2013 年 53 巻 6 号 p. 1081-1088

2013 年 53 巻 6 号 p. 1081-1088

The applicability of high chromium (Cr) steel as the main structural material in fast breeder reactors (FBR) has been explored to enhance the safety, the credibility and the economic competitiveness of FBR power plants. Vanadium (V) and Niobium (Nb) are believed to improve the high-temperature strength of high Cr steels by precipitating as carbides and/or nitrides, namely fine MX particles, although the long-term efficiency and stability of such precipitation strengthening mechanisms resulting from the fine MX particles have not been clarified yet. The effects of V and Nb on degradation of creep properties were investigated under FBR operating conditions, e.g., at 550°C for 500000 h, and the relationship between the long-term creep properties and microstructural changes was investigated considering the MX particles and the Z-phase. It was found that the optimal V and Nb contents for excellent high Cr steel of FBR grade are 0.2 mass% and <0.01 mass%, respectively, under FBR operating conditions.

For the early commercialization of fast breeder reactors (FBR), it is essential to enhance their safety, credibility and economic competitiveness with future light water reactors (LWRs) and other electric resources. One of the most practical concepts for achieving economic competitiveness is to reduce the amount of required materials by employing high chromium (Cr) ferritic steel as a main structural material, because this steel has excellent thermal properties and high-temperature strength.1) High Cr steels are used as the structural material in thermal power plants and so on2) because of their excellent thermal properties and high-temperature strength; however, degradation of long-term high-temperature creep strength and ductility has been reported for conventional high Cr steels.3,4,5,6) The structural material of FBRs must maintain its creep strength and creep fatigue strength at a maximum operating temperature of approximately 550°C throughout the lifetime of the plant (current designs are 60 years). Therefore, this study aimed to improve these properties by optimizing the use of addition elements in order to enable the use of high Cr steel as an FBR structural material.

To achieve excellent high-temperature strength, many types of strengthening elements have been added to conventional high Cr steels. However, the long-term efficiency and stability of such strengthening mechanisms under FBR conditions (550°C) have not been clarified yet, because the temperature condition of thermal power plants is greater than 600°C. The main strengthening mechanisms in heat-resistant steel are solid-solution strengthening and precipitation strengthening. In the solid-solution strengthening mechanism, Molybdenum (Mo) and Tungsten (W), which are the main solid-solution strengthening elements, are depleted from the matrix via precipitation and coarsening of the Laves phase (Fe2Mo, Fe2W) during creep and thermal aging.7) However, the Laves phase reduces the impact absorption energy during long-term usage of the materials.8,9,10) Thus, the solid-solution strengthening mechanism can affect long-term efficiency and stability of strengthening mechanisms under FBR conditions, and it is unclear whether the solid-solution strengthening mechanism can be effective for materials used in FBRs. Therefore, the long-term efficiency and stability of the solid-solution strengthening mechanism under FBR conditions has been investigated in order to determine the optimal content of Mo and W necessary for developing high Cr steel with stable characteristics of strength and ductility.11,12)

With respect to the precipitation strengthening mechanism, Vanadium (V) and Niobium (Nb) contribute to improvement in the high-temperature strength of high Cr steels by precipitating as carbides and/or nitrides, namely as fine MX particles (M denotes V and/or Nb. X denotes C and/or N.). Because the MX particles coarsen more slowly than other precipitates, they remain stable in the matrix for extended periods.13,14,15,16) However, it has been reported that the precipitation of Z-phases and the subsequent coarsening lead to the consumption of MX particles after long-term creep exposure at high temperatures in high Cr steels.13,17,18,19,20,21,22,23) Therefore, there is also concern regarding the long-term efficiency and stability of the precipitation strengthening. Previously, based on thermal aging tests using a series of trial preparatory products with different V and Nb contents as same as the materials of this study, it was clarified that the formation of Z-phases is influenced by the V and Nb contents.24)

Degradation of long-term high-temperature creep strength and microstructural stability in high Cr steels was reported.3,4,5,6) However, the individual effects of V and Nb contents on the degradation have not been investigated yet. Therefore, the relationship between the creep properties and the V and/or Nb contents was studied using the same materials with the previous study on the basis of creep test results after 500000 h at a maximum temperature of approximately 550°C, which is equivalent to FBR operating conditions. The cause of an abrupt decrease in the creep strength associated with the MX particles and Z-phases was also investigated. As a result, the optimal V and Nb contents for excellent high chromium steel of FBR grade were determined.

