Abstract

Purpose: This study aimed to evaluate the effects of surface treatments on the shear bond strengths of composite resin blocks for CAD/CAM and luting agents.

Materials and Methods: All specimens were air-abraded with alumina particles before shear bond strength testing and categorized into the following pretreatment groups: C, no treatment; S, conventional silane treatment; GP, universal silane treatment; RS, universal silane treatment after silica coating; CM, resin coating after universal silane treatment; and RM, universal silane treatment after silica coating and resin coating. The surface roughness test was conducted to determine the fitting accuracy.

Results: The CM and RM groups demonstrated significantly higher bonding durability compared to the other groups. The film thickness of the resin coating was 12.66 µm, indicating its effectiveness in improving the bond strength without compromising the fitting accuracy.

Conclusion: Thus the clinical application of the resin-coating technique may prove useful for preventing the debonding of CAD/CAM fabricated crowns.

Introduction

The fitting accuracy of crowns fabricated with computer-aided design and computer-aided manufacturing (CAD/CAM) systems has been remarkably improved and helped daily dental practices owing to the progress in digital technologies related to three-dimensional object detection [1,2,3,4,5]. Various types of milling blocks, such as titanium, ceramics, and composite resins have been used for dental restorations [6,7,8,9,10].

The modulus of elasticity of resin core build-up materials, particularly the composite resin crowns, is similar to that of the natural tooth; therefore, they are expected to offer restorations that resemble the structure of natural teeth after integration with an abutment tooth via adhesive bonding [11,12,13]. Recently, the application of this composite resin block for CAD/CAM to molar restorations is drawing the attention of clinicians. Although these CAD/CAM fabricated crowns have an advantage due to the higher reliability in quality control relative to the products manually fabricated by dental technicians, several studies have reported incidents of debonding after the delivery of the crowns [14,15,16,17]. The reasons for debonding include a decrease in bond strength over the time between the restoration and the abutment tooth and the large taper in the tooth preparations dictated by the capabilities of the milling machines [18].

In light of the abovementioned clinical observations, in addition to various surface treatment methods for CAD/CAM fabricated crowns, the adhesive effect of the resin-coating technique [19] on the inner surface of the crown was examined.

Materials and Methods

Materials

The materials used in this study are shown in Table 1. The bond strength test and measurement of the film thickness of the resin coating were performed in the present study. The bond strength was evaluated using the shear bond strength test before and after thermocycling, followed by the analysis of the fracture surface. The film thickness of the resin coating was measured using a surface roughness tester and scanning electron microscope (SEM) images.

Bond strength test

Preparation of specimen

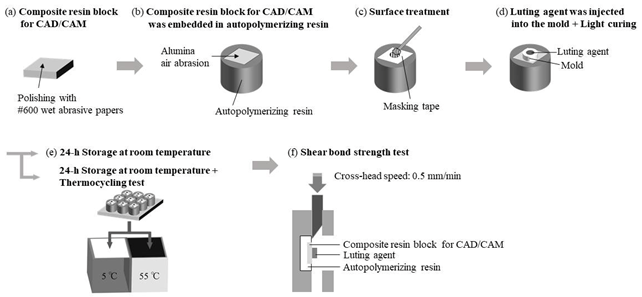

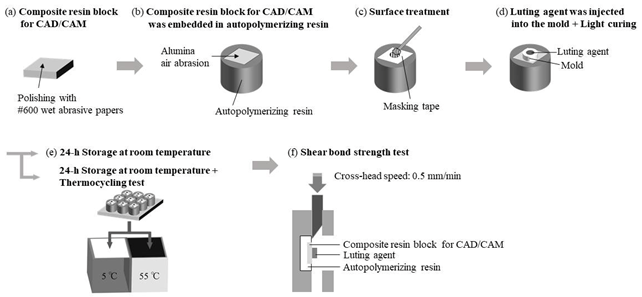

The experimental design is outlined in Fig. 1. Composite resin blocks for CAD/CAM (Cerasmart 270, GC, Tokyo, Japan) were sectioned with a low-speed precision cutting machine (Isomet, Buehler, Chicago, IL, USA), and the surface was polished with #600 waterproof abrasive papers (Sankyo Rikagaku, Okegawa, Japan). The sectioned specimens were embedded in autopolymerizing resin (Ostron II, GC) (Fig. 1a, b). The adherend surface was air-abraded with alumina particles (50 µm) at 0.3 MPa pressure for 15 s with a working distance of 10 mm, followed by rinsing in distilled water and drying by air blowing.

