2018 Volume 58 Issue 7 Pages 1204-1209

2018 Volume 58 Issue 7 Pages 1204-1209

This study investigated the characteristics of activated carbon removing ultra-fined particulates PM10 and PM2.5 from sintering flue gas, and discussed the potential mechanism. Experimental results show that activated carbon (AC) exhibited greater removal efficiency to PM10 than PM2.5, and increasing the thickness of AC or reducing AC grain size facilitated the removal of PM10 and PM2.5. The removal ratio of PM10 and PM2.5 achieved 67.3% and 58.7% when AC bed thickness and grain size were 200 mm and 3–5 mm, respectively. Bigger particles in PM10 was susceptible to inertial effect, making their easier removal and higher removal ratio. AC bed thickness and bulk porosity (negatively relatively to AC grain size) presented positive relationship with the removal efficiency of PM10 and PM2.5, which therefore exhibited higher removal ratio with the bed thickness increased and grain size reduced. The research findings benefit the effective control of ultra-fined particulates in practical sintering plants.

Particulate matters suspended in the atmosphere have become one of the important hazards. According to their aerodynamic diameters, they have been divided into 3 categories, including TSP (total suspended particulates), the ultra-fined particulates PM10 and PM2.5, with aerodynamic diameters ≤100 μm, 10 μm and 2.5 μm, respectively.1,2) Among them, PM10 was recognized as the inhalable particles, while PM2.5 can even go directly to the alveoli of the lungs.3) Since their huge specific surface area, PM10 and PM2.5 are usually the carrier of hazards, e.g. heavy metals, polycyclic aromatic hydrocarbons, dioxins etc., which exert severe potential risk to human health.4,5,6,7)

Iron ore sintering is an important process throughout the whole steelmaking chain, with its purpose to agglomerate fine-grained iron ores into lumps for ironmaking in blast furnace.8) However, this process is the main emission source of atmospheric pollutants. Besides serving as the main emitter of diverse gaseous pollutants like SO2, NOx, COx, etc., sintering process even emitted a large amount of ultra-fined particulate matters PM10 and PM2.5, the emission of which accounted for more than 40% of the total amount.9,10) Nowadays, strict emission standard has been launched by Chinese Ministry of Environmental Protection for addressed the frequently appeared hazy weather, 50 mg/m3 was the maximum emission concentration needed to reach for sintering process since 2015.11) In the coming future, 20 mg/m3 will be the target to reach for some special cities, like the metropolis Beijing, Tianjing, etc.12) However, current average emission concentration of particulate matters is obviously higher than 50 mg/m3.11)

Unfortunately, there is no effective technique to address this problem in iron ore sintering field so far. Since activated carbon (AC) characterized huge specific surface area and well-developed pore structure, it has been widely applied to purify sintering flue gas, with its main focus on reducing the emission of gaseous pollutants like SO2 and NOx. Interestingly, AC bed was also found to have the function for filtrating particulate matters from flue gas.13,14) However, there is no research about the performance of AC bed on PM10 and PM2.5 removal. Our group has been engaging in the formation and control of pollutants emitted in sintering process. Our previous research mainly focused on the physicochemical characteristics PM10 and PM2.5, and factors influencing their emissions, while gave little information about the control techniques.15,16,17,18) In this investigation, the characteristics of AC removing PM10 and PM2.5 were conducted in laboratory scale. The potential mechanism of AC bed removing PM10 and PM2.5 was also discussed. The research findings will be useful for guiding the deep removal of PM10 and PM2.5 in practical sintering production process.

Mixed iron ores, fluxes (limestone, dolomite and quicklime), solid fuel (coke breeze) and return fines (sinter < 5 mm) are necessary raw materials for sinter production. In this investigation, the chemical compositions of raw materials provided by an integrate steelwork are given in Table 1. Mixed iron ores and return fines characterized high iron contents, while limestone and quicklime mainly consisted of CaO. Dolomite mainly consisted of CaO and MgO. For meeting the requirements of ironmaking process for slag formation in blast furnace, the basicity and MgO content in the finished sinter product were respectively kept at 1.73 and 2.03% through adjusting the relative proportions of fluxes.

| Ore types | TFe | SiO2 | CaO | MgO | Al2O3 | K | Na | Pb | Zn | *LOI | Percent |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mixed iron ores | 58.88 | 4.57 | 0.95 | 0.55 | 2.14 | 0.062 | 0.029 | 0.012 | 0.035 | 5.98 | 63.63 |

| Limestone | 0.60 | 0.83 | 53.90 | 1.57 | 0.52 | 0.051 | 0.006 | 0.000 | 0.004 | 42.73 | 3.22 |

| Dolomite | 0.40 | 0.70 | 34.29 | 18.80 | 0.34 | 0.020 | 0.017 | 0.000 | 0.002 | 45.85 | 5.28 |

| Quicklime | 0.20 | 3.90 | 79.62 | 1.28 | 0.99 | 0.008 | 0.009 | 0.000 | 0.002 | 14.18 | 3.87 |

| Coke breeze | 2.32 | 6.20 | 0.91 | 0.20 | 4.34 | 0.119 | 0.102 | 0.001 | 0.004 | 83.20 | 4.00 |

| Return fines | 56.24 | 4.98 | 8.60 | 2.03 | 2.38 | 0.051 | 0.024 | 0.008 | 0.024 | 0.00 | 20.00 |

