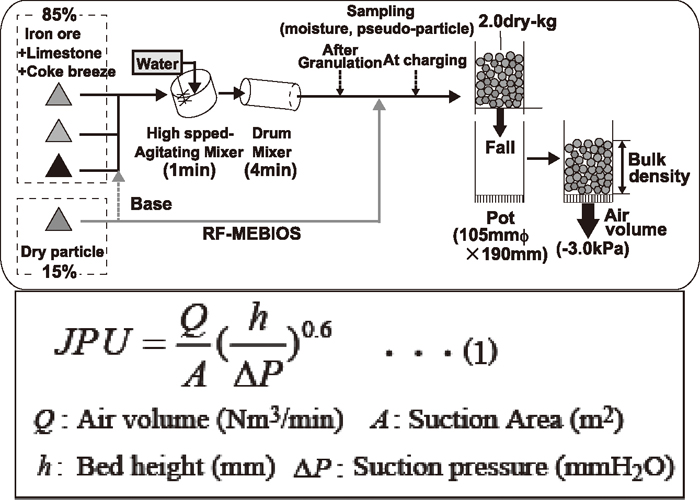

An experimental procedure is shown in Fig. 3. At first, in the case of RF-MEBIOS process, materials except dry particles (10.2 dry-kg, 85 mass% of all materials) were mixed in high speed agitating mixer with a certain amount of water for 1 min. Then they were granulated in drum mixer for 4 min. In this paper, we call the materials at that point as “materials after granulation”. Then, 2.0 dry-kg materials after granulation were sampled to measure moisture content and a pseudo-particle size after granulation. A pseudo-particle size was evaluated as “pseudo-particle (–0.25 mm)”, by measuring the amount of –0.25 mm particles achieved by sieving materials for 15 seconds after drying at 105°C for more than 2 hours. Then, 8.2 dry-kg (85 mass%) of materials after granulation were spread on a sheet, and 1.5 dry-kg (15 mass%) dry particles were sprinkled on them by using hand-size-shovel. And then they were mixed lightly by turning upside down once or twice using shovel. In this paper, we call the materials at that point as “materials at charging”. 1.7 dry-kg materials at charging were sampled to measure moisture content and a pseudo-particle size (at charging). After that, remaining 8.0 dry-kg materials at charging were divided into 4 units in increments of 2.0 dry-kg unit and charged into the 4 pots in 105 mm diameter, respectively. When charging into the pot, materials were fall from 210 mm in height. After charging, bulk density and permeability of sintering bed by suctioning 3.0 kPa were measured. Permeability was evaluated by JPU (Japanese Permeability Unit) calculated by formula (1).

Experimental procedures of pot suction test.

On the other hand, permeability of sintering bed of the base process, in which all materials including dry particles (12.0 dry-kg) were mixed and granulated, was measured for comparison.

Experimental conditions are shown in Table 2. In each series of the tests, one of the four items (moisture content at charging, dry particle brand, dry particle moisture content, and dry particle size) was changed.

In the case of moisture content at charging changing test, 1.2 mm mean size (Fig. 2) return fine was used as dry particle. In both base and RF-MEBIOS processes, moisture content at charging was varied in 5 levels by changing water amount sprayed in high speed agitating mixer. In the case of RF-MEBIOS, although moisture content at charging is the same, moisture content after granulation becomes higher than that of base because dry particles are not feed to the mixer. Relation between moisture content after granulation and at charging is calculated by formula (2). If the base case, in which there are no dry particles added after granulation (x=0), moisture content after granulation and at charging become the same value (a=a1).

| (2) |

In the case of dry particle brand changing test, 3 brand (return fine, hematite, and pisolite) of dry particles, which were fixed to the same size distributions of 1.2 mm mean size (Fig. 2), were used. Base and RF-MEBIOS are compared at the same moisture content at charging (7.0%).

In the case of dry particle moisture content changing test, 1.8 mm mean size (Fig. 2) return fine was used as dry particle. Then moisture content of dry particles is varied in 1% increments from 0% to 3%. If the moisture content of dry particles (a2) increases, moisture content after granulation (a1) relatively decreases at the same moisture content at charging.

