2018 Volume 58 Issue 1 Pages 52-59

2018 Volume 58 Issue 1 Pages 52-59

In this study, the effects of MgO content, Al2O3 content, TiO2 content and C/S (=CaO/SiO2) on slag flowability are investigated for blast furnace (BF) operation. The liquidus temperature and the viscosity of semi-synthetic slags are measured using an optical softening temperature detector and a viscometer, respectively. Based on the measured data, equations of the liquidus temperature and the viscosity for the semi-synthetic slags (SiO2–Al2O3–CaO–MgO–TiO2) were formulated via the multiple-regression method. In operation practice of BF, the slag flowability is mainly determined by both viscosity and liquidus temperature. A combined slag flowability index, including viscosity and liquidus temperature, has been designed in this research to indicate appropriate slag flowability. This index has been incorporated into the tapping system of CSC (China Steel Corporation) BF. Based on the calculated liquidus temperature and viscosity of the final slag inside BF, the system is able to predict the difficulty of slag flow for the coming tapping. It can immediately provide BF staffs some information to control the variation of slag flowability via the effective operation practice such as enforcing management of thermal state or adjusting the chemical composition of final slag via the burden of BF.

Viscosity and liquidus temperature of the slags play extremely important roles in the blast furnace (BF) operation for ironmaking. The formation of the primary slag in a blast furnace presumably occurs in the cohesive zone through fluxing of the alumina-silicate contained in iron-ore gangue and unreduced iron oxide. The molten slag then drips over lumps of coke and flux materials, such as limestone, dolomite and BOF slag. In the belly and the bosh, the slag loses its ferrous oxide and picks up calcium and magnesium oxide, where most of the silica and alumina from coke ash have not yet been released. The slag formed in the region above the tuyeres is termed bosh slag. The final slag is formed when the ash in the coke and injectants is released at the tuyere level and incorporated in the descending bosh slag which flows down to the hearth. A viscous bosh slag can cause burden hanging, impair the hearth drainage, delay tapping, and destroy hot-metal quality. For both bosh slag and final slag, viscosity and liquidus temperature must be in a proper range for a smooth BF operation.

Generally, the final slag of BF process can be approximately considered a mixture of oxides, such as CaO, SiO2, MgO, Al2O3 and TiO2, which come from the sinter, lump, flux and coke. Therefore, CaO–SiO2–Al2O3–MgO–TiO2 slag can represent the most constituents of the final slag in BF operation practice. Due to the lack of high-grade iron ore resources in the world, the Al2O3 content of the iron ore is increasing gradually. It has been recognized that the high content of Al2O3 in BF slag would increase the slag liquidus temperature and viscosity and cause operational problems, such as making the gas permeability worsen and the slag-metal separation more difficult and so on. To smoothly operate the BF at a higher level Al2O3 content, the furnace temperature needs to be increased. And, this would increase fuel consumption and CO2 emission. Therefore, the flowability of molten slags is one of the most important factors that determine the stability and productivity of BF operation.

Basically, the slag viscosity can be reduced by adjusting the slag composition, it was found that the addition of MgO can improve the flowability of the slag at a given CaO/SiO2 (C/S) ratio and Al2O3 content.1,2,3,4,5,6) Recently, some researchers investigated the effect of MgO/Al2O3 ratio on the viscosity of BF Slags with high Al2O3 content. They pointed out that the proper MgO/Al2O3 ratio can improve the stability and flowability of BF slags.7,8,9) However, the adjustment of C/S and the increase of MgO content may cause the desulfurization problems of BF hot metal and the cost increase on BF burden. In addition, the slag flowability would be worsen by the TiO2 addition for extending BF campaign in blast furnace operation. Therefore, the objective of this study is to quantitatively evaluate the effects of chemical compositions on the liquidus temperature and viscosity of BF final slags with high Al2O3 content. The tolerable range of Al2O3 content at the appropriate ranges of MgO content, TiO2 content and C/S ratio for the normal BF operation was also investigated.

