2015 Volume 55 Issue 1 Pages 36-66

2015 Volume 55 Issue 1 Pages 36-66

Progress of steelmaking technology in Japan over the last 100 years is overviewed covering hot metal pretreatment, primary steelmaking with open hearth furnaces, converters and electric arc furnaces, secondary refining of steel with degassers and ladle furnaces, and ingot- and continuous-casting.

Key issues that contributed considerably to the progress of the unit processes are highlighted with scientific, technological and engineering breakthroughs involved. Also, systematization of the unit processes is depicted for optimizing full cost, productivity and quality of steel products to meet the constraints on the resources and socioeconomic demands of the steel market at times.

Possible future development of steel technology is briefly commented on the basis of the above observation.

Celebrating the centennial anniversary of the Iron and Steel Institute of Japan, an attempt is made to give an overview of the development of steelmaking technologies in Japan in the last 100 years with own limited experiences in the field of 55 years and available literatures. The technologies cover hot metal pretreatment, primary- and secondary-steelmaking and ingot- and continuous-casting, which were improved and optimized for materials and market available at times by the lasting efforts of our predecessors. The overview is intended to give a concise but panoramic understanding of the past developments and stimulate the coming generation to further revolutionary technological advance for the future development of the steel industry.

Steelmaking furnaces so far industrialized in the world were: Converter with acidic refractory lining and air blowing bottom tuyeres in 1856, Siemens open hearth in 1857, and Martin furnace for scrap melting, and Siemens-Martin open hearth which combined the last two in 1864. It took, however, about 20 years more, when the converter and open hearth, both lined with basic refractory, successfully dephosphorized hot metal for mass production of steel with acceptable quality. Hot metal in Europe was high in phosphorus (P) since iron ore available there was high in P.

Mass production of steel in those days was dominated by Britain, Germany, Belgium and USA. Japan imported necessary pieces of equipment, materials, operational skill, and raw materials from these countries to start industrial steelmaking with crucible furnace in 1890. Acidic open hearth and acidic Siemens-Martin open hearth were installed in 1890 and 1896 at navy- and army-steelmaking factory. Annual production of the factories was a small sum of 2.4 k tons, only about 1.1% of annual steel imports of 220 k tons.

Integrated iron and steel plant ever started in Japan was in 1901 at state-owned Yawata Works.1,2,3,4) A 160 ton blast furnace (BF) was put into operation in Feb., and steel melt from a 25 ton open hearth was cast into 3 ingots in total of 10 tons in May. In November, steel melt from a 15.6 m3 Bessemer converter was cast into 5 ingots, totaling 8.5 tons. Japanese naming for open hearth, Heiro, and converter, Tenro, was given by Imaizumi.5)

After the end of the Russo-Japanese War in 1905 until the outbreak of World War I in 1914, Japanese steel industry suffered from a recession, facing plant shutdowns and mergers. Inadequacy of equipment for operation and lack of decent quality coal and iron ore were considerable. Despite the unfavorable circumstances, efforts paid by Yawata Works made it possible in 1914, 100 years ago, to convert steel ingot production from remelting and casting iron made with traditional charcoal based Tatara process (17 ktons/year) to casting steel made with Basic Open Hearth (BOH) (275 ktons/year) and acidic Bessemer converter (106 ktons/year).

Productivity of the acidic Bessemer converter was much greater than the BOH (Fig. 1),6) but the slopping loss of metal out of the converter mouth and erosion wear of the bottom tuyeres resulted in 8% lower metal yield on ingot basis and 3.4% higher cost of production. In addition, the Bessemer converter could not make P content lower than about 0.1% with the acidic lining, and hence the application of steel products was limited to commodity wire, rod and medium gauge rail. The high P content was a consequence of unavoidable use of P-bearing iron ore (0.2–0.3%P) for blast furnace due to the war time shortage of low P ore imports. To improve dephosphorization (deP), refining the converter melt with BOH was attempted by the name of Converter-BOH Combination process (double refining). However, the process was found 6% lower in metal yield and 14% higher in ingot cost, could not compete with advanced operation of BOH, and hence terminated in 1927.

Schema of Basic Open Hearth with Venturi Arrangement.6)

The recession period was followed by the Japanese participation in World War I which took place from July, 1914 to Nov. 1918. In the early period of the war, 4 BFs and 12 BOHs were made operational, added with 6 BOHs of 50 ton capacity by 1918. To supplement the insufficient supply of scrap, use of iron ore instead was practiced in BOH. With these measures, ingot production reached 440 ktons/year to suffice the demand. In the above period, private steel companies also started steel supply with new plants which include: (1) Sumitomo Cast Steel Works (later Sumitomo Metal, now Nippon Steel Sumitomo Metal, NSSM) at Osaka in 1902, (2) Kawasaki Shipyard Plate Plant (later Kawasaki Steel, now JFE Steel) at Hyogo in 1907, (3) Kobe Steel at Kobe in 1911, (4) Nippon Kokan (later NKK, now JFE Steel) at Kawasaki in 1914, all with BOHs of 3.5 ton to 15 ton capacity.

2.2. The Rise and Fall of the BOH SteelmakingNew installations and modifications of BOHs to larger capacity continued after 1915 to meet the increasing steel demands with the progress of domestic industry after World War I and the outbreak of the Manchurian Incident in1933. Total number of BOHs reached 113 (91 above 25 ton capacity) in 1933 to produce 3.06 million tons, excluding those in Manchuria and Korea in Japanese occupation. Among them, BOHs operated by the private steel companies with pig iron and scrap increased to 77 (59 above 25 tons). Pig iron of 0.455 million tons and 0.172 million tons was imported from Manchuria and India, while scrap of over 1 million tons was imported from USA. In 1934, the imperial congress passed a bill for the merger of the state-owned Yawata Works to form Nippon Steel Company (abbreviated as Nittetsu, now NSSM) with private plants including Wanishi, Kamaishi, Fuji, Kyusyu and Ken-Ninpo. Suspected short supply of scrap and pig iron with the developing Incident promoted the approval, construction and operation of 200–1000 ton/day class BFs of each company.

The Manchuria Incident developed into the Sino-Japanese war during 1937 and 1945. In 1939, 2.17 million tons and 0.11 million tons of scrap were imported from USA and India to increase all Japan production of BOH steel to 5.65 million tons. This level of production was somehow maintained until 1943. However, World War II broke out in 1939, import of scrap was prohibited, and hence BOH was forced to operate with high ratio of hot metal instead of scrap. As a countermeasure, NKK introduced 3 basic refractory lined bottom air blown 20 ton Thomas converters from Germany, and started operation with high P hot metal in 1938. Two more Thomas converters were installed by 1941 to produce 0.35 million tons of steel in 1942. However, bombed out circumstances compelled all the converters to shut down in 1945.

Progress of steelmaking technology in Japan until 1945, when Japan was defeated in World War II, was the period of conversion from traditional Tatara process into modern processes with Bessemer converter and BOH. Our predecessors implemented the modern processes, optimized them to fit Japanese conditions, making them competitive in productivity and quality with those of advanced countries. In the era when the disturbances dominated over the society and economy of Japan, unique technology was not invented. Depicted below are, however, noteworthy progresses made under the very difficult conditions:

(1) Decrease of the refining time and energy consumption in BOH steelmaking with shift of fuel from generator gas to heavy oil or mixture of coal gas and BF gas,

(2) Industrialization of the use of pig iron with ore, or hot metal with scrap to replace 100% scrap operation in BOH,

(3) Implementation of hot metal mixer for hot metal pretreatment for homogenization,

(4) Enlargement of BOH for greater productivity, and

(5) Domestic production of furnace refractory of acceptable quality.

As a consequence, all Japan BOH steel total of 5.63 million tons was produced even in 1943, among which 3.38 million tons, 60%, was due to Nittetsu. At the end of 1945, the number of BOHs amounted to 197 among which 67 were 50–80 tons, 10 were 100 tons and 11 were 150 tons capacity. As the impact of the war got worse, supply of good quality iron ore and scrap became scarce, and the equipment and personnel for steel production were damaged and decreased by bombing, resulting in a sharp decrease of steel production to 1.23 million tons in 1945 when World War II ended. Situation deteriorated further in 1947 when post-war disturbances still remained. We saw only 20 BOHs in operation, producing a very limited amount of 0.4 million tons/year of carbon steel.

The General Head Quarters (GHQ) of the United Nation forces (UNf) demanded to dismantle 91 BOH to indemnify in kind UNf for war damage. Fortunately, it was soon withdrawn to promote economic self-reliance of Japan and meet the need of GHQ to supply materials to support UNf for the Korean war which lasted during 1950 and 1953. Thus, steel industry in Japan was made exempt from crashing down. Increase of steel production started, followed by the removal in 1948 of embargo on the import of iron ore and coal.

