2017 Volume 86 Issue 1 Pages 37-44

2017 Volume 86 Issue 1 Pages 37-44

Harvesting of asparagus spears is hard work because farmers have to harvest spears in a crouching posture. We previously developed electric long-shafted shears and a large-wheeled cart to improve the harvest posture, and we reported that the visibility of spears can be improved by modified branch training using string, without any yield or quality reduction. In the present study, we investigated the harvest efficiency, harvest posture, and subjective burden with electric long-shafted shears and a large-wheeled cart under modified branch training methods (the new standing harvest method) for labor-saving asparagus spear harvesting. Two male subjects in their 30s and 60s harvested spears for 60 min using (standing harvest) and without using (control) the new standing harvest method. The harvest efficiency of the new standing harvest method was 18% lower than that of the control. In the standing harvest, subjects had to pull the shears up to take the harvested spear from the shears with their left hand after each spear was cut (“take”). The subjects needed time for the “take” action, and the time necessary to harvest a spear with the electric long-shafted shears was longer than that required for the control. We also evaluated the harvest posture using the Ovako Working Posture Analyzing System (OWAS). For the subject in his 30s, action category(AC)2 and AC3 accounted for 72% and 14% of the postures recorded in the control, respectively, whereas in the standing harvest, AC1 and AC2 accounted for 57% and 41%, respectively. For the subject in his 60s, AC2 and AC3 accounted for 41% and 58% of the postures recorded in the control, respectively, whereas in the standing harvest, AC1 and AC2 accounted for 27% and 70%, respectively. Unfavorable postures during harvest were reduced by the new standing harvest method. The subjective physical burden on the subjects was evaluated using a modified Borg scale after 60 min of harvesting using and without using the new standing harvest method. The subjective physical burden in both subjects was highest (> 8) at the waist in the control, whereas the scores were lower than 3 in the standing harvest. Thus, the new standing harvest method reduced harvest efficiency, but resulted in substantial improvements in posture and reduced the physical burden on the subjects.

Maintaining mother stem cultivation (Ito et al., 1994) of asparagus is widely used all over Japan. In this cultivation, mother stems are allowed to grow to the fern stage after the spring harvest of young spears. The young spears sprouting around the base of the mother stem are also harvested in the summer in this cultivation. The production of young spears is enhanced by photosynthate translocation from the mother stems. Farmers have to harvest spears in a crouching posture because they have to cut young spears using shears (Katahira, 2004; Sakamoto et al., 2011). New young spears must be harvested daily during the harvest season, when they reach commercial length. Furthermore, harvesting is often conducted twice a day, in the morning and the evening, in the summer season. Therefore, the physical burden is large during asparagus harvesting, and an improvement in the harvesting method is necessary.

Labor saving in asparagus harvesting has mainly focused on the development of harvesting tools such as carts for sitting harvesting (Katahira, 2004) and long-shafted shears (Chigusa, 2014; Saitou, 2009a, b; Yoshimura, 2009). In the sitting harvest method using a cart, the forward bending posture is decreased while moving and processing, but the upper body still bends forward in the harvesting action (Katahira, 2004). In contrast, the harvest efficiency and fatigue alleviation effects for harvesting using long-shafted shears are not clear. The long-shafted shears developed previously are operated by a hand grip, i.e., manually. We therefore developed electric long-shafted shears (hereafter referred to as “long-shafted shears”) that can be operated using minimal force (Sakamoto, 2011, 2012).

For harvesting of asparagus, carts with 9-inch (22.9 cm in diameter) wheels are commonly used to carry the harvested spears. However, when the terrain is muddy after rain or highly uneven, smooth movement of the carts with 9-inch wheels is difficult. Carts used for standing harvesting need to be able to be easily operated with one hand, because the farmers always use the long-shafted shears with their right arm. We thus developed a cart with 14-inch (35.6 cm in diameter) wheels (hereafter referred to as “the large-wheeled cart”, Sakamoto, 2012) that can be moved with less power than carts with 9-inch wheels.

In the spring harvest, long-shafted shears are easily used because the mother stems that present obstacles to harvesting are not present. However, it is difficult to find and harvest young spears using long-shafted shears during the summer while still maintaining mother stem cultivation because these spears are hidden by the mother stems with numerous lateral branches. It has been reported that the visibility of young spears can be improved by branch training using string without any reduction in spear yield or quality (Sakamoto et al., 2015). In this study, the harvest efficiency, harvest posture, and subjective burden with the long-shafted shears and the large-wheeled cart under modified branch training (the new standing method) were evaluated in comparison to the conventional harvest method.