Table 1 Materials used in this study

| Brand name |

Composition |

Batch no. |

Manufacturer |

| Cerasmart 270 |

Bis-MEPP, UDMA, silica and barium nano glass |

1806051 |

GC, Tokyo, Japan |

| Panavia V5 Paste |

Bis-GMA, TEGDMA, hydrophobic aromatic dimethacrylate, hydrophilic aliphatic dimethacrylate, initiators, accelerators, silanated barium glass filler, fluoroalminosilicate glass filler, colloidal silica, silanated aluminum oxide filler, dl-camphorquinone, pigments |

7V0037

CK0069 |

Kuraray Noritake Dental, Tokyo, Japan |

| G-Cem Link Force A2 |

Bis-GMA, Bis-MEPP, UDMA, dimethacrylate, initiator, pigments, barium glass filler |

1808172 |

GC |

| Ceramic Primer |

Liquid A: 3-trimethoxysilylpropyl methacrylate, ethanol |

1607061 |

GC |

| Liquid B: methyl methacrylate, ethanol, UDMA, organic acid |

| G-Multi Primer |

3-trimethoxysilylpropyl methacrylate, 10-MDP, MDTP, ethanol |

1809251 |

GC |

| Ceramic Primer Plus |

3-trimethoxysilylpropyl methacrylate, MDP, ethanol |

7R0018

2D0023 |

Kuraray Noritake Dental |

| Rocatec Soft |

30 μm silica-coated alumina particles |

16 |

3M ESPE, Seefeld, Germany |

| Clearfil Megabond 2 Bond |

MDP, Bis-GMA, HEMA, dl-camphorquinone, hydrophobic aliphatic dimethacrylate, initiators, accelerators, colloidal silica |

5T0062 |

Kuraray Noritake Dental |

Bis-MEPP, 2,2-bis(4-methacryloxypolyethoxyphenyl)propane; UDMA, urethane dimethacrylate; Bis-GMA, bis-phenol-A-diglycidylmethacrylate; TEGDMA, triethyleneglycol dimethacrylate; MDP, methacryloyloxydecyl dihydrogen phosphate; MDTP, methacryloyloxydecyl dihydrogen thiophosphate; HEMA, 2-hydroxyethyl methacrylate

Fig. 1 Experimental design

The bonding area of the composite resin block for CAD/CAM was delineated by attaching a masking tape, and the surface treatment was conducted as follows (Fig. 1c).

-

• Group C (no treatment): No treatment was conducted on the surface (control group).

-

• Group S (conventional silane treatment): A conventional silane-coupling agent (Ceramic Primer, GC) was applied to the surface.

-

• Group GP (universal silane treatment): A silane-containing universal primer (G-Multi Primer, GC) was applied on the surface.

-

• Group RS (universal silane treatment after silica coating): 30 μm silica-coated alumina particles (Rocatec Soft, 3M ESPE, Seefeld, Germany) were used to coat the surface and G-Multi Primer was applied. The silica coating was performed for 15 s at a distance of 10 mm from the specimen using a pressure of 0.3 MPa.

-

• Group CM (resin coating after universal silane treatment): After the application of a silane-containing universal primer (Ceramic Primer Plus, Kuraray Noritake Dental, Tokyo, Japan), a resin coating was applied on the surface. A light-cure bonding agent (Clearfil Megabond 2, Kuraray Noritake Dental) was applied on the surface according to the manufacturer’s instructions. Subsequently, after air blowing, the surface was photopolymerized using a LED curing light unit (Elitedent Q-4, Rolence, Chungli, Taoyuan, Taiwan ROC) for 30 s at an irradiance of 1,400 mW/cm2.