In the case of dry particle size changing test, 3 sizes (–1.0 mm, 1.0–2.0 mm, 2.0–4.0 mm) of return fine were used. Base and RF-MEBIOS are compared at the same moisture content at charging (7.0%).

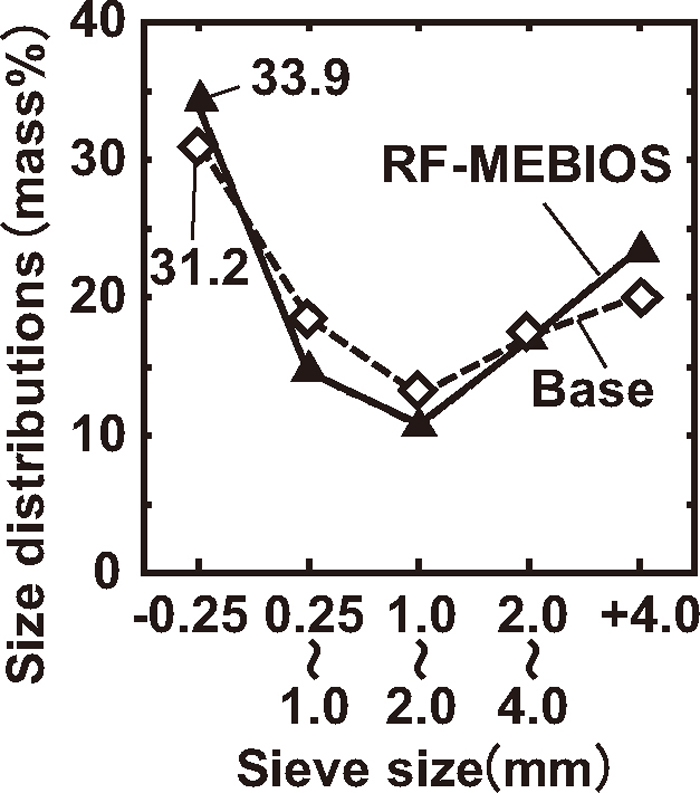

In RF-MEBIOS process, dry particles are not feed to the mixer. On the other hand, all materials are feed to the mixer in base process. Therefore, the size distribution of the materials granulated in the mixer is thought to change. In the RF-MEBIOS case, it is calculated that there are approximately 3% larger amount of initial –0.25 mm particles in the mixer as shown in Fig. 4. It is considered that they cause a decrease tendency of granulation. In addition, an occupation area ratio in the drum mixer also changed. In the RF-MEBIOS case, it is expected to decrease by 1.5% at the granulation stage as shown in Table 3. In the experimental condition of this test, it seemed that there are normal cascade rolling condition9,10) with or without of the RF-MEBIOS. And in that case, it is considered that the decrease of an occupation area ratio cause an increase tendency of granulation, according to the DEM simulation about granulation by Kano et al.11)

Effect of removing dry particle on initial size distribution.

| Base | RF-MEBIOS | |

|---|---|---|

| Dry particles added after granulation | 0% | 15% |

| Materials feed into the mixer | 100% | 85% |

| Occupation area ratio in the drum mixer | 10.1% | 8.6% |

However, relation between moisture content after granulation and pseudo-particle (–0.25 mm) is almost same as shown in Fig. 5. So it is evaluated that the influence of the difference of materials feed in the mixer is relatively small than that of the moisture content.

Effect of removing dry particle on pseudo-particle (–0.25 mm).