2.3. Enlargement of BOH after World War II and Development of Oxygen Steelmaking7,8,9,12)German type BOHs were dominantly utilized in Japan in the war time. During 1948 and 1949 after World War II, equipment and operation of USA type BOHs, which were superior to German type, were introduced to Japan by USA specialists. Delegation to implement the BOH technology was also sent to USA for training. Consequent improvements transferred were:

(1) Enlargement of stationary hearth BOH with hung down refractory ceiling structure,

(2) Movable down-spout for tapping, and jet tapper,

(3) Venturi combustion system with enlarged gas port, gas uptake, and checker brickwork in recuperater chambers,

(4) Blaw-knox type valve to change gas flow,

(5) Quick charging of scrap box,

(6) Positive pressure operation of BOH to prevent the intake of ambient air,

(7) Conversion of generator gas or mixed gas combustion to heavy oil combustion due to the removal of oil embargo,

(8) Utilization of sensor controlled operation with pressure gauge, gas flow meter and thermometer,

(9) Use of basic refractory bricks for the front- and rear-wall and the ceiling of BOH, and

(10) Magnesia stamping and dolomite gunning on the hearth.

During 1949 and 1957, average capacity per heat of BOHs increased from 62 tons to 92 tons, maximum nominal capacity being 150 tons. In 1957, the number of BOHs with heavy oil combustion or heavy oil mixed combustion reached 115 out of 124. In the following 5 years, BOH capacity kept increasing. Within the major 4 companies, Yawata, Fuji, NKK and Kawasaki, for example, 4 × 150 ton Märtz/Märtz Böhrens* type stationary- and tilting-BOHs with Venturi combustion system and 3 × 200 ton BOHs were installed together with revamped 9 × 150 ton BOHs and 11 × 200 ton BOHs (*Note: All basic refractory brick structure with checker brickwork type No.1 chamber and ordinary type No.2 chamber. First put into operation at Sumitomo Metal Wakayama Works in 1959).

Also, oxygen injection steelmaking process, which was popular in USA, was introduced after joint industrial tests carried out by 8 domestic companies. This was in collaboration with the installation of Linde-Frenkel type mass production system for pure oxygen. The oxygen steelmaking process12) utilized oxygen for:

(1) Enhancing the combustion of fuel from burner,

(2) Cutting the scrap debris before melting down, and

(3) Bessemerizing of steel melt after the melt down.

These measures considerably improved the productivity and fuel consumption of BOH.

In fact, the peak production of steel with BOH oxygen steelmaking in Japan recorded a high 16.17 million tons in 1961. At Fuji iron and Steel (now Nippon Steel Sumitomo Metal, NSSM) Hirohata Works, scrap 210 tons were overcharged in a 150 ton BOH, converted into steel in 6 h (productivity 33 tons/h) with 25 Nm3O2 at a fuel consumption of 1420 kJ/ton, much better than 12 h (16 tons/h) and 4180 kJ/ton for normal operation. Similarly, at Kawasaki Steel (now JFE Steel) Chiba Works, scrap 185 tons were overcharged in a 150 ton BOH, and converted into steel with large supply of oxygen in 2 h 40 min. With 6 of the BOH and oxygen supplied from Linde-Frenkel oxygen generators in total of 13400 Nm3/h, average productivity of steel achieved 65 tons/h/BOH. Maximum productivity surged to 100 tons/h/BOH when maximum oxygen supply of 50 Nm3O2/ton was executed. Chiba with the 6 BOHs counted the highest production record of 180 ktons/mo. as a single BOH plant in Japan.

Bessemerizing (oxygen injection) was made via calorized steel tube inserted in steel bath in BOH through a view port at the charging doors of BOH. It was quite an experience of the author to watch the surface of the bath while pushing the consumable pipe into the bath on shoulder as it melted away during the Bessemerizing. As bath temperature rose with time, decarburization and refining proceeded with carbon boil. Top slag on the bath was mixed up with metal on vigorous break up of CO bubbles. When compared with chemical analysis report of samples taken from time to time, the author realized how decarburization and refining went on. It was a marvelous moment of on site and real time observation of metallurgy of steelmaking.

Oxygen top blown Linz Donawitz converter (LD) started its operation at Vöest Linz with 3 × 30 t vessels in 1952 and at ÖMAG (Alpine) Donawitz with 2 × 30 t vessels, all with BOH hot metal. In Europe, Thomas converter process was in operation with high P hot metal smelted from European iron ores with high P content. However, such P-bearing iron ores were not available in Austria where only low P hot metal was produced. Low P hot metal was insufficient to sustain heat balance in Thomas converter. In addition, demands for steels low in P and N were uprising to guarantee better cold formability. Thomas converter steel was difficult to meet such demands. Attempts were made to decrease N in the converter steel with oxygen enriched air blow, but not successful due to heavy tuyere erosion. Scrap supply was insufficient in Austria to sustain BOH operation despite the fact that BOH steel lower in P and N is better in cold formability.

To solve the problems, Dürrer and colleagues carried out experiments with pure oxygen blown from water cooled top lance to the steel melt surface with success. Vöest and ÖMAG adopted the technology, went into joint development, and succeeded to operate 2 ton vessel, subsequently 12–15 ton vessels in 1949, making the contents of P, N and O reduced below BOH steel.

3.2. Transfer of LD Steelmaking Process to Japan10,11,12)Regarding pneumatic converter operation in Japan, Yawata had operational experiences of Bessemer converter which lasted until 1927 and of 5 ton top blown converter since 1954. NKK revitalized basic Thomas converter operation in 1954 with oxygen enriched air blow. The two companies had an exposure to the information on the LD operation in Austria via Ministry of International Trade and Industry (MITI) and a trading company of Japan. They were stimulated by the operational advantages over Thomas converter or BOH of LD that fits low P hot metal, lower scrap ratio, lower refractory consumption, and needed no heavy oil as fuel. Also, productivity, installation cost, labor cost, operating cost and steel quality of LD were speculated better than Thomas converter or BOH, although the process technology was still in its infancy of industrial mass production.

The two companies sent separately their representatives to confirm the speculation on sites, believed the future potential of LD process, and attempted to negotiate independently with Alpine to introduce LD technology. In view of national interest, however, they accepted, under the auspices of MITI, to let NKK as the sole representative licensee of the use and granting in Japan of the technology. Accordingly, the licensee contract was struck between NKK and Brassert Oxygen Technik AG (BOT, licensing company) via Alpine in 1956. Yawata struck with NKK sub-licensee contract which has been kept open for domestic third parties. Installation and operation of 50 ton LD at Yawata and 42 ton LD at NKK started soon in 1957 and 1958, as the milestone in the history of LD steelmaking in Japan.

The aforementioned advantages combined with financial support by MITI on the second rationalization program of Japanese steel industry prompted other steel companies to install LD converters (Fig. 2,16) upper left). The share of LD steel production started around 5% in 1958, surpassed BOH steel share in 1965 to reach 55%, and achieved in 1970 a high 79% with a production of 73.51 million tons, top in the world. New installations of LDs and conversion of BOHs to LDs, and revamping and merger of obsolete LDs to build new LDs continued until 1973, just before the oil shock crisis. It was the time when we saw a total of 92 LDs including 11 × 250 ton vessels and 6 × 300–340 ton vessels kept the leading position in both the amount and share of LD steel production in the world, exceeding West Germany, USA, Britain and USSR.

LD (BOF), Mixed Blowing BOFs and Bottom Blown BOF (Q-BOP)16) (partly modified).

In contrast, BOH steel production declined sharply. In 1970, BOHs in major steel companies were all shut down, leaving only 1.99 million tons produced in 1971 in Japan. Last BOH was shut down at Tokyo Steel Okayama works in 1977, closing long glorious history.

3.3. Development of LD Steelmaking Process in Japan12,13,14)The prosperity of LD process was brought about by such advantages as a few times greater productivity, lower production cost (~10% for carbon steel, ~30% for HSLA steel) and lower need of scrap than BOH process. The advantages were materialized due to the following improvements and developments in equipment and operation elaborated after the LD technology transfer:

(1) Enlargement of the shell volume, supporting and tilting mechanism for the vessel with concentric tulip profile and taphole, eliminating detachable bottom. For a 300 ton vessel, inner steel shell volume and height/diameter ratio were set, for example, to be 553 m3 and 1.3. Top cone angle was optimized, and trunion ring support and stepless variable speed tilting system were selected,

(2) Water cooled main lance with multiple hole nozzle tip was invented to prevent spitting and bottom refractory erosion during the blow (1962–1970),

(3) Automatic exchange system of sub-lance, equipped with temperature sensor and carbon meter, was made fully operational (1966–),

(4) Non combustive off-gas recovery system (OG) was developed by Nippon Steel (now Nippon Steel Sumitomo Metal, NSSM) to retain off-gas energy and minimize off-gas volume and particulate emission (1962–1969). The system has been upgraded and popularly accepted in the world,

(5) Considerable reduction of vessel refractory consumption to ~7 kg/ton-steel with the development of tar bonded dolomite, stabilized dolomite bricks followed by magnesia carbon bricks,

(6) Significant improvement of the hit rate of carbon content and temperature (C-T) window at the blow end was achieved with a static and dynamic computer control of the main lance height and oxygen flow rate, utilizing accumulated blow data calibrated with C-T values measured on time with the sub-lance,

(7) Production of hot metal low in Si and P for LD by use of advanced operation of BF with low P iron ores imported from Brazil and Australia, accompanied by decreased return of P-bearing BOH slag to BF,

(8) Development and implementation of hot metal pretreatment process and secondary refining process prior to and after the LD blowing,

(9) Advance of single slag and catch carbon blowing technique for medium and high carbon steels, low alloy steels and stainless steels to the extent that the resulting steel quality was approved by the standards in JIS specifications,

(10) Prolongation of vessel life beyond 5000 heats/campaign by developing zone lining of refractory, hot gunning refractory repair technology and enrichment of magnesia in LD slag during the blow, resulting in increased LD productivity,

(11) Progress in (a) Measurements at elevated temperatures of thermodynamic quantities and physical properties of the materials relevant to the process, (b) Equilibrium calculation for steelmaking reactions, (c) Modeling of heat, mass and energy transport phenomena for the process analysis, (d) Fluid dynamic simulation of the process, and

(12) Development of the theory and system for the control and automation of the process.

