2016 Volume 56 Issue 10 Pages 1796-1799

2016 Volume 56 Issue 10 Pages 1796-1799

Cu is always present in the matrix when ferritic steels were prepared from ferrous scrap. When the ferritic steels are aged thermally, Cu particles start appearing and dispersing finely and homogeneously, which may result the steels strengthened by dispersion strengthening. In this study, the interactions between Cu particles and dislocations were examined via high-temperature in-situ TEM straining. Cu-added ferritic stainless steel (Fe-18.4%Cr-1.5%Cu) was used in the present study. Specimen was aged at 1073 K for 360 ks. Microstructure of specimen was analyzed by JEM-3200FSK and high-temperature in-situ TEM straining was conducted using JEM-1300NEF. Progressing dislocations in matrix contacted with the Cu particle at right angle. This result implies that there is an attractive interaction between dislocations and the Cu particle. Furthermore, dislocations pass through the particle after contacting it, so that the interaction with dislocations and particles should be explained by Srolovitz mechanism.

Currently, it has been promoted to suppress the emission of carbon dioxides and to reuse of the iron scrap for recycling natural resources, during the steelmaking process. Nevertheless, the iron scraps are the assembly of various steel scraps in general, so that the contamination of impurity elements is unavoidable. In addition, it is extremely difficult to remove tramp elements, such as Cu and Sn, from steel by oxidation refining and others process.1) The amount of residual tramp elements will be increased further in iron scrap after the repetition of recycling processes. In particular, Cu is commonly included in the electrical components of automobiles, such as in the wire harness and the motor,2) Cu in the iron scraps are expected to be increased with the increase of electric vehicle productions. Cu is usually very harmful towards mechanical properties of steel products. The hot shortness is caused by the liquid embrittlement during the hot working, namely the formation of the liquid Cu-enriched phase through preferential oxidation of Fe atoms at the steel/scale interface and penetration of the Cu-enriched phase into the grain boundaries.3) Therefore, there have been several extensive researches with respect to the complete removal of Cu from scrap during the recycling process of Cu-contained scraps so far,4,5) but it has not been established yet. On the other hand, there have been several technological improvements, such as the hot rolling without the formation of red shortness at the hot working temperature,6) and discovery of the effective elements, such as Ni and B, for the suppression of red shortness.7,8) Therefore, it is expected to exploit residual Cu in the iron scrap as the effective strengthening element for dispersion strengthening of steels in recent years. Moreover, the red shortness does not occur in stainless steels,9) Cu can intentionally be added to them for the corrosion resistance,10) antibacterial,11) and heat-resistance.12)

The diffusivity of Cu atoms in the iron is much slower than that of the Cu atoms,13) so that the growth rate of the Cu particles is slower than that of the cementite. In addition, Cu particles is known to be finely and homogeneously dispersed in the matrix,14) Cu particles would act as the particle for the dispersion strengthening. Interaction between dislocations and second phase particles are the most important factor governing the deformation behavior of dispersion strengthened materials because of their impeding of moving dislocations. The mechanisms of the interaction between dislocations and particles are evidently dependent on the size of particles and the type of dislocations. Therefore, the interactions between particles and dislocations should be investigated at microscopic scales for further understanding the dispersion hardening mechanisms.

Fe–Cu steels exhibit dispersion strengthening through the dispersion of fine Cu particles within the ferrite matrix, which provide a good combination of strength, toughness and weldability.15) To date, a large number of microstructural characterizations have been carried out to investigate the role of Cu to the hardness increase in Fe–Cu steels. It has been assumed that the interaction mechanisms between dislocations and Cu particles with less than 70 nm in diameter were cutting from the ex-situ TEM observation, before and after the tensile experiments.15) Furthermore, the interaction between the dislocation and the Cu particles at high temperatures (~873 K) should be different from that at the room temperature, and are based on the Srolovitz mechanisms.16) Nevertheless, the mechanisms were only investigated from the still images taken after the tensile experiment, and in-situ experiments had always been desired.

In-situ tensile testing in TEM has been the most favorable method to reveal the behaviors of the dislocations in the matrix under the applied stress at the nanoscale dynamically. Fraczkiewicz et al. conducted in-situ observation tension within the TEM to investigate the behavior of dislocation in single crystal foils of an FeAl alloy containing Ni and B at elevated temperatures, and slip plane of the dislocation, slip direction, 12 that further elucidate the decomposition and contractile response of dislocation.17) Yamada et al. confirmed the suppression of dislocation slip in Ti- and Mo-added steel by measuring the breaking angles and the particle distances using in-situ tensile testing in TEM.18) In-situ tensile experiment is capable of observing the movements of dislocations and particles dynamically, so that the it is the method to elucidate the dispersion strengthening mechanisms.