Table 2 gives the basic physical characteristics of commercial AC, which was used for purifying the sintering flue gas. During the testing process, for illuminating the influences of fine-grained AC adhered on the subsequent analysis of particulate matters, the AC was washed by deionized water and dried before use. An automatic injection apparatus (Pore Master-60) was employed to measure the porosity, specific surface area and pore volume of AC with the pore diameter exceeding 1 μm, and the results were automatically recorded by a computer. It can be found that the porosity, pore volume and specific surface area of AC with grain size of 8–12 mm were 20.38%, 0.0726 cm3/g, and 9.70 m2/g, respectively. Moreover, with the grain size of AC decreasing, the porosity, pore volume and specific surface area of single AC particles all achieved a rise. The bulk porosity of AC bed exhibited increasing tendency.

| Grain size/ mm | Porosity/ % | Pore volume/ (cm3/g) | Specific surface area/(m2/g) | Bulk porosity/% |

|---|---|---|---|---|

| 8–12 | 20.38 | 0.0726 | 9.70 | 67.90 |

| 5–8 | 20.43 | 0.0730 | 9.75 | 68.50 |

| 3–5 | 20.45 | 0.0735 | 9.83 | 69.06 |

A laboratory-scale sinter pot was employed to simulate the real sinter production process, as schematically illustrated in Fig. 1. For making sinter, the raw materials presented in Table 1 firstly underwent the mixing process to reach well blending, during which prescribed water added. Secondly, raw mixtures underwent the granulating process in a horizontally-installed drum of length 1400 mm and diameter 600 mm, with revolving speed and granulation time at 15 rpm and 4 min, respectively. After that the granulated mixtures were fed into the sinter pot. After feeding, the coke breeze in the surface raw mixture layer was initially ignited by an ignition hood, and the combustion front then moved downwards with the support of a downdraught system. The ignition period was 1 min at 1050 ± 50°C, with a pressure drop of 5 kPa. However, the pressure drop was changed to 10 kPa for sintering and then to 5 kPa for cooling. The total sintering time and total flue gas flow were measured from the start of ignition to the point at which the sinter waste gas had reached its maximum temperature.

Schematic diagram of the equipment for ultra-fined particulates removing and sampling.

For investigating the influences of AC on particulate emissions, a stainless-steel tube with inner diameter of 100 mm was used to simulate the practical absorber after feeding AC (Fig. 1). During the testing process, the particulate matters containing flue gas passed through the AC bed with the help of the vacuum pump. A low-pressure cascade impactor (Model WY-1, China) was used to collect particulate matter from flue gas using glass fiber filter. The removal ratio of particulate matters by AC bed was calculated by Eq. (1). XRF was used to analyze the chemical composition of particulate matters collected by filter, and SEM-EDS was utilized to examine the morphology of particulate matter on filter and AC.

| (1) |

Where A is the removal ratio of particulate matters, %; wb is the emission concentration of particulate matters free of AC absorption, mg/m3; wa is the emission concentration of particulate matters after flue gas passing through the AC bed, mg/m3.

Figure 2 illustrated the influences of the thickness of AC bed on emission characteristics of ultra-fined particulate matters. From Fig. 2(a) it can be found that with the thickness of AC bed increasing, the emission concentration of particulate matters with various aerodynamic diameters exhibited a decreasing tendency. When the thickness was 300 mm,the emission concentration of PM10 and PM2.5 shown in Fig. 2(b) considerably dropped from 72.5 mg/m3 and 41.6 mg/m3 to 31.5 mg/m3 and 21.4 mg/m3, respectively. Figure 2(c) showed that increasing the thickness of AC bed improved the removal ratio of particulate matters. Moreover, particulate matters with larger diameter showed higher removal ratio by AC. When the bed thickness was 300 mm, the removal ratio of PM10 and PM2.5 respectively enhanced from 30.5% and 21.3% to 56.6% and 48.5% when increasing the bed thickness from 100 mm to 300 mm (Fig. 2(d)).

Influences of the thickness of AC bed on PM10 and PM2.5 emissions. (a) Influences on emission concentration of particles with different grain sizes; (b) Influences on emission concentration of PM10 and PM2.5; (c) Influences on removal ratio of particles with different grain sizes; (b) Influences on removal ratio of PM10 and PM2.5.