The experimental procedure for the flowability measurement in this study is shown in Fig. 1. The semi-synthetic slag samples with different Al2O3 content, MgO content and C/S ratio were prepared by adding pure oxide powers (reagent grade) into the base material which was the water-quenched slag obtained from the blast furnace tapping. Then, the mixed sample was pre-melted in the graphite crucible under the atmosphere of Ar gas (0.4 L/min) at 1773 K for slagging and assimilation. Afterward, the melt was cooled to form solid slag, then milled into fine powder. In the sample preparation, MgO, Al2O3 and C/S ranged at 0–15 mass%, 10–20 mass% and 0.5 to 1.40, respectively. Subsequently, experimental works conducted for each slag sample were as follows:

Experimental approach for a final slag flowability measurement in this study.

(a) Measurement of the softening and melting temperature via the observation of deformation of the cylinder-shaped specimen during heating up.

(b) Measurement of the slag viscosity using a viscometer at high temperature.

(c) Analysis of the chemical composition.

Finally, the mathematic equations for estimating slag liquidus temperature and slag viscosity were established in the multiple regression form based on the measured data of liquidus temperature and viscosity.

The measured data of liquidus temperature was 1523–1963 K for the slag samples with chemical compositions of C/S = 0.5–1.4, Al2O3 = 10–20 mass%, MgO = 0–15 mass% and TiO2 = 0–5 mass% were used to get an equation as Eq. (1) by the multiple-regression method with R2 = 0.91.

| (1) |

This study adopted the similar method10) to find out a correlation between the measured deformation temperature (Tdeform.) and liquidus temperature (Tliquidus) of semi-synthetic slag samples (Fig. 2). The Tdeform. could be expressed as a linear function of Tliquidus according to Eq. (2):

| (2) |

Correlation between slag deformation temperatures (Tdeform.) and liquidus temperatures (Tliquidus) of semi-synthetic slag samples.

The data for viscosity (2–75 poise), slag composition (C/S = 0.9–1.4, Al2O3 = 5–20 mass%, MgO = 0–15 mass% and TiO2 = 0–5 mass%) and slag temperature (1573–1858 K) were used to get equations as Eq. (3) by the multiple-regression method with R2 = 0.93. In this study, two regression Eqs. (4) and (5) are obtained by using the two-stage linear regression method as shown in Fig. 3 with the proposed slag deformation temperature as the turning point. Equations (4) and (5) were also developed to take the effect of the solid phase precipitated in melt on the viscosity of slags into consideration.11)

| (3) |

| (4) |

| (5) |

In combination with Eqs. (1), (2), (3), (4), (5), the calculated slag viscosity vs. metal tapping temperature could be obtained in this study, and taking it to compare with the measured viscosity of practical blast furnace slag, as shown in Fig. 4. It has been indicated from Fig. 4 that the slag viscosity calculated from the formula is close to the experimental results during the cooling stage (1600 K–1800 K). This formula had been applied to blast furnaces in CSC to provide a more accurate and easy-to-use viscosity prediction model for blast furnace staff.

Comparison of the slag viscosity calculated from the formula in this study and the measured viscosity of practical blast furnace slag during the cooling stage (1600 K–1800 K).

The liquidus isotherms diagram was obtained via normalizing the sum of five oxides with the formula as SiO2+CaO+Al2O3+MgO+TiO2=100% at fixed mass% (TiO2, MgO) or (Al2O3, MgO). The iso-viscosity distribution diagram was obtained at fixed (mass% TiO2, MgO and temperature) or (mass% Al2O3, MgO and temperature) using the same method as the liquidus isotherms diagram.