Many of the above depended on the progress achieved in Europe and USA. Among them, however, original development and industrialization progressed in Japan were items (2) and (4), and considerable progresses achieved in Japan after they were originally introduced from abroad were items (5) through (12). Cooperation among the licensee companies to share relevant information on timely technological advances at the meetings and plant visits of LD committee (later Discussion Meetings for Japan LD Technology) promoted by NKK and Yawata for Japan BOT members (1958–1966), contributed greatly to the progresses. The meetings were succeeded by the Steelmaking division of Joint Study committee of the Iron and Steel Institute of Japan (ISIJ). Also, joint activities among academia and industry held by the Joint Study committee for the Fundamentals of Iron and Steel, by Melt Refining division and by bi-annual Meetings, all held under the auspices of ISIJ, and those held by 19th committee (1934–) of the Japan Society for Promoting the Science (JSPS), all enhanced the progresses greatly. It must also be noted that these activities were supported by the Japan Iron and Steel Federation (JISF) and MITI either directly or indirectly.

3.4. Maturation of LD Process for High ProductivityLD operation continued to proceed toward higher productivity with extended flexibility for hot metal ratio under favorable economy which prevailed after 1967. Notable technologies that supported maturation of LD for higher productivity were:

(1) Charge time reduction with large capacity torpedo/ladle car to transport hot metal to steelmaking shop, and the same with scrap loading in charging shoot in separate building,

(2) Thinner refractory lining to enlarge the inner volume of the vessel with developed magnesia-carbon brick,

(3) Hot gunning of magnesia or dolomite with vessel profile monitoring, and slag coating, both to cutback the repair time and prolong service life of the vessel refractory,

(4) Computer control of the main lance height and oxygen flow rate, and optimization of the multiple hole lance tip design, both to minimize slopping and enhance deP under much increased oxygen flow rate,

(5) Three vessels operation out of 3 vessels installation,

(6) Development of “Direct tapping” which eliminated the time consuming end point sub-lance measurement of C and T, as the ultimate in dynamic blow control.

Consequently, average productivity of LDs reached 240 tons/h in 1974 with the improved equipment and operation. End point hit rate for C-T window in many LD plants achieved about 90% for low C steels, although scrap rate was limited. Vessel refractory life was very much prolonged, record being 10110 heats/campaign established at Nippon Steel (now NSSM) Kimitsu Works.

Noteworthy progress of LD process since then has been further prolonged vessel refractory life with slag splashing practice developed in USA.16) After tapping, dolomite is added to remaining slag on the bottom of the vessel, main lance is lowered some 70 cm above the bottom, and the magnesia enriched molten slag at the bottom is splashed with nitrogen gas blown from the main lance to weld coat the inner surface of the vessel refractory. No particular equipment is necessary, operation is simple, lasting within a short period of time to proceed to the subsequent blow, and hence the splashing technique soon has become popular worldwide. Refractory life from fresh lining to the 1st relining exceeded some 20000 heats. In the slag splash coating practice, however, clogging of tuyeres installed at the bottom of mixed blown converters (see later) was worried about in the beginning. It was resolved by controlling bottom gas flow rate at the nitrogen gas flushing. Recent presentation17) reportedly said that delivery of inert gas through concentric bottom tuyeres combined with proper gas flushing program made the refractory life extended up to 50000 heats/campaign. Caution is, however, necessary to keep reasonable trade off, i.e., not to worsen proper blow characteristics in the vessel with off-design distorted inner profile which may result from too many times of the splashing.

Regarding the automatic blow operation, the C-T hit rate was made better for narrower target window. Trimming the blow pattern was refined for reduced spitting and slopping with amended material addition. These were made possible on the basis of integrated computer analysis of the data acquired with sensors for the volume and composition of off-gas, temperature and compositions of the steel melt, vibration of the vessel, and acoustic wave characteristics in the vessel.

Except for its own advantages mentioned above, LD exhibited some drawbacks, i.e.,

(1) Insufficient mixing of metal bath, resulting in heterogeneity in temperature and chemistry of the bath,

(2) Sluggish molten slag formation of added lime,

(3) Loss of iron caused by excessively high temperature and over oxidation at the impinging points of oxygen jet on the metal bath, and

(4) Difficulty to prevent the slopping when abrupt CO bubble evolution occurred due to the over oxidation and heterogeneity of carbon distribution in the bath. The multiple hole lance tip was to some extent effective to reduce the slopping by decreasing the heterogeneity, but not fully. The slopping happens when the bubbles in the molten slag do not break up easily and retained in the slag under unfavorable combination of temperature and the bubble breakability of the slag when deC rate is high.

Thomas converter could avoid the heterogeneity and hence the slopping. As mentioned before, however, it could not take up more than 40% oxygen in the blowing gas due to the serious incidence of the tuyere erosion. Savard and Lee20) of Canadian Liquid Air overcame the erosion problem with a new idea to employ concentric double tube tuyeres after many difficult trials. Hydrocarbon gases (propane, methane) were passed through outer slit of the concentric tuyere tube as a coolant which endothermically decomposed to cool the tip of the tube. Oxygen gas and lime powder were injected through the inner tube into the melt. A porous accretion called “mushroom” was formed on the tip which prevented direct contact of steel melt to the tip, and cool decomposed gas was allowed to pass through the pores.21)

Brotzmann of Maxhütte decided to replace the tuyeres with the concentric ones at 20 ton Thomas converter of Maxhütte, made trials in 1967, and succeeded in the industrialization in 1968 by the name of Oxygen Bottom Blown Maxhütte (OBM). Later, US Steel implemented the OBM in large scale at Gary works 200 ton basic oxygen furnace (BOF, same as LD, but claimed to be USA origin) in 1973 and at Fairfield works 160 ton BOFs in 1974, by the name of Q-BOP which stands for Quick refining, Quiet blowing, Quality Basic Oxygen Process.

Major problem encountered with Q-BOP was poor endurance of the bottom tuyeres. It was necessary to keep the mushroom accretion on all tuyeres in similar size for long life of the tuyere bottom. If imbalance in the cooling happened to let a mushroom melt away, the tip of the tuyere burned back excessively to damage the bottom. In an extreme case, the burn back proceeded to the outer side of the bottom, caused back fire to burn through the tuyere, and burned the connecting oxygen gas piping, resulting in steel melt leakage out of the vessel.

4.2. Blowing Characteristics of Q-BOP18)In Japan, Kawasaki Steel introduced Q-BOPs in 1977 to build two 230 ton Q-BOPs with 18 and 22 tuyere bottoms at Chiba (Fig. 2, upper right).16) Parameters to control the blowing process were established through extensive investigation with a water model and a 5 ton Q-BOP for the melt flow in the vessel, mode of lime injection, characteristics of steelmaking reactions, and wear of refractory.

Q-BOP is distinctly different from LD as follows due to the full injection of oxygen gas and lime powder from the bottom tuyeres:

(1) Quick remelting of charged scrap,

(2) Very fast homogenization of steel melt is sustained to low C range. In terms of the time required for uniform mixing of the melt, Q-BOP takes only about 10% of that for LD (Fig. 3),23)

Mixing Time of Melt in Various BOFs vs. Bottom Gas Flow Rate.23)

(3) The rate of decarburization (deC) is also very fast, proceeding in near equilibrium for C-O reaction,

(4) Loss of Fe and Mn in slag caused by over oxidation is smaller, and hence yield of Fe and Mn is higher. For example, total Fe content in slag (T.Fe) at 1630°C and 0.04%C is ~12% against ~23% for LD,

(5) Oxgen consumption for Q-BOP is lower, accordingly. Decarburization oxygen efficiency for LD decreases from unity at 0.8%C down to 0.6 at 0.2%C, whereas for Q-BOP, it keeps unity until 0.4%C and decreases to 0.9 at 0.2%C. Decarburization limit of Q-BOP is lower than LD, can be less than 0.02%C,

(6) Slag formation is quicker, over oxidation and slag amount are much smaller, and hence sample taken with sub-lance represents C and T of the melt bulk better. Consequently, the hit rate at blow end reaches near 99% and reblow rate less than 1% for a target window of 0.05 ± 0.015%C and 1610 ± 10°C at 10% scrap operation,

(7) Slopping is much decreased and off-gas recovery with OG reaches 1.4 GJ/ton,

(8) Desulfurization (deS) ratio is better, and deP ratio is not much different from LD despite lower (T.Fe), provided that split injection of lime in the initial period and later period of blowing is properly executed.

