2017 Volume 57 Issue 1 Pages 84-90

2017 Volume 57 Issue 1 Pages 84-90

Effect of a weak transverse magnetic field (B ≤ 0.7 T) on the microstructures in directionally solidified Zn-2.2 at.% Cu peritectic alloy has been investigated experimentally. The results indicate that the magnetic field causes the formation of a transition from the primary dendrite to peritectic phase, macrosegregation of the Cu solute in the primary dendrite, a change in the volume fraction of the primary phase, and the refinement of the primary dendrite. Furthermore, energy dispersive spectrometer (EDS) analysis reveals that the magnetic field increases the Cu solute content in the solid and front of the solid/liquid interface. The Seebeck voltage near the solid/liquid interface in directionally solidified Zn-2.2 at.% Cu alloy at various growth speeds is measured in situ, and the result shows that a thermoelectric current exists near the solid/liquid interface. The thermoelectric magnetic convection (TEMC) in the liquid under the magnetic field is numerically simulated, and the result reveals that a unidirectional TEMC forms in the liquid near the solid/liquid interface during directional solidification under the transverse magnetic field. The modification of the microstructures in directionally solidified Zn-2.2 at.% Cu alloy under the transverse magnetic field should be attributed to the TEMC driven solute transport.

Recently, the magnetic field has been extensively used in the process of solidification, and many interesting phenomena have been observed. Especially, it has been found that the application of the magnetic field is capable of controlling the solidification structure of alloys during directional solidification.1,2,3) The effects of the magnetic field on the shape of the solid/liquid interface,4) the dendritic spacing,5) the orientation of crystal,6) and the macrosegregation7,8,9) during directional solidification have been widely investigated. Moreover, the application of the magnetic field could control the distribution of the solidification structures.10,11) Distribution and content of the primary phase in peritectic solidification is important for the mechanical properties of some commercially important peritectic alloys.12) The primary phase formed in the peritectic solidification often is an intermetallic phase. The amount of primary phase, i.e. intermetallic compound, will affect strength and conductivity up to solidification conditions.13) Consequently, it is necessary and desirable to study the effect of a magnetic field on the solidification behavior of peritectic alloys during directional solidification.

As is well known, the presence of convection in the melt can significantly alter the microstructures of peritectic alloys during directional solidification.14) Conventional wisdom may suggest that the application of a magnetic field will restrain the convection. However, Tewari et al.15) and Alboussière et al.16) found that large freckles appeared in Pb–Sn and Bi–Sn alloys during directional solidification under a transverse magnetic field, respectively. Freckles appear under the magnetic field, showing that a new convention has formed. Lehmann et al.17) found some experimental evidence for the convention, namely, thermoelectric magnetic convention (TEMC) induced by the interaction between the Seebeck effect and the magnetic field. In our previous works,18) in situ monitoring of the initial transient in directionally solidified Al–Cu alloys under a transverse magnetic field were carried out by means of synchrotron X-ray radiography. The authors found that the TEMC was created approximately along the direction perpendicular to the magnetic field. However, so far, little work has been carried out on the effect of a transverse magnetic field on the solidification behaviors of Zn–Cu peritectic alloys.

The aim of the present work has two aspects: one is to investigate the effect of a weak transverse magnetic field on the microstructures of Zn-2.2 at.% Cu peritectic alloy during directional solidification; and the other is to study the TEMC under the magnetic field, thus enhancing a deeper understanding of the effect of the convection on the solidification behavior in peritectic system.

Zn-2.2 at.% Cu alloy used in this study was prepared with high purity Zn (99.99 wt.%) and Cu (99.99 wt.%) in a vacuum induction furnace. The cast sample was placed in tube of high purity corundum with an inner diameter of 3 mm and a length of 200 mm for directional solidification under a weak transverse magnetic field. The experimental apparatus comprised of a static electromagnet and a Bridgman furnace equipped with a controlling temperature system and pulling regime. The electromagnet can produce a transverse static magnetic field with adjustable intensity up to 0.7 T. The furnace, which consists of nonmagnetic material, has a negligible influence by the magnetic field. The temperature in the furnace can reach 1500 K and stabilize at a precision of ±0.1 K. The temperature gradient in the sample is 60 K/cm. A water cooled cylinder containing liquid Ga–In–Sn metal (LMC) was used to cool down the sample. The growth speed of the sample can be adjusted from 0.5 μm/s to 10000 μm/s by the pulling regime. During directional solidification, the magnetic field was applied in the whole process and the solid/liquid interface of the sample was always put into the centre of the magnetic field. The etched samples obtained from these experiments were examined by the optical microscope. The energy dispersive spectrometer (EDS) was used to measure the distribution of the solute Cu. The numerical simulation was performed by using the finite element commercial code with Thermoelectric Effect and Laminar Flow modules. The study configuration is 3D-dimensional, and both the liquid and the solid regions were considered.