Based on Eq. (1), the dependence of slag liquidus temperature on Al2O3 with a range of 13–20 mass% under the conditions of C/S = 1.0−1.2, 7.0 mass% MgO and 0.5 mass% TiO2 is shown in Fig. 5. It indicates that liquidus temperature decreases from 1641 K to 1633 K with increasing Al2O3 content from 13 mass% to 17 mass%. On the contrary, it increases from 1633 K to 1668 K with the high Al2O3 content from 17 mass% to 20 mass%. In addition, the liquidus temperature also has an increase of 68 K when C/S increases from 1.0 to 1.2. Each curve in the isotherms diagram of SiO2–CaO–Al2O3–MgO–TiO2 semi-synthetic slag (see Fig. 6) represents an isotherm of liquidus temperature which has a series of the slags with different compositions. The liquidus temperature increases from 1673 K to 1703 K with the high Al2O3 content between 15.5 mass% and 17.5 mass% at the range of C/S from 1.0 to 1.2. It indicates that the slag liquidus temperature can be controlled to the lower temperature of 1703 K for the slag with the high Al2O3 content.

Dependence of slag liquidus temperature on Al2O3 content (13–20 mass%) at C/S = 1.0–1.2, MgO = 7.0 mass% and TiO2 = 0.5 mass%.

Liquidus isotherms diagram for a SiO2–CaO–Al2O3–MgO–TiO2 semi-synthetic slag at MgO = 6.5 mass% and TiO2 = 0.5 mass%.

Figure 7 shows the variation of slag liquidus temperature with a high MgO range of 5–10 mass% under the conditions of 1.0–1.2 slag basicity (C/S), 16 mass% Al2O3 and 0.5 mass% TiO2, which was obtained from the formula calculation in this study. It indicates that the liquidus temperature increases from 1622 K to 1656 K with increasing MgO content from 5 mass% to 10 mass%, and also has an increase of 65 K when C/S increases from 1.0 to 1.2. It is clearly known in Figs. 5 and 7 that the C/S adjustment is very sensitive to the liquidus temperature. And, the appropriate control of liquidus temperature is an easy and effective measure to stabilize the slag flowability.

Dependence of slag liquidus temperatures on MgO content (5–10 mass%) at C/S = 1.0–1.2, Al2O3 = 16.0 mass% and TiO2 = 0.5 mass%.

Figure 8 shows the effect of MgO content of the slags with a large range of 5–10 mass% on the slag viscosity that were calculated from Eqs. (3), (4), (5) at the temperature of 1723 K and under the conditions of a constant basicity of C/S = 1.1, 15–20 mass% Al2O3 and 0.5 mass% TiO2. When MgO content increases from 5 mass% to 8 mass%, the slag viscosity reduces from 9.5 poise to 9 poise. However, MgO addition is an effective way for reducing the slag viscosity for the slags with the high Al2O3 content of 17–20 mass%. Figure 9 shows the isotherms diagram for the slags with a fixed viscosity (=15 poise) under the conditions of MgO = 6.5 mass% and TiO2 = 0.5 mass%. It reveals that slag temperature should be higher than 1683 K for the slag viscosity lower than 15 poise for the conditions of C/S = 1.0–1.2 and Al2O3=15.5–17.5 mass%.

Effect of MgO content (5–10 mass%) on slag viscosity at 1723 K (1450°C), at Al2O3 = 15–20 mass%, C/S = 1.1, and TiO2 = 0.5 mass%.

Slag isotherms diagram for a SiO2–CaO–Al2O3–MgO–TiO2 semi-synthetic slag at a fixed viscosity (= 15 poise), MgO = 6.5 mass% and TiO2 = 0.5 mass%.

From the viewpoint of BF operation, the higher slag temperature is helpful to maintaining a smooth tapping because the increase in slag viscosity would decay the slag flowability. Based on the characteristic curves of viscosity-temperature line for BF slags, it was considered as guidelines that the slag temperature should be kept higher to avoid too close to the temperature at the turning point of the characteristic curve. Also, a too higher slag temperature would increase the fuel rate and production cost of hot metal. From the aforementioned, this study suggests that the tolerable Al2O3 content is ranged 15–17 mass% for an acceptable slag viscosity (<10 poise) for the precondition of the hot metal temperature above 1768 K. Considering the low production cost, the addition of 6–8 mass% MgO is a feasible measure to decrease the liquidus temperature of the final slags at C/S < 1.15.