On the other hand, inherent disadvantages of Q-BOP are:

(1) Higher cost of investment,

(2) Refractory life of the tuyere bottom is still shorter than that of the vessel, calling for 2–3 times of the bottom exchanges during a campaign of the vessel refractory,

(3) Scrap charge ratio becomes less to the extent equivalent to the heat loss caused by the coolant gas usage,

(4) Blow end hydrogen content in Q-BOP melt, even after Ar flushing, is higher (4–7 ppm) than LD melt (2–3 ppm) due to the hydrogen input generated by the decomposition of the hydrocarbon coolant. In modern steelmaking system where vacuum degassing is commonly equipped, this may not be a serious issue, though.

As a similar process to Q-BOP, kerosene coolant was used instead of hydrocarbon gases in 240 ton LWS converter at Sollac in 1978.

The above mentioned blowing characteristics were semi-empirically well explained by Nakanishi et al.23) in terms of an Index for Selective Carbon Oxidation (ISCO) based on model study and on site operation data. The ISCO consists of the product of two terms;

(1) Thermodynamic term stands for the partial pressure of CO which defines C-O equilibrium on the melt bath surface, and

(2) Relative mass transfer term represents the ratio of mass flux of oxygen supplied from the bottom tuyeres (or main lance) to the gas/melt boundary to the mass flux of C supplied from the melt bath to the boundary. Here, the mass flux of C was approximated by the average melt flow rate, q, in the bath, and q was defined proportional to the inverse of uniform mixing time, τ, of the melt (q = 1/τ). τ was determined proportional to about –0.4 power of the mixing energy, ε, supplied to the bath (τ ∝ε–0.4). Term (2) shows the predominance of either the oxidation of Fe or the oxidation of C of the melt under a given CO pressure. The smaller the ISCO value, the better is the preferential deC to lower C range without much loss of Fe into top slag.

The ISCO value successfully described the first time in an integrated way the relation between the degree of melt stirring and the oxidation into slag of constituent elements in the metal bath for a variety of primary and secondary refining furnaces (Figs. 3 and 4, for example),18,23) and considered to be a great contribution to process metallurgy. Later, Kai et al.24) proposed an amended index, Balance of Oxygen and Carbon Feeding Rate (BOC), eliminating term (1) and replacing the metal flow rate in term (2) in ISCO with mass flux of C. BOC was reported to give a bit better correlation in describing the behavior of (T.Fe) than ISCO within a range of 0.02–0.22%C for LD.

4.3. Development of Q-BOP Toward Mixed Blowing ConvertersA mixed blowing form between LD and Q-BOP, with 70% oxygen blown from top lance and 30% oxygen injected from bottom tuyeres, has been put into operation at Mizushima (3 × 250 tons) and Chiba (2 × 85 tons) during 1980–1981. The top and bottom blowing converter was named K-BOP (Kawatetsu-BOP where the prefix means Kawasaki Steel in Japanese, Fig. 2 bottom center). The ISCO value for the K-BOP is determined to be 64, close to 58 for the Q-BOP, and much smaller than about 230 for 160 ton LD, despite the limited fraction of oxygen bottom injection. K-BOP exclusively blows oxygen from top and bottom until critical C of 0.10–0.15% is reached, followed by inert gas bottom injection to promote deC in the range below the critical C (called Inert gas Decarburization, ID). It is capable of changing the main lance height to prevent slopping, acquiring better freedom to form slag and better control of deP operation.

Similar mixed blowing or top and bottom blowing LD with the bottom blowing through the concentric tuyeres, called LD-OB (LD-Oxygen Bottom Blowing) has also been industrialized in total of 10 at Nippon Steel Yawata, Oita, Kimitsu and Nagoya in 1984. Total number of the top blowing converters with oxygen bottom blowing (OBM, Q-BOP, K-BOP, LD-OB etc,, all inclusive) amounts to 110 in the world. Sumitomo Metal (now NSSM) industrialized a top and bottom blowing, STB (Sumitomo Top and Bottom), with CO2 as bottom tuyere coolant in place of hydrocarbon gases.

It was known in Thomas converter and secondary refining furnace that bottom injection of gases promotes the stirring and flow of steel melt. However, the considerable improvement of blowing characteristics for LD with the oxygen bottom injection was a fresh surprise to those who were engaged in steelmaking, triggering off the evolution of a variety of top and bottom blowing converters.

As noted before, uniform mixing time, τ, is inversely proportional to 0.4 power of energy ε of stirring imposed and dissipated in the melt. Average flow rate q (ton/s) of the melt is inversely proportional to τ, i.e., q = 2 W/τ, with W (ton) being the mass of steel melt.

For an inert gas bottom stirring 250 ton LD (LD-KGC) at Mizushima, τ is calculated to be 37 s at a small 10% bottom injection of Ar, much shorter than about 75 s for LD without the bottom injection, and not too much longer than 14 s for Q-BOP at Chiba. Concentration product of C and O in the melt in mixed blowing converters is found to decrease below the equilibrium concentration product of Ceq and Oeq at a shorter τ. In former times, this anomaly was interpreted to have been caused by lower partial pressure of CO than unity in the converters due to decomposed hydrocarbon coolant. Kishimoto et al.26) showed, however, that O content in the melt did not change with the species of hydrocarbon coolant, but decreased with increased q (= shorter τ). They considered that the anomaly is caused by the following: At the impinging points of oxygen jet on the steel melt, the activity of (FetO) formed by the oxidation of the melt is unity and O in the melt may come close to the equilibrium value corresponding to C and T around there. When melt stirring or melt flow rate is large enough, however, O in the bulk melt should be dominated with (FetO) which is generated at the impinging points but diluted in slag which covers much wider surface area of the melt than the area of fire spots. The stronger the stirring or the greater the flow rate, the lower the (FetO) which dominates the O in the melt, and hence O decreases with q.

4.4. Wide Spreading Development of LD with Bottom Injection of Inert GasesIn view of the considerable improvement of blowing characteristics of LD with a small amount of inert gas injection from the bottom, the inert gas injection soon replaced oxygen and lime injection from the concentric tuyeres to eliminate the exchangeable bottom with the tuyeres and reduce the necessary investment and running cost.

The following type LDs with gas stirring have been industrialized by developing different types of Ar or N2 bottom injection, resolving the erosion of gas inlet plug and increasing the gas flow rate: LBE by IRSID-ARBED, LD-BC by CRM and UBDT by Krupp employ either slit brick or permeable brick for the plug, while metal tube (mostly single one) is used by LD-AB by Nippon Steel, LD-KGC by Kawasaki Steel, LD-OTB by Kobe Steel and NK-CB by NKK. Injected gas flow rate ranged from 0.01–0.50 Nm3/min.ton (Fig. 5),16) mostly less than 0.2 Nm3/min.ton.

Variants of Mixed Blowing BOFs as Developed from LD/BOF and Q-BOP/OBM.16)

The inert gas bottom stirring LDs decrease critical C content where the rate controlling step for deC changes from mass transfer of O to mass transfer of C, and hence the decarburization oxygen efficiency in the lower C range is improved to make (T.Fe) lower than 20% with increased iron yield. Thus, conventional LDs were rapidly converted into the gas stirring variants.

To avoid the confusion of the naming, LD in Europe and BOF in USA are collectively denoted here as BOF, gas stirred BOFs with bottom injection of inert gas are collectively designated as “Inert Gas Stirred BOFs”, BOFs with bottom oxygen blowing as “Top and Bottom Blowing BOFs”, and the two types of BOFs are collectively named as “Mixed Blowing BOFs or Combination Blowing BOFs”.

In 2000s, even better productivity was demanded for the mixed blowing BOFs. However, when greater oxygen gas flow was supplied into the BOFs for increasing the productivity, the top gas jet and melt flow interfered between the fire spots where the jet impinged onto the melt surface, generating spitting of melt drops out of the BOFs. The spitting became considerable when slag lean operation (see later section) with pretreated hot metal low in Si, P and S got popular. Fukagawa27) designed a new main lance nozzle tip with 6 nozzle holes aligned and inclined in a special way. Oxygen jets from the nozzles did not interfere with each other at the impinging points, preventing the formation of the spitting. The nozzle tip has been mounted on the main lance for 250 ton mixed blowing BOFs at Wakayama, making it possible to produce 300 ktons/month with 1 out of 2 converters in operation at a blowing time of 9 min and tap-to-tap time of 20 min.

4.5. Application of Mixed Blowing BOF to Scrap Melting and Smelting ReductionIn an integrated steel plant where OG system is installed, top and bottom blowing BOFs are capable of melting scrap, which keeps accumulating in market, with less energy consumption (~3.9 GJ/t, recovered off gas credit deducted) than electric arc furnace (EAF) (~4.5 GJ/t). Hirohata converted a BOF into top and bottom blowing one, and industrialized it as a coal base scrap melting BOF28) in 1993. Existing off-gas recovery system was utilized. When the combustion rate of off-gas in the vessel was increased up to 30%, scrap ratio increased by only 10% vs. 0% combustion. Addition of carbon bearing fuel material from the BOF mouth did not work either, since the material was blown away from the mouth. These shortcomings were resolved by hot heel operation of high C melt into which oxygen and pulverized coal with low volatile materials were blown in with nitrogen as carrier gas through the bottom tuyeres. Scrap was charged from shoot on top of the vessel, oxygen was blown from the top lance to enhance scrap melting by secondary combustion of off-gas in the vessel. High speed and stable low temperature melting practice increased the utilization efficiency of the coal, prolonged refractory lining life, and sustained to keep both the heat for melting and calorie contained in recovered off-gas by controlling the degree of the secondary combustion. Also, evolution of dust and slopping caused by bubble burst, enhancement of deP by controlling (T.Fe), maintaining optimum C content of the high C melt, and stabilizing heat compensation were all optimized by controlling S and ash content in the coal, ratio of oxygen blown from the top lance and amount of addition of iron oxide pellets. Resulting hot metal was decarburized in another BOF to produce high quality steel which is said better than EAF steel.