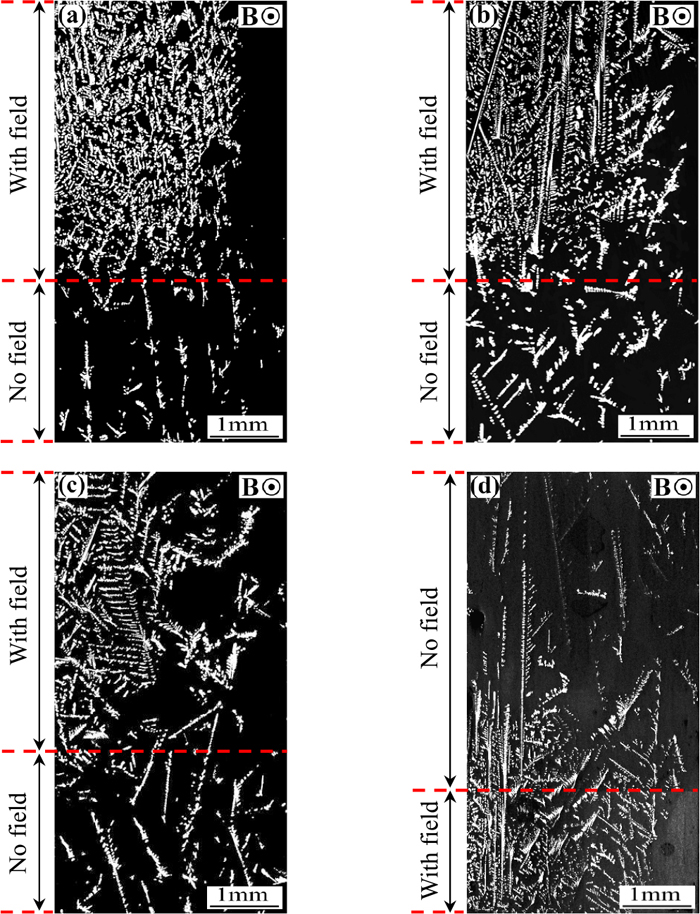

Figure 1 shows the longitudinal structures at the beginning of the solidification in directionally solidified Zn-2.2 at.% Cu alloy at various growth speeds without and with a 0.3 T magnetic field. The growth length at quenching was 60 mm. It can be found that, in the case of no magnetic field, the primary dendrite is uniformly distributed in the matrix of the peritectic phase. However, when a 0.3 T magnetic field is applied, a transition from the primary dendrite to peritectic phase occurs, and the primary dendrite refines during directional solidification. Figure 2 shows the longitudinal structures at the beginning of the solidification in directionally solidified Zn-2.2 at.% Cu alloy at a growth speed of 5 μm/s under various magnetic fields. It can be found that the transition distance from the initial solidification to the interface of the primary dendrite and peritectic phase is decreased as the magnetic field increases. The transition distance is measured and the results are shown in Fig. 3. It can be found that the application of the magnetic field enhances the formation of the transition from the primary dendrite to peritectic phase and this effect is weakened as the growth speed increases.

Longitudinal structures at the beginning of the solidification in directionally solidified Zn-2.2 at.% Cu alloy at various growth speeds without and with a 0.3 T magnetic field: (a) 1 μm/s; (b) 2 μm/s; (c) 10 μm/s.

Longitudinal structures at the beginning of the solidification in directionally solidified Zn-2.2 at.% Cu alloy at a growth speed of 5 μm/s under various magnetic fields: (a) 0 T; (b) 0.1 T; (c) 0.3 T; (d) 0.5 T; (e) 0.7 T.