A total of eight types of steels were used in the current study. The chemical compositions of the steels are shown in Table 1. The steels were rolled to a thickness of 30 mm from a manufactured 150 kg ingot using vacuum melting. The optimum contents of V and Nb for obtaining the best creep strength in conventional high Cr steel are 0.20 and 0.05 mass%, respectively.25,26) In this study, considering the ductility that is required for FBR structural material, the contents of these elements were slightly reduced. Heat treatment of the steels included normalizing at 1060°C for 1 h and tempering at 760°C for 1 h.

| No. | C | Si | Mn | P | Cr | Mo | N | V | Nb |

|---|---|---|---|---|---|---|---|---|---|

| VN00 | 0.106 | <0.002 | 0.69 | 0.002 | 10.19 | 1.21 | 0.050 | – | – |

| VN01 | 0.109 | <0.002 | 0.68 | 0.002 | 10.15 | 1.16 | 0.052 | – | 0.010 |

| VN02 | 0.108 | 0.003 | 0.68 | 0.002 | 10.11 | 1.18 | 0.048 | – | 0.031 |

| VN03 | 0.108 | 0.003 | 0.68 | 0.002 | 10.16 | 1.18 | 0.049 | – | 0.051 |

| NV10 | 0.108 | <0.002 | 0.68 | 0.002 | 10.18 | 1.21 | 0.051 | 0.06 | – |

| VN20 | 0.108 | <0.002 | 0.69 | 0.002 | 10.19 | 1.19 | 0.049 | 0.12 | – |

| VN30 | 0.108 | <0.002 | 0.69 | 0.002 | 10.16 | 1.20 | 0.049 | 0.18 | – |

| VN22 | 0.105 | <0.002 | 0.69 | 0.002 | 10.10 | 1.21 | 0.047 | 0.12 | 0.032 |

Creep tests were conducted on the basis of Japanese Industrial Standard (JIS) Z2271 (1999). The creep test temperature was set at 600°C, which is 50°C higher than the maximum FBR operating temperature of approximately 550°C, in order to investigate the microstructural stability after long-term creep exposure at high temperature using temperature acceleration. A temperature of 600°C or greater is not desirable for evaluating the microstructural stability under FBR conditions, because the precipitation nose of the Laves phase is between 620°C and 670°C.27)

Metallurgical examination and quantitative analysis were conducted before and after the creep test using transmission electron microscopy (TEM) at 200 kV. Precipitates were observed using extracted replicas, and identification of the precipitates was conducted using electron diffraction patterns and the chemical compositions. Approximately 300 precipitates were analyzed around the prior-austenite grain boundary (PAGB) in each specimen.

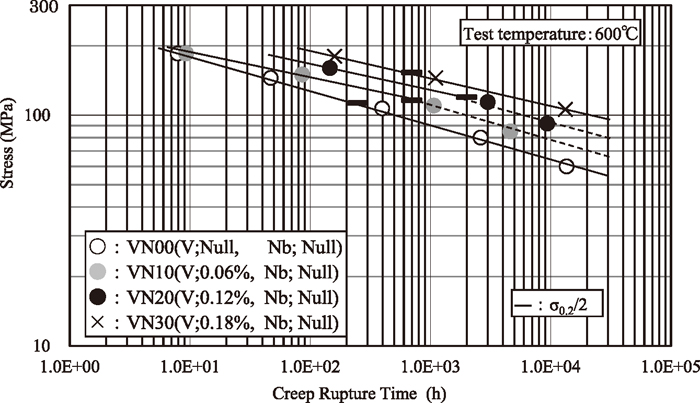

Figures 1, 2, and 3 show the creep rupture data at 600°C for trial preparatory products with different V and Nb concentrations. The influence of the Nb content on creep strength in V-free steels can be seen in Fig. 1. It was observed that the creep strength could be improved by addition of 0.01 mass% Nb. However, the effect of Nb on the creep strength appeared to level off at higher Nb concentrations. This result suggests that the number of fine Nb(C, N) particles that are precipitated during the tempering process does not change at Nb concentrations greater than 0.01 mass%, because the solubility limit of Nb in the steels is approximately 0.01 mass%.28) Therefore, Nb added at concentrations over 0.01 mass% does not contribute to creep strengthening of the steel. One half of the 0.2% proof stress value obtained from the tensile test at 600°C for each steel is also shown in Fig. 1. One half of the 0.2% proof stress (σ0.2) is equivalent to the proportional limit.29) In the low-stress region below the proportional limit (long-term region), the climbingmotion of the dislocation is the primary mechanism of creep deformation because diffusion is the predominant factor. In the high-stress region above the proportional limit (short-term region), creep deformation is promoted by plastic deformation.30) In this study, the one half of 0.2% proof stress value was used to split the regions on the basis of the creep deformation mechanism. Change of the slope of the relationship between the creep rupture time and stress in the long-term region from the short-term region(Degradation of long-term region creep strength) for VN00 (V: Null, Nb: Null) was not observed, whereas degradation of long-term region creep strength in Nb-containing steels, such as VN01 (V: Null, Nb: 0.01 mass%), VN02 (V: Null, Nb: 0.03 mass%) and VN03 (V: Null, Nb: 0.05 mass%), was detected.