Top and bottom blowing BOFs were also developed for the smelting reduction of Cr ore to produce stainless steel. Okuyama et al.29) charged into the first stage K-BOP at Chiba 50% of deP hot metal, Cr ore pellet sintered in a rotary kiln, cokes and stainless steel scrap to reduce the Cr ore pellet, and obtained Cr and Ni bearing hot metal. The hot metal was separated from slag, poured into a large size mixer equipped with a channel heater which takes up addition of stainless scrap to trim Ni and Cr content. The hot metal was subjected to deC and deP blowing in the second stage K-BOP to produce SUS 304 and 430 since the latter half of 1980. The smelting reduction process provided Chiba with freedom to choose Cr sources depending on the market situation.

Recently, additional lance has been installed to add Cr ore fines with burner heating into the hot metal in the first stage K-BOP. Here, hydrogen bearing fuel is combusted with oxygen, and granular Cr ore is preheated in the combusting flame to compensate for the 20%/(unit mass Cr ore) of the endothermic heat of reduction. Emission of CO2 is naturally decreased, together with the erosion of refractory lining. Furthermore, top addition of coal to the hot metal combined with oxygen top blown through auxiliary lance has been in operation since the latter half of 2000s. The coal disintegrates and disperses as fine particles in the top slag, favorably reducing the Cr ore granules preheated and suspending in the slag. The auxiliary lance is with multiple hole tip, designed to combust the CO gas evolving in the vessel space from the Cr ore reduction to fully compensate for the heat loss of the reduction.

To obtain high Cr ferritic stainless steels extra low in C and N, the melt from the second K-BOP is further refined under vacuum with Vacuum Oxygen Decarburization (VOD) process or SS-VOD process. Total amount of stainless steels produced with the duplex K-BOP process has been about 0.7 million tons/yr.

Traditionally stainless steels have been produced from stainless steel scrap, Ni sources and Fe–Cr alloys with EAF and converter such as AOD (Argon Oxygen Decarburization) or CLU (Creusot Loire Uddeholm). AOD and CLU control oxygen partial pressure in a wide range during the deC blowing to minimize the loss of Cr. The steels are then refined additionally with ladle refining furnaces (LRF) depending on the quality requirement. The smelting reduction type duplex K-BOP route is reported to consume about 35% less energy than EAF-AOD route.

Steelmaking and refining processes for stainless steels are quite diversed.30) In fact, Muroran installed RH-OB in 1972, Yawata put 150 ton LD-VAC (VOD) into operation in 1979 and hot metal pretreatment with soda ash combined with LD-OB in 1980, Wakayama started oxygen top blowing AOD in 1982, Nippon Metal AOD-VOD in 1982, Wakayama AOD-VOD/VOD-PB in 1990, Fukuyama top and bottom blowing BOF type Smelting Reduction Furnace (SRF) for Ni ore and Cr ore reduction in 1990, Daido Specialty Steel vacuum AOD (VCR) in 1991, Yawata REDA (see later) in 1995 and Hikari VOD in 1996. The choices are supposed to meet local conditions for each plant, but there are so many varieties.

Steel melt primarily refined in BOF, BOH and EAF is usually deoxidized (deO), desulfurized (deS) and removed of non-metallic inclusions (inclusion hereafter) in ladle. For the objectives, common practice was to cover the melt surface in ladle with non-oxidizing basic slag, inject Ar from the bottom of the ladle, and bring the melt flow caused by the gas injection stirring into contact with the top slag for refining.

Multi component top slag with Mannesmann Index (%CaO)/[(%SiO2)·(%Al2O3)] = 0.3–0.4 and alike were favorably used for deS. Optimization of the melt flow was made by controlling plume eye. For deS and inclusion control, Thyssen Niederrhein method (TN) and similar Scan Lancer method, both inject CaC2 or CaSi granules with inert gases through lance immersed into the melt, were popular since mid-1970s. For deO and deS, injection of cored wire, steel sheath with FeCa or CaSi core, into the gas stirred melt was practiced since 1980.

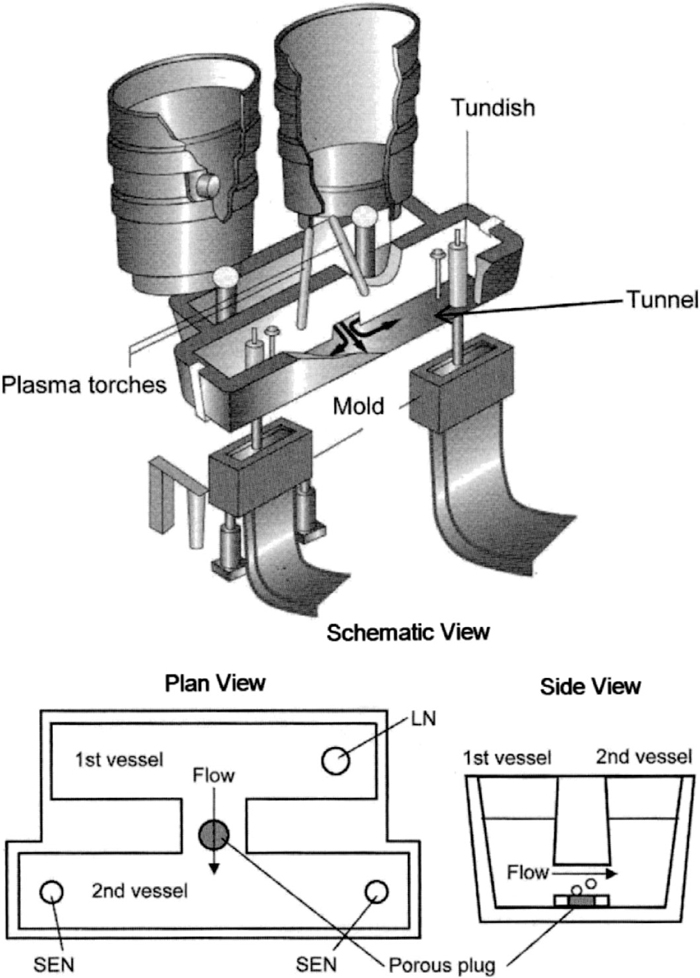

5.2. Development of a Variety of Ladle Refining Processes14,15)Ladle refining and secondary refining furnaces (collectively LRFs) have been commercialized in Europe and USA since 1952 to decrease impurity elements, H, N, O, P and S and inclusions, trim alloying elements in primarily refined steel melt, and control the melt temperature suitable for casting. In Japan, introduction of LRFs started with vacuum degassing of melt stream with Bochmer Verein process (BV) in 1958, followed by Dortmund Hölder process (DH) and Rheinstahl Heraus process (RH), all increased rapidly after 1970. Simultaneously, TN process, Vacuum Oxygen Decarburization process (VOD) of Witten, Vacuum Arc Degassing process (VAD) of Finkl, Ladle Furnace (LF) of ASEA-SKF and AOD were also installed. The cited processes are classified according to the function, equipment and objective, and differ in application. Generally, steel melt is processed in vacuum, heated, added with alloys, and stirred for the removal of impurity elements and inclusions and for the uniformity of temperature and chemistry (Fig. 6).32)

Variants of Secondary Refining Vessels.32)

TN and ASEA-SKF refine the melt with slag under ambient pressure. TN injects slag particles with inert carrier gas through lance immersed into the melt, whereas ASEA-SKF utilizes electromagnetic rotation of the melt which is in contact with top slag and removed of the impurities and inclusions. In terms of equipment, TN and ASEA-SKF are the opposite extreme. AOD decarburizes the melt by blowing Ar and O2 at varied ratio, VOD by blowing O2 under vacuum, VAD heats the melt with arc under reduced pressure, all for refining stainless steel at a minimum loss of Cr. VAD and ASEA-SKF are equipped with arc heating function, and hence used to produce alloy steels and extra-heavy plates in batches. Later, ASEA-SKF has been furnished with vacuum degassing facilities. During 1965 and 1977, 8 AODs, 7 VODs, 3 ASEA-SKFs and 5 others were installed in Japan.

5.3. Development of DH and RH which Combine BOF with Continuous Caster33)In an integrated iron and steel plant, more than several heats of steel are usually cast in a sequence into continuous casting machine (CCM) to secure better yield and quality of the cast strand. LRF is situated in between BOF and CCM, and plays important role to:

(1) Synchronize the sequence and keep productivity, and

(2) Control temperature and chemistry of steel melt to meet the quality demands of down stream processes, CC inclusive.

In the early stage of the introduction, upgrading of the function of LRF itself was carried out to maturity by the latter half of 1970. Since when CC was fully industrialized in 1970, efforts were paid to optimize the functions (1) and (2).

Important issues for such optimization were:

(1) High speed evacuation of large capacity degassing vessel,

(2) Enlargement of the interfacial areas between steel melt and vacuum or steel melt and slag ,

(3) Acceleration of the melt flow rate to promote the mass transfer of the impurity elements and inclusions,

(4) Chemistry control and removal of slag,

(5) Addition and homogenization of alloying elements,

(6) Heating to compensate for the temperature drop of the melt during processing, and

(7) Refractory which withstands the erosion and exfoliation and does not contaminate the melt.

Many of the above are more or less in common with the issues for BOF. However, the processing capability of LRF has been much advanced to meet the demands for increasing productivity of BOF and decreasing impurity concentrations of steel melt. The progress of highly productive secondary refining processes, RH and DH (Fig. 6, bottom), popular in integrated steel plants, are summarized as follows:14,15,19,31,33)

DH: Steel melt in ladle is spout out via. off-centered tube up into the vacuum vessel located above the ladle. Removal of H, N, O and inclusions are carried out from the free surface of the melt in the vessel. The melt in the vessel is subsequently returned through the tube and mixed in the remaining melt in the ladle. This cycle is repeated several times/min by up and down motion of the vessel. Yawata introduced DH in 1959, enlarged the vessel and tube, added electric heater in the vessel, made the cycle motion quicker (15 m/min for 180 ton ladle) in 1969 with a lever type mechanism, installed a device for Ar injection into the melt in vessel in 1974 to promote deC (DH-AD method), and adopted magnesia chromites brick to materialize in sequence the improvements listed in (1)–(7) in the above.

Nippon Steel converted DH in late 1990s into REDA (Revolutionary Degassing Activator) by removing the spout tube, extending the bottom end of large diameter cylindrical vessel to be immersed into the melt in ladle, and injecting Ar from the bottom plug of the ladle. The melt is sucked up into the vessel by evacuation, stirred with Ar injected from the ladle bottom, and circulated back into the melt in ladle. REDA reportedly exhibited similar degassing capability to RH, and has been used for refining steels low in C, N, O and stainless steels.

RH: RH was first introduced to Hirohata in 1963, put into operation as 100 ton facility. One each of upleg- and downleg-snorkel installed at the bottom of a cylindrical vacuum vessel are immersed into the melt in ladle to suck up the melt in the lower part of the vessel. Ar is injected in the lower part of the up-snorkel to give rise and spout the melt into the vessel with the air lift pump action. The difference in the height of the melt at the spout surface above the upleg-snorkel and the melt surface above the downleg-snorkel in the vessel drives the melt through the downleg-snorkel back into the ladle to be mixed with the bulk of the melt. Thus, the melt keeps circulating from ladle→upleg-snorkel→vacuum vessel→downleg-snorkel→ ladle (Fig. 7). The melt is degassed at the interface of Ar bubbles and melt in the upleg- snorkel and the melt surface in the vessel including melt splash surface created by bubble break up. Agglomeration and removal of inclusions in the melt take place with turbulent stirring in the circulating melt.

Advanced RH Refiners with Oxygen and/or Flux Injection into Vessel.

Basic equipment and necessary operation for RH were largely ready by the middle of 1960. Further improvements including those by licensee companies by early 1990s were:

(1) Large capacity evacuation system for quicker achievement of high vacuum in the vessel to enhance degassing even in the very early stage of the processing,

(2) Increasing diameters of the snorkels and the vessel, and enhanced Ar delivery rate through stainless steel tubing into upleg-snorkel, all for greater circulatory rate of the melt,

(3) Refractory brick changed to direct bond magnesia chromite for better durability, and

(4) Installation of electric resistance heater in the vessel to compensate for the temperature drop of the melt and to melt away the accretion of melt splash on the inner wall of the vessel.

In 1972, Muroran developed RH-OB, top blowing oxygen on the melt in the vessel with AOD type concentric tuyere (O2 from inner tube, Ar, N2, CO2 from outer slit) for stainless steel deC. In the latter half of 1970s, injection of O2 and refining flux with concentric tuyere from the side wall of the vessel into the melt was also developed as RH-OB-FD for deC, deS and heating up of carbon steels. Uniform mixing of the melt stream from downleg-snorkel and bulk melt in ladle was questioned in former times, but tracer measurement and CFD calculation confirmed the uniform mixing, provided that the circulatory rate is made sufficiently high.

During these periods, height and diameter of the vessel, the diameter of upleg- and downleg-snorkel and Ar injection rate were all made greater to further increase the circulatory rate, and RH has matured as a highly productive LRF. Today, the melt circulatory rate for 250–300 ton ladle is set about 150 ton/min, and the time for a circulation of 300 ton melt is about 2 min.

Once upon a time, RH and DH were employed for mass production of partially deoxidized steel melt to be continuously cast as a rimmed steel alternative (cf. Riband steel in later section).

RH is particularly useful for high productivity refining of extra low C steel. Other than RH-OB, Kawasaki Steel installed top lance to blow O2 onto the surface of the melt in the vessel as RH-KTB (Kawasaki Top Blowing) in the latter half of 1980s to enhance deC rate in RH vessel. Advantages of RH-KTB over RH are:

(1) End point C of BOF melt does not need to be made extra low, and hence productivity and yield of BOF melt have increased,

(2) Combustion of CO gas evolved in the vessel with the top blown O2 prevents temperature loss of the melt, enables to decrease the temperature of BOF melt at tap,

(3) Eliminates the troublesome formation and removal of the splash accretion on the inner wall of the vessel, and hence

(4) C-reversal of the melt caused by the fall of high C accretion into the melt in the vessel is minimized.

RH-KTB (Fig. 7 right) has been widely in use abroad as well.

Another enhancement of deC and deN to extra low concentrations has been developed at NKK which injected H2 into the steel melt through the upleg-snorkel to be absorbed as H in the melt. During ascending to the surface in the vacuum vessel, the dissolved hydrogen forms H2 bubbles into which C as CO and N as N2 are removed and evacuated into exhaust system when the bubbles break up.

In 1990s, Nippon Steel commercialized RH-MFB (Multiple Function Burner) to combust LNG blown from a top lance inserted in the vacuum vessel to remove splash accretion on the inner wall of the vessel while RH processing is at rest. The removal helps preventing the pick up of C (contained in the accretion) in the subsequent heats. The lance is made functional during the processing to blow O2 through it to heat and deC the melt. RH-MFB has also found popular use abroad.

Refining steel melt with slag or flux during RH processing was introduced from late 1980s to early 1990s, including RH-Injection at Nagoya, RH-PB at Oita and RH-PB at Wakayama in sequence. At Nagoya, flux is injected into the melt below the upleg-snorkel in ladle through a lance tip which is immersed in ladle melt and directed upward to the bottom opening of the upleg-snorkel. At Oita, flux is injected into the melt in the RH vessel through a submerged concentric tuyere tube. At Wakayama, flux is blown from a top lance with Laval nozzle tip onto the surface of the melt in the bottom of the RH vessel (Fig. 7, left). S ≤ 3 ppm and N ≤ 20 ppm were obtained with the injection of 8 kg/ton CaO–CaF2 and C ≤ 10 ppm was attained with the injection of 10 kg/ton iron ore powder for 160 ton melt.34) In 2012, the nozzle tip of the lance has been replaced with Spike tip for processing 250 ton melt, decreasing S from the initial 20–25 ppm to 10–12 ppm in 27 min.35)

SIVA (SImplified all-round VAcuum treatment) process was developed early in 2000, RH vessel is equipped with a top blowing lance, and vessel bottom is removed and connected to the top rim of ladle for evacuation with Ar blown from the ladle bottom, like REDA process for DH. The vessel has been capable of strong melt stirring and inclusion removal, alloy addition and Ca wire injection, while preventing melt reoxidation and contamination caused by ladle slag. Refining capability is said similar to the combination of LF and RH.

5.4. Diverse Application of LF and LRFLF was first commercialized for 100 ton melt early in 1970 at Nippon Specialty Steel for alloy addition and removal of S, O and inclusions with highly basic fluxes. Steel melt in ladle with Ar injection from ladle bottom is Arc-heated with graphite electrodes inserted through top lid of the ladle to prevent temperature drop during the operation. To minimize refractory erosion, oxidation resistant magnesia carbon bricks are used at the slag line of the ladle. Some 10 years later, LF has been equipped with flux injection lance, and the ladle has been contained in vacuum chamber for degassing, making itself like ASEA-SKF.

Traditionally, EAF steelmaking consisted of melting and oxidizing (deC, deP) operation followed by finishing reducing operation with replaced white slag. LRF took over the latter operation, making EAF specialized for melting and oxidizing. The above separation has increased the productivity of EAF considerably, and improved the quality of EAF steel much better.

LRF has been further developed for large scale refining of BOF steel for demanding applications such as line pipe, heavy plate for large input energy welding, plate with low temperature toughness, all of them call for extra low concentration of impurity elements. LRFs thus developed in 1980–1990 and operating under ambient pressure with flux injection lance include NKK Arc refining Process (NK-AP) and Nippon Steel Kimitsu Injection Process (KIP). KIP later implemented vacuum processing, and was named V-KIP. All of the three feature strong stirring refining with reducing slag under arc heating, capable of attaining S < 10 ppm.