Effect of the transverse magnetic field on the transition distance from initial solidification to the interface of the primary dendrite and peritectic phase: (a) the transition distance as a function of the magnetic field at various growth speeds; (b) the transition distance as a function of the growth speed under various magnetic fields. (Online version in color.)

To confirm the effect of the magnetic field on the distribution of the primary dendrite, a given magnetic field was applied at different stages during directional solidification. Figure 4 shows the microstructures of the sample in directionally solidified Zn-2.2 at.% Cu alloy at different stages without and with a 0.1 T magnetic field. Figures 4(a)–4(c) show the microstructures as the 0.1 T magnetic field is imposed after growing to 10 mm at various growth speeds. It can be found that the magnetic field causes the refinement of the primary dendrite and this effect is weakened as the growth speed increases. Figure 4(d) shows the microstructures as the 0.1 T magnetic field is removed after growing to 10 mm at a growth speed of 10 μm/s. It can be found that, as the magnetic field removed, the refined dendrite transformed into discrete.

Microstructures of the sample in directionally solidified Zn-2.2 at.% Cu alloy: (a) imposed a 0.1 T magnetic field after growing to 10 mm at a growth speed of 2 μm/s without magnetic field; (b) imposed a 0.1 T magnetic field after growing to 10 mm at a growth speed of 5 μm/s without magnetic field; (c) imposed a 0.1 T magnetic field after growing to 10 mm at a growth speed of 10 μm/s without magnetic field; (d) removed the magnetic field after growing to 10 mm at a growth speed of 10 μm/s with a 0.1 T magnetic field. (Online version in color.)

EDS is used to analysis the distribution of the Cu solute content on the scales of the dendrite and sample. Figure 5 shows the distribution of the Cu solute content in directionally solidified Zn-2.2 at.% Cu alloy at a growth speed of 1 μm/s without and with a 0.1 T magnetic field. It can be found that the application of the magnetic field causes the formation of the macrosegregation of the Cu solute in the primary dendrite, and the Cu solute content to increase in the solid during directional solidification. Figure 6 shows the distribution of the Cu solute content near the solid/liquid in directionally solidified Zn-2.2 at.% Cu alloy at a growth speed of 5 μm/s under various magnetic fields. One can notice that the distribution of the Cu solute content in the liquid increases, and this content gets closer to the peritectic point under the magnetic field. It is also found that the value of the Cu solute content in the solid increases as the magnetic field increases. This implies that the application of the magnetic field causes the macrosegregation of the Cu solute in the primary dendrite and induces the increase in the solid solubility in the solid during directional solidification.

EDS analysis for the samples directionally solidified at a growth speed of 1 μm/s without and with a 0.1 T transverse magnetic field: (a) micrograph; (b) EDS map; (c) average solid composition as a function of the fraction solid. (Online version in color.)

EDS analysis near the solid/liquid interface in directionally solidified Zn-2.2 at.% Cu alloy at a growth speed of 5 μm/s under various magnetic fields: (a) 0 T; (b) 0.1 T; (c) 0.3 T; (d) 0.5 T. (Online version in color.)

Furthermore, the volume fraction of the primary phase is measured and the results are shown in Fig. 7. It can be found that, with the application of the magnetic field, the volume fraction of the primary phase increases to a maximum value when the magnetic field increases to a critical value and then decreases as the magnetic field still increases. This effect is weakened with the increase in the growth speed.

Effect of the transverse magnetic field on the volume fraction of the primary phase: (a) the volume fraction of the primary phase as a function of the magnetic field at various growth speeds; (b) the volume fraction of the primary phase as a function of the growth speed under various magnetic fields. (Online version in color.)