-

• Group RM (universal silane treatment after silica coating, followed by resin coating): After silica coating using Rocatec Soft as described for Group RS, Ceramic Primer Plus was applied on to the surface followed by resin coating, which was performed as described for Group CM.

Six specimens were fabricated for each treatment surface to test the initial bond strength. Eight specimens were prepared for the CM and RM groups to test the bond strength after thermocycling. After completing the treatments on each surface, the amount of luting agent was standardized by attaching an aluminum pipe (internal diameter, 5.0 mm; height, 2.0 mm) to the adherend using sticky wax. Resin luting agent was incrementally placed into the aluminum pipe and photopolymerized for 20 s using the LED light-curing unit (Fig. 1d). G-Cem Link Force A2 (GC) was used for Groups C, S, GP, and RS, whereas Panavia V5 (Kuraray Noritake Dental) was used for Groups CM and RM.

Specimen storage

Six specimens from each surface treatment group were stored at room temperature for 24 h to examine the initial shear bond strength. Likewise, eight specimens from Groups CM and RM were stored at room temperature for 24 h in the same manner. The specimens were thermocycled (30,000 cycles) between 5 and 55˚C with a dwell time of 40 s to assess the bonding durability (Fig. 1e).

Shear bond strength measurement

After bonding and storing the specimens, the shear bond strength test was conducted using a universal testing machine (EZ Test, Shimadzu, Kyoto, Japan) at a crosshead speed of 0.5 mm/min (Fig. 1f). Kolmogorov-Smirnov test (p = 0.200) for each measurement showed normal distribution in all experimental groups. Levene’s test of equality of error variances was performed to assess the equality of variances in the shear bond strength of all experimental groups. The variance through the groups was found to be equal (p = 0.247), which permitted a one-way analysis of variance (ANOVA) to be conducted. The shear bond strength was subject to a comparative analysis using the one-way ANOVA test at a significance level of α = 0.05. Significant differences between the groups within the same one-way ANOVA test were further analyzed using Scheffé’s method (significance level, α = 0.05). The SPSS program (Ver. 25 for Windows, SPSS, Chicago, IL, USA) was used for the statistical analysis. The fractured specimens were examined visually to determine the failure modes, which were classified as cohesive within the composite resin block for CAD/CAM, adhesive between the luting agent-composite resin block for CAD/CAM interfaces or mixed.

Measurement of the film thickness of the resin coating

Using a surface roughness tester and a SEM, the film thickness of the resin coating applied on the surface of the composite resin block for CAD/CAM was measured.

Measurement using a surface roughness tester

A composite resin block for CAD/CAM was sectioned using a low-speed precision cutting machine. The surface was polished with waterproof abrasive papers (#600) to fabricate three types of pretreated surfaces as follows.

-

• Polishing: The surface as polished with waterproof abrasive papers (#600).

-

• Alumina air abrasion: The surface was treated by alumina air abrasion based on the fabrication of the specimen for the shear bond strength test.

-

• Alumina air abrasion + Silica coating: After alumina air abrasion, the surface was treated with silica coating according to the fabrication of the specimen in Group RS.

-

• Resin coating: After alumina air abrasion and silica coating, the surface was treated with resin coating according to the fabrication of the specimen in Groups CM and RM.

Resin coating was applied on half of the testing surface only. The surface roughness after polishing, alumina air abrasion, and alumina air abrasion + silica coating was evaluated using a surface roughness tester (Surfcom 590A, Tokyo Seimitu, Hachioji, Japan). The mean deviation of the assessed profile (Ra) was measured under the following conditions: cut-off value, 0.8 mm; measurement length, 4.0 mm; and measurement speed, 0.3 mm/s. The film thickness of the resin coating was calculated by measuring the difference in the level between the resin-coated and the control surfaces. Five specimens were used for each measurement to obtain the mean for the comparative analysis.