Relationship between Nb content and creep strength.

The influence of the V content on the creep strength in Nb-free steels can be seen in Fig. 2. It was observed that the creep strength could be improved by the addition of V. Unlike the V-free steels, degradation of long-term region creep strength was not observed in the VN30 (V: 0.18 mass%, Nb: Null). Degradation of long-term region creep strength was observed in the VN10 (V: 0.06 mass%, Nb: Null), and small degradation of long-term region creep strength was observed in the VN20 (V: 0.12 mass%, Nb: Null). V(C, N) can be observed only in the steels which contain V more than 0.12 mass%.28) Therefore, the additive amount of V (precipitation of V(C, N)) contributes to the long-term stability of creep strength. It was confirmed that VN30, with 0.18 mass% V, had high long-term stability of creep strength.

Relationship between V content and creep strength.

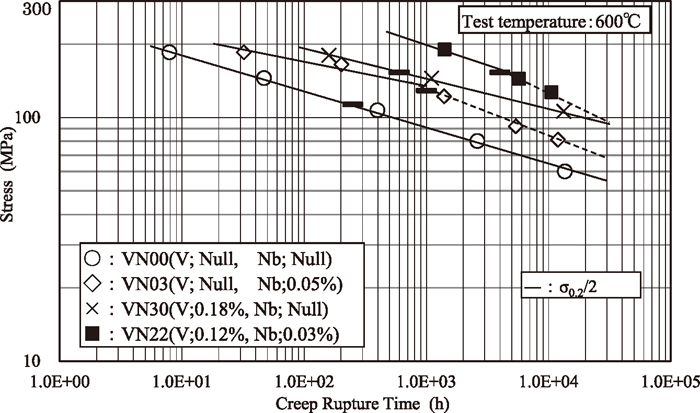

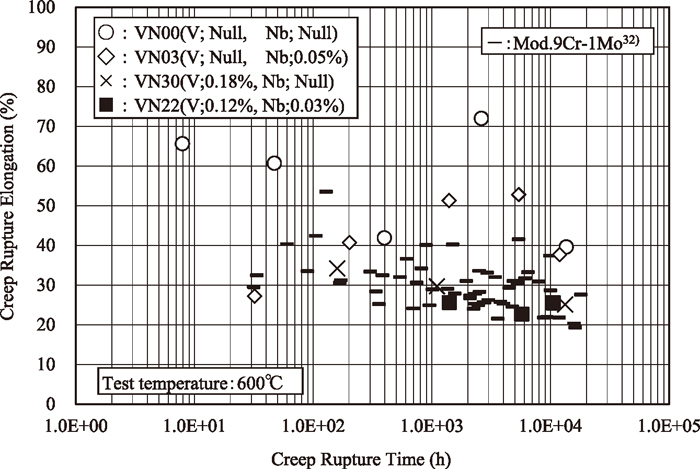

Results for VN00, VN03, VN30, and VN22 are shown in Fig. 3. It showed a comparison of the influence of the V and/or Nb contents on the creep strength. Although the V and Nb contents have different effects, the increase in creep strength due to V addition is larger than that obtained with Nb addition. In addition, the increase in creep strength with V addition is greatly enhanced by also adding Nb. Furthermore, degradation of the long-term region creep strength for the Nb-containing steel VN03 and VN22 was observed but not for the Nb-free steel VN00 and VN30. However, the creep strength is highest at 600°C for 10000 h using combined V and Nb addition.

Relationship between V and/or Nb contents and creep strength.

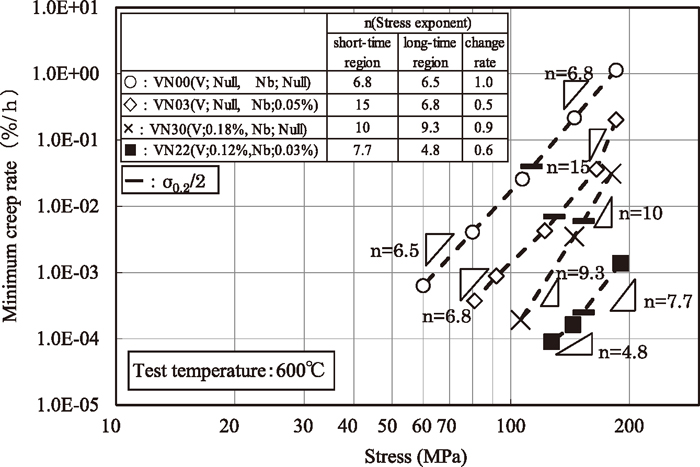

The minimum creep rate for VN00, VN03, VN30, and VN22 are plotted against stress in Fig. 4.