In this study, in-situ tensile testing in high-voltage TEM was carried out of Fe–Cu ferritic steels to achieve the direct information of the interaction between Cu particles and dislocations by observing the dislocation movement through Cu particles.

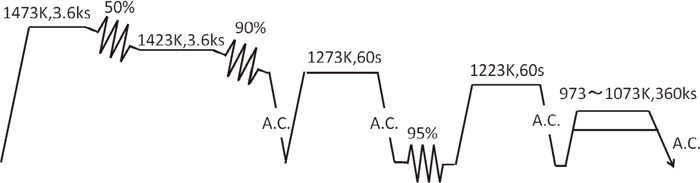

The chemical composition of raw materials used in this experiment is given in Table 1. The ingot of the steel was produced with vacuum melting furnace, preheated in a hearth furnace at 1473 K for 3.6 ks, hot-forged to 50 mm thickness and further hot-rolled to 5 mm thick plate after holding at 1423 K for 3.6 ks, then air-cooled, as shown in Fig. 1. The air-cooled specimen was annealed at 1273 K for 60 s, and cool-rolled to 0.3 mm and annealed at 1223 K, followed by air-cooling. The air-cooled specimen was aged at 1073 K for 360 ks to introduce Cu particles in the ferrite matrix.

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.001 | 0.03 | 0.001 | 0.001 | 0.0006 | 0.1 | 18.4 | 0.01 | 1.53 |

Processing and heat treatments.

Specimens for in-situ TEM straining experiments were prepared with the geometry as shown in Fig. 2 by cutting from a bulk sample using wire saw, ROBOCUT α-0iC (Fanuc Corp., Japan), with 2.5 and 11.5 mm dimension and mechanical grounded to 100 μm thick thin foil. A notch was intentionally introduced one side at the middle of the sample, so that dislocations could propagate during the in-situ TEM straining experiments easily. In addition, the bottom of the notch was further thinned by focused ion beam, Quanta 3D 200i.

Shape of the sample for high-temperature in-situ TEM straining experiment.

Both TEM and STEM observation were performed on JEM-3200FSK operated at 300 kV acceleration voltages to acquire images of Cu particles and dislocations by bright-field TEM, dark-field TEM as well as selected area electron diffraction (SAED) pattern. Elemental distributions were examined by the combination of scanning transmission electron microscopy (STEM) and energy dispersive X-ray spectroscopy (EDS).

2.4. In-situ TEM Straining ExperimentsIn-situ TEM straining experiments were conducted on JEM-1300NEF with the acceleration voltage at 1250 kV and a Gatan Model 654 single-tilt straining holder. The whole specimen was subjected to uniaxial loading at 1073 K. Samples were first slowly heated up to 1073 K, just enough to hold the foil clamped in the stage jaws. Mechanical testing started once the test temperature was reached. Video frames were recorded to reveal the interaction between the moving dislocation and the Cu particles.

