Article ID: 24-39

Article ID: 24-39

This research investigates frost growth characteristics on silver iodide (AgI) and platinum (Pt) stripe patterned surfaces, fabricated using UV-lithography, under desublimation and condensation frosting conditions. Different frost growth behaviors were observed between AgI and Pt patterns, i.e. horizontal frost with dendrite-shaped ice crystals grew on the AgI stripes, and a combined frost growth of dendritic horizontal growth at the stripe edges and random growth at the top were observed for the Pt stripes. This study provides new insights into the influences of ice nucleation agents such as AgI for controlling the frost height and density.

* Institute of Industrial Science, The University of Tokyo, Meguro-ku, Tokyo, 153-8505, Japan

This research investigates frost growth characteristics on silver iodide (AgI) and platinum (Pt) stripe patterned surfaces, fabricated using UV-lithography, under desublimation and condensation frosting conditions. Different frost growth behaviors were observed between AgI and Pt patterns, i.e. horizontal frost with dendrite-shaped ice crystals grew on the AgI stripes, and a combined frost growth of dendritic horizontal growth at the stripe edges and random growth at the top were observed for the Pt stripes. This study provides new insights into the influences of ice nucleation agents such as AgI for controlling the frost height and density.

Keywords: Heat exchanger, Frost growth, AgI micropattern, Condensation frosting, Desublimation

1. Introduction

Frost formation is widely observed in a variety of engineering applications, such as air source heat pumps, refrigeration systems, etc. [1]. Frosting on surfaces poses significant problems in thermal systems, as it deteriorates heat and mass transfer. Therefore, various surface modification techniques have been investigated for a long time to prevent and control frost growth. Silver iodide (AgI) is one of the most effective nucleation agents in the natural world, which is widely used because of its ability to promote ice nucleation with very small subcooling [2, 3]. Hygroscopic materials such as salts [4] or cellulose fibers [5] are also investigated to absorb moisture from the atmosphere, which may delay frost formation by depressing local pressure. However, the effects of ice nucleation agents and hygroscopic materials on frost growth are not well understood, and these surfaces tend to degrade in performance over time. On the other hand, micropatterns are often tested to retard frost formation, e.g. superhydrophobic surfaces that mimic lotus leaf to make water droplets jump away and to prevent frost formation.

Our previous work demonstrated that AgI stripe patterns on cold surfaces promote horizontal frost growth, effectively suppressing overall frost height [6, 7]. However, the experimental conditions were limited to 20 minutes under condensation frosting conditions at air temperature of Ta = 23.8 ± 1.9 °C and relative humidity of RH = 30 ± 5% [6], leaving the long-term behavior and underlying mechanisms of patterned surfaces unexplored. In particular, it remained unclear whether AgI’s nucleation agent properties or the stripe pattern itself played a dominant role in initiating horizontal frost growth. To address these gaps, we extended our observation period to three hours and expanded the environmental conditions to include both desublimation (dew point below the freezing point) and condensation frosting (dew point above the freezing point) conditions [7]. These two regimes involve distinct ice nucleation pathways and condensation behaviors, providing insights into the fundamental mechanisms of frost formation on engineered surfaces.

In the present study, we introduce a second stripe material, platinum (Pt), a common inert metal, to distinguish the effect of ice nucleation characteristics of the material. By systematically examining desublimation and condensation frosting across various temperature and humidity conditions, this study aims to clarify the dynamic characteristics of frost growth on both AgI and Pt stripes compared with bare Si surface. Ultimately, our objective is to determine how surface material and micropattern geometry affect the onset and development of horizontal frost growth.

2. Experiments

2.1 Sample preparation

AgI and Pt stripe patterns were fabricated using UV-lithography. SU8 photoresist was spin-coated onto a silicon (Si) wafer and pre-heated at 95 °C. The AgI/Pt slurry was then spin-coated onto the SU8 layer, and further heated to remove the solvent. The pattern was solidified with a UV light, followed by post-exposure heating and wet development processes. The sample was sintered at 480 °C to crystallize the AgI and Pt patterns. SEM and EDS images in Fig. 1 show stripe patterns with a pitch of 400 µm for both AgI and Pt micropatterns. Despite using the same fabrication procedure, the AgI stripe-micropatterned surface exhibited discontinuous porous stripes, while

Fig. 1 SEM images (left), EDS images (middle) and enlarged SEM images of the stripes (right) of (a) AgI stripe [6] and (b) Pt stripe patterns.

the Pt stripe-micropattern displayed more dense structure. In both cases, the micropatterned stripes range in thickness from 5 to 10 µm.