4.2. Effect of TiO2 Content on Slag FlowabilityFigure 10 shows the effect of TiO2 content on the viscosity of semi-synthetic slags at 1723 K and 1773 K, respectively, under the conditions of C/S=1.25, MgO=6.5 mass%, Al2O3=15 mass%, and holding time (at 1773 K) =2 hours. And, it indicates that the slag viscosity increases with the decreasing slag temperature for the low TiO2 content (<1 mass%), but the slag viscosity become higher (>15 poise) for the range of TiO2 content = 1–4 mass%. It is obviously different from the results on the literature12) which indicates that the slag viscosity decreases with the increasing TiO2 content. Figure 11 shows the slag viscosity is a function of the holding time at the constant-temperature of 1773 K) with the same conditions as the case in Fig. 10. It was found that the slag viscosity maintains constant without TiO2 addition, but the viscosity increases with the increasing holding time under the range of TiO2=0.5–5 mass%. And, the highest viscosity was found to lie in the condition of TiO2=3 mass% for the range of slag compositions studied in this work. According to the literature,13) the rapid viscosity increase of the slag containing high TiO2 content may be resulted from due to the generated precipitates of perovskite (CaO‧TiO2) in the slag melt.

Effect of TiO2 content on the viscosity of SiO2–CaO–Al2O3–MgO–TiO2 semi-synthetic slags at different temperatures (Al2O3=16.5 mass%, MgO=6.5 mass%, C/S= 1.25).

Viscosity is a function of slag holding time at constant temperature, 1773 K (1500°C) (Al2O3=16.5 mass%, MgO=6.5 mass%, C/S =1.25, TiO2=0–5 mass%).

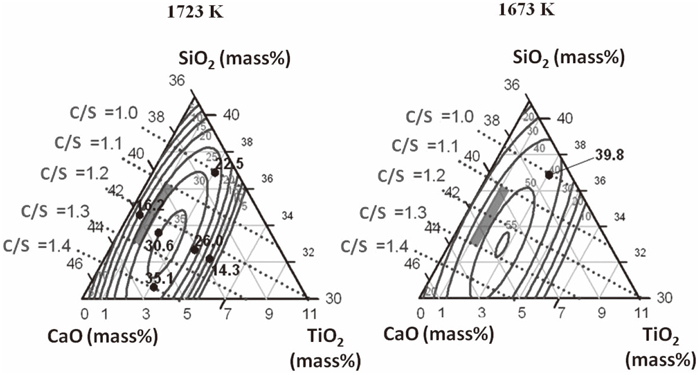

Figure 12 shows that the iso-viscosity distribution diagram under the conditions of MgO=6.5 mass% and Al2O3=15 mass% with the slag holding time of 2 hours, at 1773 K. The difference of slag viscosity increases obviously when increasing TiO2 content from zero to 3 mass% of the slag. The iso-viscosity distribution diagrams with the temperature of 1723 K and 1673 K, respectively, are shown in Fig. 13 for the range of slag compositions used for the hearth protection of BF operation in CSC. The ranges of the slag viscosity are 20–30 poise and 40–50 poise at 1723 K and 1673 K, respectively. It was indicated that the viscosity is quite sensitive to the TiO2 content of the slags at lower temperature.

Iso-viscosity distribution diagram for slag temperature=1773 K (1500°C), Al2O3= 16.5 mass%, MgO=6.5 mass%.

Iso-viscosity distribution diagrams for the case of lower constant-temperature operation (Al2O3=16.5 mass%, MgO=6.5 mass%).

Figure 14 shows the slag isotherms distribution diagram under the conditions of MgO=6.5 mass% and Al2O3=15 mass% at a fixed viscosity (15 poise). From this diagram, it is known that the center circle represents the isotherms of 1773 K. And, the slag temperature of isotherms gradually decreases from the inside out. Based on the slag isotherms with the liquidus isotherms distribution diagrams. Figures 14 and 15, it was found out for the hearth protection that a way to stabilize the flowability of final slags is to maintain C/S at 1.2 firstly, then gradually add TiO2 up to 0.5–1.5 mass%. However, for the case of TiO2 content >1.5 mass%, the first step is to lower C/S to about 1.0, then gradually increase TiO2 content for avoiding the flowability decay in the hearth protection operation.