When keeping the thickness of AC bed at 200 mm, the influences of varying AC grain size on particulate matter emissions were given in Fig. 3. When decreasing the grain size of AC, the emission concentration of particulate matters with various aerodynamic diameters presented a dropping tendency (Fig. 3(a)). Especially, with the grain size decreased from 8–12 mm to 3–5 mm, the emission concentration of PM10 and PM2.5 dropped from 72.5 mg/m3 and 41.6 mg/m3 to 23.7 mg/m3 and 17.2 mg/m3, respectively (Fig. 3(b)). Moreover, Fig. 3(c) indicated that decreasing the grain size of AC increased the removal ratio of AC to particulate matters. When the grain size of AC was 3–5 mm, the removal ratio of PM10 and PM2.5 reached 67.3% and 58.7%, respectively (Fig. 3(d)).

Influences of the grain size of AC bed on PM10 and PM2.5 emissions. (a) Influences on emission concentration of particles with different grain sizes; (b) Influences on emission concentration of PM10 and PM2.5; (c) Influences on removal ratio of particles with different grain sizes; (b) Influences on removal ratio of PM10 and PM2.5.

Figure 4 shows the chemical composition of PM2.5 before and after the flue gas passing through the AC bed. As can be found that the contents of Fe, Ca, Si, Al and Mg in PM2.5 all presented a rise when the flue gas passed the activated bed compared with that of the base case, while the contents of K, Na, Pb, Zn, and Cl in PM2.5 all appeared a drop. Figure 5 give the SEM image of the PM2.5 collected in the filter after the flue gas undergoing the AC layer, it was observed that after been removed by AC bed, the number of bigger particles mainly consisted of K and Cl decreased (Figs. 5(b)–5(d)) compared with the base case (Fig. 5(a)), while there were numerous smaller particles like the spherical ones (in the inset of Fig. 5(d)) that mainly comprised Fe and Ca. This phenomenon well agreed with the changed chemical composition of PM2.5. Moreover, compared with the case using AC bed of thickness 200 mm and grain size 8–12 mm (Fig. 5(b)), less big K-Cl-rich particles appeared and numerous smaller spherical Fe-Ca-rich particles appeared for the cases using AC of thickness 300 mm, grain size 8–12 mm and thickness 200 mm, grain size 5–8 mm. It should be mentioned that the distribution of bigger K-Cl-rich particles in the whole sample was observed and found that less amount of K-Cl-rich PM existed in samples “Thickness of AC bed is 200 mm and grain size is 8–12 mm (Fig. 5(b)) and Thickness of AC bed is 300 mm and grain size is 8–12 mm (Fig. 5(c))”. Based on this phenomenon, less big K-Cl-rich particles could be found in Figs. 5(b)–5(d) was determined. However, the statistical method will be employed to judge the number of special particulates in SEM image.

Influences of AC adhering on chemical compositions of PM2.5.

Influences of AC adhering on morphology of PM2.5. (a) No AC layer; (b) Thickness of AC bed is 200 mm and grain size is 8–12 mm; (c) Thickness of AC bed is 300 mm and grain size is 8–12 mm; (d) Grain size of AC is 5–8 mm and thickness is 200 mm.

Figure 6 shows the surface structure and pore size distribution of AC before adhering particulate matters. From the typical SEM images in inset it was obviously found that pores with different sizes about 10 μm, 5 μm, 2 μm and <1 μm appeared and the surface was considerably rough. The pore size distribution curve of AC even indicated that a large number of pores with size ranging from 0.1 μm to 100 μm were widely existed. This phenomenon implied that AC has enough space to accommodate particulate matters with different diameters, which therefore can serve as the explanation to the dropped emission concentration of particulate matters.

Morphological properties and pore size distribution of AC before adhering particulate matters.