2.2 Experimental conditions

The prepared samples were placed on a Peltier device to reduce the surface temperature below the freezing point. To comprehensively investigate the frost growths on AgI and Pt stripe patterns, two environmental conditions were tested, i.e. desublimation and condensation frosting conditions. For the desublimation condition, the air temperature and relative humidity were set at Ta = 4.5 ± 1.0°C and RH = 37.0 ± 2.0%. A high-speed camera (VW-9000SP, Keyence, Japan) equipped with a 200× objective lens and a resolution of 2.39 μm/pixel was used for detailed in-situ observations. For the condensation frosting condition, experiments were conducted in an open room environment regulated by an air conditioning system. The temperature was maintained at Ta = 23.9 ± 2.0°C with a relative humidity of RH = 25.0 ± 5.0%. A confocal laser scanning microscope (VK-X1000, Keyence, Japan) provided in-situ observations with a resolution of 1.05 μm/pixel. The surface temperatures is measured at the sample surface using 0.5mm diameter of K-type thermocouple. In addition, frost on the bare Si surface was also observed for comparison.

3. Results and discussion

For the desublimation condition, the ambient temperature of 4.5 ± 1.0°C and a relative humidity of 37.0 ± 2.0% gives a dew point of -7.9°C, which is below the freezing point. The surface temperature was maintained at Ts = -13.4°C. In the top-view images of Fig. 2, the stripe patterned samples were placed vertically. It is evident that both the AgI and the Pt stripe patterns can suppress frost coverage compared with the reference bare Si surface. Patterns created frost-free zones, and frost exhibited horizontal plate-like dendritic growth, where the frost coverage on the Pt surface appeared to be slightly larger than that on the AgI surface. Over time, the frost on the AgI stripe pattern maintained horizontal growth, with some stripes appearing dark at 180 min. In contrast, the frost on the Pt stripe exhibited horizontal growth between the stripes, but random direction frost growth was observed on the top of the stripe, showing much darker color similar to that on the bare surface. This indicates that the frost on the top of the Pt stripe grew vertically, since the focus of the high-speed camera shifts out of the plane.

Fig. 2 Comparison of frost growths under desublimation condition between (a) AgI micropattern, (b) bare surface and (c) Pt micropattern, at Ta = 4.5 ± 1.0 °C, RH = 37.0 ± 2.0 % and Ts = -13.4 °C.

Fig. 3 Comparison of frost growths under condensation frosting condition between (a) AgI micropattern, (b) bare surface and (c) Pt micropattern, at Ta = 23.9 ± 2.0 °C, RH = 25.0 ± 5.0 % and Ts = -12.0 °C.

For the condensation frosting condition, the ambient temperature was maintained at 23.9 ± 2.0°C with a relative humidity of 25.0 ± 5.0%, resulting in a dew point of 2.7°C, which is above the freezing point. The surface temperature was set at Ts = -12.0°C. Figure 3 shows the time variations of frost growths on three surfaces, where the stripe patterned samples were placed horizontally. At 5 min, distinct differences in frost formation were apparent between the three surfaces. On the bare Si surface, water droplets remained, indicating delayed freezing, while droplets on both AgI and Pt stripes had frozen, with ice crystals growing horizontally along the stripe patterns. Specifically, at 5 min, the frost on the AgI surface (Fig. 3a) appears hexagonal, whereas on the Pt surface (Fig. 3c) it appears dendritic. We think these distinct initial frost shapes reflect the intrinsic properties of each material, ultimately influencing the subsequent frost growth. Nonetheless, further research is needed to fully elucidate the mechanisms behind the peculiar frost growths from AgI patterns and Pt patterns, which will be conducted in the future work. In the experiment, a confocal microscope with a 10× lens (CF Plan X10, Nikon Corporation, Japan) was used, of which the depth of field was 4.49 µm. The initial focus was set on the substrate surface, ensuring that frost within 4.49 µm height remained in focus, while frost exceeding this height appeared blurred in the image. Once the experiment began, no further focus adjustments were made. This horizontal growth is evident from the clear focus of the optical images on the AgI and Pt surfaces, in contrast to the bare Si, where dropwise condensation continued without substantial frost formation. The frost on Pt-patterned surface exhibited a unique behavior, i.e. frost initiation concentrated along the stripe edges. Here, porous defects or irregularities likely provided additional nucleation sites and enhanced localized humidity absorption, acting hygroscopically to promote frost growth. As the experiment progressed, more pronounced differences became apparent. By 30 min, frost on the bare Si surface became increasingly blurred, suggesting a less organized frost structure and random ice nucleation. In contrast, frost on the AgI surface remained well focused and clear, indicating horizontally organized ice growth across the stripes and preserving the initial morphology. On the Pt-patterned surface, the frost along the edges remained well-organized, similar to the AgI surface. However, frost on the top of the Pt stripes became increasingly blurred over time, indicating that ice nucleation and frost growth dynamics are different depending on the positions. The frost on the central part of Pt stripe is similar to the condensation-driven frost growth observed on the bare silicon surface.