Slag isotherms distribution diagram at a fixed viscosity (15 poise) (Al2O3=16.5 mass%, MgO=6.5 mass%).

Slag liquidus isotherms distribution diagram for the case of BF hearth protection operation (Al2O3=16.5 mass%, MgO=6.5 mass%).

In CSC, the operation practice for maintaining a stable slag flowability inside the blast furnace is as follows:

<1>. Slag liquidus temperature should be lower than hot metal temperature (HMT) up to a magnitude of above 80 K under a normal operation.

<2>. The lower slag liquidus temperature can be obtained by means of reducing the basicity (C/S) to ensure good slag flowability.

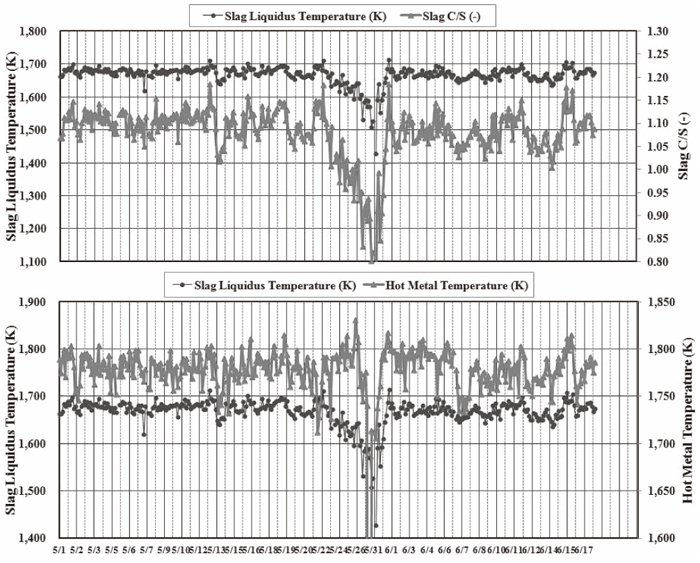

The trends of Tliquidus vs. C/S, and Tliquidus vs. HMT for this operation practice applied in CSC BF is shown in Fig. 16.

Trends of Tliquidus vs. C/S, and Tliquidus vs. HMT from No. 2 BF operation in CSC.

It was indicated that the difference between the hot metal temperature and the slag liquidus temperature are calculated and named as superheat temperature. The higher the superheat temperature is, the better the slag flows. The operation characteristic of BFs slag is identified based on the analysis of slag properties of production data. A slag operation concept is built for reference by the operation viscosity and the superheat temperature. The operation viscosity is 3.4±0.2 Poise and the superheat temperature is 80±10 K.14)

4.3.2. Slag Viscosity(1) Decreasing C/S:

Figure 17 shows the effect of Al2O3 content and C/S on the viscosity of SiO2–CaO–Al2O3–MgO–TiO2 slags under different metal tapping temperature, at MgO = 7 mass% and TiO2 = 0.5 mass%. The slag viscosities in Fig. 17 were calculated by Eqs. (3), (4) and (5) in this work. Generally, the analyzed compositions of the BF final slags in CSC are about 15 mass% Al2O3, 7 mass% MgO and C/S =1.2 for normal operation. And, it is found that there is no significant increase in slag viscosity for the increase of Al2O3 by 17 mass% during the higher temperature (>1673 K). However, it has a starting point for rapid rise on the slag viscosity at the temperature lower than 1673 K. Furthermore, the temperature of the starting point for rapid rise of viscosity is at the lower temperature when the C/S is reduced from 1.2 to 1.1 (see Fig. 17). Therefore, it was believed that the rapid rise of the final slag viscosity was suppressed due to the lower liquidus temperature by lowering C/S of the slag.

Effect of Al2O3 content and C/S on viscosity of SiO2–CaO–Al2O3–MgO–TiO2 slags with metal tapping temperature at MgO = 7 mass% and TiO2 = 0.5 mass%.