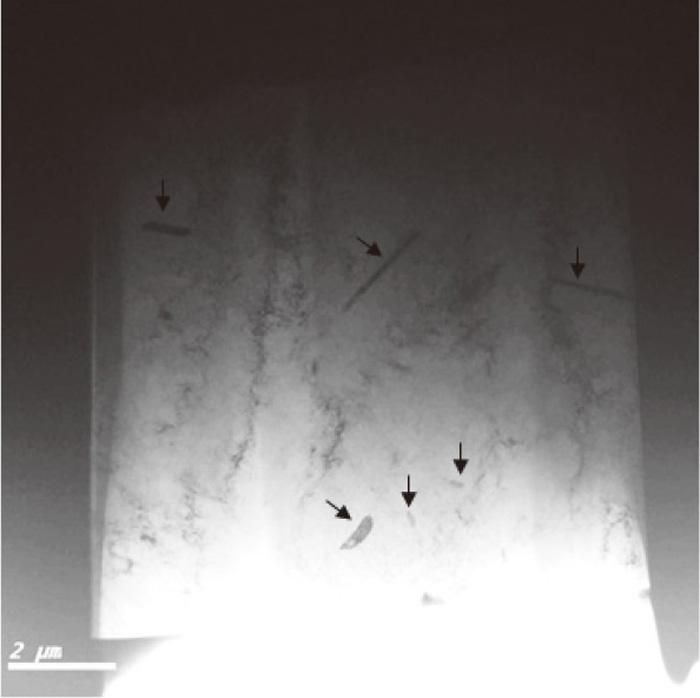

Figure 3 shows a low-magnified bright-field TEM image of Fe–Cu alloy sample prepared by FIB before the high-temperature in-situ TEM straining experiment. There are particles with rod-shape having the length of 1–2 μm, and with ellipsoidal morphology having the length of hundreds nm as well as the number density as 0.188 μm−2, as pointed by black arrows. Contrast was varying from the top to the bottom of the image due to the thickness variations.

Low-magnified bright-field TEM image of the region of interest before conducting the high-temperature in-situ TEM straining experiment.

STEM-EDS was carried out to investigate the elemental distribution map within the Fe–Cu alloy. Figure 4 show (a) STEM-BF image and elemental distribution maps of (b) Cu, (c) Fe and (d) Cr, where the particle was found very rich in Cu. In addition, contrast of Cu was almost negligible within the matrix so that the matrix was assumed to be free from Cu solutioning. Furthermore, it was clearly recognizable that there were several dislocations entangled with particles, as shown in bright-field STEM image, Fig. 4(a).

Bright-field STEM image (a) and EDS elemental maps of the region including particle, (b) Cu, (c) Fe and (d) Cr, respectively.

Figures 5(a) and 5(b) show a set of bright-field and dark-field TEM images from a typical particles found within the matrix where ellipsoidal Cu particles about 300 nm in long axis was observed. Figure 5(c) shows a selected area electron diffraction pattern obtained from the Cu particles, where schematic representations of diffraction patterns were also overlaid. It was confirmed that the orientation relationship between the ferrite matrix (bcc) and the Cu particles (fcc) was Kurdjumov–Sachs, maintaining the close packed grains and close-packed directions being parallel, so that the low-energy orientation relationship, (011)α−Fe//(111)ε−Cu and [111]α−Fe//[011]ε−Cu.

Bright-field TEM image (a), dark-field TEM image (b) and selected-area electron-diffraction pattern (c) from the region including particle.

Figure 6 show a part of images extracted from a video of in-situ TEM strain experiment carried out at 1073 K, and a schematic diagram of them respectively. There is a spherical Cu particle having the diameter of about 100 nm at the central part of the view with several dislocations. Upon the in-situ TEM straining experiment, the dislocation approached towards Cu particle, as shown in Fig. 6(a), and attracted, pinned then unpinned, as shown in Figs. 6(b), 6(c) and 6(d) respectively. Another dislocation started appearing as shown in Fig. 6(b), and approached towards, interacted with Cu particle, as shown from Figs. 6(c) to 6(d). It should be noted that when dislocations approached towards particle, they were attracted by the particle and contacting it at right angle. Several pinning points are clearly visualized along the dislocation. These dislocation pinning–depinning processes were frequently observed during the in-situ TEM straining experiment.

Bright-field TEM images from (a) to (d) for high-temperature in-situ TEM straining showing the interaction between dislocations and Cu particles, and schematic diagram of them from (a)’ to (d)’, respectively.

Progressing dislocations contacted with Cu particles at almost right angle, as seen in the results obtained by in-situ TEM straining experiments at 1073 K, which implied that there were attractive interactions between dislocations and Cu particles, as shown in Fig. 6. Dislocations passed through Cu particles after contacting it, so that the interaction between dislocations and Cu particles should be explained by Srolovitz mechanism.19)

According to the Arrhenius law, the diffusion coefficient at 1073 K, D1, and that at room temperature, D2, can be measured as;

| (1) |

| (2) |

The direct information of the interaction between Cu particles and dislocations was achieved by in-situ TEM straining experiment at high temperature in Fe–Cu ferritic steels, and the following findings were obtained.

(1) The orientation relationship between the ferrite matrix and the Cu particle was found as Kurdjumov–Sachs to maintain the low-energy orientation relationship.

(011)α−Fe//(111)ε−Cu and [111]α−Fe//[011]ε−Cu.

(2) There were attractive interactions between dislocations and Cu particles, and the interaction mechanisms between Cu particles and dislocations were assumed to be Srolovitz mechanisms. The strain field of the dislocation was relaxed by the lattice diffusion, interfacial diffusion between the matrix and the particle, and slip.