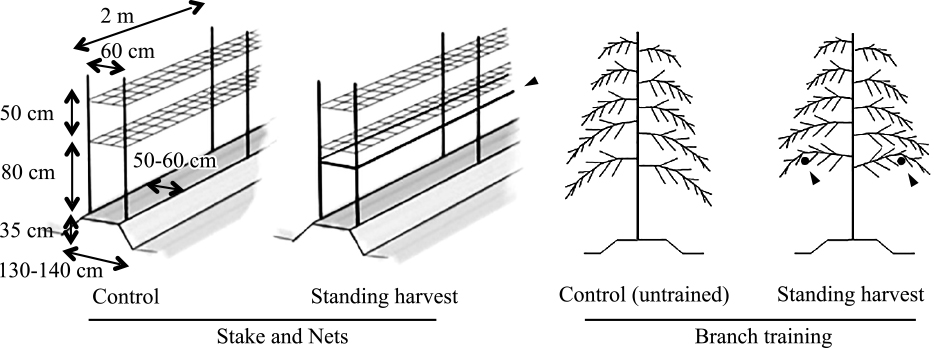

The five-year-old asparagus ‘Welcome’ was used in this study, which was conducted at the field of the Hiroshima Prefectural Technology Research Institute, Agricultural Technology Research Center in 2012. In May 2008, asparagus seedlings were planted along raised ridges at 40 cm intervals (125 seedlings per are (100 m2)). The distance between the centers of the ridges was 200 cm. Stakes (iron pipes, 22.2 mm diameter) were installed perpendicularly at 60 cm intervals every 2 m along the ridges (Fig. 1); nets (20 cm wide × 3 frames) were installed horizontally at heights of 80 cm and 130 cm above the ridge to prevent the mother stems from lodging (Sakamoto et al., 2015).

Diagrams showing the installation of stakes, nets, and strings to prevent the mother stems from lodging and strings for modified branch training (Sakamoto et al., 2015), and diagrams showing the branch training. The strings for branch training (triangles).

Young spears with a diameter of 12–15 mm were selected to be grown as mother stems (Tanaka, 2004), and 10 mother stems per meter were established from May 21, 2012. Young spears with diameters less than 12 mm and greater than 15 mm were established when the number of suitable spears was not sufficient. All lateral branches with a height of less than 50 cm were removed from the ridge, and the main stems were not pinched.

Effect of modified branch training and use of long-shafted shears on harvest efficiency, harvest posture, and physical burdenWe compared two harvest methods. One method was the conventional method with a crouching or half-sitting posture using the horticultural shears and a cart with 9-inch wheels, and also using untrained branches (hereafter referred to as “control”). The other method was the new standing harvest method using the long-shafted shears and the large-wheeled cart together with training of the branches (hereafter referred to as “standing harvest”). Two male subjects with different physical characteristics, a 36-year-old man (height: 173 cm, weight: 62 kg, hereafter referred to as the “30s subject”) and a 63-year-old man (height: 162 cm, weight: 55 kg, hereafter referred to as the “60s subject”) performed both harvest methods. The subjects were skilled at both control and standing harvest methods. The subjective burdens of the parts of their body were low before harvest. The interval between the applications of the two methods was more than 10 days, such that the burden after harvesting did not influence subsequent performance, and each harvest method was performed as one repetition. The 30s and 60s subjects performed the control harvest on September 11th (highest temperature: 28.7°C) and 13th (highest temperature: 30.8°C), and they performed the standing harvest on August 31 (highest temperature: 30.1°C) and 30 (highest temperature: 32.0°C) in 2012, respectively. The weather was mostly clear on these days.