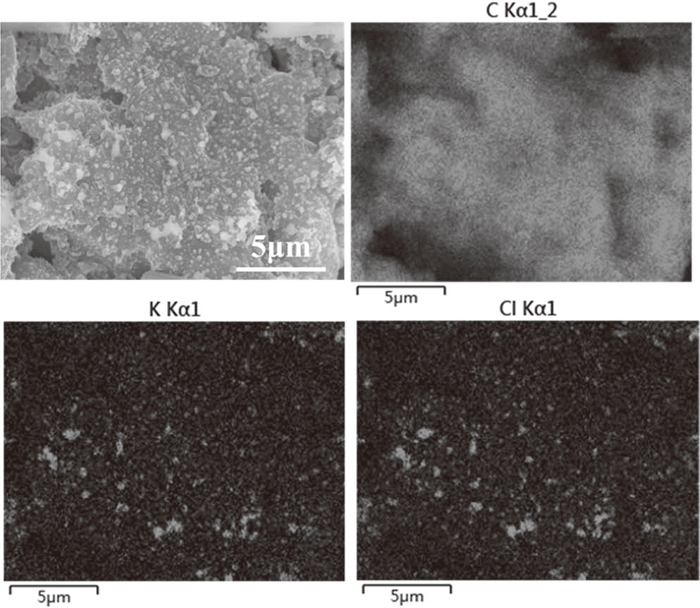

Figure 7 presents the morphology of AC after adhering particulate matters, where can be found that numerous particles were distributed in the pores or on the surface of AC. Figures 7(a)–7(c) shows the particles distributed in the pores with sizes about 20 μm, 5–10 μm and 1 μm. Figure 7(d) shows the particles distributed on the surface of AC, the diameter of which were almost less than 1 μm. Figure 8 gives the SEM mapping of particles distributed in pores, which indicated that a large number of particles was K-rich, and they mainly existed in the form of chloride or sulfates. The appearance of these particles corresponded to the decrease of K and Cl contents in PM2.5. Figure 9 gives SEM mapping of particles distributed on the surface, where can be found that the fine-grained particles also mainly consisted of K and Cl.

Morphological properties of AC after adhering ultra-fined particulate matters.

SEM mapping of collected ultra-fined particulate matters on AC surface.

SEM mapping of collected ultra-fined particulate matters on AC surface.

As for the granular bed filter, the typical mechanism for adhering particulate matters including gravity settling, electrostatic forces, and inertia collision and diffusion.19) As the investigation mainly focused on the removal of AC to ultra-fined particulates PM10 and PM2.5, the gravity effect could be ignored. Moreover, the electrostatic forces could also be ignored because they were uncharged particles. In this investigation, the conceptual mode for single AC particles controlling PM10 and PM2.5 emission was schematically shown in Fig. 10. Generally, bigger particles exhibited greater inertia than the smaller ones, which therefore made the relatively bigger ones of ultra-fined particulates more easily captured. As for smaller particles, especially for the ones less than 1 μm, diffusion was their mainly path to be captured by AC particle, as shown in Fig. 7(d).

Conceptual mode for AC removing PM10 and PM2.5 from flue gas.

According to previous research,20,21) the filtration efficiency of granular bed ηA for particulate matters can be expressed by Eqs. (2) and (3). Before calculating, we proposed the hypothesis that the filtration efficiency of individual activated particle ηs is constant. Therefore, the ηA is only related to the bed thickness H and bulk porosity ε.

| (2) |

| (3) |

Where, ηA is the filtration efficiency of AC granular bed; ε is the bulk porosity of AC granular bed; ηs is the filtration efficiency of individual activated particle; N is the number of individual AC unit calculated by Eq. (3); L is the length of individual AC unit, which can be regarded as 100 mm in this investigation; H is the thickness of AC granular bed, mm.

When keeping the grain size of AC unchanged, the bulk porosity can be regarded as constant. The removal efficiency showed a positive relationship with the bed thickness according to Eqs. (2) and (3). Therefore, increasing the thickness of AC bed exhibited higher removal ratio to PM10 and PM2.5. Potential reason can be described as increasing the bed thickness extended the function time for particulate matters in bed, which actually increased the collision probability and achieved higher removal ratio for particulate matters. Moreover, when keeping the thickness of AC constant, the removal efficiency showed positive relationship with the bulk porosity. Consequently, since bulk porosity between individual AC particles appeared a rising tendency when reducing the AC grain size (Table 2), the AC with smaller size exhibited higher removal efficiency to PM10 and PM2.5. As a consequence, for reaching the deep removal of PM10 and PM2.5 by AC in real flue gas purification process, increasing the bed thickness and reducing the grain size of AC will be the effective strategy. However, more work will be done to analyze the influences of AC layer thickness and AC grain size on PM10 and PM2.5 removal efficiency in quantitative manner.

(1) AC bed can remove PM10 more effectively than PM2.5, and increasing the thickness of AC bed or reducing AC grain size facilitated the removal of ultra-fined particulates. The removal ratio to PM10 and PM2.5 achieved 67.3% and 58.7% when AC bed thickness and grain size were 200 mm and 3–5 mm, respectively.

(2) AC particles characterized widely-distributed pores with different diameters and rich surface area, which served as the place to accommodate ultra-fined particulates.

(3) Bigger ones in ultra-fined particulates were more susceptible to inertial effect, making their easier removal and higher removal ratio. AC bed thickness and bulk porosity (negatively related to AC grain size) presented positive relationship with the removal efficiency of PM10 and PM2.5, which interpreted their higher removal ratio with the bed thickness increased and grain size reduced.

This work was supported by the National Natural Science Foundation of China (No. U1660206 and No. U1760107), and Hunan Provincial Co-Innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources.