2018 Volume 58 Issue 6 Pages 1181-1183

2018 Volume 58 Issue 6 Pages 1181-1183

The effect of instrumental correction on X-ray line profile analysis was discussed in cold rolled low carbon ferritic steel. It was confirmed that the effect of instrumental broadening is underestimated by utilizing Gaussian correction in comparison with Voigt correction. The values of micro-strain, which were evaluated by the recently developed direct fitting method, were overestimated slightly in Gaussian correction. As a result, the following equations were established in the relation between micro-strain (ε) and dislocation density (ρ) for each case:

ρ [m−2] ≒ 1.5×1020 ε2 (Gaussian correction)

ρ [m−2] ≒ 1.9×1020 ε2 (Voigt correction)

Since the full width at half maximum (FWHM: βm) in X-ray diffraction (XRD) peaks contains the information about dislocation density and crystallite size, XRD is widely used to evaluate the micro-strain in highly dislocated metals.1) However, it should be noted that the original βm contains the effect of instrumental broadening. In order to obtain accurate results, it is essential to correct the effect of instrumental broadening. The magnitude of instrumental broadening is different depending on the equipment used for the diffraction analysis, thus the instrumental broadening has to be evaluated in each equipment by using standard sample.2,3,4) For example, Fig. 1 shows the relation between diffraction angle θ and instrumental broadening β0 in the commercial and well annealed low carbon ferritic steel (0.0056% C steel). Good agreement is found in both samples and β0 value gradually increases with an increase of diffraction angle. If diffraction peaks can be fitted by Lorentz function (mainly crystallite size broadening), the corrected β value of measured specimen is obtained by the following equation (i.e. Lorentz correction):2,3,4)

| (1) |

| (2) |

Relation between instrumental broadening (β0) and diffraction angle (θ) of various diffraction peaks in standard samples; Well annealed low carbon ferritic steel (0.0056% C steel) was prepared by Subjecting 90% cold rolled specimen to anneal at 700°C for 1 h followed by furnace cooling. The wave length of present X-ray (λ, Cu-Kα) is 0.15418 nm.

It is well-known that the effect of instrumental broadening is overestimated by Lorentz correction. Hence Eq. (2) has been applied for the correction of instrumental broadening in many cases.2,3,4,5) When βm value is much larger than β0 value, it is expected that the correction errors for instrumental broadening is not so significant. However, in the case that βm value is not so large in comparison with β0 value, the instrumental correction should give clearer effect on the analyzed results. Cold worked ferritic steel just fits to this case, because dislocation density in cold worked materials is not so high and cell size is large.4,6) Therefore, in this paper, the effect of instrumental correction on X-ray line profile analysis was discussed in cold rolled low carbon ferritic steel (0.0056% C steel). The detailed experimental procedure is given in recent publication.4)

To estimate the micro-strain ε in highly dislocated metals, Williamson and Hall proposed the following equation:1)

| (3) |

| (4) |

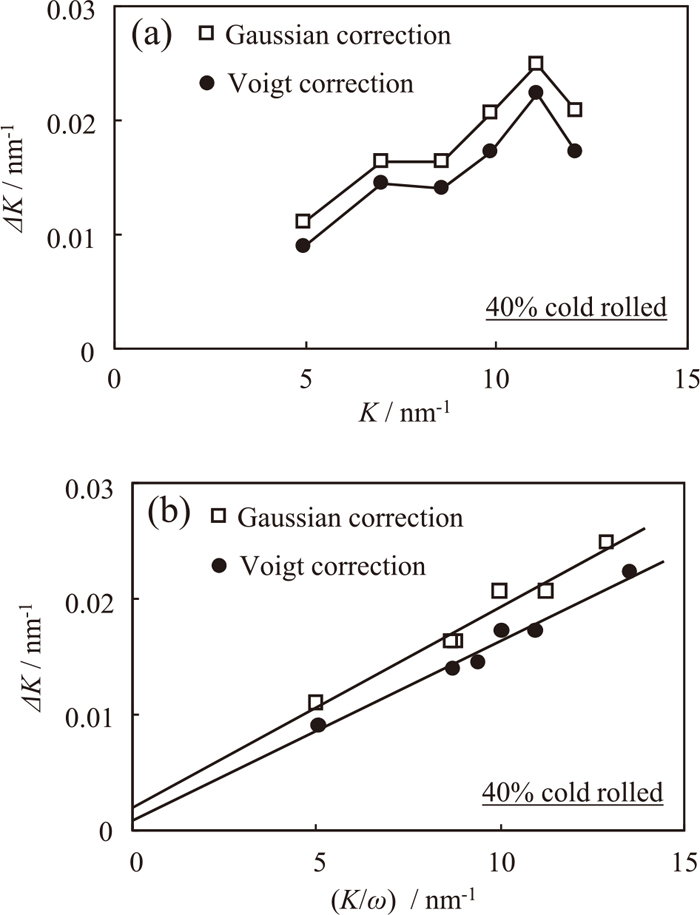

Effect of instrumental correction on (a) Williamson-Hall plots and (b) direct fitting plots in 0.0056% C steel.

The value of micro-strain ε is not well obtained in the original WH plots because of clear strain anisotropy. Recently, the effect of elastic anisotropy can be corrected moderately by the direct fitting (DF) method.4) In DF method, the parameter ω, i.e. Young’s modulus ratio, is applied to correct the irregular effect from strain anisotropy in WH plots:

| (5) |

| (6) |

| (7) |

| (8) |

Variation of micro-strain as a function of thickness reduction by cold rolling in 0.0056% C steel.

In cold worked metals, the increment of strength (Δσ) is proportional to square root of dislocation density (ρ1/2), so called Bailey-Hirsch relation. Transmission electron microscopy (TEM) is also a useful tool to evaluate dislocation density and there are several reports for cold worked iron.6,7,8,9) Authors summarized the reported results and indicated that the following Bailey-Hirsch relation stands up for cold worked iron:10)

| (9) |

(a) Comparison of Bailey-Hirsch plots with different dislocation density estimation methods, i.e., combined TEM-yield stress method (solid line) and mWH/mWA method (solid circle) and (b) Relation between micro-strain and dislocation density under different instrumental corrections in 0.0056% C steel.

Further, Fig. 4(b) shows the relation between micro-strain ε and dislocation density ρ. It was theoretically confirmed that the dislocation density is proportional to square of micro-strain.12) In this study, it was reconfirmed that good linearly is realized in the relation of ρ vs. ε2 but the coefficients are different depending on the correction process for instrumental broadening as follows:

| (10) |

| (11) |

This research was performed by the support of JSPS, KAKENHI Grant number JP15H05768. This work was also partially supported by the Research Society for quantum-beam analysis of microstructures and properties of steels.