Relationship between V and/or Nb contents and minimum creep rate.

The rates are evaluated by the bilinear relationship; a short-term region is equivalent to the higher stress level over σ0.2/2 and a long-term region to lower stress level below σ0.2/2. The relationship between the minimum creep rate and stress is the same as the relationship between the creep rupture time and stress from points of views of V and Nb additions. The steel with added V and Nb has the lowest minimum creep rate at the same stress compared with the other steels. However, the stress exponent, n, of the minimum creep rate changes from the short-term region to the long-term region, and the value in the long-term region reaches a minimum of 4.8. For VN03, n is 15 in the short-term region and decreases to 6.8 in the long-term region. Notably, the change rate of the stress exponent for the Nb-containing steel is as large as that for the steel containing both V and Nb. On the other hand, the change rate of the stress exponent barely changes for VN00 and VN30. These results indicate that the steel with added V also has the highest long-term stability with respect to the minimum creep rate.

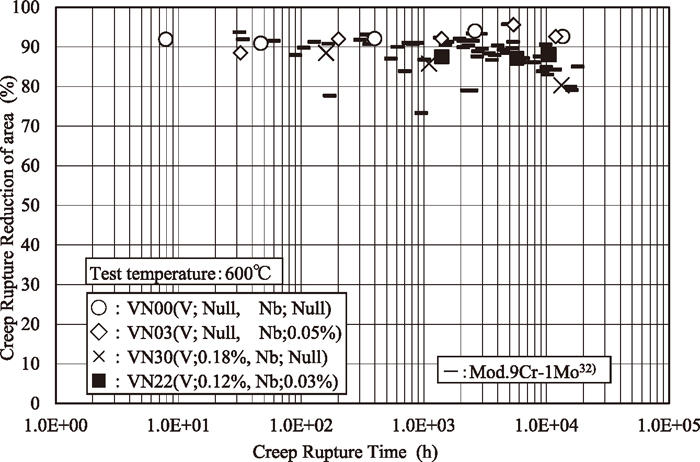

3.3. Effect of V and Nb Contents on Creep DuctilityIn addition to the creep properties, the creep fatigue performance of structural materials used in FBRs is important. Creep fatigue strength and creep ductility are related each other.31) Therefore, from the viewpoint of the long-term creep fatigue strength, a stable long-term creep fracture ductility is required. It has been reported that a significant drop in ductility appears predominantly as a reduction of area in creep, with reduction in the area decreasing from approximately 80% or more in the short-term region to less than 10% in the long-term region in some high Cr steels.6)Figure 5 shows the relationship between the reduction of area in creep and the creep rupture time, and Fig. 6 shows the relationship between the elongation at creep rupture and creep rupture time. Figures 5 and 6 also shows data of modified 9Cr-1Mo steel, which is to be used for the Japanese demonstration FBR.32) The creep ductility in low-strength VN00 and VN03 is higher compared with that of high-strength VN22 and VN30. In addition, for all steel specimens, the reduction of area in creep is over 80% and elongation at creep rupture is over 20%. The creep ductility in VN30, defined by reduction of area or elongation at creep rupture time as shown in Figs. 5 and 6, tends to decrease with increasing creep rupture time. Therefore, the trial preparatory products with different V and/or Nb contents have excellent creep ductility equal to that of modified 9Cr–1Mo steel. Based on these results, it was concluded that the V and/or Nb contents is reduced from that in modified 9Cr–1Mo steel, because creep ductility is an important parameter for structural materials used in FBRs. Hence, it can be presumed that VN22 and VN30 have excellent creep fatigue properties because they have high creep strength and excellent ductility.

Relationship between creep rupture time and reduction of aria in creep varying the additions of Nb and V contents.

Relationship between creep rupture time and elongation at creep rupture varying the additions of Nb and V contents.