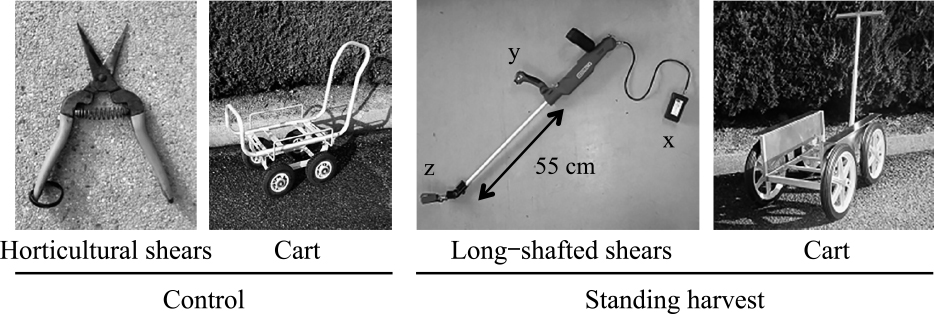

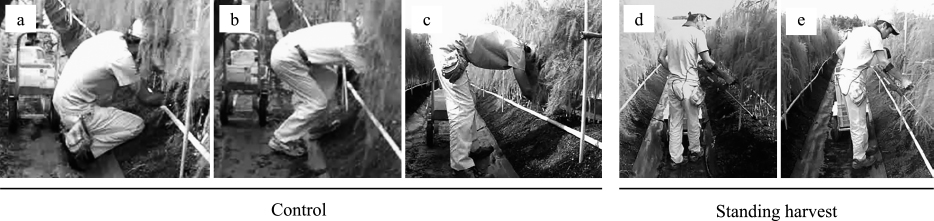

The shears and carts used for harvesting are shown in Figure 2, and examples of the posture observed in each method are shown Figure 3. In the control, the shears weighed 113 g and the cart had standard 9-inch wheels. In the standing harvest, the shears (Kinboshi-ooshima Kogyo Co., Ltd., Ono, Japan) weighed 1500 g and had a shaft length of 55 cm, and the cart had 14-inch wheels. The standing harvest procedure was the same as that of our previous report (Sakamoto et al., 2015). First, the long-shafted shears and a battery were attached to the subject’s right arm and waist, respectively. The subjects used a support belt around their necks to support some of the weight of the shears. Second, the shears were positioned around a young spear. A button was used to activate the shears and cut the spear. When the subjects pressed this button, the shears cut the young spear and grips attached to the shears grasped the young spear. Thereafter, the subjects pulled up the shears and caught the spear with their left hand. The grips opened when the subject released the button, and the subjects then took the spear with their left hand. The subjects then continued harvesting holding the harvested young spears with their left hand. The subjects placed the young spears into a basket when their hands were full. Two containers (52 cm × 36.5 cm × 30.5 cm) were placed on the large-wheeled cart, and the harvested young spears were kept in a basket on the containers at 80 cm above the ground to reduce the degree of crouching required.

The shears and carts that were used for harvesting asparagus. The photographs of the long-shafted shears and cart in standing harvest are from Sakamoto et al., 2015. Shears and grip for cutting young spears (z). Operating grip (y). Battery (x).

Characteristic harvest posture in control and standing harvesting. Kneeling posture (back: bent, upper limbs: both limbs below shoulder, lower limbs: kneeling, AC2 (a)). Forward back bent posture with half-sitting (back: bent, upper limbs: both limbs below shoulder, lower limbs: loading on both limbs, bent, AC3 (b)). Forward back bent posture with standing (back: bent, upper limbs: both limbs below shoulder, lower limbs: loading on both limbs, straight, AC2 (c)). Standing posture without back bent (back: straight, upper limbs: both limbs below shoulder, lower limbs: loading on both limbs, straight, AC1 (d)). Standing posture with forward back bent (back: bent, upper limbs: both limbs below shoulder, lower limbs: loading on both limbs, straight, AC2 (e)).

We simulated a harvest using young spears that had been previously harvested. This allowed us to standardize the density of the spears and conduct each trial in the same location (Sakamoto et al., 2015). We inserted polyvinyl chloride pipes (VP13; 13 mm inside diameter and 18 mm outside diameter) with a length of 10 cm in each ridge and inserted pre-harvested young spears in these pipes. The young spears were set up at approximately 20–30 cm above the ridge. There were 100 spears per are (100 m2) determined as the average density of spears recorded at Hiroshima Prefectural Technology Research Institute, Agricultural Technology Research Center field from July to September in 2011 (data not shown).

