Abstract

In order to find out effect of operating factors on mixing pattern which affects liquid/liquid mass transfer rate drastically, cold model experiment was carried out with liquid paraffin or tetradecane as a dispersed phase and ion-exchanged water as a continuous phase in a mechanically stirred vessel. There exist three types of liquid/liquid mixing pattern in a mechanical agitation. I: region where each liquid phase separates and has no dispersion, II: region where vortex of dispersed phase (liquid/liquid interface) arrives at impeller position and its dispersion begins into continuous phase, III: region where gas/liquid interface as well as liquid/liquid one arrives at impeller position and dispersion occurs heavily. The transition of I–II accelerated along with the increases in rotation speed, ratio of dispersion phase volume to continuous one, density of dispersion phase, impeller diameter and vessel diameter, and the decrease in impeller depth. The transition of II–III accelerated along with the increases in rotation speed, density of dispersion phase and impeller diameter, and the decrease in impeller depth.

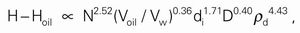

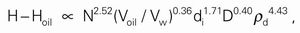

The multi regression equation for the transition of I–II is expressed as,

where H: distance between free surface of oil and upper part of impeller (mm), H

oil: bath depth of dispersed phase(mm), N: rotation speed(rpm), V

oil/V

w: ratio of dispersion phase volume to continuous one(–), d

i: impeller diameter(mm). D: vessel diameter(mm),

ρd: density of dispersion phase(kg/m

3), whereas that on transition of II–III is H ∝ N

2.18d

i1.96ρd1.33.