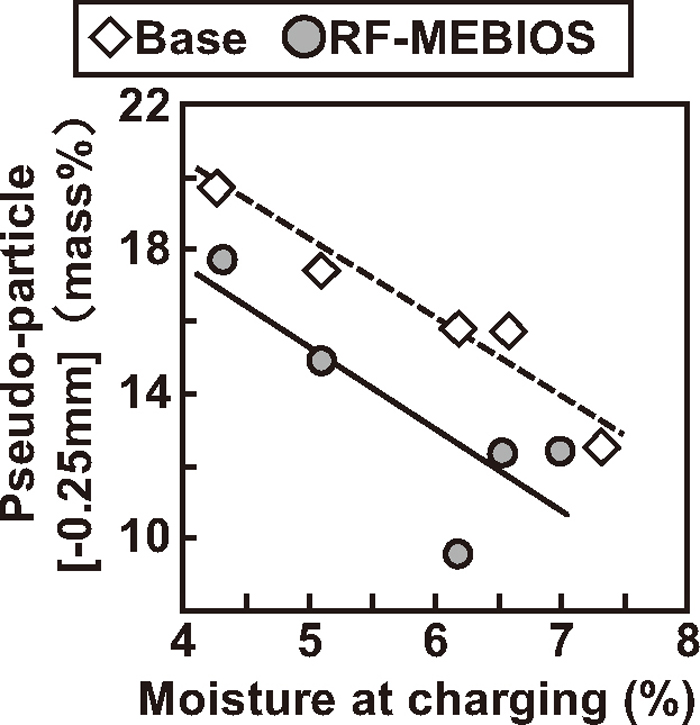

Figure 6 shows the relation between moisture content at charging and pseudo-particle (–0.25 mm) at charging. Both base and RF-MEBIOS process, pseudo-particle (–0.25 mm) decreased by increasing of moisture content. But at the same moisture content, pseudo-particle (–0.25 mm) of RF-MEBIOS is lower than that of base.

Effect of RF-MEBIOS on pseudo-particle (–0.25 mm).

Figure 7 shows the relation between moisture content at charging and bulk density at charging. Bulk density increased by increasing of moisture content because it considered that high moisture content at charging causes a collapse of the vacancy of sintering bed. But at the same moisture content, bulk density of RF-MEBIOS is lower than that of base.

Effect of RF-MEBIOS on bulk density.

Figure 8 shows the relation between moisture content at charging and permeability of sintering bed. Both base and RF-MEBIOS process, permeability of sintering bed increased by increasing of moisture content in the range up to about 7.0% moisture content, and then became maximum value at about 7.0%, and then turned decreased. There are many reports focused on the role of water at granulation;12,13,14,15,16,17,18) Sato et al.13) explain that the relation as shown in Fig. 8 is achieved by the combination of the increasing of adhering small particles and the decreasing of void filled by excess water, and Matsumura et al.17) report that the moisture content which indicates the maximum permeability is different by ore brand because absorbing water capacity are different.

Effect of RF-MEBIOS on permeability of packed bed.

In the case of RF-MEBIOS, the permeability of packed bed is higher than that of base at the same moisture content.