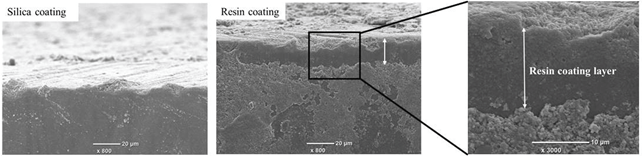

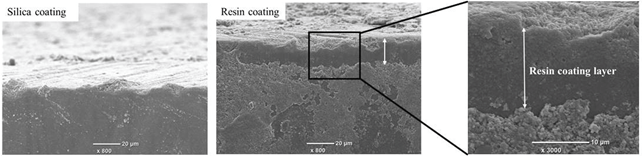

SEM analysis

A section of the composite resin block for CAD/CAM was produced using a low-speed precision cutting machine and polished with #600 waterproof abrasive papers. Then, the surfaces were treated with silica coating followed by resin coating. Cross-sectional images of the surface-treated blocks were observed to evaluate the thickness of the resin coating using an electron microscope (JCM-6000Plus, JEOL, Akishima, Japan) at an accelerating voltage of 10 kV and a magnification of ×800 and ×3,000.

Results

The results of the shear bond strength tests are summarized in Table 2. No significant differences in the shear bond strengths were observed among the different pretreatment groups (Groups C, S, GP, and RS; p > 0.05) before the thermocycling test. These groups were treated without bonding agents and presented with similar shear bond strength values (7.0-9.3 MPa). Likewise, no significant differences were observed between the two groups that were treated with bonding agents (Groups CM and RM). However, the shear bond strengths of these two groups were significantly higher than those of the groups treated without bonding agents (Groups C, S, GP, and RS), except for Groups RS and RM. After the thermocycling test, no significant differences in shear bond strength were observed between the two groups treated with bonding agents (Groups CM and RM). Thermocycling loading did not change the shear bond strength values of the two groups treated with bonding agents, and no significant differences were observed before and after fatigue simulation (p > 0.05).

Table 2 Shear bond strengths of the luting agent to composite resin block for CAD/CAM

| Surface treatment |

C |

S |

GP |

RS |

CM |

RM |

| Before thermocycling |

7.0 (3.7)A |

7.8 (2.6)A |

7.1 (2.6)A |

9.3 (1.9)A, C |

15.5 (2.9)B, a |

13.7 (1.4)B, C, a |

| After thermocycling |

|

|

|

|

14.9 (1.8)A, a |

15.3 (1.8)A, a |

Bond strength mean (MPa) and standard deviation in parentheses.

Significant differences are visualized with different letters; capitals within one row, small letters within a column.

Table 3 Distribution of failure modes among all the groups

| Surface treatment |

C |

S |

GP |

RS |

CM |

RM |

| Before thermocycling |

50/0/50 |

83/0/17 |

83/0/17 |

83/0/17 |

0/100/0 |

0/100/0 |

| After thermocycling |

|

|

|

|

0/37/63 |

0/63/37 |

A/B/C (%): A, adhesive failure between luting agent-composite resin block for CAD/CAM interface; B, cohesive failure within the composite resin block for CAD/CAM; C, mixed failure (A and B)

Table 4 Surface roughness and film thickness

| Surface roughness (Ra: μm) |

Film thickness (μm) |

| Polishing |

Alumina air abrasion |

Alumina air abrasion + Silica coating |

Resin coating |

| 0.25 (0.03) |

2.81 (0.20) |

3.38 (0.37) |

12.66 (0.59) |

Mean and standard deviation in parentheses.

Fig. 2 Cross-sectional scanning electron microscopic (SEM) images of a composite resin block for CAD/CAM treated with silica coating followed by resin coating at magnifications of 800× and 3,000×. The arrows in the figure show the thickness of the resin coating layer (approximately 12 to 15 μm).

The distribution of the failure modes in all the groups is shown in Table 3. Before the thermocycling test, none of the specimens in the four groups treated without bonding agents (Groups C, S, GP, and RS) demonstrated cohesive failure; however, all the specimens presented with adhesive failures between the luting agent-composite resin block for CAD/CAM interfaces or mixed failures. In the two groups treated with bonding agents (Groups CM and RM), all specimens presented with cohesive failures within the composite resin blocks for CAD/CAM. After the thermal cycling test, the failure modes of all specimens were classified as cohesive or mixed in the two groups treated with bonding agents (Groups CM and RM). Specifically, the proportion of cohesive failure was higher in Group RM relative to Group CM.

The results of the surface roughness evaluations on the pretreated surfaces after polishing, alumina air abrasion or alumina air abrasion + silica coating, as well as the film thickness of the resin coating, are presented in Table 4. The Ra values after polishing, alumina air abrasion, and alumina air abrasion + silica coating were 0.25, 2.81, and 3.38 µm, respectively.

Figure 2 shows the cross-sectional SEM images of the composite resin block for CAD/CAM pretreated with silica coating followed by resin coating. The film thickness values of the resin coatings using the surface roughness tester and the cross-sectional SEM values were 12.66 µm and 12 to 15 µm, respectively.

Discussion

A composite resin block for CAD/CAM presents with higher physical properties compared to light-cure paste type composite resins [20]. Furthermore, it has better esthetic than alloys, thus eliminating the concern of metal allergy. The composite resin block for CAD/CAM is expected to play a significant role in metal-free restorations; hence, a surge in its demand has been predicted. However, the high frequency of debonding has been reported due to the increase in the application of these composite resin blocks for CAD/CAM [14,15,16,17,18].

Fillers and matrix resins are heat-polymerized under high temperature and pressure during composite resin blocks for CAD/CAM fabrication [20]. Therefore, the composite resin blocks for CAD/CAM show a higher degree of polymerization in the matrix resin and establish more stable cross-links compared to composite resins that are developed using the conventional build-up method [21]. On the contrary, the bonding could be compromised due to the meager amount of unpolymerized matrix resin, which is essential for cross-linking during bonding between luting agents.

Given this characteristic of the composite resin blocks for CAD/CAM, several methods are recommended to achieve adhesive cementation such as alumina air abrasion that increases the surface area and the mechanical retention by adding micro irregular patterns, and silanization particularly used for chemical bonding between silica fillers [22]. Nonetheless, the shear bond strength values in Groups S and GP were not significantly different from that of Group C, which was treated with alumina air abrasion alone, thus indicating the absence of any positive effects of the conventional silane-coupling agent or the silane-containing universal primer on the shear bond strength.

No significant difference in shear bond strength values was observed between Group RS (alumina air abrasion and tribochemical silica coating) and Groups C, S, and GP, although Group RS presented with a higher value (9.3 MPa) than the other groups. The Rocatec method used in the present study forms a silica layer by air abrasion with unique silica-coated irregular alumina particles on the adherend [23]. This process increases the surface free energy resulting in an improvement in wetting [23]. In general, the wetting of the solid surface is affected by the fine geometric structure of the surface its chemical properties [24]. Fine grooves called “fractal structure” widely exist on the snail shell surface in the millimeter to nanometer range. This surface structure is considered to provide hydrophilicity to the shell [25]. Similarly, in the present study, it was suggested that a nanoscopic foamy structure [26] was formed in Group RS with silica coating. This nano-level fine structure is related to super-hydrophilicity; the improved wetting helped the penetration and coverage of the silane-containing universal primer resulting in improved bond strengths.

