2019 年 59 巻 1 号 p. 39-45

2019 年 59 巻 1 号 p. 39-45

The effects of MgO, Al2O3 and basicity on the heat capacity and enthalpy change of CaO–SiO2–MgO–Al2O3 slags at 1673 K and 1773 K as well as the thermal stability were investigated. The enthalpy change at 1773 K increased with the addition of Al2O3 and MgO, but decreased with increasing basicity. Thus, the higher basicity helped to reduce the heat consumption and fuel ratio of blast furnace. With increasing MgO content, the fluctuations of the temperature and viscosity caused by the reduction of the slag heat quantity decreased. Furthermore, the slag will have a better fluidity and thermal stability when MgO content is greater than 8 mass%. The increase of Al2O3 content deteriorated the fluidity and thermal stability of the slag to some extent. When the reduction of the slag heat quantity was fixed, as the basicity increased, the slag temperature increased obviously and the viscosity significantly decreased. Also, the fluctuations of slag temperature and viscosity became less pronounced with increasing basicity. The increase of the basicity was favorable to improve the fluidity and thermal stability of the slag. For the slag system of this experiment, the suitable basicity was 1.10–1.15.

Viscosity is a key physicochemical property of the blast furnace slag,1,2) which plays an important role in the gas permeability, heat transfer, reduction of SiO2 and FeO.3,4,5) Currently, the related researches are generally focused on the effect of slag composition on the viscosity at a certain temperature. Kim et al.6) studied the effect of MgO on the viscosity of CaO-SiO2-MgO-20 mass%Al2O3 slag system. The results showed that the viscosity of the slag decreased with the addition of MgO while the decreasing trend seemed to be inhibited at the higher basicity. Mudersbach et al.7) found that the slag viscosity first decreased and then increased with the increase of MgO content at 1773 K and the basicity of 1.05. Park et al.8,9) revealed the amphoteric behavior of Al2O3 in slag and showed that the viscosity increased initially and then decreased with increasing Al2O3 content. Gao et al.10) reported the effect of basicity on the viscosity of CaO-SiO2-MgO-9 mass%Al2O3 slags and found that the higher basicity lowered the viscosity.

However, under the condition of varying heat quantity of the slag, the influence of the slag composition on the viscosity has yet to be fully understood. In practical terms, when the fuel ratios or other operation conditions change, it will inevitably cause fluctuations in slag heat quantity, thereby affecting the fluidity of the slag. Therefore, an in-depth understanding about the viscous behavior of the slag at various heat quantities is critical to optimize blast furnace operation.

In this study, based on the thermodynamic data of the slag compositions, we calculated the heat capacity and enthalpy change of the slag with different MgO contents, Al2O3 contents and basicities at 1673 K and 1773 K, and measured the viscosity at various heat decrement to analyze the effect of slag compositions on the thermal stability.

The detailed information of slag compositions is shown in Table 1, and the total mass of slags in the calculation and experiment is 120 g. According to the first law of thermodynamics, under constant pressure conditions, the enthalpy change of the slag at a certain temperature is equal to the heat absorbed by the slag. However, it should be pointed out that the slag usually has the heat of crystal transition, phase change heat and the chemical reaction heat in the melting process. To improve the accuracy of the calculations, on the basis of the formulas (1), (2), (3), (4), (5), (6), (7), (8), the calculations were performed using the FactSage thermodynamics software which has been widely used to predict thermodynamic data of multi-component slag systems.11,12,13,14)

| No. | Chemical Compositions (mass%) | Basicity (C/S) | Liquidus Temperature (K) | |||

|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | |||

| 1 | 44.18 | 36.82 | 4 | 15 | 1.20 | 1688 |

| 2 | 43.09 | 35.91 | 6 | 15 | 1.20 | 1703 |

| 3 | 42.00 | 35.00 | 8 | 15 | 1.20 | 1707 |

| 4 | 40.91 | 34.09 | 10 | 15 | 1.20 | 1702 |

| 5 | 39.82 | 33.18 | 12 | 15 | 1.20 | 1720 |

| 6 | 43.64 | 36.36 | 10 | 10 | 1.20 | 1751 |

| 7 | 42.55 | 35.45 | 10 | 12 | 1.20 | 1689 |

| 8 | 41.45 | 34.55 | 10 | 14 | 1.20 | 1696 |

| 9 | 40.36 | 33.64 | 10 | 16 | 1.20 | 1708 |

| 10 | 39.27 | 32.73 | 10 | 18 | 1.20 | 1724 |

| 11 | 37.50 | 37.50 | 10 | 15 | 1.00 | 1672 |

| 12 | 38.41 | 36.59 | 10 | 15 | 1.05 | 1683 |

| 13 | 39.29 | 35.71 | 10 | 15 | 1.10 | 1692 |

| 14 | 40.12 | 34.88 | 10 | 15 | 1.15 | 1698 |

| 15 | 40.91 | 34.09 | 10 | 15 | 1.20 | 1702 |

In the calculation process, the initial temperature and pressure are assumed to be 298 K and 101.325 kPa. First of all, the heat capacity and enthalpy change of the slag were calculated at 1673 K and 1773 K. Then, based on the average enthalpy changes of the slag with different MgO contents, Al2O3 contents and basicities at 1773 K, the average enthalpy changes were reduced by 10%, 5% and 2.5% successively and were taken as the heat input of the slag, and the corresponding equilibrium temperatures can be obtained. Wherein, the equilibrium temperature refers to the temperature at which the slag reaches thermal equilibrium under the given heat. As shown in Table 1, the liquidus temperatures of each group of slags can also be calculated.

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

Where, CpCaO (J/g·K), CpSiO2 (J/g·K), CpMgO (J/g·K) and CpAl2O3 (J/g·K) are the specific heat capacity of CaO, SiO2, MgO and Al2O3, respectively;15,16,17) Cpi (J/g·K) represents the specific heat capacity of slag component;

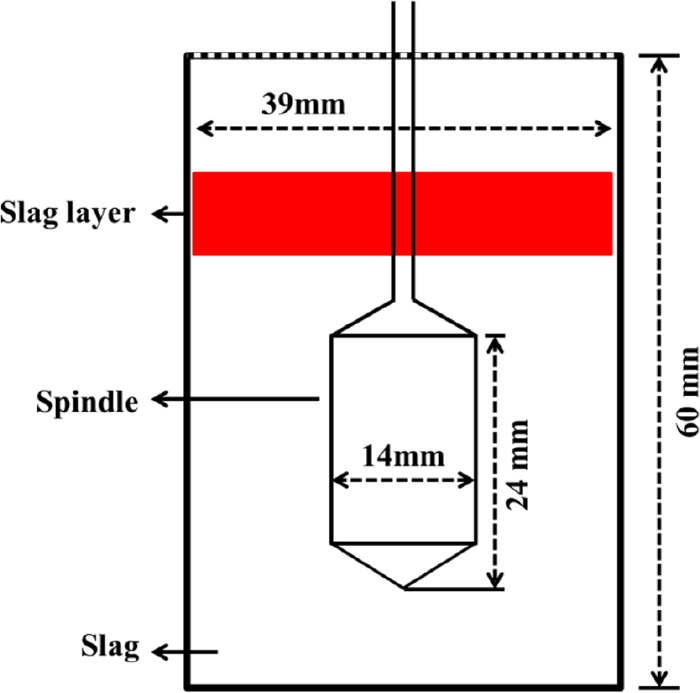

Slag samples were prepared using reagent grade chemicals of CaO, SiO2, MgO and Al2O3 in desired proportions. The reagents were baked at 1273 K for 6 hours before weighing. The chemical composition of the slag samples has been given in Table 1. Each group of slags were weighed 120 g precisely and then mixed in the agate mortar thoroughly. Molybdenum crucible (with inner diameter of 39 mm and height of 60 mm) and graphite crucible (with inner diameter of 40 mm and height of 80 mm) were used to hold slag samples. The mixtures were packed into Mo crucible which was coated with a graphite crucible in the experiment.

2.2.2. Apparatus and ProcedureThe viscosity measurement was carried out with a comprehensive tester for physical properties of melts (RTW-10 Type) using the typical rotating cylinder method. The comprehensive tester was connected with a digital viscometer which was developed by Northeastern University in China, and mainly consisted of a computer, viscometer, controller cabinet, and high temperature electric resistance furnace with six U-shaped MoSi2 heating elements. The schematic diagram of the experiment apparatus is shown in Fig. 1. Furnace tube (inner diameter 53 mm, height 630 mm) is made of high alumina corundum tube.

Experimental apparatus for the measurement of slag viscosity. (Online version in color.)

The slag sample was filled into a double crucible and placed within the constant hot zone of the furnace, which was measured using a PtRh30-PtRh6 thermocouple and controlled within ±2 K using a proportional-integral-derivative controller (PID). During the experiment, it was heated to 1273 K at a heating rate of 5 K/min and then heated to 1823 K with 3 K/min. The high-purity Ar (99.999%) with a flowrate of 1 L/min was used as protective gas throughout the experiment. Moreover, before the viscosity measurement, the viscometer was calibrated using castor oil with a known viscosity at room temperature.

The furnace was heated to 1823 K and sufficiently held for 3 hours before immersion of the rotating molybdenum spindle into the slag to achieve thermal equilibrium. It should be noted that in this experiment, the target temperature of the viscosity measurement is calculated by FactSage assuming the slag is in thermal equilibrium. However, the slag may also not be in full equilibrium when certain viscosity measurements are carried out. Therefore, in order to ensure that the melt is as uniform and stable as possible, all the measurements of viscosity were taken at each target temperature during a 5 K/min cooling cycle after 30 minutes of soaking. Additionally, it’s important to note that both the crucible and the spindle should be properly aligned along the axis of the viscometer because a slight deviation from the axis will cause obvious experimental error.

During the measurement, the variations of viscosity due to the different rotating speeds of 100, 150 and 200 rpm were less than 2%, confirming that the slags melts was Newtonian fluid. Then the average viscosity value at each target temperature was adopted as the final viscosity value. Moreover, in view of the higher rotating speed of the spindle, it is necessary to check whether the laminar flow is maintained during the viscosity measurements or not. According to Eq. (9), the Reynolds number of the system can be calculated.18,19) Combining the actual dimensions of the crucible and spindle in Fig. 2, Eq. (9) can be transformed into Eq. (13).

| (9) |

| (10) |

| (11) |

| (12) |

| (13) |

Schematic diagram of dimensions of the molybdenum spindle and crucible. (Online version in color.)

Where, Re is the Reynolds number; ω (rad/s) is the angular velocity of rotating; ri (m) refers to the radius of the molybdenum spindle; v (m2/s) is the kinematic viscosity the slag fluid; r (m) refers to the inner radius of the molybdenum crucible; d refers to the difference of radius between the crucible and spindle; n (r/min or rpm) is the rotating speed of the spindle; μ (Pa·s) is the viscosity of the slag fluid; ρ (kg/m3) is the slag density. After Couette,20) the critical Reynolds number is 1900. In this study, n is at 100–200 rpm; μ ranges from 0.35 to 0.90 Pa·s, and the slag density can be taken as 2.65×103 kg/m3 approximately.21) From these values, the Reynolds number was estimated to be less than 14. Therefore, the slag fluid in the measurement conformed to laminar flow characteristics.

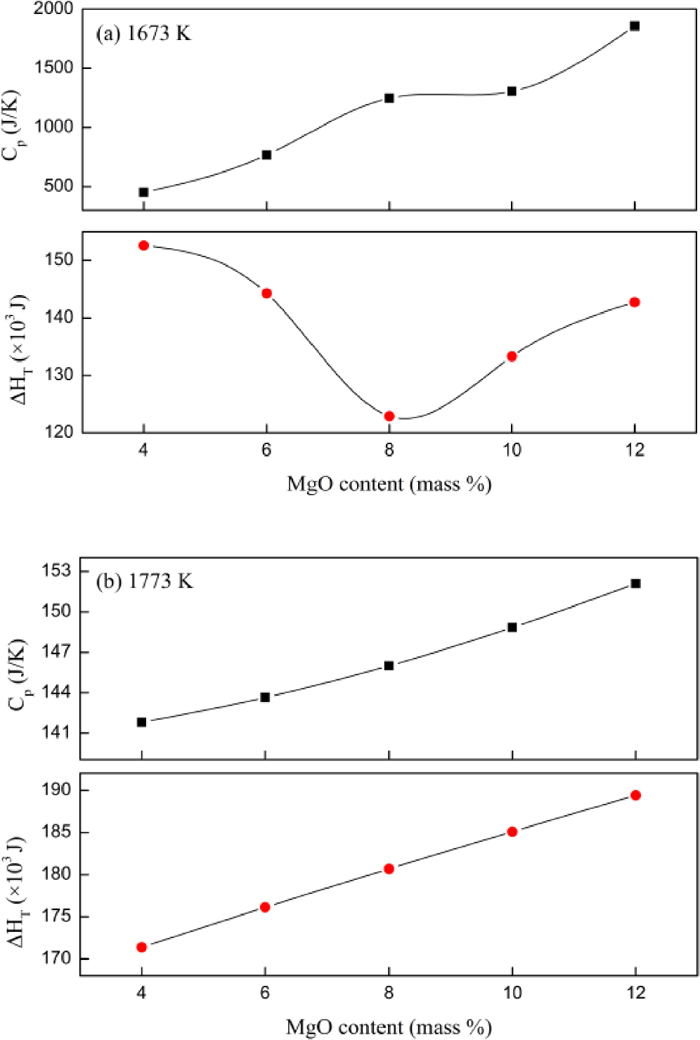

The effects of MgO on the heat capacity and enthalpy change of the slag at 1673 K and 1773 K are shown in Fig. 3. From Fig. 3(a), at 1673 K, the slag heat capacity increases with the increase of MgO content while the enthalpy change first decreases and then increases. The enthalpy change of the slag reaches a minimum at the MgO content of 8 mass%. As shown in Fig. 3(b), the heat capacity and enthalpy change of the slag almost linearly increase with increasing MgO content at 1773 K. By comparison, the enthalpy change of the slag at 1773 K is larger than that at 1673 K as expected. However, the heat capacity at 1773 K is significantly lower than that at 1673 K. Furthermore, in the view of absolute value, the heat capacity at 1673 K is obviously influenced by MgO content compared with that at 1773 K.

Effect of MgO on the heat capacity and enthalpy change of slags at (a) 1673 K and (b) 1773 K. (Online version in color.)

Combined with the liquidus temperature of the slag in Table 1, it can be seen that the liquidus temperatures of the slag with different compositions are between 1673 K and 1773 K. As a consequence, the heat capacity and enthalpy change of the slag with varying MgO contents show different trends at 1673 K and 1773 K respectively, which may be related to the type and quantity of solid phase compounds in the slag at 1673 K.

Figure 4 shows the slag temperature varies with MgO content when the heat quantity of the slag is reduced by 10%, 5%, and 2.5%, respectively. At the fixed heat decrement of the slag, the slag temperature increases as the MgO content increases from 4 mass% to 8 mass% and then decreases when the MgO content exceeds 8 mass%. In addition, it can be seen that with the addition of MgO, the fluctuation of slag temperature caused by different heat decrement becomes less pronounced gradually. But when the MgO content is more than 8 mass%, MgO additions seem to be less effcetive on the fluctuation of the slag temperature. From this point of view, the appropriate MgO content is 8 mass% or more for the slag system in the experiment.

Effect of MgO on the equilibrium temperature of slags at various heat decrement. (Online version in color.)

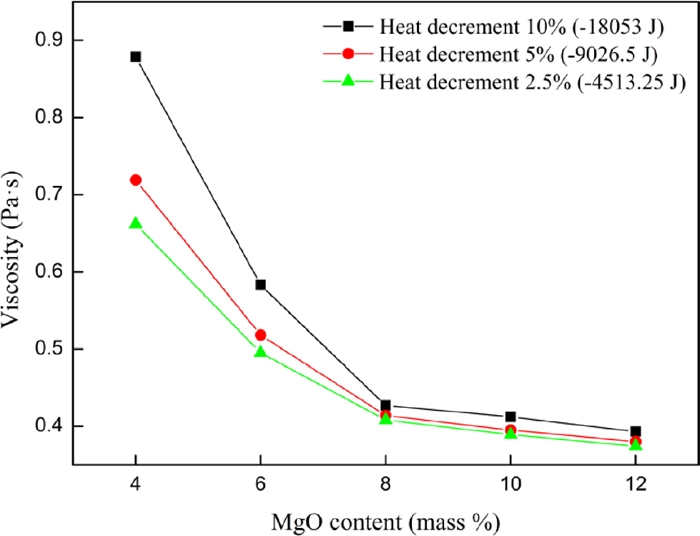

The viscosity of the slag varies with MgO content at different fixed heat decrement is described in Fig. 5. At the certain heat decrement, the viscosity decreases significantly with the increase of MgO content from 4 mass% to 8 mass%, while the decreasing trend is damped to some extent when the MgO content was greater than 8 mass%. This is because MgO is a basic oxide that can provide free oxygen ions and behaves as a network modifier in the slag.6,22) It can be speculated that as the MgO content increased from 4 mass% to 8 mass%, free oxygen ions (O2−) in the slag increased and reacted with bridge oxygen (O0), thereby changing the complex three-dimensional network structure of the silicate into discrete anionic groups containing simple chains or rings.23,24) Besides, as shown in Fig. 4, the slag temperature increases progressively as the MgO content increases from 4 mass% to 8 mass%. Accordingly, the sufficient excess thermal energy further promoted the depolymerization of network structure reducing the viscosity of the slag obviously. Nevertheless, when the content of MgO is more than 8 mass%, the decrease of the slag temperature restrained the decreasing trend of the viscosity to a certain degree. Meanwhile, the other possible reason was that the slag structure had been depolymerized considerably,23) and the depolymerization of the network structure would be weakened with the further addition of MgO. It should be pointed out that the conjecture needs to be approached with caution because of no solid evidence.

Effect of MgO on the viscosity of slags at various heat decrement. (Online version in color.)

In addition, it can be found that with the increase of MgO content, the viscosity fluctuation caused by the reduction of heat quantity of the slag gradually decreases, and the fluctuation begins to become inconspicuous when the MgO content is greater than 8 mass%. It suggests that the proper increase of MgO content not only helps to improve the fluidity of the slag, but also reduces the fluctuation of the viscosity and enhances the thermal stability of the slag. Therefore, the suitable MgO content for this experimental slag system is 8 mass%.

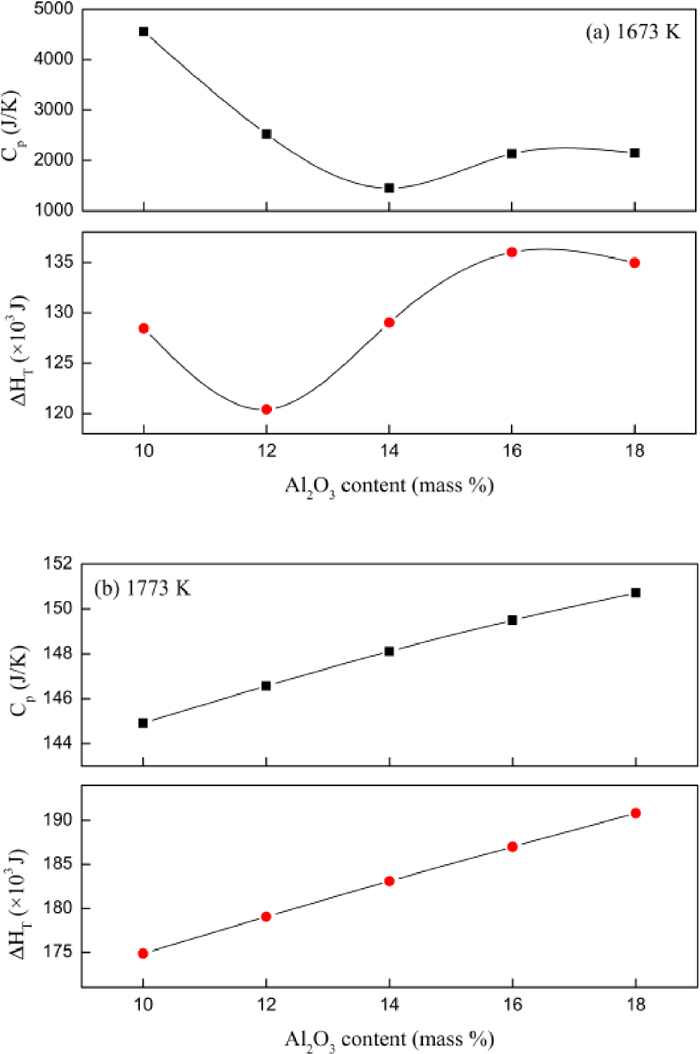

3.2. Effect of Al2O3 on the Heat Capacity, Enthalpy Change and Viscosity of the SlagFigure 6 shows the heat capacity and enthalpy change varies with Al2O3 content at 1673 K and 1773 K. At 1673 K, with increasing Al2O3 content, the change of heat capacity and enthalpy change basically tend to decrease first and then increase, and then decrease again. In contrast, the heat capacity and enthalpy change increase approximately linearly with increasing Al2O3 content at 1773 K. What’s more, it can be found that the heat capacity of the slag at 1673 K is obviously greater than that at 1773 K, and the former seems to be more sensitive to the Al2O3 content than the latter. Similar to the discussion in Section 3.1, this difference may be related to the solid phase compounds present in the slag at 1673 K. Considering that the temperature of the final slag is usually about 1773 K,25,26) and thus the increase of Al2O3 content will lead to the increase of heat consumption of blast furnace. On the other hand, when the Al2O3 content of the slag increases due to the increasing use of low-grade ores or pulverized coal injection,6,27) the fuel ratio should be appropriately increased to maintain the temperature and fluidity of the slag.

Effect of Al2O3 on the heat capacity and enthalpy change of slags at (a) 1673 K and (b) 1773 K. (Online version in color.)

The slag temperature varies with Al2O3 content at different heat decrement is provided in Fig. 7. It may be noted that the slag temperature rises first then decreases, and then rises again with the increase of Al2O3 content. Meanwhile, as expected, the greater heat decrement results in the lower the slag temperature. Furthermore, with the increase of Al2O3 content, the fluctuation of the slag temperature caused by the reduction of heat quantity tends to be more obvious. Hence, the higher content of Al2O3 will be unfavorable to maintain the stability of slag temperature, especially when the furnace condition fluctuates. However, when Al2O3 content lies in 10 mass% to 12 mass%, the fluctuation of the slag temperature is relatively not apparent.

Effect of Al2O3 on the equilibrium temperature of slags at various heat decrement. (Online version in color.)

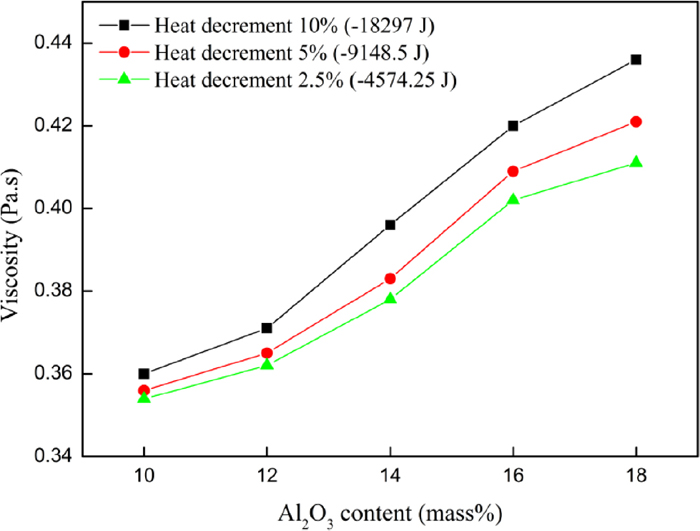

Figure 8 shows the variation of slag viscosity with Al2O3 content at different heat decrement. At a certain heat decrement, the slag viscosity still increases with Al2O3 additions despite the change of the slag temperature. This is basically consistent with previous studies at constant temperature,2,28,29) although the composition and temperature of the slag are different. This can be understood from the relationship between slag structure and viscosity. As we know, Al2O3 is a typical amphoteric oxide, and it behaves as an acidic oxide and acts as a network former when the molar ratio of Al2O3 to basic oxides is less than unity.8,9,30,31) Consequently, in the present slag system, the Al3+ ions would exist as a form of the [AlO4]-tetrahedral incorporated into the [SiO4]-tetrahedral units.8) Moreover, Al3+ cations in the tetrahedral configuration require charge-balancing cations due to the different valence states of Al3+ and Si4+, and the cations such as Ca2+ and Mg2+ are needed to coordinate with [AlO4]-tetrahedral to achieve charge balance.32,33) Also, the charge-balancing cations are constrained near aluminates and have less effect on decreasing viscosity. Simultaneously, [AlO4]-tetrahedral tends to be surrounded by [SiO4]-tetrahedral and forms a more complex network structure of aluminosilicate melts.34,35) As a result, the increase of Al2O3 content shows an increasing trend in viscosity.

Effect of Al2O3 on the viscosity of slags at various heat decrement. (Online version in color.)

The variations of the heat capacity and enthalpy change with the basicity at 1673 K and 1773 K are illustrated in Fig. 9. With the increase of the basicity, the heat capacity increases first and then decreases at 1673 K, while increases gradually at 1773 K. Interestingly, compared to the variation of the heat capacity at 1673 K, the effect of basicity on the heat capacity at 1773 K can be almost negligible. At 1673 K and 1773 K, the enthalpy change of the slag decreases with increasing basicity. In this sense, the proper increase of the basicity is beneficial to reduce the heat consumption of blast furnace and thus lowers the fuel ratio.

Effect of basicity on the heat capacity and enthalpy change of slags at (a) 1673 K and (b) 1773 K. (Online version in color.)

Additionally, by comparison with Figs. 3 and 6, it can be speculated that below the liquidus temperature, the heat capacity and enthalpy change have no obvious consistent law with the slag composition, but they vary approximately linearly with slag composition when the temperature is higher than the liquidus temperature.

Figure 10 shows the slag temperature varies with the basicity when heat quantity of the slag is reduced by 10%, 5% and 2.5% respectively. The slag temperature increases clearly with increasing basicity at the fixed heat decrement. What’s more, with the increase of the basicity, the temperature fluctuation resulted from the reduction of heat quantity of the slag tends to be less obvious. In particular when the basicity is greater than 1.10, the increase and fluctuation of temperature begins to become less distinct with the further increasing basicity. As a consequence, for the current slag system, the slag will have a good ability to resist temperature fluctuation when the basicity is more than 1.10.

Effect of basicity on the equilibrium temperature of slags at various heat decrement. (Online version in color.)

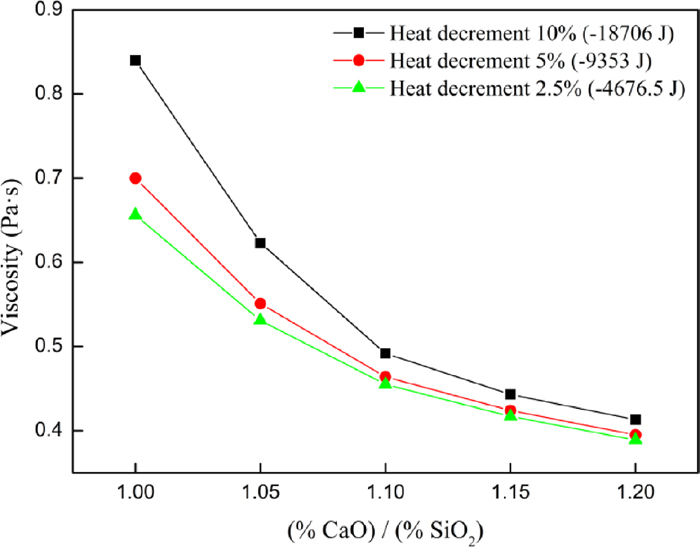

The variation of the slag viscosity with basicity at different heat decrement is depicted in Fig. 11. When the reduction of heat quantity is constant, the slag viscosity decreases appreciably with the increase of the basicity. In addition, it can be found that the fluctuation of the viscosity decreases with increasing basicity. This is mainly because CaO is a basic oxide and provides free oxygen ions.27,36) As the basicity of the slag increases, free oxygen ions (O2−) produced by the dissociation of CaO increase and react with the bridge oxygen (O0) to depolymerize the complex network structure of silicate. With the exception of the increasing basicity itself, as shown in Fig. 10, the attendant slag temperature rises obviously, thereby increasing the excess thermal energy of the slag.37,38) As a result, the viscosity of the slag is significantly reduced under the joint action of chemical and thermal depolymerization of the network structure. Therefore, one can see that the increase of the basicity is favorable to improve the fluidity and thermal stability of the slag. Moreover, as the basicity further increases, the network structure may have been largely depolymerized into the simpler polymer type, and the effect of depolymerization by free oxygen ions (O2−) on viscosity is limited relatively.2,4,6) Hence, both the viscosity and the fluctuation of the slag become relatively insignificant at this time. If the cost factor was taken into account extra, it appears that the suitable basicity for the slag system in the experiment is 1.10–1.15.

Effect of basicity on the viscosity of slags at various heat decrement. (Online version in color.)

In the present work, FactSage thermodynamic software was applied to calculate the heat capacity and enthalpy change of the CaO–SiO2–MgO–Al2O3 slags at 1673 K and 1773 K. The slag temperatures were also calculated when the heat quantity of the slag at 1773 K decreased by 10%, 5% and 2.5% successively, and then the viscosities at corresponding temperatures were measured. The key findings of this study are summarized as follows:

(1) There is no obvious consistent law of the heat capacity and enthalpy change that vary with slag composition at 1673 K, while the heat capacity and enthalpy change vary approximately linearly with the slag composition at 1773 K. Meanwhile, the enthalpy change of the slag increases with increasing Al2O3 and MgO content, and decreases with increasing basicity. Therefore, a proper increase in basicity contributes to lowering the heat consumption of the blast furnace and the fuel ratio.

(2) When the reduction of heat quantity is constant, with the addition of MgO, slag temperature increases first and then slightly decreases while slag viscosity decreases appreciably. Furthermore, as the MgO content increases, the fluctuations of the temperature and viscosity due to the reduction of heat quantity decrease thereby improving the thermal stability of the slag. The slag system in the experiment will have a better fluidity and thermal stability when the MgO content is more than 8 mass%.

(3) With Al2O3 additions, the slag temperature rises first and decreases subsequently and then increases again, while the viscosity increases gradually. Simultaneously, the fluctuations of temperature and viscosity become relatively pronounced. The addition of Al2O3 will increase the viscosity and deteriorate the thermal stability of the slag to some extent.

(4) As the basicity increase, the slag temperature increases significantly while the viscosity decreases clearly at the fixed heat decrement. Besides, the fluctuations of the temperature and viscosity decrease. Thus the higher basicity helps to improve the fluidity and thermal stability. For the current slag system, the appropriate basicity should be 1.10–1.15.

This work was financially supported by the National Science Foundation for Young Scientists of China (51704019).