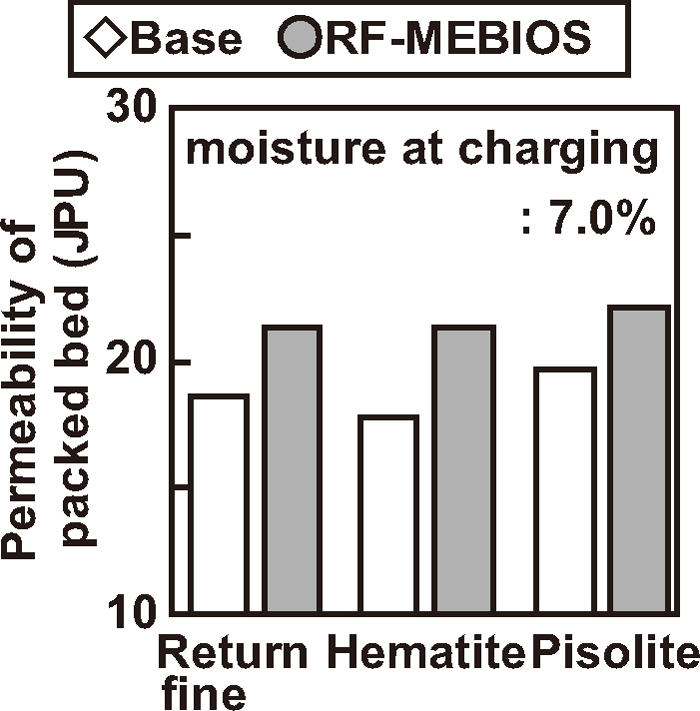

3.4. Effect of Dry Particle Conditions on RF-MEBIOS ProcessFigure 9 shows the effect of changing dry particle brand on permeability of sintering bed. Bed permeability of RF-MEBIOS is higher than that of base although changing dry particle brand. In addition, JPU values are almost same level when using the same dry particle size.

Effect of dry particle brand on RF-MEBIOS.

Figure 10 shows the effect of changing dry particle moisture content on permeability of sintering bed. Within the range of 3% dry particle moisture content, bed permeability of RF-MEBIOS is higher than that of base. But the difference of JPU value from base decreased by increasing of dry particle moisture content, because moisture content at granulation stage decrease by increasing of dry particle moisture content (Fig. 2).

Effect of dry particle moisture on RF-MEBIOS.

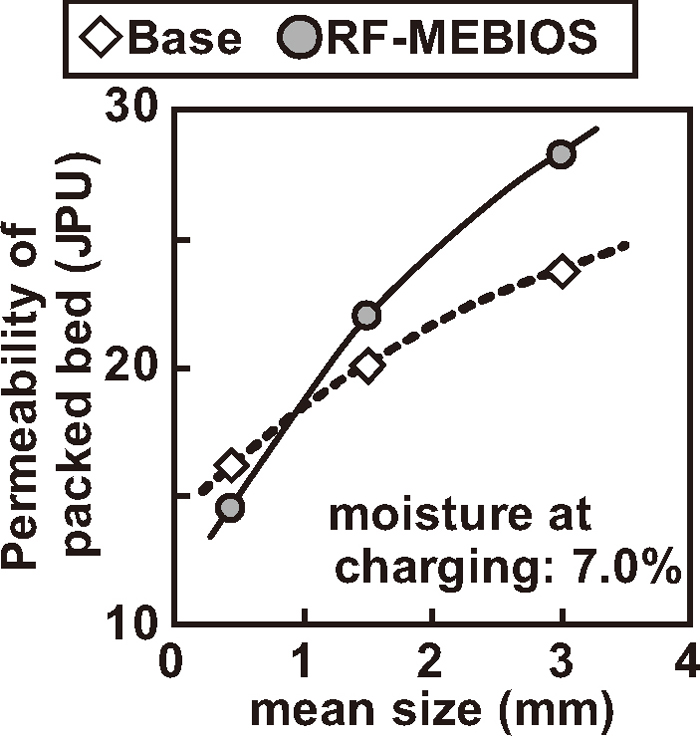

Figure 11 shows the effect of changing dry particle size on permeability of sintering bed. Both base and RF-MEBIOS process, permeability of sintering bed increased by increasing of dry particle size because mean size of all materials increase. If dry particles size is bigger than 1 mm, bed permeability of RF-MEBIOS is higher than that of base. On the other hand, if dry particles size is smaller than 1 mm, bed permeability of RF-MEBIOS is lower than that of base.

Effect of dry particle size on RF-MEBIOS.

According to experimental results, permeability of sintering bed of RF-MEBIOS is higher than that of base when moisture content at charging is the same (Fig. 8). And it is caused by decreasing of pseudo-particle (–0.25 mm) (Fig. 6) and decreasing of bulk density (Fig. 7). In addition, the effect of RF-MEBIOS on permeability is enhanced if dry particles are completely dry (Fig. 10) and big (Fig. 11). The effect of dry particle brand is relatively small (Fig. 9). So the mechanisms of decreasing of pseudo-particle (–0.25 mm) and decreasing of bulk density were analyzed separately.