Owing to the Seebeck effect, a TEMC will be produced in the liquid near the solid/liquid interface during directional solidification under a magnetic field. The Seebeck effect can be characterized as follows. If two materials of different thermoelectric powers (ηl, ηs) are connected together at a temperature gradient (ΔT), a thermoelectric current will form in the system, and then the Seebeck voltage (ΔE) can be measured according to ΔE = (ηl−ηs)ΔT19) where ηl is the thermoelectric power of the liquid and ηs is the thermoelectric power of the solid. When a transverse magnetic field is applied during directional solidification, the thermoelectric current and the magnetic field are not parallel, a thermoelectric magnetic force will be produced by the interaction between the thermoelectric current and the magnetic field. Then, a unidirectional TEMC will develop in the liquid near the solid/liquid interface during directional solidification under the transverse magnetic field. To confirm the existence of the thermoelectric current near the solid/liquid interface, the Seebeck voltage in directionally solidified Zn-2.2 at.% Cu alloy has been measured in situ. Figure 8(a) shows the schematic illustration of the measurement device. It consists of two furnaces each with a neighboring heat sink that are cooled by the LMC. One of the furnaces is fixed, while the other can be moved at a given velocity on a pulling platform. Therefore, two solid/liquid interfaces are created and linked together with the liquid phase in the sample during directional solidification. Due to the Seebeck effect, the Seebeck voltage will be measured between the both ends of the sample. Figure 8(b) shows a typical Seebeck curve obtained in directionally solidified Zn-2.2 at.% Cu alloy at a growth speed of 10 μm/s. It can be found that a plateau is obtained on the Seebeck curve, which indicates the establishment of a steady state after heating up. Subsequent to obtaining a new steady state, when the furnace translation is began. It should be noted that the wave amplitude in curve contributions from grain boundaries during directional solidification. When the furnace ceased to move, the curve gradually rebound to the pre-drop levels. The magnitude of the curve drop corresponds directly to the Seebeck voltage near the solid/liquid interface. Table 1 shows the Seebeck voltage as a function of the growth speed. It can be found that, with the increase of the growth speed, the Seebeck voltage increases and reaches a maximum value when the growth speed is about 10 μm/s, and then decreases as the growth speed continues to increase.

Seebeck voltage measurements: (a) schematic illustration of the experimental device; (b) a typical Seebeck curve in directionally solidified Zn-2.2 at.% Cu alloy at a growth speed of 10 μm/s.

| Growth speed (μm/s) | 2 | 5 | 10 | 15 | 20 | 30 | 50 |

| Seebeck voltage (μV) | 0.92 | 1.95 | 5.83 | 4.27 | 3.76 | 2.88 | 1.57 |

Furthermore, the TEMC near the solid/liquid interface has been numerically simulated in directionally solidified Zn-2.2 at.% Cu alloy under a transverse magnetic field. The numerical simulation was performed by using the finite element commercial code with Seebeck Effect and Laminar Flow modules. The study configuration is 3D-dimensional, and both the liquid and the solid (primary phase ε and peritectic phase η) regions were considered. Table 2 shows the physical properties used in the computations. Figure 9 shows the typical distribution of the mesh, the thermoelectric current density, the thermoelectric power, and the TEMC around a modeled cell/dendrite interface in the liquid in directionally solidified Zn-2.2 at.% Cu alloy under a transverse magnetic field. The thermoelectric current forms around the cell/dendrite. Figures 9(d1)–9(d4) show the general 3D view of the TEMC and the corresponding 2D view seen from a different axis under a 0.7 T magnetic field. The TEMC flows extending longitudinally in parallel relationship from edge of the sample to the region higher in the liquid. Figure 10 shows the distribution and amplitude of the TEMC in the liquid in directionally solidified Zn-2.2 at.% Cu alloy under various magnetic fields. It can be found that, with the increase of the magnetic field, the TEMC increases. The maximal values of the TEMC velocity near the solid/liquid and around the cell/dendrite interfaces as a function of the magnetic field intensity are shown in Fig. 11. It can be found that the velocity of the liquid flow near both the solid/liquid and cell/dendrite interfaces increase as the increase of the magnetic field intensity.

| Properties | Liquid | Solid (ε) | Solid (η) |

|---|---|---|---|

| Electric conductivity (σ, Ω−1·m−1) | 8.8×106 | 15.8×106 | 16.6×106 |

| Thermoelectric power (S, V·K−1) | 2.0×10−6 | 0.5×10−6 | 1.0×10−6 |

| Thermal conductivity (k, W·m−1·K−1) | 140 | 160 | 116 |

| Dynamic viscosity (mu, Pa·s) | 8.6×10−4 | 5.0×106 | 5.0×106 |

| Density (ρ, kg·m−3) | 6.57×103 | 7.2×103 | 7.14×103 |

| Heat capacity (CP, J·kg−1·K−1) | 375 | 364 | 389 |

| Temperature gradient (G, K·cm−1) | 60 | 60 | 60 |

Computed the TEMC around the modeled cell/dendrite interface in directionally solidified Zn-2.2 at.% Cu alloy under a 0.7 T magnetic field: (a) mesh; (b) thermoelectric current density streamliner near the interface (in A/m2); (c) thermoelectric power (in V); (d) the simulative TEMC (red arrows represent the direction of the flow, and the colored slice is the magnitude) under seen from different axes. (Online version in color.)