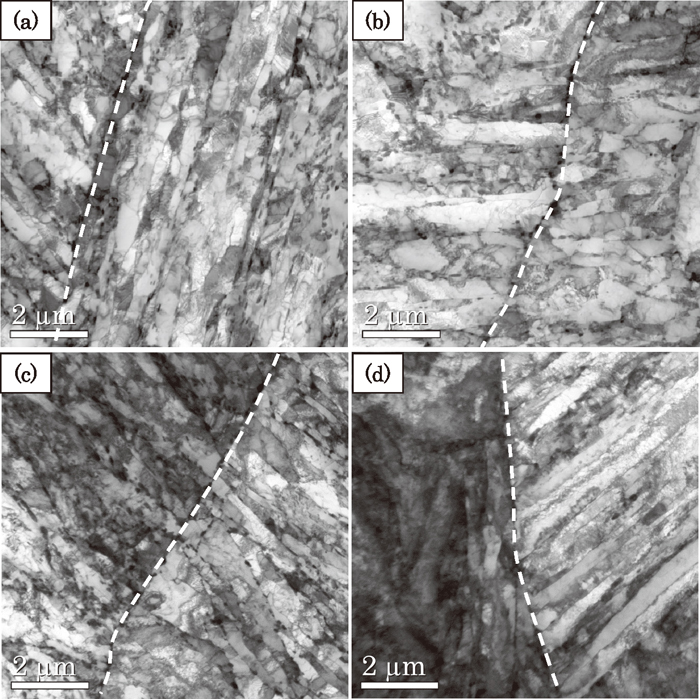

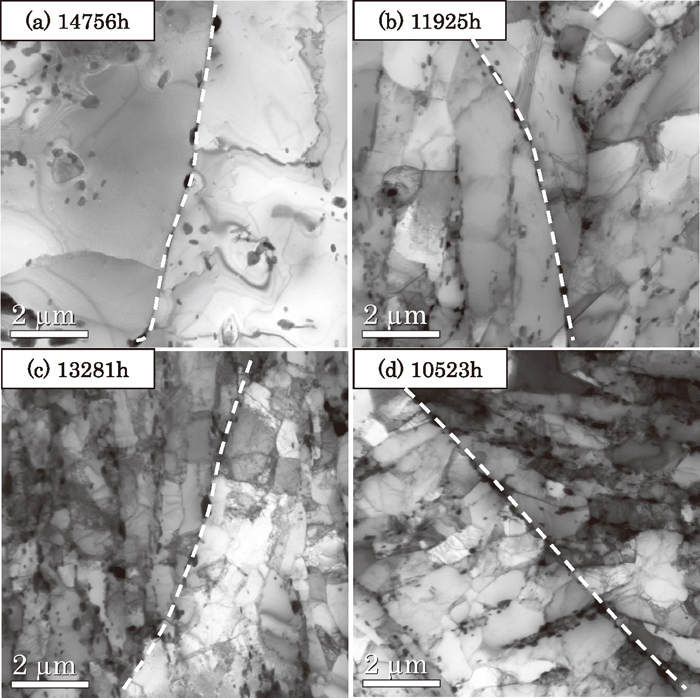

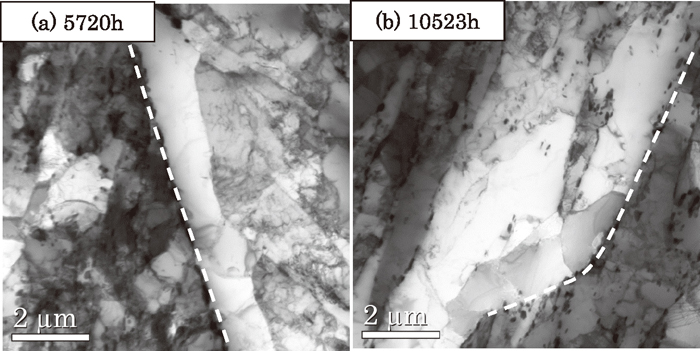

TEM micrographs of the virgin samples VN00, VN03, VN30, and VN22 are shown in Fig. 7. The virgin materials had fine subgrains and high dislocation densities, which is typical for martensitic structures. In addition, the V and/or Nb contents were observed not to affect the change of microstructure. TEM micrographs of the materials after the creep test at 600°C for approximately 10000 h can be seen in Fig. 8. In the sample VN00 with no V or Nb content (Fig. 8(a)), a remarkable growth of subgrain was observed in nearly all areas. This recovery of the martensitic structure indicates that the MX precipitates have a strong influence on the recovery of the microstructure. In sample VN03, which contains only Nb (Fig. 8(b)), the growth of subgrain was less than that in VN00, but greater than that in VN30 and VN22. Only a minor growth of subgrain was observed in VN30 and VN22, no significant difference was seen between these two materials (Figs. 8(c) and 8(d), respectively). However, preferential recovery around the PAGB was occasionally observed after creep in VN22, as can be seen in Fig. 9, but it was only observed under long-term region stress conditions, such as 144 MPa and 127 MPa as shown in Fig. 3. Kushima et al. reported that martensite recovery occurs preferentially near the PAGB after creep rupture in Gr.91.33) On the other hand, in VN30, homogeneous recovery and non-preferential recovery around the PAGB were observed after creep rupture.

TEM micrographs of the virgin materials of (a) VN00, (b) VN03, (c) VN30, and (d) VN22.

TEM micrographs of the crept materials of (a) VN00, (b) VN03, (c) VN30, and (d) VN22.

TEM micrographs of preferential recovery around the PAGB in the crept materials of VN22.

Results of the analyses of the precipitates of VN30, VN03, and VN22 around the PAGB before and after creep ruptures (VN30: 13281 h, VN03: 11925 h, VN22: 10523 h) are listed in Table 2. The analyses of the precipitates were conducted around the PAGB, because the preferential recovery of the microstructure was observed. In addition, transgranular precipitations were also analyzed, but any significant difference was not seen between around the PAGB and in the transgranular. Three types of precipitates can be observed before creep in the V-containing steel VN30, including V(C, N), (Fe, Cr)23C6, and Cr2(C, N). After creep rupture at 13281 h, (Fe, Cr)23C6 and Cr2(C, N) grew slightly and a few Laves phases could be observed. On the other hand, V(C, N) has high long-term stability because the mean diameter and density of V(C, N) did not change. It should be noted that the Laves phase is not listed in Table 2 because the Laves phase is barely observed in all steel samples. Generally, the Laves phase precipitates in high Cr steels after creep at 600°C.13) However, it has been reported that precipitation of the Laves phase is delayed in the long-term due to the reduction of the Si content.34,35) In this study, because oxidation resistance is required for FBR structural material, the content of Si was reduced to less than 0.002%.The low Si content is believed to be the reason why the Laves phase barely precipitated with creep in the steels.24)

| Virgin material | Creep ruptured at 600°C for 13281 h | |||||

|---|---|---|---|---|---|---|

| mean diameter (nm) | standard deviation | mean diameter (nm) | standard deviation | number of density (Crept/Virgin) | ||

| VN30 | (Fe, Cr)23C6 | 103 | 36.3 | 124 | 61.7 | 0.4 |

| Cr2(C, N) | 64 | 29 | 100 | 51.4 | 0.5 | |

| V(C, N) | 56 | 21.7 | 51 | 27.4 | 0.9 | |

| Z-phase | — | — | — | — | — | |

| Virgin material | Creep ruptured at 600°C for 11925 h | |||||

|---|---|---|---|---|---|---|

| mean diameter (nm) | standard deviation | mean diameter (nm) | standard deviation | number of density (Crept/Virgin) | ||

| VN03 | (Fe, Cr)23C6 | 108 | 40.5 | 137 | 60.2 | 0.5 |

| Cr2(C, N) | 80 | 41.5 | 316 | 117.7 | 0.1 | |

| Nb(C, N) | 35 | 11.4 | 39 | 10.3 | 0.2 | |

| Z-phase | — | — | 37 | 14.1 | — | |

| Virgin material | Creep ruptured at 600°C for 10523 h | |||||

|---|---|---|---|---|---|---|

| mean diameter (nm) | standard deviation | mean diameter (nm) | standard deviation | number of density (Crept/Virgin) | ||

| VN22 | (Fe, Cr)23C6 | 106 | 41.8 | 113 | 49.1 | 0.5 |

| Cr2(C, N) | 59 | 27.4 | 125 | 72.3 | 0.2 | |

| MX | 49 | 14.7 | 26 | 15.5 | 0.5 | |

| Z-phase | — | — | 48 | 30.3 | — | |

Three types of precipitates can be observed before creep in the Nb-containing VN03, including Nb(C, N), (Fe, Cr)23C6, and Cr2(C, N). Creep rupture at 11925 h, Nb(C, N), (Fe, Cr)23C6, Cr2(C, N), Laves phases, and Z-phases could be observed. (Fe, Cr)23C6 grew slightly, whereas Cr2(C, N) grew markedly. However, the mean diameter of Nb(C, N) did not change, and the density decreased to one fifth that of the virgin material.

Four types of precipitates can be observed before creep in the VN22 sample containing both V and Nb, including MX (V(C, N) and/or Nb(C, N)), (Fe, Cr)23C6, and Cr2(C, N). After creep rupture at 10523 h, MX, (Fe, Cr)23C6, Cr2(C, N), Laves phases, and Z-phases could be observed. (Fe, Cr)23C6 and Cr2(C, N) grew slightly and a few Laves phases precipitated, while precipitation of Z-phases and a decrease in number of MX particles were observed, as was the case for VN03. Based on extracted residue analysis, it was confirmed that most of the Nb content in the steels precipitated before creep.24) Therefore, precipitation of Z-phases that contain Nb must consume MX. Thus, it was concluded that the decrease in number of MX particles in VN03 and VN22 resulted from the precipitation of Z-phases. It has also been reported that MX decreases owing to the precipitation of Z-phases in other high Cr steels.13,34) No Z-phases were observed after creep in the Nb-free steel VN30, whereas they were detected in the Nb-containing steels VN03 and VN22. Moreover, some Z-phase precipitations that adjoined Nb(C, N) were observed, as shown in Fig. 10. Therefore, it can be concluded that precipitation of Z-phases and Nb(C, N) are closely related.

TEM micrographs of extraction replicas taken from the Z-phase (NbCrN) and Nb(C, N) after creep at 600°C for 11925 h in VN03.

The relationships between the microstructural changes and the long-term creep properties are shown in Fig. 11. The stress dependence of creep strength and minimum creep rate for the V-containing steel VN30 did not change throughout 10000 h at 600°C as shown in Figs. 3 and 4. In addition, the precipitate distribution, such as the mean diameter and density of V(C, N), barely changed and Z-phases did not precipitate. Furthermore, from the viewpoint of the microstructural changes, homogeneous recovery and no preferential recovery around the PAGB was observed after creep rupture. Therefore, it was determined that the precipitation strengthening mechanism for V addition has high long-term efficiency and stability. On the other hand, for VN03 and VN22, which contain Nb only and both V and Nb, respectively, degradation of the long-term region creep strength and a change in the stress exponent of minimum creep rate from the short-term region to the long-term region were observed. The differences both between VN30 and VN03 and between VN30 and VN22 are the Nb contents. Therefore, it can be concluded that Nb affects the long-term creep properties.

Schematic illustrations of relationship between changes in the microstructure and long-term creep properties.

First, the reason for the degradation of the long-term region creep strength of the Nb-containing steel VN03 was considered. Before creep test, the difference in the microstructures of VN03 and VN30 was the precipitation of Nb(C, N). After creep test, there were two differences; those are, a decrease in Nb(C, N) due to the precipitation of Z-phases and the recovery of the martensitic structure. The reason for the degradation of the long-term region creep strength in VN03 is not the recovery of the martensitic structure, because no preferential recovery around the PAGB was observed and the growth of subgrain was less than that in VN00, but greater than that in VN30. Therefore, it was concluded that the degradation of the long-term region creep strength in VN03 is due to the decrease in Nb(C, N) resulting from the precipitation of Z-phases.

Next, the reason for the degradation of the long-term region creep strength in the V- and Nb-containing steel VN22, which is similar to conventional high Cr steels, was considered. Once again, before creep test, the difference in the microstructures of VN22 and VN30 was the precipitation of Nb(C, N). After creep test, there are also two differences, including the decrease in MX due to precipitation of Z-phases and preferential recovery around the PAGB. As for VN03, it was concluded that degradation of the long-term region creep strength in VN22 is due to the decrease in MX resulting from the precipitation of Z-phases. In addition, it is believed that preferential recovery around the PAGB is also a factor, because it was only observed under long-term region conditions (Fig. 9). Therefore, the degradation of the long-term region creep strength of VN22 is greater than that of VN03 because VN22 has two degradation mechanisms: the decrease in MX due to the precipitation of Z-phases and preferential recovery around the PAGB.

Finally, the reason for the observation of preferential recovery around the PAGB only in the VN22 steel was considered. Preferential recovery around the PAGB was observed in VN22, which had precipitated Z-phases, but not in VN30, which did not have precipitated Z-phases. These results suggest that the precipitation of Z-phases is related to preferential recovery around the PAGB. In addition, Sawada et al. reported that preferential recovery around the PAGB results from a decrease in number of MX particles due to the precipitation of Z-phases.21,36) Moreover, it can be concluded that there is a close relationship between the precipitation of Z-phases and Nb(C, N), as mentioned above. Thus, it was concluded that the degradation of the long-term region creep strength has two causes: preferential recovery around the PAGB and a decrease in number of MX particles. Furthermore, both causes are related to the precipitation of Z-phases; that is, the degradation of the long-term region creep strength arises owing to or is accelerated by Nb addition. On the other hand, in VN03, which had precipitated Z-phases, preferential recovery around the PAGB was not observed. Martensite recovery was easy because there were few Nb(C, N) in VN03, and hence, homogenous recovery occurred.

FBR structural material must have creep properties for 500000 h at a maximum operating temperature of approximately 550°C. In this study, the creep test temperature was set at 600°C in order to estimate the creep properties for 500000 h at 550°C using temperature acceleration in the following equation.