Groups CM and RM (with resin coating) showed significantly higher shear bond strengths relative to the groups without resin coating, thus indicating that the bonding resin, as well as the silane-containing universal primer, had penetrated and covered the irregular composite resin block for CAD/CAM surface after alumina air abrasion more effectively. In addition, it is suggested that the existence of the unpolymerized oxygen inhibition layer on the surface of the bonding resin improved the wetting of the low viscous luting agent thereby assuring the bonding. Although the luting agent tused in this study was of the dual-cure type, the pigments and the thickness could be factors that may have affected the penetration of the irradiated light. Insufficient irradiance and time could cause insufficient polymerization of the luting agent [27,28]. The irradiation is performed after crown insertion in actual clinical situations; hence, it is challenging to provide sufficient light for photopolymerization on the intaglio surface of the CAD/CAM fabricated crowns. However, a sufficient amount of irradiation is essential to achieve a high degree of conversion even in the case of dual-cure type luting agent [29]. On the other hand, it is possible to directly photopolymerize the bonding agent before crown insertion in the resin-coating technique [30]. No significant difference in shear bond strength values was noted between Group CM and Group RM (tribochemical silica coating). Therefore, the bond strength achieved after resin coating, which was performed without the Rocatec method (silica coating) after the alumina air abrasion process, was similar to that after the Rocatec treatment.

In terms of the fitting accuracy, the Ra values obtained after alumina air abrasion and silica coating using the surface roughness tester were 2.81 ± 0.20 µm and 3.38 ± 0.37 µm, respectively. Furthermore, the film thickness of the resin coating was approximately 12.66 ± 0.59 µm. These findings were confirmed by SEM imaging. One study reported that the film thickness of the resin coating using a bonding agent was about 10 µm [31], suggesting the possibility of providing a resin coating with a constant thickness using proper treatment methods. When a CAD/CAM crown is designed and fabricated, an appropriate amount of luting agent space should be selected by the clinician. It has been reported that the acceptable level of zinc phosphate cement space is 120 µm or less based on the particle size and viscosity of the zinc phosphate cement [32,33,34]; however, the new standard is within 80 µm, demanding further improvements in accuracy [35]. In the present study, the effect of resin coating on the fitting accuracy was 12.66 ± 0.59 µm. It is possible to conduct resin coating treatment on the intaglio surface of the CAD/CAM fabricated crown without compromising the fitting because a CAD/CAM fabricated crown requires proper luting agent space that can be adjusted by changing the parameter setting.

The resin-coating technique was proposed for restorative procedures in the early 90s [19]. In this method, the internal walls and floors of a finished preparation are sealed with a bonding agent or flowable resin; in some cases, the abutment tooth surface is coated with a bonding agent after crown preparation [19]. This method is expected to improve the bond strength [36], marginal sealing [37], and cavity adaptation [38], and protect the dentin and pulp tissue. In the present study, the failure modes at the initial shear bond strength testing of Groups CM and RM with resin coating demonstrated no adhesive failure between the luting agent-composite resin block for CAD/CAM interfaces or mixed failures; however, 100% cohesive failure was observed within the composite resin block for CAD/CAM. This finding indicates that the bond strength was higher than the fracture strength of the block itself. Although both mixed and cohesive failures were observed after the thermocycling test, the cohesive failure in Group RM was 63% indicating its high bond durability.

In conclusion, the findings of the present study suggest that the clinical application of the resin-coating technique could be a viable option for preventing the debonding of CAD/CAM fabricated crowns.

Acknowledgments

This work supported by KAKENHI Grant Number JP18K09670.

Conflicts of Interest

None

References

- 1. Syrek A, Reich G, Ranftl D, Klein C, Cerny B, Brodesser J. Clinical evaluation of all-ceramic crowns fabricated from intraoral digital impressions based on the principle of active wavefront sampling. J Dent 2010; 38: 553-9.

- 2. Miyazaki T, Hotta Y. CAD/CAM systems available for the fabrication of crown and bridge restorations. Aust Dent J 2011; 56: 97-106.

- 3. Brawek PK, Wolfart S, Endres L, Kirsten A, Reich S. The clinical accuracy of single crowns exclusively fabricated by digital workflow the comparison of two systems. Clin Oral Investig 2013; 17: 2119-25.

- 4. Awada A, Nathanson D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J Prosthet Dent 2015; 114: 587-93.

- 5. Paula Silveria AC, Chaves SB, Hilgert LA, Ribeiro AP. Marginal and internal fit of CAD-CAM-fabricated composite resin and ceramic crowns scanned by 2 intraoral cameras. J Prosthet Dent 2017; 117: 386-92.

- 6. Hey J, Beuer F, Bensel T, Boeckler AF. Metal-ceramic-fixed dental prosthesis with CAD/CAM-fabricated substructures: 6-year clinical results. Clin Oral Investig 2013; 17: 1447-51.

- 7. Lauvahutanon S, Takahashi H, Shiozawa M, Iwasaki N, Asakawa Y, Oki M, et al. Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J 2014; 33: 705-10.

- 8. Ruse ND. Sadoun MJ. Resin-composite blocks for dental CAD/CAM applications. J Dent Res 2014; 93: 1232-4.

- 9. Strasser T, Preis V. Behr M, Rosentritt M. Roughness, surface energy, and superficial damages of CAD/CAM materials after surface treatment. Clin Oral Investig 2018; 22: 2787-97.

- 10. Rödiger M, Schneider L, Rinkes S. Infuluence of material selection on the marginal accuracy of CAD/CAM-fabricated metal-and all-ceramic single crown copings. Biomed Res Int 2018; 2018: 2143906.

- 11. Furukawa K, Inai N, Tagami J. The effects of luting resin bond to dentin on the strength of dentin supported by indirect resin composite. Dent Mater 2002; 18: 136-42.

- 12. Ino S, Mehl A, Hickel R, Fujita T, Toyoda M. Fracture resistance of composite veneered ceramic crowns. Bull Kanagawa Dent Col 2005; 33: 45-9.

- 13. Lawson NC, Jurado CA, Huang CT, Morris GP, Burgess JO, Liu PR, et al. Effect of surface treatment and cement on fracture load of traditional zirconia (3Y), translucent zirconia (5Y), and lithium disilicate crowns. J Prosthodont 2019; 28: 659-65.

- 14. Vanoorbeek S, Vandamme K, Lijnen I, Naert I. Computer-aided designed/ computer-assisted manufactured composite resin versus ceramic single-tooth restorations: a 3-year clinical study. Int J Prosthodont 2010; 23: 223-30.

- 15. Sailer I, Makarov NA, Thoma DS, Zwahlen M, Pjetussin BE. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FPDs)? A systematic review of the survival and complication rates. Part I: Single crowns (SCs). Dent Mater 2015; 31: 603-23.

- 16. Schepke U, Meijer HJ, Vermeulen KM, Raghoebar GM, Cune MS. Clinical bonding of resin nano ceramic restorations to zirconia abutments: A case series within a randamized clinical trial. Clin Implant Dent Relat Res 2016; 18: 984-92.

- 17. Miura S, Kasahara S, Yamauchi S, Katsuda Y, Harada A, Aida J, et al. A possible risk of CAD/CAM-produced composite resin premolar crowns on a removable partial denture abutment tooth: a 3-year retrospective cohort study. J Prosthodont Res 2019; 63: 78-84.

- 18. Kawaguchi-Uemura A, Mine A, Matsumoto M, Tajiri Y, Higashi M, Kabetani T, et al. Adhesion procedure for CAD/CAM resin crown bonding: Reduction of bond strengths due to artificial saliva contamination. J Prosthodont Res 2018; 62: 177-83.

- 19. Nikaido T, Tagami J, Yatani H, Ohkubo C, Nihei T, Koizumi H, et al. Concept and clinical application of the resin-coating technique for indirect restoration. Dent Mater J 2018; 37: 192-6.

- 20. Lauvahutanon S, Takahashi H, Shiozawa M, Iwasaki N, Asakawa Y, Oki M, et al. Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J 2014; 33: 705-10.

- 21. Hamano N, Lee MC, Ino S, Toyoda M. A study of the effects of self-etching primers on the polymerization of bonding agents using electron spin resonance (ESR) spectroscopy. Dent Mater J 2004; 23: 533-8.