Secondary refining, both ladle refining and degassing, contributed greatly to:

(1) Share a part of the function of primary refining furnace and meet demands for increased productivity and upgrading the quality of refining system, and

(2) Bridge primary refining furnace, BOF or EAF, and continuous casting machine (CCM) to keep the consistency of their productivities, while stabilizing CCM operation and improving the quality of CC strand.

Thus, investment and utilization of secondary refining facilities have increased with time. In recent years, about 85% of steel melt are processed with secondary refining and about 75% with vacuum degassing.

5.5. Diverse Application of Simple Ladle Refining31)For steels of less demanding, cost and quantity oriented application, simpler refining processes have been developed. Composition Adjustment by Sealed argon bubbling (CAS) commercialized by Yawata in 1974 employs Ar bottom injection into ladle melt. Contamination by air oxidation and slag entrainment at plume eye is suppressed with Ar sealed closed-top refractory cap immersed in the melt around the plume eye. Addition of deoxidizing alloys and alloys for chemistry trimming is made simple and less costly without the contaminations. Injection of O2 through top lance has been made possible with CAS-OB. CAS and CAS-OB have also found popular use abroad.

BOF slag contains harmful P as well as useful CaO, MgO and iron oxides. To recover the useful components, the slag is recycled as an additive to sintering and resulting sinter is fed into BF. The recycling makes P in hot metal increased beyond the tolerable value for BOF blowing to meet low P, S for quality steels. Also, the blowing of high P hot metal necessitates increased use of CaO which in turn brings forth a large amount of slag against the environmental requirement to minimize the slag. In BOF blowing of hot metal, thermodynamic requirements for deP are lower temperature and higher oxygen potential, contradictory to higher temperature and lower oxygen potential for deS. Therefore, it is difficult to achieve both deP and deS in single BOF vessel with single slag operation (exception is to use sodium carbonate instead of CaC2 for simultaneous deP and deS, but it causes reversal of P from slag to steel at tapping temperatures with single slag and single vessel operation).

In Japan, integrated iron and steel plants need to run BOF at high hot metal ratio for economic reasons with sufficient supply of hot metal. Under such circumstances, BOF + LF process was not the best choice in many aspects, and hence developed were:

(1) Carrying out deS for high temperature hot metal at tapping from BF under low oxygen potential, and

(2) Subsequently executing deP for hot metal and scrap mixture at relatively low temperatures with high oxygen potential slag formed in the early period of oxygen blow in BOF.

Origin of elementary hot metal pretreatment (HMPT) dates back to an early era of BOH when hot metal mixer was employed to normalize fluctuating temperature and chemistry of hot metal from BF. HMPT deS was developed and quickly commercialized during 1965 and 1974 to refine high S (0.023–0.030%) hot metal for increasing production of quality steels such as ship plate (S < 0.02%) and plates with good low temperature toughness and resistant to hydrogen induced cracking (HIC) for line pipe for arctic areas (S < 0.01%, today < 10 ppm). In the middle of 1960s, soda ash was added to hot metal in the tapping trough of BF and transfer ladle, followed by the addition or injection of lime base flux to the ladle or torpedo car. However, deS rate was low and fluctuating (20 ± 10% for initial S of 0.05% with soda ash 2 kg/ton), and deS operation was not smooth. Accordingly, alternative deS method, shaking ladle, was worked out which showed much better rate but difficult for mass production. Many variants were put into operation since, and Kanbara Reactor (KR) has been developed among them, and industrialized successfully in 1965 at Hirohata.

KR has an impeller immersed and rotating in ladle to engulf and disperse deS flux in hot metal, providing hot metal with deS sites at the interfaces of engulfed/suspended flux particles and hot metal and top slag and meniscus of hot metal bulk. Large interfacial areas and long retention time of the particles in the melt make the utilization of deS flux better, and the speed of deS is much improved. KR has been installed at Tsurumi, Kamaishi, Muroran, Nagoya, Mizushima, Kashima, Kokura, Chiba, Fukuyama and Ohgishima in this order during 1967 and 1976. For deS flux, CaC2 was utilized in the beginning, but replaced later by CaO base flux for environmental concern. Optimization of KR processing has progressed greatly since. According to the author’s own experience, 180 ton hot metal containing 0.045% S at 1415°C could be reduced to 3 ppm S in 12 min and 270 ton hot metal containing 0.03% S at 1240°C to 10 ppm S in 10 min, both with 8 kg/ton of CaO–CaF2 mixture rather consistently, provided that the rotation rate and immersion depth of the impeller have been optimized. KR is even today an excellent reactor for deS, low in investment, running cost and waste flux to be disposed. Reuse of the disposed flux has been made in 2000s. Recently, Kikuchi et al.36) improved deS rate of KR with the addition of propane gas into and onto the hot metal bath around the impeller to decrease oxygen potential in the area where engulfment of deS flux occurs.

Until late 1960s when steels extra low in S were not demanded, deS was executed with CaC2 placed on top of hot metal in transfer ladle where N2 was blown from the ladle bottom in different ways. PDS employed at Yawata and Continuous Ladle Desulfurization (CLDS) utilized at Wakayama, Fukuyama, Kawasaki, Kashima and Hirohata fall in this category. For CLDS, hot metal containing 0.02–0.06%S was poured into intermediate ladle where 5 kg/ton of CaC2 was charged in advance. Turbulent hot metal flow during the pouring and subsequent 5 min stirring in transfer ladles with N2 injected from 3 bottom tuyeres decreased S to less than 50 ppm. Since early 1970s, lance injection of CaC2 into hot metal mixer was widely used for better productivity at Nagoya, Sakai, Yawata, Kashima, Wakayama, Kimitsu, Oita, Mizushima, Chiba and Kakogawa in this order. At Chiba, CaC2 powder was replaced for the environmental issue by CaO powder of improved fluidity with a surfactant addition. Kakogawa commercialized a facility to deS with a rotating bubble pump type reactor (GMR) in the ladle. Wakayama put into operation of Mg-coke method which immersed Mg-impregnated coke into hot metal for deS. As a result of these implementations, hot metal deS rate in Japan attained nearly 100% in 1977.

In recent years, injection of 20%Mg–CaO mixture into hot metal has been practiced for its convenience and less amount of slag formation. MgS, formed from S in hot metal and injected Mg, combines with CaO, ascends and is absorbed into top slag, preventing the reversal of S to attain lower S. Tools for hot metal deS for BOF steels of extra low S grade (<10 ppm) and low S grade (<50 ppm) seem to have converged to be KR process and Mg–CaO injection process.

In BOF, S originating from scrap is additional, and hence supplemental deS is required in RH, DH or LF for extra low S grades. Also, increasing demands for better strength and ductilities of steels have requested further reduction of the size and quantity of oxide-, sulfide- and oxysulfide-inclusions. Secondary refining has become mandatory means to meet the demands, accordingly, making the secondary refining ratio about 80% at BOF plants and over 50% at EAF plants in 1987.

6.2. Development of Hot Metal Dephosphorization in Transfer VesselsEarly stage in BOF blowing has been known suitable for deP since temperature is relatively low and slag gets high in oxygen potential. Under the constraint that single BOP only is available for primary blowing, double slag process with deslagging in the early stage of the blowing or LD-AC (ARBED-CNRM) process to inject powder CaO from main lance into BOF could have been a solution to blow steels low in P as it was the case in Europe (cf. NKK was a licensee of LD-AC process).10)

The double slag process promoted early formation of liquefied slag for deP in the early stage of BOF blowing when bath temperature is not high, removed the slag rich in P after deP blowing at the expense of BOF productivity, and prevented the reversal of P from slag in the following high temperature stage of deC blowing. However, large amount of slag required for deP increased heat loss and slopping, decreased iron yield and productivity, and was contradictory to the waste slag reduction. LD-AC also had operational disadvantages including powder transfer and powder injection through the lance.

As a hedge against these drawbacks, each company in Japan commercialized, after about 1980, deSi of hot metal at the BF cast house runners combined with deP in either torpedo cars or transfer ladle with high basic oxidizing slag mix. The flux was injected into the desiliconized hot metal with O2 as career, or added on top of gas stirred hot metal onto which O2 was blown. Low Si operation of BF and preliminary deSi with removal of slag rich in SiO2, were the prerequisites to minimize deP flux for subsequent BOP blowing.

Early in 1980s, Kawasaki steel commercialized a torpedo car deP process where CaO–CaF2 flux was added on the deSi hot metal, and CaO–CaF2–Fe2O3 flux was injected through lance into the hot metal in torpedo car with O2 as carrier gas. At the point of the injection, highly basic iron oxide rich calcium ferrite base slag droplets are formed and dispersed to facilitate deP around the point. The droplets, containing deP product, 3CaO·P2O5, reduce their iron oxide content during flotation through C-bearing hot metal, and dissolve to be diluted into high basic top slag low in iron oxide. Hot metal bath is stirred by CO bubbles formed by O2 injection, and reacts with the top slag to be desulfurized. This is a process where transitory reaction promotes deP and permanent reaction enhances deS at two different reaction sites in a single vessel.37) After the pretreatment, the hot metal was removed of slag and subjected to deC blowing in BOF on commercial basis.