(2) Increasing MgO:

Figure 18 shows the relationship between the calculated slag viscosity and temperature at different contents of Al2O3 and MgO while the C/S and the TiO2 content are fixed. It can be found that viscosity is slightly lowered by the increase of MgO content from 7 mass% to 11 mass% at the case of Al2O3 = 17 mass%. Therefore, it is suggested that controlling the appropriate C/S control is more effective than increasing MgO content on the slag viscosity.

Effect of Al2O3 and MgO contents on viscosities of SiO2–CaO–Al2O3–MgO–TiO2 slag with metal tapping temperature at C/S = 1.2 and TiO2 = 0.5 mass%.

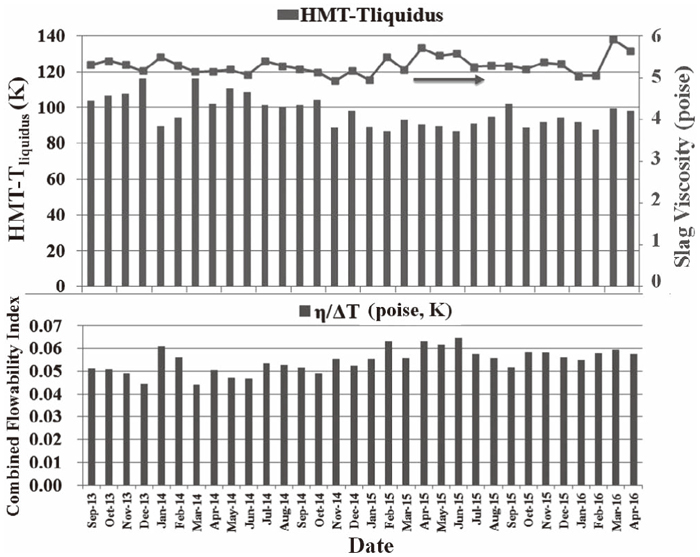

In this study, a combined slag flowability index (η/ΔT) that is a combination of slag viscosity (η), the temperature difference between the hot metal temperature (HMT) and the slag liquidus temperature (TLiquidus), ΔT = HMT−TLiquidus, was defined to measure the flowability of the slags. The index of the slag increases with the increase in viscosity and the decrease in the temperature difference. When the slag flowability become worsen, the value of the index goes higher. While the index is in negative value (< 0), the slag would be solidified. A series of month-averaged data of (HMT-Tliquidus), slag viscosity and the combined slag flowability index during September, 2013- April, 2016 in the operation of CSC No. 2 BF is presented in Fig. 19. When ΔT > 80 K, it is indicated that η< 6 poise and η/ΔT < 0.07 are the appropriate criteria for the final slags with good flowability during BF operation. For the slags with 16–17 mass% Al2O3, the viscosity is still low enough for a normal BF operation at the lower HMT or the higher slag basicity. However, η/ΔT is larger than 0.15 because of the much lower ΔT (< 50 K), listed in Table 1. It is also found from this table that the ΔT is larger than 80 K while η/ΔT is lower than 0.08 for C/S < 1.2. Based on this study, it is suggested that the criteria to distinguished a good slag flowability are ΔT > 80 K and η/ΔT < 0.08 for BF operation.

Data of HMT-Tliquidus (ΔT), slag viscosity (η) and combined slag flowability index (η/ΔT) during 2013.9–2016.4 from No. 2 BF operation in CSC.