- 22. Higashi M, Matsumoto M, Kawaguchi A, Miura J, Minamino T, Kabetani T, at al. Bonding effectiveness of self-adhesive and conventional-type adhesive resin cements to CAD/CAM resin blocks. Part 1: Effects of sandblasting and silanization. Dent Mater J 2016; 35: 21-8.

- 23. Yamaguchi H, Ino S, Hamano N, Okada S, Teranaka T. Examination of bond strength and mechanical properties of Y-TZP zirconia ceramics with different surface modifications. Dent Mater J 2012; 31: 472-80.

- 24. Saxena N, Naik T, Paria S. Organization of SiO2 and TiO2 nanoparticles into fractal patterns on glass surface for the generation of superhydrophilicity. J Phys Chem C 2017; 121: 2428-36.

- 25. Mitsuda S, Ino S, Nihei T, Umeda Y, Watanabe M, Takai O, et al. Effects of hydrophilic and hydrophobic surface modifications on poly (methyl methacrylate) denture base resins. Asian Pac J Dent 2019; 19: 1-8.

- 26. Fukuyama T, Hamano N, Ino S. Effects of silica-coating on surface topography and bond strength of porcelain fused to CAD/CAM pure titanium. Dent Mater J 2016; 35: 325-32.

- 27. Ilie N, Hickel R. Correlation between ceramics translucency and polymerization sufficiency through ceramics. Dent Mater 2008; 24: 908-14.

- 28. Inokoshi M, Pongprueksa P, De Munck J, Zhang F, Vanmeensel K, Minakuchi S, et al. Influence of light irradiation through zirconia on the degree of conversion of composite cements. J Adhes Dent 2016; 18: 161-71.

- 29. Hamano N, Ino S, Hojo S, Yoshino F, Watanabe T, Katsumata Y, et al. A study of the effects of irradiation on the polymerization of a dual-cured bonding agents using electron spin resonance (ESR) spectroscopy. Bull Kanagawa Dent Col 2007; 35: 165-70.

- 30. Hamano N, Ino S, Hojo S, Yoshino F, Watanabe T, Katsumata Y, et al. A study of the effects of irradiation on the polymerization of a dual-cured resin composite for core build-up using electron spin resonance (ESR) spectroscopy. Bull Kanagawa Dent Col 2007; 35: 159-63.

- 31. Takahashi R, Nikaido T, Ariyoshi M, Kitayama S, Sadr A, Foxton RM, et al. Thin resin coating by dual-application of all-in-one adhesives improves dentin bond strength of resin cements for indirect restorations. Dent Mater J 2010; 29: 615-22.

- 32. MacLean JW, Von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J 1971; 131: 107-11.

- 33. Komine F, Iwai T, Kobayashi K, Matsumura H. Marginal and internal adaptation of zirconium dioxide ceramic coping and crowns with different finish line designs. Dent Mater J 2007; 26: 659-64.

- 34. Miura S, Inagaki R, Kasahara S, Yoda M. Fit of zirconia all-ceramic crowns with different cervical margin designs, before and after porcelain firing and glazing. Dent Mater J 2014; 33: 484-9.

- 35. Boitelle P, Mawussi B, Tapie L, Fromentin O. A systematic review of CAD/CAM fit restoration evaluations. J Oral Rehabil 2014; 41: 853-74.

- 36. Okuda M, Nikaido T, Maruoka R, Foxton RM, Tagami J. Microtensile bond strengths to cavity floor Dentin in indirect composite restorations using resin coating. J Esthet Restor Dent 2007; 19: 38-46.

- 37. Kitayama S, Pilecki P, Nasser NA, Bravis T, Wilson RF, Nikaido T, et al. Effect of resin coating on adhesion and microleakage of computer-aided design/computer-aided manufacturing fabricated all-ceramic crowns after occlusal loading: a laboratory study. Eur J Oral Sci 2009; 117: 454-62.

- 38. Jayasooriya PR, Pereira PN, Nikaido T, Burrow MF, Tagami J. The effect of a "resin coating" on the interfacial adaptation of composite inlays. Oper Dent 2003; 28: 28-35.