NKK developed Zero Slag Process (ZSP) which was industrialized in 1998 (Fig. 8).38) Hot metal in transfer ladle is removed of Si at deSi station with O2 injection, deslagged, subjected to deS with KR and then to deP with deP flux blown through immersed lance with O2 as career gas. The amount of slag in BOF after deC blowing reduced to 10 kg/t, and total sum of the slags for deSi, deP and deC decreased to 60 kg/t, only about one half of the sum for conventional BOF operation. Operational benefits obtained were better end point hit rate of C and T, improved iron yield and increased productivity by 20%. Also, smelting reduction of Mn ore during deC blowing became favorable due to decreased loss of Mn ore in the reduced amount of slag in BOF which in turn decrease Fe–Mn alloy addition.38) Consequently, annual crude steel production of 10 million tons at Fukuyama has been totally replaced by ZSP.

Zero Slag Process (ZSP) for Primary Steelmaking at NKK. (Online version in color.)38)

Advantages of above mentioned variants of hot metal deP processes in transfer vessels are that additional investment is small, processing period of time is made in match with the cycle time of BOF, not causing bottle neck for BOF operation. On the other hand, unit process steps involved are too many, and improvements are required in slag/metal mixing intensity and utilization rate of slags for deS and deP, exhaust gas treatment, deslagging and heat loss.

6.3. Development of Hot Metal Dephosphorization with BOFIn 1983, Chiba trialed production scale deP of hot metal by utilizing intensive bath stirring, bottom injection of CaO and O2, quick deP in the early stage of blowing, high free board and good separation of slag and steel at tap, of Q-BOP (Fig. 9)18) while benefited with existing off-gas processing system. 20 kg/ton CaO, 3 kg/ton CaF2, 28 kg/ton iron ore and 6 Nm3/ton O2 were used to blow 230 ton hot metal containing 4.5%C, 0.2%Si, 0.40%Mn, 0.14%P and 0.02%S at 1370°C for about only 3 min to get hot metal of the composition 3.7%C, tr. Si, 0.3%Mn and 0.010%P, S, and virtually without temperature loss. As no extra Q-BOP was available at that time, commercialization was not attempted despite the operational success.

Hot Metal Dephosphorization with 230 t Q-BOP at Kawasaki Steel.18)

In 1988, Nagoya commercialized a HMPT process, named Optimizing Refining Process (LD-ORP)39) with mixed blowing BOF (Fig. 10, top).40) DeS hot metal was subject to deSi and deP together with scrap melting in the BOF. Slag rich in P was separated at tapping from steel which is subsequently decarburized in LD-OB. Inflow of slag containing P and S to LD-OB was minimized, and hence reversal of P at deC blowing was suppressed, amount of slag reduced, and smelting reduction of Mn in LD-OB was carried out favorably. Nippon Steel produced nearly 30% of total crude steel with LD-ORP in 2009.40)

LD-ORP and MURC Process for Primary Steelmaking at Nippon Steel. (Online version in color.)40)

Similar process to the above with BOF was industrialized by Sumitomo Metal in 1990 as Smart Refining Process (SRP, Fig. 11).41) Hot metal preliminarily treated for deS and deSi, leaving 0.1%P and 0.1%Si at 1300°C was blown with O2 in the 1st mixed blowing BOF with an addition of 16 kg/ton iron ore and 4 kg/ton CaF2 to get 0.032%P melt which was subjected to deC and deP in the 2nd mixed blowing BOF with 10 kg/ton CaO as flux to reach 0.012%P. Slag from the 2nd BOF (20 kg/ton with 2.2% P2O5) was reused as a source of CaO and FeO for the 1st BOF. The reuse considerably decreased the amount of waste slag containing 10.8% P2O5 from the 1st BOF to 25 kg/ton.

Smart Refining Process (SRP) for Primary Steelmaking at Sumitomo Metal.41)

In 2000, Nippon Steel commercialized Multi-Refining Converter (MURC, Fig. 10 bottom)42) as a variant of BOF based HMPT. Hot metal was subject to deS with KR or Mg–CaO injection, and charged into a mixed blowing BOF with scrap for deP blow. After tilting the BOF for slag removal, deC blow was carried out in the same BOF. De-P is promoted with the mixed blowing BOF, and the slag left in the BOF after deC blow is employed as the slag for the next deP blow. When the composition of the slag after the deP blow was controlled to be (CaO/SiO2) = 1.5–2.0 and (T.Fe) = 15–20%, hot metal containing 0.15%P at 1170°C is reduced to 0.02%P in 8 min with total consumption of CaO only 10 kg/t for both deP and deC blow at 60% of deslagging rate after deP. Not only the consumption of CaO and the amount of slag formation, but also accompanied heat loss decreased. About 55% of hot metal produced at Nippon Steel in 2009 was reported40) to have been processed with MURC. When the deslagging rate stayed below 70%, P ≤ 0.010% was difficult to reach for medium C steels of 0.5%C class. However, 100% deslagging has been made successful to industrially blow the low P grades by the name of F-MURC.

After 2010, Sumitomo Metal have improved SRP to industrialize SRP-Z43) at Kashima, Wakayama and Kokura. Hot metal is desulfurized with KR, deslagged, charged in the 1st stage mixed blown BOF with scrap, lump CaO, iron ore and recycled CaO–Al2O3 type LF slag, and blown with pulverized CaO and O2 through Spike type top main lance for deP. After deP, the hot metal is processed for deC in the 2nd stage mixed blown BOF. Major characteristics of SRP-Z include:

(1) Quick molten slag formation of CaO powder blown at the high temperature impinging points makes CaO utilization efficiency high, CaO consumption and slag volume decreased, resulting in a high speed deP in less than 6 min,

(2) Occurrence of fume and dust out of the BOF is reduced,

(3) The recycled LF slag accelerates melting and assimilation of lumpy CaO, and resulting slag dissolves calcium ferrite quickly to promote deP,

(4) Foaming of slag often observed at this stage is suppressed by the top blow of pulverized CaO,

(5) Slag formed in the deC BOF is returned to the deP BOF for deP blow, and

(6) Waste slag out of the deP BOF bears low amount of undissolved CaO, and hence usable for road pavement with a short period of cure.

It is of interest to note that double slag and LD-AC process formerly developed in Europe have been improved in many aspects and systematized to revive for blowing high quality steels with much lower P content.

6.4. Choice of HMPT ProcessesEach steel plant in Japan has made choice of some of the above mentioned processes for their HMPT by optimizing the choice fits best to their intrinsic pieces of equipment, environment, technologies and products. Keywords for the choice were, availability of excess BOF, pros and cons of the investment to build new mixed blowing BOF for HMPT, which are influenced by the productivity of the process, heat loss, iron yield, unit consumption of flux additives, amount of waste slag formed, P- and S-buckel caused by retained slag in BOF, carry over of BOF slag into ladle, refractory life, matching of the productivity with preceding- and succeeding-process, and cutting back the loss of processing time for each unit and all over the system. Today, HMPT process is fully utilized for virtually all the hot metal produced in integrated iron and steel plants in Japan.40)

History of electric arc furnace (EAF) steelmaking in Japan dates back to 1916 when 1.5 ton Heroult furnace was made domestically and put into operation at Denki Seikosyo, now Daido Steel.3,4,7) The number of the EAF increased to 7 in 1927, although their capacity was ≤ 10 ton each. Demands of armed forces for EAF steels increased to fulfill wartime need since then, and installation of larger Heroult furnaces continued to produce specialty steels and stainless steels with 104 EAFs of ≤ 20 ton capacity in 1934. In 1951, total EAF steel production reached 2.39 million tons with 406 EAFs of ≤ 40 ton capacity.

It was in 1952, after World War II, when Daido Steel struck technical agreement with Lectromelt Co. to install a swing top type, top charging high voltage long arc EAF with domestic components and started production. Process for oxidizing refining changed from the use of iron ore to O2 blowing in the early half of 1950s. The latter half of 1950s saw increased number of installation and enlargement of Lectromelt-, American Bridge- and Demag-type EAFs. As a result, average capacity of EAFs increased to 26 tons and the number of EAF over 50 ton capacity counted 12 in 1962. As an extreme, Chubu Kohan put into operation of Lectromelt-type 250 ton EAF (40 MVA, hearth diameter 7.62 m), nominal productivity being 1000 tons/day of carbon steel ingots in 1952.

7.2. Progress from Ultra High Power and Oxygen Steelmaking to Scrap Preheating OperationEAF then stepped into the era of Ultra High Power (UHP) operation where 2–3 times of electric power could be put into the same size of conventional EAF by implementing high voltage large capacity transformer. UHP-EAF found popular acceptance owing to:

(1) Stability of arc,

(2) Reduced time for melting down,

(3) Consistency to continuous casting operation for the sake of increased productivity,

(4) Reduction of uprising price of electricity, that was made possible by the use of automatic electrode position adjustment system with thyristor controlled electromagnetic coupling, vacuum switch, water cooled electricity feeding cable and tapered nipple connection of the electrodes.