The experimental ridges had a height of 35 cm, a width of 130–140 cm at the base, and a width of 50–60 cm at the top at the time of investigation. Furthermore, asparagus branches were trained using string to improve visibility in the standing harvest experiment. The branch training method followed the method of Sakamoto et al. (2015), and the branches were trained with string attached to pipes supporting the mother stems at a height of 60 cm (Fig. 1).

The 30s and 60s subjects harvested spears for 60 min under each condition. In addition, the subjects were allowed to take short breaks to stretch during harvesting as necessary. We recorded the number of harvested young spears every 10 min, and harvest efficiency was evaluated as the number of harvested young spears per minute. We considered the results for 10 min as one repetition, and we evaluated the data using the t-test.

We recorded the harvesting posture for 10 min from the start of harvest using a digital camera in movie mode. We evaluated the harvesting posture by assigning action categories (AC) ranging from 1 to 4 by using the Ovako Working Analysis System (Karhu et al., 1977; Louhevaara and Suurnakki, 1992; hereafter referred to as “OWAS”). In these categories, higher numbers indicate a larger burden for the posture and indicate that corrective action is urgently required (AC1 = no corrective measures; AC2 = corrective measures in the near future; AC3 = corrective measures as soon as possible; and AC4 = corrective measures immediately). In addition, we used JOWAS software (Seo, 2001) to determine OWAS. Furthermore, we categorized the subjects’ movements every second as “harvesting young spears with the horticultural shears or the long-shafted shears (harvest)”, “taking the young spears that have been cut and catching them with the long-shafted shears (take)”, “placing the young spears in the basket (place)”, “looking for young spears (look)”, and “walk”. “Harvest”, “take”, and “place” were actions that included walking. “Walk” was grouped only with walking. The subjective burden of the 30s and 60s subjects was evaluated on a modified Borg scale of 0–10 (Borg, 1982) at the start and finish of each trial. We surveyed the impression of the harvest and the possibility of continuing the harvest after 60 min of work.

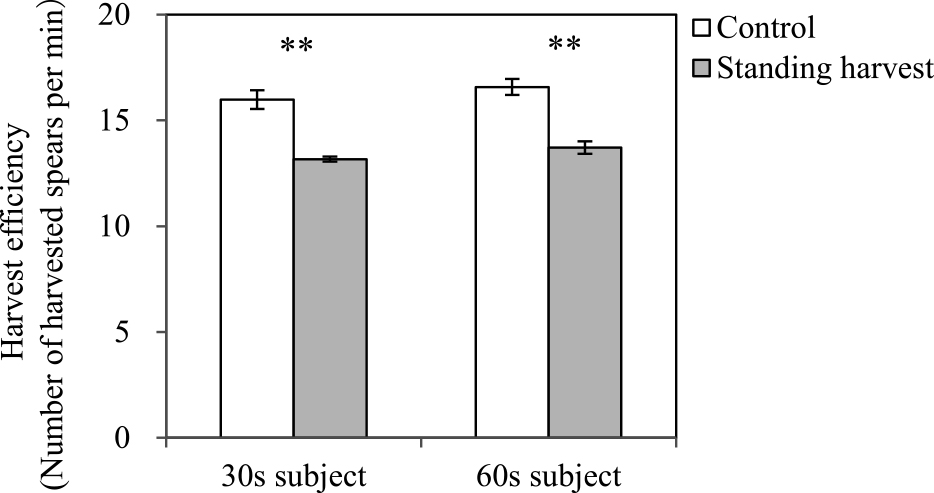

The harvest efficiencies for 10–min intervals over 60 min of work are shown in Figure 4. There was a significant difference in harvest efficiency between two methods conducted by each subject. The 30s subject harvested 16.0 and 13.2 spears per minute in the control and standing harvest, respectively, and the 60s subject harvested 16.6 and 13.7 spears per minute, respectively. The harvest efficiency for the standing harvest was 18% lower than that in the control for both subjects.

Effect of branch training and using long-shafted shears on harvest efficiencies in maitaining mother stem cultivation of asparagus. Values are mean ± SE (n = 6). ** indicate significant difference by t-test at P < 0.01.

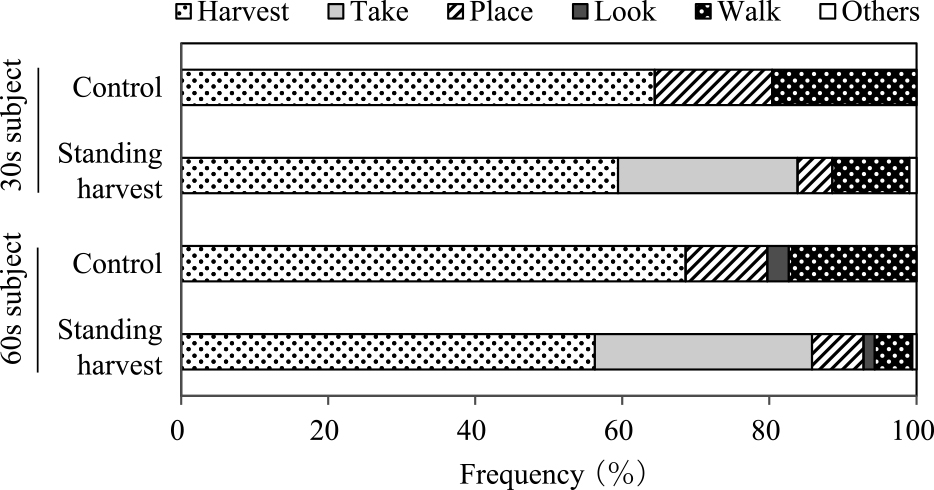

The proportion of time in which each action was performed in the first 10 min of harvest is shown in Figure 5. The action that was the most frequently observed in both control and standing harvest was “harvest”, which accounted for more than 50% of the time in both trials. This action accounted for 5 points and 13 points less time in the standing harvest than in the control for the 30s and 60s subjects, respectively. The “take” action accounted for 24% and 30%, respectively, of the time during only the standing harvest. The action “place” was more frequent in the control than in the standing harvest for both the 30s and 60s subjects, and this was particularly notable in the case of the 30s subject. The 30s subject moved the cart, harvesting in his reachable range. With each movement, the 60s subject moved the cart 2–3 times farther than the 30s subject and he harvested asparagus spears within his reach, two or three at a time. Therefore, the “place” rate was higher for the 30s subject than 60s subject. The action “walk” was more frequent in the control than in the standing harvest. In the standing harvest, subjects could set their shears close to the young spear while walking. In contrast, in the control, subjects could not easily continue to work while walking because of their crouching posture with the arms extended forward.

Effect of branch training and use of long-shafted shears and large-wheeled cart on proportion of actions in harvesting asparagus while maintaining mother stem cultivation. Except for movements from ridge to ridge, the actions were investigated every 1 s for 10 min from the start of harvest.

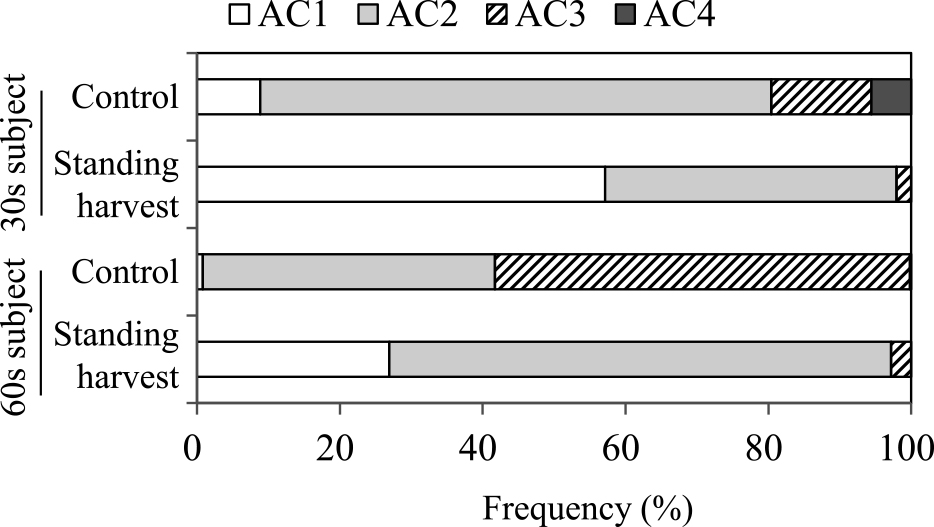

The effects of harvest method on harvest posture were evaluated using OWAS (Fig. 6). For the 30s subject, AC2 was the most frequent score (72%) in the control, followed by AC3 (14%). In the control, AC1 and AC4 accounted for only 9% and 6% of the scores, respectively. In the standing harvest, AC1 and AC2 accounted for 57% and 41% of the scores, respectively. Furthermore, AC3 comprised only 2% of the scores, and AC4 did not occur in the standing harvest for the 30s subject. For the 60s subject, in the control, AC2 and AC3 accounted for 41% and 58% of the scores respectively, and AC1 and AC4 comprised less than 1%, whereas in the standing harvest, AC1 and AC2 accounted for 27% and 70% of the scores, respectively; these two categories accounted for 97% of the total posture scores for the 60s subject.

Effect of branch training and use of long-shafted shears and large-wheeled cart on harvesting posture while maintaining mother stem cultivation of asparagus. Harvesting posture was evaluated by OWAS (Karhu et al., 1977; Louhevaara and Suurnakki, 1992). Action category (AC) indicates the following. AC1: no corrective measures. AC2: corrective measures in the near future. AC3: corrective measures as soon as possible. AC4: corrective measures immediately.

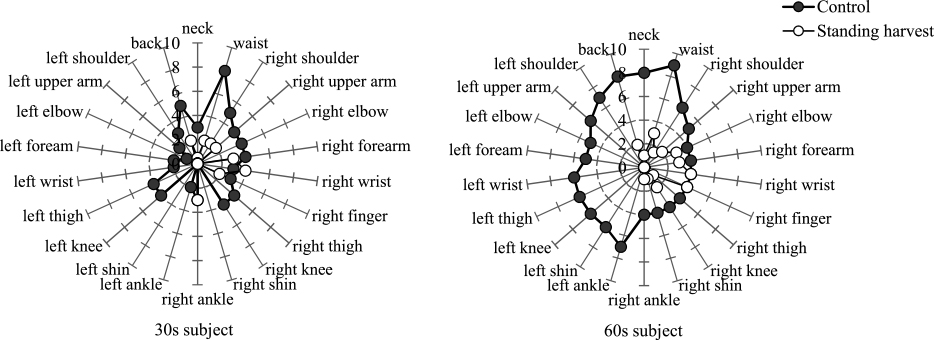

The effect of harvest method on subjective physical burden after 60 min harvesting is shown in Figure 7. In the control, modified Borg scale scores for the 30s subject were the highest for the waist (8), followed by the right shoulder and back (5). In the case of the 60s subject, the highest score was also obtained for the waist (9), followed by the neck and back (8). Furthermore, the 60s subject had scores from 5 to 7 in 10 body parts, such as the right shoulder and right upper arm; he felt a burden over his whole body. In both subjects, the modified Borg scale scores were higher than 5 in the waist, back, and right shoulder. The quantified burden for these parts was particularly large in the control asparagus harvesting method. In the standing harvest for the 30s and 60s subject, the modified Borg scale scores for the waist were lower than 3, indicating a reduction in the waist burden. The scores for the right wrist were higher for the standing harvest than for the control in the 30s subject.

Effect of branch training and use of long-shaft shears and large-wheeled cart on subjective fatigue in harvesting of asparagus while maintaining mother stem cultivation. Values indicate subjective burden, which was evaluated using a modified Borg scale (Borg, 1982) after 60 minutes of harvesting (0: Nothing at all, 0.5: Very, very weak (just noticeable), 1: Very weak, 2: Weak (light), 3: Moderate, 4: Somewhat strong, 5: Strong (heavy), 7: Very strong, 10: Very, very strong (almost max)). The subjective fatigue of all parts before harvest was 0 in the 30s subject. Both subjective fatigue scales for the neck and waist before harvest were 0.5, and those of other parts were 0, in the 60s subject.

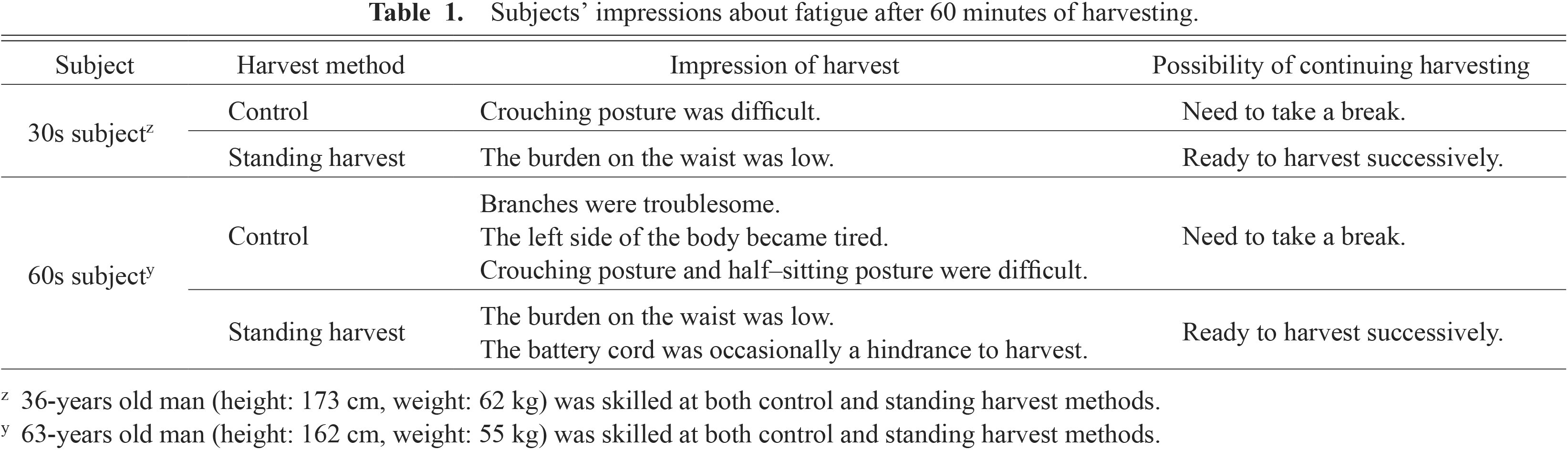

The subjects’ impressions regarding fatigue after 60 min of harvesting are shown in Table 1. In the control, both subjects felt that the crouching or half-sitting posture was difficult, and the 60s subject felt that branches made it difficult to harvest the spears in summer. In the standing harvest, the 60s subject felt that the battery cord occasionally hindered the harvesting activity, whereas both subjects felt that the burden on the waist was low. In addition, the 30s and 60s subjects requested a break after 60 min of harvesting with the control method, but they felt ready to harvest for more than 60 min using the standing method.

Subjects’ impressions about fatigue after 60 minutes of harvesting.

The harvest efficiency in the standing harvest was lower than that in the control (Fig. 4), and the proportion of time spent on each action was different between the two methods (Fig. 5). In the control, subjects continuously harvested spears with their right hand while holding harvested spears in their left hand. However, in the standing harvest, subjects had to pull the shears up to take the harvested spear from the shears with their left hand after each spear was cut. For this reason, subjects needed time for the action “take”, and the time necessary to harvest a spear with the long-shafted shears was longer than that required for the control.

OWAS is a work posture assessment method that is also used in agriculture (Miyazaki and Kataoka, 2004; Nwe et al., 2012). There is a high proportion of AC3 in the conventional harvesting of asparagus (Katahira, 2004; Sakamoto et al., 2011). However, the subjective physical burden cannot be evaluated by OWAS. In the present study, we were able to determine the numerical value of the subjective physical burden by using a modified Borg scale.

In the control, the occurrence of AC3 was high, similar to previous reports (Katahira, 2004; Sakamoto et al., 2011). Even though the age and physique of the subjects and conditions of the fields were different, the subjective physical burden was universally large when using the conventional asparagus harvesting method.

The AC proportions differed between the 30s and 60s subjects. Particularly in the control, the occurrence of AC2 was high for the 30s subject, whereas the occurrence of AC3 was high for the 60s subject. Many kneeling postures and postures without bent knees (angle of the knee > 150°) were found for the 30s subject, whereas many postures with bent knees (angle of the knee < 150°) were found for the 60s subject (Fig. 3). These differences in posture explain some of the differences in AC between the two subjects.

Yamamoto et al. (2004) reported that the limit for forward-bend posture standing with both knees bending or half–sitting (AC3) is less than 5% of the time spent working, and that there was a high frequency of acute low back pain in the workplace where such posture was observed among 4.5% of the total work time. In the control for the 60s subject, postures scoring higher than AC3 were observed approximately 60% of the time, and in the 30s subject, posture scores higher than AC3 were observed during 20% of the work time; thus the AC3 + 4 proportion was higher than 5% for both subjects. Furthermore, in both subjects, the modified Borg scale score was higher than 8 at the waist, and these results show that immediate improvement of the harvest method is necessary. In the standing harvest, the proportion of AC1 and AC2 differed between the 30s and 60s subjects, but the new standing harvest method reduced the proportion of AC4 and AC3 scores to less than 3%.

In the standing harvest for the 60s subject, AC1 was infrequent, and AC2 was more frequent in the 60s subject than in the 30s subject. The posture received a score higher than AC2 when the inclination of the upper body was greater than 20°. Postures with the upper body inclined at an angle less than 20° comprised approximately 60% of the total work postures of the 30s subject, but postures with the upper body inclined at an angle greater than 20° comprised more than 73% of the total work postures of the 60s subject. Therefore, the occurrence of AC2 was higher for the 60s subject than for the 30s subject. However, in the standing harvest for both subjects, the modified Borg scale scores for the waist were lower than 3, indicating that the forward bending posture of the 60s subject was not problematic. The harvest efficiency and harvest postures may be affected by the shaft length of the shears, but the shaft length of already-developed shears cannot be adjusted. The heights of the subjects in the present study were 173 and 162 cm; therefore, it is expected that subjects in this height range can obtain similar effects when the ridge height is 35 cm. The harvest efficiency and labor-saving effect of using long-shafted shears in different conditions will need more investigation in the future.

The score for the right wrist was higher for the standing harvest than for the control in the 30s subject. This effect was thought to be caused by the weight of the long-shafted shears that we used for this experiment (1500 g), which was approximately 13 times higher than that of the horticultural shears used in the control (113 g). However, the modified Borg scale scores for the right shoulder, right upper arm, right elbow, and right forearm in the standing harvest were lower than the values in the control. In the RULA (rapid upper limb assessment) system, postures with large angles between the upper arm and body generate greater physical loads than postures with small flexion between the upper arm and body (McAtamney and Corlett, 1993). In this system, flexion is classified as lower than 20°, 20°–45°, 45°–90°, and higher than 90°, as indicated by scores of 1, 2, 3, and 4, respectively, where high numbers indicate a large burden. In the case of the control in our experiment, the horticultural shears used were light at 113 g, but postures with greater than 90° flexion between the upper arm and body were frequently observed because both subjects harvested with their hands extended forward. In contrast, the long-shafted shears were heavy at 1500 g, but required less flexion between the upper arm and body than the control and could be used with a support belt. It is considered that these factors contributed to the lower subjective burden on the right arm in the standing harvest than in the control. This finding suggests that weight of the long-shafted shears was tolerable for at least 60 min for the 30s and 60s subjects.

When newly developed technology is introduced, economic evaluation is important. However, economic evaluation of fatigue alleviation effects is difficult (Hayashi et al., 2004; Miyagi prefecture, 2006). Therefore, a long-term evaluation such as measurement of the maintenance of constant work efficiency without health disorders is necessary (Miyagi prefecture, 2006). Suenaga et al. (1986) investigated work posture during strawberry harvesting in which farmers harvested with a stooped and crouching posture. They reported that the frequency of standing increased over a period of months. They also reported that standing interrupted continous strawberry harvesting, as it was thought that the subjects could take small breaks by standing. Furthermore, the occurrence of standing increased over the course of a day, which suggested a cumulative burden around the waist. In the present study, neither subject took similar small standing breaks in our 60 min experimental harvests; however, both 30s and 60s subjects requested a break after 60 min of harvesting with the control method. Furthermore, the asparagus farmers indicated that they take small breaks as needed to alleviate the burden on the waist and back. For example, during harvesting, they stretch their backs or sit down and pull out weeds. To better understand the harvest efficiency of the new standing harvest method, it is necessary to study the cumulative burden throughout the entire harvest period in a commercial field.

The introduction of such new techniques with improvement in the field is difficult because asparagus is a perennial crop. Farmers can easily introduce the new standing harvest method because improvement in the field is not needed. However, the use of the long-shafted shears is limited in rain because they are electrically driven. Waterproofing of the shears will thus be necessary in the future.

Our results suggest that efficiency was reduced by 18% with the new standing harvest method, but this method is effective for improving the posture and reducing the burden of farmers in harvesting asparagus while maintaining mother stem cultivation.