The determination of constant C is important for time extrapolation using the Larson-Miller parameter (L.M.P.) method.37) The parameter is widely used to characterize the creep rupture behavior in the engeeering materials. For creep rupture curve formulation using the L.M.P. method, constant C is small for steels that experience degradation of the long-term region creep strength and is large for steels with creep strength that has long-term stability. Therefore, it was assumed that the value of C for VN22, which experiences degradation of the long-term region creep strength, would be small and that the value of C would be large for VN30, which has creep strength with long-term stability. For the time extrapolation in this study, a small value of constant C should give a conservative estimate. Therefore, the value of constant C for VN22 was applied to all of the steels. The chemical composition of VN22, which contains both V and Nb, is similar to that of conventional high Cr steels. Kimura et al. reported that constant C ranges from 20 to 36 for conventional high Cr steel that is similar to VN22.38) Therefore, a value of C = 20, which is the lower limit of constant C for similar steels, is appropriate for the conservative evaluation of the long-term creep strength based on time extrapolation.

4.2. Optimal Content for FBR Grade High Cr SteelAs mentioned above, the steel containing only V had the highest long-term stability from the viewpoint of the creep properties and the microstructural changes. Creep data were collected for the V-containing steel VN30 for 13281 h at 600°C, which is considered to be equivalent to that at 550°C for approximately 390000 h on the basis of the L.M.P. method (C = 20). The precipitation strengthening mechanism due to V addition is effective until the end of the life of an FBR plant, because 390000 h is approximately 80% of 500000 h, which is the expected life of an FBR plant. A high value was obtained for the creep ductility, which correlates to creep fatigue strength, through approximately 80% of the FBR plant life. Therefore, the V-containing steel is a candidate optimal high Cr steel for FBRs.

As mentioned above, in the steel containing both V and Nb, degradation of the long-term region creep strength was observed owing to preferential recovery around the PAGB and a decrease in the MX resulting from the precipitation of Z-phases. However, the creep strength of the VN22 steel containing V and Nb was the highest at 600°C for 10000 h. Creep data on this steel is available for 10523 h at 600°C, which is considered to be equivalent to 550°C for approximately 300000 h based on the L.M.P. method (C = 20). The precipitation strengthening mechanism due to V and Nb addition is also effective until the end of the expected life of an FBR plant, because 300000 h is approximately 60% of the 500000 h of FBR plant life. Moreover, from the viewpoint of the long-term creep fatigue strength, the long-term creep fracture ductility of the steel containing both V and Nb is more stable than the steel with only V. Therefore, the compound addition steel is also a candidate optimal high Cr steel for FBRs.

However, the addition of Nb above 0.01 mass% does not contribute to creep strengthening as shown in Fig. 1, and it is believed that there is a close relationship between the degradation of long-term region creep strength and Nb content. Therefore, the optimum concentration of Nb is less than 0.01 mass%. In addition, a higher creep strength was obtained with an increase in the V content in the V-containing steel, but a higher creep strength was not necessarily obtained with an increase in the V content of the steel containing both V and Nb.39) Thus, the optimum content for V is 0.2 mass% based on the creep data. Therefore, it was concluded that the optimum contents of V and Nb are 0.2 mass% and less than 0.01 mass%, respectively, on the basis of the creep strength and creep ductility at 550°C for 500000 h.

The relationship between the creep properties and V and/or Nb contents was investigated under FBR operating conditions, e.g. at 550°C for 500000 h. In addition, the relationship between the long-term creep properties and microstructural changes was investigated considering the MX particles and Z-phases. From the analyses results, the following conclusions were made:

(1) The V-containing steel had the highest long-term stability from the viewpoint of both the creep properties and microstructural changes, and thus, it is a candidate optimal high Cr steel for use in FBRs.

(2) The Nb-containing steel exhibited a remarkable drop in the creep rupture strength with decrease in stress due to decrease in Nb(C, N) resulting from the precipitation of Z-phases.

(3) The steel containing both V and Nb also exhibited a remarkable drop in the creep rupture strength with a decrease in stress due to decrease in number of MX particles resulting from the precipitation of Z-phases and preferential recovery around the PAGB. However, the creep strength for the steel containing both V and Nb was the highest under FBR operating conditions. Moreover, from the viewpoint of the long-term creep fatigue strength, the long-term creep fracture ductility was greater than that of the V-containing steel. Thus, the steel with added V and Nb is also a candidate optimal high Cr steel for use in FBRs.

(4) The optimum content of V and Nb are 0.2 mass% and <0.01 mass%, respectively, on the basis of the creep strength and creep fatigue strength at 550°C for 500000 h.