| CASES | Al2O3 (%) | MgO (%) | B2 (–) | HMT (K) | TLiquidus (K) | η (poise) | ΔT=HMT–TLiquidus (K) | η/ΔT (poise, K) |

|---|---|---|---|---|---|---|---|---|

| 1 | 17.0 | 6.2 | 1.11 | 1705 | 1669 | 10.94 | 36 | 0.31 |

| 2 | 17.6 | 6.1 | 1.29 | 1770 | 1727 | 6.22 | 43 | 0.14 |

| 3 | 17.8 | 6.0 | 1.21 | 1749 | 1703 | 7.73 | 46 | 0.17 |

| 4 | 17.0 | 6.5 | 1.22 | 1760 | 1707 | 6.56 | 53 | 0.12 |

| 5 | 16.9 | 6.6 | 1.22 | 1772 | 1707 | 5.83 | 65 | 0.09 |

| 6 | 18.0 | 6.1 | 1.19 | 1765 | 1698 | 6.74 | 67 | 0.10 |

| 7 | 17.0 | 6.4 | 1.2 | 1769 | 1700 | 6.05 | 69 | 0.09 |

| 8 | 17.2 | 6.5 | 1.17 | 1766 | 1691 | 6.27 | 75 | 0.08 |

| 9 | 19.0 | 6.3 | 1.24 | 1799 | 1724 | 5.32 | 75 | 0.07 |

| 10 | 17.6 | 6.3 | 1.2 | 1777 | 1701 | 5.86 | 76 | 0.08 |

| 11 | 16.9 | 6.4 | 1.15 | 1766 | 1684 | 6.17 | 82 | 0.07 |

| 12 | 16.8 | 6.5 | 1.16 | 1773 | 1689 | 5.76 | 84 | 0.07 |

| 13 | 16.9 | 6.3 | 1.18 | 1779 | 1692 | 5.51 | 87 | 0.06 |

| 14 | 16.8 | 6.1 | 1.18 | 1778 | 1690 | 5.55 | 88 | 0.06 |

| 15 | 16.9 | 6.4 | 1.2 | 1792 | 1702 | 4.91 | 90 | 0.05 |

| 16 | 17.4 | 6.2 | 1.16 | 1778 | 1687 | 5.74 | 91 | 0.06 |

In this study, it was proposed that adjusting the slag C/S < 1.15 and controlling the MgO content in 6–8 mass% is applicable to maintain a stable BF operation with high-alumina slag. The proposal was adopted and has been proven feasible in CSC No. 2 BF operation, see Figs. 20 and 21.

Trends of Al2O3 content vs. DP/V (permeable resistance) for the case of high-alumina slags in CSC No. 2 BF operation.

Trends of MgO content and C/S for the case of high-alumina slags in CSC No. 2 BF in CSC.

To sum up the above, this study presents a strategy for the BF operation with high-alumina slags to maintain a good slag flowability at the normal hot metal temperature. The slag viscosity would be in an acceptable range while adjusting the appropriate C/S to control the combined slag flowability index (η/ΔT) < 0.08.

The calculated flowability index for the SiO2–CaO–Al2O3–MgO–TiO2 semi-synthetic slags based on experimental results was used to identify the effects of Al2O3, MgO, TiO2 and C/S on the liquidus temperature and viscosity of final slag for controlling a stable BF operation. The conclusions are summarized as follows:

(1) The C/S adjustment is very sensitive to the liquidus temperature. The appropriate control of the liquidus temperature is a preferred step to stabilize the slag flowability.

(2) Generally, an acceptable viscosity (< 10 poise) at the hot metal temperature above 1768 K for the normal BF operation with low production cost. To be under the acceptable viscosity, the tolerable Al2O3 content is ranged 15–17 mass% for the slag with 6–8 mass% MgO and C/S < 1.15. For the BF hearth protection via TiO2 (1–5 mass%) addition. it was proposed that the C/S should be lowered to about 1.0 before adding TiO2 to avoid the bad slag flowability inside the BF hearth.

(3) In this study, the equations for estimated temperature and viscosity of (CaO–SiO2–Al2O3–MgO–TiO2) slags was established based on the measured data in the experiments. Furthermore, a combined slag flowability index was built and developed as a flowability prediction system of the BF final slag. Due to be able to predict the difficulty of slag flow for the coming tapping, the system has been applied in CSC blast furnace operation. It can provide BF staffs information in time to control the variation of slag flowability via the effective operation practice such as enforcing management of thermal state or adjusting the chemical composition of final slag via the burden of BF.