Figure 4 shows the frost growth images measured by the confocal laser scanning microscope at 120 min, where upper figures show optical images capturing frost morphology and bottom figures showing frost height distributions. Red areas indicate higher frost regions, while blue areas are the lower regions. From the Pt stripe edges, frost grew horizontally as shown in Fig. 4(c), resembling the frost growth seen on the AgI surface in Fig. 4(a). However, the out-of-focus image in Fig. 4(c) reveals that frost from the top of the Pt stripe grew randomly.

The frost on the Pt stripes got highest at the center of the stripe as indicated by the red color, while frost height from the stripe edges remained comparatively low. The height map of the AgI-patterned surface reveals that frost distribution across the stripes remained relatively uniform, with only a small region being red, indicating slight variations in frost height. Figure 4(b) shows frost on bare Si surface, which is similar to the frost on the top of the Pt stripe, but very different from the frost shapes that grew from the AgI stripe and Pt edges.

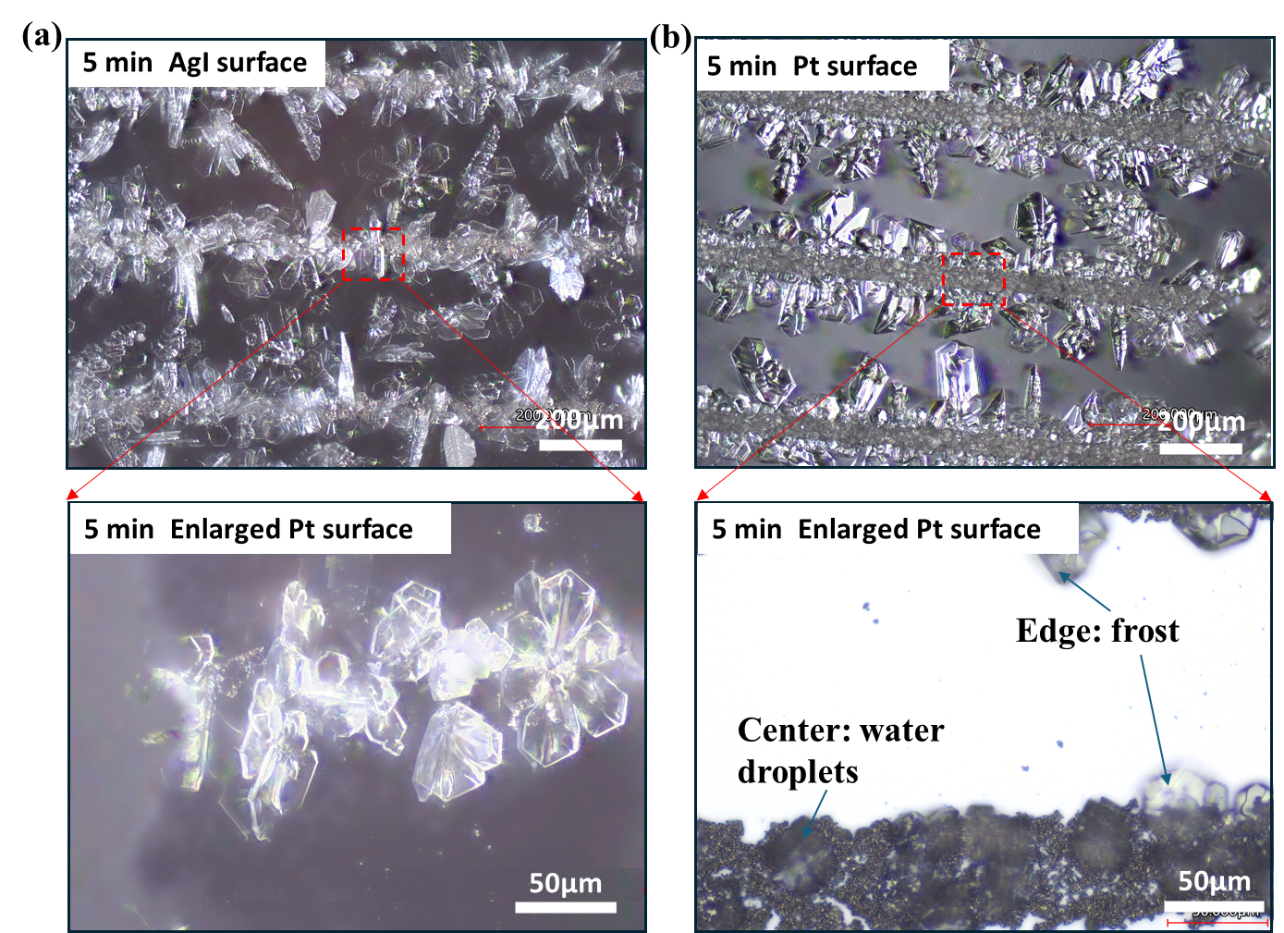

To observe the differences of frost growth modes between AgI and Pt patterns, magnified images captured by a scanning laser microscope at the early stage at 5 min are shown in Fig. 5. On the AgI stripe shown in Fig. 5(a), frost initiates in a flower-like shape, which indicates organized nucleation and crystal growth. In contrast, frost on the Pt stripe initiates with dendritic structures along the edges, while on the top central area, droplets accumulated and eventually froze as shown in Fig. 5(b).

Fig. 4 Comparison of frosting processes using laser scanning microscope under condensation frosting conditions between (a) AgI-patterned, (b) bare Si, and (c) Pt-patterned surfaces under condensation frosting condition at time of 120 min. Upper optical images capture frost morphology, and bottom figures show frost height distributions.

Fig. 5 Scanning laser microscope images of frost shapes at the early frost growth stage (5 min) on (a) AgI stripe-patterned surface [6], with bottom enlarged view showing horizontal plate-like frost, and (b) Pt stripe-patterned surface, with bottom highlighting horizontal frost growth along the edges and remained water droplets in the center of the stripes.

Comparison between the frost growth modes on three surfaces highlights that material properties and surface patterning significantly influence the frost morphology and its growth dynamics. The horizontal frost growth observed on the AgI surface demonstrates that the ice nucleation agent material effectively promotes organized and systematic ice nucleation and subsequent crystal growth, likely to be attributed to its superior nucleation capabilities. This peculiar horizontal frost growth results in low height frost distribution across the surface. In contrast, the Pt-patterned surface displayed combination of two distinct frost growth behaviors depending on the position of the micropattern. Specifically, along the stripe edges, frost followed a desublimation-driven horizontal growth process, similar to the AgI pattern, where ice transitioned directly from vapor to solid. Although Pt itself is inert and lacks inherent ice nucleation properties, the fabricated stripe has a porous and rough surface, which may promote local nucleation ability. This desublimation-driven ice growth is similar to that of the AgI stripe pattern. Consequently, frost tips from the edge grew faster. However, in the top central region of the Pt stripes, frost growth was dominated by condensation frosting. Water droplets formed and froze, which eventually grew in a random pattern. This combined frost growth modes, i.e. desublimation at the edges and condensation frosting in the center, can be attributed to the variations in surface topography and local environmental conditions across the micropatterned Pt surface.

4. Conclusions

The effects of AgI and Pt materials on frost growth from the stripe-patterned surfaces were investigated. The experiments showed that frost on the AgI stripe surface grew primarily through desublimation, resulting in a thin horizontal frost layer. In contrast, the Pt stripe surface exhibited a combination of two types of frost growth, i.e. horizontal growth from the edge and random growth from the center of the stripe. These findings highlight the potential of using ice nucleation agents such as AgI for controlling the frost height and density.

References