4.1. The Mechanism of Decreasing Pseudo-particle (–0.25 mm)It is considered that Fig. 5 suggests the influence of moisture content is bigger than that of an initial –0.25 mm particles amounts or an occupation area ratio in the drum mixer on pseudo-particle (–0.25 mm), by removing 15 mass% of materials from granulation stage. Therefore, to analyze the mechanism, two hypotheses are supposed. First, pseudo-particle (–0.25 mm) after granulation decrease by increasing moisture content and the value is determined by moisture content after granulation (Fig. 5) even if the initial amounts of –0.25 mm or an occupation area ratio of the drum mixer are changed by RF-MEBIOS (Fig. 4). Second, when dry particles are added on materials after granulation, there are no interaction (ex. breaking or adherence) between each other.

By supposing these two, the relation between moisture content and pseudo-particle (–0.25 mm) is calculated and shown in Fig. 12. In the figure, the relation between moisture content after granulation and pseudo-particle (–0.25 mm) is shown as the line “L0”. And the initial –0.25 mm amounts of dry particle are shown as the point “①”. In the base case, the materials after granulation and at charging are the same, so pseudo-particle (–0.25 mm) at charging also overlaps on the line “L0”. On the other hand, in the case of RF-MEBIOS, dry particles (15 mass%) are added on the materials after granulation (85 mass%). So the pseudo-particle (–0.25 mm) at charging moves to the point which is calculated by the combination of “L0” and “①” using lever rule (0.85:0.15) (Fig. 12-(a)). And the assembly of those relations with various moisture contents is drawn as the line “L1”. Eventually, the decreasing of pseudo-particle (–0.25 mm) of RF-MEBIOS is evaluated by the difference between “L0” and “L1”.

Effect of RF-MEBIOS process on pseudo-particle (–0.25 mm).

For example, if the moisture content at charging value is “w”, pseudo-particle (–0.25 mm) of RF-MEBIOS become to be “②”, which is lower than that of base (“④”) by “delta y”. Furthermore, in the case of RF-MEBIOS, moisture content and pseudo-particle (–0.25 mm) after granulation are shown as “w0” and “③” because they are calculated as an extrapolation of the line segment of “①” to “②” using lever rule (①–②:②–③=0.85:0.15) (Fig. 12-(b)).

Figure 13 shows some plots of the actual measurement value of experiments put on Fig. 12. Rhombic symbols (◇) are pseudo-particle (–0.25 mm) (both after granulation and at charging) of base. And triangle symbols (▲) are pseudo-particle (–0.25 mm) after granulation of RF-MEBIOS. It is found that both of them are almost on the line “L0”. Rectangular symbols (■) are –0.25 mm amounts of dry particles. Circle symbols (●) are pseudo-particle (–0.25 mm) at charging of RF-MEBIOS, in other words, combination of dry particles (■) and materials after granulation (▲). It is found that circle symbols are almost overlapped with the calculated value of combination of dry particles and materials after granulation shown as solid line crossing to chain line. According to this result, two hypotheses in this analysis are basically reasonable.

Effect of making compound between dry and wet particles on pseudo-particle (–0.25 mm).

Additionally, by using this diagram, it is also described that the effect of changing dry particle conditions. Figure 14(a) shows the effect of increasing dry particles moisture content (Fig. 10). If dry particles are not dry (“①” moves to “①a”), the relation between moisture content and pseudo-particle (–0.25 mm) also move from “L1” to “L2”. So the decrease of pseudo-particle (–0.25 mm) becomes smaller than original (from “④–②” to “④–②a”) Fig. 14(b) shows the effect of dry particles size (Fig. 11). If –0.25 mm particles in dry particles decrease (“①” moves to “①c”), then “L1” also move to “L3” and pseudo-particle (–0.25 mm) become lower than original (④–②c). On the other hand, if –0.25 mm in dry particles increase (“①” moves to “①f”), “L1” move to “L4” and pseudo-particle (–0.25 mm) become higher than original (④–②f). Figure 14(c) shows the effect of dry particles amount. If the amount of dry particles added after granulation decrease from 15% to 10%, “L1” move to “L5” and pseudo-particle (–0.25 mm) become higher than 15% (④–②d).

Effect of dry particle condition on pseudo-particle (–0.25 mm).

As shown in Fig. 7, the bulk density increased by increasing moisture at charging. It indicates decreasing of vacancy of the packed bed because the excess water fills voids of the packed bed.7,13) RF-MEBIOS, which makes the compound of dry particles and wet particles, seems to have the role on control the vacancy of the packed bed. Thus, a direct shear test was carried out to investigate the change of friction among materials at charging. The experimental procedure and conditions are shown in Fig. 15 and Table 4, respectively. At first, 76.4 dry-g pisolite ores (4.7% initial moisture content) and 20.0 dry-g return fines (0% initial moisture content) were prepared. Then, they were crushed to –0.25 mm to reduce the measurement variability by interrupting large particles on the shear surface. Also, the moisture content target was changed to suitable value (around funicular or capillary area) reflecting an increase of specific surface area by crushing. In the case of RF-MEBIOS, only pisolite ores were sprayed water (14.0% moisture after granulation) and granulated. Then, 20.0 dry-g return fines were added (11.1% moisture at charging) and they were inserted into the test cell. After that, the cell sheared by 3.0 mm/min and measured shear stress during three levels of perpendicular stress are lorded (49, 98, 147 kPa). Finally, friction and adhesion of materials were calculated by mole-coulomb yield criterion formula (3).

Experimental procedures of shear test.

| Base | RF-MEBIOS | ||

|---|---|---|---|

| Iron ore (dry-g) | 76.4 | 76.4 | 76.4 |

| Dry particle (dry-g) | 20.0 | 20.0 | 0.0 |

| Moisture after granulation (%) | 3.7 | 11.1 | 14.0 |

| Dry particle (add) (dry-g) | 0.0 | 0.0 | 20.0 |

| Moisture at charging (%) | 3.7 | 11.1 | 11.1 |

The results of shear tests are shown in Fig. 16 and Table 5. In the figure, tilt of lines indicates friction and y-intercept indicates adhesion by formula (3). In comparison of base (3.7%) and base (11.1%), it is confirmed that lower moisture content cause lower adhesion but higher friction. And in comparison of base (11.1%) and RF-MEBIOS (11.1%), it is confirmed that making compound of dry particles and wet particles cause lower adhesion but higher friction even if the total moisture content are the same. Terashita et al.19) report that the powder and granular material has the highest friction when 0% moisture content and it decreases by increasing water. They also say friction of the powder and granular material sharply decreases at pendular area. Therefore, higher friction of RF-MEBIOS is caused by existence of dry particles, which has high friction, in the packed bed. At the sinter process, materials after granulation are charged into sintering machine by falling from chute. Higher friction of the packed bed functions as resistance from bed shrinkage by impact of falling charge, and the vacancy becomes easy to maintain as illustrated in Fig. 17.

Improvement of friction coefficient by RF-MEBIOS.

| Case (moisture content) | tanφ : Friction coefficient | C: adhesion |

|---|---|---|

| Base (3.7%) | 0.274 | 0.0 |

| Base (11.1%) | 0.124 | 7.8 |

| RF-MEBIOS (11.1%) | 0.159 | 5.8 |

Increasing vacancy of packed bed by RF-MEBIOS.

The effect on permeability of sintering bed of RF-MEBIOS (Return Fine - Mosaic Embedding Iron Ore Sintering) process, in which dry particles are added to granulated raw materials and make compounds of dry and wet particles, are investigated and analyzed basically. As a result, the following are confirmed.

(1) If –0.25 mm ratio of dry particles lower than that of other materials, pseudo-particle (–0.25 mm) decrease by RF-MEBIOS.

(2) The existence of dry particles in the packed bed causes higher friction, and it functions as resistance from shrinkage by impact of falling charge.

(3) The influence of the dry particle brand on permeability is not so strong, but larger dry particles make the permeability higher.