Distribution and amplitude of the TEMC around the modeled cell/dendrite interface in directionally solidified Zn-2.2 at.% Cu alloy under various magnetic fields: (a) 0.1 T; (b) 0.2 T; (c) 0.3 T; (d) 0.5 T. (Online version in color.)

Maximal value of the TEMC velocity as a function of the magnetic field in directionally solidified Zn-2.2 wt.% Cu alloy under a transverse magnetic field: (a) the TEMC velocity near the solid/liquid interface as the function of the magnetic field; (b) the TEMC velocity around the cell/dendrite interface as the function of the magnetic field.

The above experimental results reveal that the application of a transverse magnetic field in directionally solidified Zn-2.2 at.% Cu alloy causes the formation of a transition from the primary dendrite to peritectic phase (see Fig. 1). This should be attributed to the effect of the TEMC at the sample on the distribution of the solute Cu content during directional solidification under the magnetic field. As is well known, the heavier solute in the bulk melt will migrate down to front of the solid/liquid interface during directional solidification due to the gravitational force. The concentration gradient in the liquid can cause the density to increase with distance from the solid/liquid interface and possibly cause solute convection. Experiments on the transition from the primary dendrite to peritectic phase in directionally solidified Zn-2.2 at.% Cu alloy without the magnetic field exhibit only a relatively small growth speed (≤ 1 μm/s), which can be explain by the solute diffusion alone. The formation of a obviously transition from the primary dendrite to peritectic phase in directionally solidified Zn-2.2 at.% Cu alloy under the magnetic field is strong evidence that convection, not solute convection caused by the concentration gradient, should be responsible for the formation of the transition. Under the transverse magnetic field, a unidirectional TEMC will form in the liquid near the solid/liquid interface during directional solidification. Furthermore, the TEMC will induce a longitudinally loop flow from edge of the sample to the region higher in the liquid, as shown in Fig. 9. These flows will induce the heavier Cu solute in the bulk melt to move along with the TEMC and precipitate in front of the solid/liquid interface. As a result, the concentration of the Cu solute will increase in front of the solid/liquid interface. When the concentration of the Cu solute reaches a certain value, the stable peritectic phase will nucleate and grow in front of the solid/liquid interface. Because the TEMC can keep the Cu solute to the peritectic phase, the primary phase will be covered by the peritectic phase soon. In addition, the TEMC also causes an increase in the solid composition during directional solidification under the magnetic field. The transition from the primary dendrite to peritectic phase appears to occur when the solid composition is close to the peritectic composition that the peritectic phase growth becomes stable during directional solidification. After the stability growth of the peritectic phase is established, the peritectic phase growth continues until the bulk liquid composition go over the peritectic composition. Hence, the transition from the primary dendrite to peritectic phase occurs when the TEMC at the sample under the magnetic field has caused the composition of the liquid to increase to a level satisfies that a stability growth of the peritectic phase. From the Fig. 10, it can be found that the TEMC increases as the magnetic field increases when the applied magnetic field is less than 0.7 T. Therefore, the formation of the transition is enhanced with the increase in the magnetic field, as shown in Fig. 2.

4.3. Macrosegregation under a Transverse Magnetic FieldThe formation of the macrosegregation of the Cu solute in the primary dendrite under the magnetic field should be attributed to the TEMC between the primary dendrites and the solute transport caused by the TEMC. As shown in Fig. 9, the unidirectional TEMC and corresponding recycle loop flow caused by the TEMC will form during directional solidification under a transverse magnetic field. The TEMC between the primary dendrites will drive the solute transport along with the flow, enhance the diffusion of the solute to the primary dendrite, and then cause the increase in the solid solubility in the primary dendrite. As a result, the macrosegregation will form in the primary dendrite, as shown in Fig. 5. Because the diffusion will take a while for the solute to spread into the primary dendrite, the macrosegregation occurs only for alloys at lower growth speed during directional solidification under the magnetic field.

4.4. Volume Fraction of the Primary Phase under a Transverse Magnetic FieldThe above results also reveal that, with the application of the magnetic field, the volume fraction of the primary phase increases to a maximum when the magnetic field increases to a critical value and then decreases as the magnetic field still increases. There should be two competing factors governing the effect of the magnetic field on the volume fraction of the primary phase in Zn-2.2 at.% Cu alloy during directional solidification. The increase of the volume fraction of the primary phase under the magnetic field should be attributed to the effect of the TEMC and corresponding recycle loop flow caused by the TEMC on the composition in the liquid during directional solidification. By using the boundary layer model, the volume fraction of the primary phase increases with the composition in the liquid. The concentration of the Cu solute in the liquid increases as the magnetic field applied, as shown in Fig. 6. It is not difficult to understand that the TEMC and corresponding recycle loop flow caused by the TEMC enhance the rate of solute transport and increases the composition in the liquid. Therefore, the increase in the volume fraction of the primary phase under the magnetic field should be attributed to the increase of the composition in the liquid caused by the TEMC driven solute transport. The decrease of the volume fraction of the primary phase under the magnetic field should be attributed to the formation of the macrosegregation and the suppression of the primary phase induced by the formation of the peritectic phase. When the macrosegregation occurs, the primary dendrite will be limited to growth during directional solidification under the magnetic field. In addition, for peritectic solidification the formation and growth of the peritectic phase will soon surround the primary phase and separate the primary phase from the liquid. Moreover, peritectic reaction and peritectic transformation will consume some primary phase, which resulting in the decrease of the volume fraction of the primary phase. From the previous analysis, it can be found that the application of the transverse magnetic field enhance the formation of the peritectic phase. Therefore, the decrease in the volume fraction of the primary phase under the magnetic field should be attributed to the formation of the macrosegregation and peritectic phase caused by the TEMC.

The combined effect of these two factors results in the volume fraction of the primary phase in directionally solidified Zn-2.2 at.% Cu alloy fist increases with increase in the magnetic field, and then decreases with further increase in the magnetic field. For our present results, no maximum value of the volume fraction of the primary phase was observed at the growth speed of 20 μm/s probably due to that the applied magnetic field was not large enough to suppress the formation of the primary phase, as shown in Fig. 7.

4.5. Refinement of the Primary Dendrite under a Transverse Magnetic FieldThe above results reveal that the application of the magnetic field caused the refinement of the primary dendrite. With the increase of the magnetic field, the primary dendrite spacing decreases. The refinement of the primary dendrite should be attributed to the TEMC induced by the application of the magnetic field during directional solidification. Lehmann et al.17) have investigated the effect of the convection on the dendrite spacing (λ), with the expression

The effect of a weak transverse magnetic field on the microstructures of Zn-2.2 at.% Cu peritectic alloy during directional solidification was investigated, and the results obtained are summarized as follows:

(1) The application of the magnetic field caused the formation of a transition from the primary dendrite to peritectic phase, the macrosegregation of the Cu solute in the primary dendrite, and a change in the volume fraction of the primary phase during directional solidification.

(2) Seebeck voltage near the solid/liquid interface in directionally solidified Zn-2.2 at.% Cu alloy at various growth speeds was measured in situ, and the result shows that a thermoelectric current exists near the solid/liquid interface.

(3) Numerical simulation results revealed that a unidirectional TEMC formed in the liquid near the solid/liquid interface and the TEMC increased as the magnetic field during directional solidification under the transverse magnetic field.

(4) The formation of the transition and the macrosegregation should be attribution to the TEMC at the sample and between the primary dendrites, respectively.

(5) The change of the volume fraction of the primary phase should be attributed to the combined effect of the TEMC driven solute transport at the sample and between the primary dendrites during directional solidification under the transverse magnetic field.

(6) The refinement of the primary dendrite under the magnetic field should be attributed to the TEMC around the dendrite.

This work is supported partly by the European Space Agency through the B1-inter 09-473220, National Natural Science Foundation of China (Nos. 51271109 and 51171106) and the Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning.