2021 Volume 61 Issue 2 Pages 591-598

2021 Volume 61 Issue 2 Pages 591-598

To develop ultrahigh-strength steels for automotive impact safety parts, the effects of the microstructure and nitrogen content on the fatigue properties of ultrahigh-strength low alloy transformation-induced plasticity (TRIP)-aided steels with martensite (TM), bainitic ferrite-martensite (TBM), and bainitic ferrite (TBF) matrices were investigated. Compared to TBF steels, both the TM and TBM steels achieved high tensile strength, of more than 980 MPa, and excellent fatigue properties. This results from the suppression of crack propagation due to the effective TRIP of the relatively stable interlath retained austenite and the increase in tensile and yield strengths attributed to the low isothermal transformation treatment. The fatigue strengths of the ultrahigh-strength low alloy TRIP-aided steels were slightly increased by the addition of 100 ppm of nitrogen. The increase in fatigue strength of TM, TBM, and TBF steels with 100 ppm of nitrogen was caused by the fine and uniform martensite and bainitic ferrite matrices and retained austenite, along with the increase in carbon concentration in the retained austenite due to the precipitation of AlN.

High-strength steel sheets, of 980 and 1180 MPa grades, which are referred to as ultrahigh-strength steels, have been positively applied to automobile structural parts because of the reduction in weight and improvement in impact safety of the vehicles. The conventional ultrahigh-strength steel sheets, with tensile strength of up to 1180 MPa, have been applied to automotive structural parts after press forming. However, increasing tensile strength over 980 MPa in the steels decreases not only press formabilities but also impact, fatigue properties and delayed fracture resistance. It is expected that the application of ultrahigh-strength low alloy transformation-induced plasticity (TRIP)1)-aided steels with bainitic ferrite matrix (TBF steels)2,3,4,5) will solve these problems. Moreover, TRIP-aided martensitic (TM) steels,6,7,8,9) and TRIP-aided bainitic ferrite-martensite (TBM) steels10,11) have been developed to improve the tensile strength in comparison with TBF steels.

The simultaneous improvement in strength and corrosion resistance can be achieved by adding nitrogen to the austenitic steels12,13,14,15) because of the solid solution effects and the precipitation of nitride. Thus, it is expected that the addition of nitrogen to TM, TBM, and TBF steels will improve their strength and corrosion resistance. Besides, the addition of nitrogen may improve their fatigue strength because the fatigue strength of metals,16) including TRIP-aided steels,9,17) increases with increasing tensile strength.

In this study, the effects of the matrix structure and nitrogen content on the fatigue properties of ultrahigh-strength low alloy TRIP-aided steels were investigated to develop advanced high-strength steels for automotive structural parts.

Three types of cold rolled sheets, each of 1.2 mm in thickness and with the chemical composition presented in Table 1, were used in this study. Various nitrogen contents, of approximately 0, 100, and 200 mass ppm (hereafter ppm), were utilized in the steels, and the same amount of carbon content was removed to keep the sum of carbon and nitrogen contents constant (C + N = 0.2 mass%). The steels containing 0, 100, and 200 ppm of nitrogen were named as A, B, and C, respectively. The martensite-start temperature (MS),18) calculated by the following Eq. (1), is also listed in Table 1.

| (1) |

| Steel | C | Si | Mn | Al | Nb | N | MS |

|---|---|---|---|---|---|---|---|

| A | 0.20 | 1.00 | 1.50 | 0.48 | 0.049 | 0.0009 | 434 |

| B | 0.187 | 1.01 | 1.50 | 0.48 | 0.050 | 0.0106 | 438 |

| C | 0.176 | 1.04 | 1.50 | 0.53 | 0.052 | 0.0188 | 444 |

MS: martensite start temperature (°C)

First, hot rolling from 30 mm to 3.2 mm followed by cold rolling to 1.2 mm thickness was conducted to the steels, as shown in Fig. 1(a). Then, the tensile and fatigue specimens were cut from the rolled sheets by laser processing. The sheet specimens were heat-treated to produce ultrahigh-strength TRIP-aided steels (Fig. 1(b)). The TM steels were produced by annealing at 950°C for 1200 s and isothermal treatment at 250°C for 1000 s in salt baths. To produce the TBM and TBF steels, annealing at 950°C for 1200 s and isothermal treatment at 350 and 450°C for 1000 s in the salt baths were conducted, respectively.

(a) Hot and cold rolling processes and (b) annealing and isothermal transformation treatment processes of ultrahigh-strength low alloy TRIP-aided steels.

The microstructure of the steels was observed by scanning electron microscope (SEM)–electron backscatter diffraction (EBSD) measurements. The sample was mounted in an acryl polymer and ground using waterproof papers of #320, #600, #1200, and #2000 grids, followed by polishing with 3 and 1 μm single crystal diamond slurries, 0.3 and 0.05 μm alumina suspensions, and 0.04 μm colloidal silica for 30 min each. The EBSD analyses were conducted in an area of 40 μm × 40 μm with a beam step size of 0.2 μm operated at an acceleration voltage of 15 kV.

The volume fraction of the retained austenite (fγ) was obtained by the integrated intensities of diffraction peaks of (200)α, (211)α, (200)γ, (220)γ, and (311)γ measured by Cu-Kα radiation.19) The carbon concentration in the retained austenite (Cγ) was estimated by Eq. (2)20) using a lattice parameter (aγ (×10−10 m)) measured from the (200)γ, (220)γ, and (311)γ diffraction peaks of Cu-Kα radiation.

| (2) |

Tensile tests were carried out on a servohydraulic testing system (8872, Instron Corporation, High Wycombe, UK) at a crosshead speed of 1 mm/min (i.e., strain rate of 8.33 × 10−4 s−1) at 25°C using a tensile specimen with the gauge length of 15 mm, width of 6 mm, and thickness of 1.2 mm, as shown in Fig. 2(a).

Dimensions of (a) tensile and (b) fatigue specimens. The unit in these samples are in mm.

Load-controlled fatigue tests were conducted on a servohydraulic testing system (8872, Instron Corporation, High Wycombe, UK) with a sinusoidal waveform of 10 Hz at a stress ratio of 0.1 at 25°C using a fatigue specimen of 5 mm in width at notch root, 2.5 mm in radius of notch root, and 1.2 mm in thickness (Fig. 2(b)). The stress concentration factor at the notch tip was 1.6. The fatigue specimens were polished with waterproof papers #320 and #600 before the fatigue tests. The fatigue limit in this study was defined as the stress amplitude (Δσ = (σmax − σmin)/2) at which no failure occurred until 1 × 107 cycles. The net stress was adopted to evaluate the fatigue properties in this study.

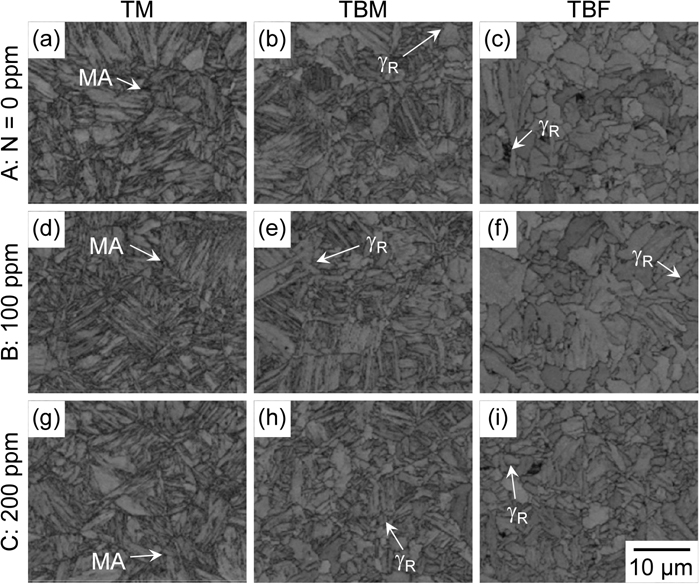

Figure 3 shows band contrast maps of the TRIP-aided steels analyzed by EBSD. The TM, TBM, and TBF steels exhibited a uniform and fine lath martensite matrix, bainitic ferrite-martensite matrices, and a uniform bainitic ferrite matrix, respectively. The retained austenite, of filmy type, was located at the lath boundaries in the TM and TBM steels. In addition, the martensite–austenite (MA) constituent, which consists of hard and fine martensite and fine retained austenite, existed at the prior austenite, packet, and block boundaries in the TM steels. The addition of nitrogen refined the structure of the lath matrices in all the TRIP-aided steels, and the retained austenite was changed from a filmy to blocky type.

Microstructures of (a, d, g) TM, (b, e, h) TBM and (c, f, i) TBF steels added nitrogen of (a, b, c) 0 ppm, (d, e, f) 100 ppm and (g, h, i) 200 ppm. γR and MA represent retained austenite and martensite-austenite constituent, respectively.

Figure 4 shows the weight fraction of NbC and AlN at equilibrium in the chemical component systems of steels A (N = 0 ppm), B (100 ppm), and C (200 ppm) calculated by Thermo Calc. NbC of 0.06 wt% was exhibited at a temperature between 200 and 900°C in all steels. Moreover, 0.03 wt% and 0.06 wt% of AlN was precipitated in steel B, with 100 ppm of nitrogen, and steel C, with 200 ppm of nitrogen, respectively. The inverse pole figures and phase maps of the AlN precipitated in the TM steels are shown in Fig. 5. The precipitation of AlN was not confirmed in steel A, whereas AlN with an approximate size of 10 μm was observed in steel B. In steel C, coarse AlN, with a size of approximately 25 μm in the rolling direction, was observed.

Variations in weight fraction of NbC and AlN at equilibrium in chemical component systems as a function of temperature calculated by Thermo Calc in steels (a) A, (b) B and (c) C.

(a, b, c) Inverse pole (IPF) figure and (d, e, f) phase maps of steels (a, d) A, (b, e) B and (c, f) C. ND, RD and TD represent normal direction, rolling direction and transverse direction, respectively. (Online version in color.)

Table 2 lists the tensile properties and retained austenite characteristics of the TRIP-aided steels. The TM steels exhibited a tensile strength (TS) of 1370 MPa grade and total elongation (TEl) of 13.8%–15.1%. In TBM steels, TS of 1180 MPa grade and TEl of 11.7%–16.1% were obtained. Moreover, the TS and TEl of the TBF steels were 980 MPa grade and 23.5%–25.1%, respectively. The addition of nitrogen slightly increased the TS, whereas TEl was hardly altered. The volume fraction of the retained austenite (fγ0) and the carbon concentration (Cγ0) of the TM steels were 3.0–3.2 vol% and 0.62–0.85 mass%, respectively. In the TBM steels, fγ0 of 3.8–4.7 vol% and Cγ0 of 1.18–1.41 mass% were obtained. The TBF steels exhibited fγ0 of 2.7–4.2 vol% and Cγ0 of 0.74–0.93 mass%. The fγ0 and the Cγ0 increased due to the nitrogen addition of 100 ppm in the three types of the ultrahigh-strength TRIP-aided steels, whereas the Cγ0 of the TBM and TBF steels decreased with the addition of 200 ppm of nitrogen.

| Steel | fγ0 | Cγ0 | YS | TS | UEl | TEl | σW | |

|---|---|---|---|---|---|---|---|---|

| A | TM | 3.0 | 0.62 | 1048 | 1390 | 5.4 | 14.2 | 270 |

| TBM | 3.8 | 1.37 | 1031 | 1140 | 4.0 | 11.7 | 261 | |

| TBF | 3.3 | 0.82 | 677 | 849 | 13.2 | 25.0 | 252 | |

| B | TM | 3.0 | 0.63 | 994 | 1395 | 6.2 | 13.8 | 243 |

| TBM | 3.9 | 1.41 | 860 | 1181 | 5.5 | 16.1 | 270 | |

| TBF | 2.7 | 0.93 | 692 | 849 | 12.0 | 25.1 | 252 | |

| C | TM | 3.2 | 0.85 | 1101 | 1401 | 6.3 | 15.1 | 234 |

| TBM | 4.7 | 1.18 | 930 | 1103 | 4.6 | 12.3 | 243 | |

| TBF | 4.2 | 0.74 | 663 | 855 | 13.4 | 23.5 | 234 |

fγ0 (vol%): initial volume fraction of retained austenite,

Cγ0 (mass%): initial carbon concentration in retained austenite.

TS (MPa): tensile strength, YS (MPa): yield strength,

TEl (%): total elongation, UEl (%): uniform elongation

σW (MPa): fatigue limit

Figure 6 shows the relationship between stress amplitude (Δσ = (σmax − σmin)/2) and number of cycles to failure (N) in the ultrahigh-strength TRIP-aided steels. The variation in fatigue limit as a function of tensile strength (TS) in the ultrahigh-strength TRIP-aided steels is shown in Fig. 7 and Table 2. The fatigue limits of the TM and the TBM steels were higher than that of the TBF steels regardless of the nitrogen contents (Figs. 6, 7). The addition of 100 ppm nitrogen increased the fatigue limit, whereas the fatigue limit was decreased by the addition of 200 ppm nitrogen in all the types of TRIP-aided steels (Fig. 7). Figure 8 shows fracture surfaces at the crack initiation regions, which correspond to the notch root in the TRIP-aided steels. The fracture surfaces revealed that the fatigue crack initiated at the inclusion located near the notch root. Particularly, steels B with 100 ppm nitrogen and C with 200 ppm nitrogen exhibited a large size inclusion at the notch root in comparison with steel A, which was the base steel. It is noted that the fracture surfaces at the fatigue crack propagation region exhibited the typical fatigue fracture morphology in the TRIP-aided steels.

S–N curves of TM, TBM and TBF steels of steels (a) A, (b) B and (c) C. (Online version in color.)

Variations in fatigue limit as a function of tensile strength in ultrahigh-strength low alloy TRIP-aided steels. (Online version in color.)

Fracture surfaces of (a, d, g) TM, (b, e, h) TBM and (c, f, i) TBF steels of steels (a, b, c) A, (d, e, f) B and (g, h, i) C. The white arrows represent inclusions.

Figure 9 shows SEM images of the fatigue surface cracks in steel A. To observe the main fatigue surface cracks, the fatigue tests were stopped at N = 33897 cycles for the TM steel, N = 26213 cycles for the TBM steel and N = 16416 cycles for the TBF steel. Regardless of the matrix types of the TRIP-aided steels, the crack propagated at the lath, block, and packet boundaries. In the TM steel, the crack propagated accompanied by a small amount of slip band at the vicinity of the crack tip. In the TBM steel, the propagation of the crack was accompanied by the formation of a slip band at the bainitic ferrite matrix. On the other hand, the slip band around the crack tip in the TBF steel was small compared with that in the TM and TBM steels. It is noted that the crack propagation behavior of steels B and C had a tendency similar to that of steel A, even though nitrogen was added to steels B and C.

Scanning electron micrographs of (a, b, c) crack path and (d, e, f) crack tip of (a, d) TM (Δσ = 400 MPa, N = 33897 cycles), (b, e) TBM (Δσ = 400 MPa, N = 26213 cycles) and (c, f) TBF steels (Δσ = 400 MPa, N = 16416 cycles) of steel A.

Figure 10 shows IPF and phase maps analyzed by EBSD of branched crack tip of fatigue-fractured TM, TBM and TBF steels of the steel A. The EBSD analyses were conducted in an area of 15 μm × 15 μm with a beam step size of 0.05 μm operated at an acceleration voltage of 15 kV. The crack propagated along the block, packet and prior grain boundaries in the TRIP-aided steels as explained in Fig. 10. It is noted that the retained austenite at the vicinity of crack disappeared. This fact implies that the retained austenite around the crack transformed to martensite due to the crack propagation during fatigue tests.

(a–c, g–i) RD-Inverse pole figure (RD-IPF) and (d–f, j–l) phase maps of the regions (a–f) without and (g–l) with branched cracks of the fatigue-fractured (a, d, g, j) TM (Δσ = 297 MP), (b, e, h, k) TBM (Δσ = 270 MP) and (c, f, i, l) TBF (Δσ = 261 MP) steels of steel A. ND, RD and TD represent normal direction, rolling direction and transverse direction, respectively. (Online version in color.)

It has been reported that the behavior of fatigue crack propagation in TRIP-aided steels depends on (i) the plastic deformation resistance of the matrix and transformed martensite and (ii) the relaxation of stress concentration due to the strain-induced transformation of the retained austenite.21,22,23) Regarding (i) the plastic deformation resistance of the matrix, a high crack propagation resistance might be obtained in the TM and the TBM steels. This occurs because the TM steels with martensite matrix and the TBM steels with martensite-bainitic ferrite matrices exhibited higher TS than the TBF steels with bainitic ferrite matrix. In addition, the strain-induced martensite improved the work hardening rate, which is due to the existence of transformed martensite containing high carbon concentration. Thus, the strain-induced transformation of the retained austenite might also affect the plastic deformation resistance and improve the crack propagation resistance of the TRIP-aided steels. With respect to (ii) the relaxation of stress concentration due to the strain-induced transformation of the retained austenite, Sugimoto et al.23) investigated the fatigue properties of the low alloy TRIP-aided steels at a fatigue testing temperature ranging between 20 and 200°C to clarify the role of strain-induced transformation of the retained austenite against the fatigue properties. They reported that the propagation of cracks was suppressed by the plastic relaxation of local stress concentrations due to the transformation of the retained austenite around the slip band and, as a result, the stability of the retained austenite affected the fatigue strength. In the present study, the retained austenite around the crack transformed to martensite as shown in Fig. 10. In addition, transformation-induced crack closure24,25) may be obtained because volume expansion accompanying the martensitic transformation occurs in the ultrahigh-strength TRIP-aided steels that exhibit a uniform distribution of fine retained austenite. Particularly, TBM steels tend to exhibit a high volume fraction and high carbon concentration in retained austenite in comparison with other TRIP-aided steels, as shown in Fig. 11. Thus, it was suggested that the TBM steels effectively suppressed the fatigue crack propagation because of the relaxation of stress concentration at the fatigue crack tip and the transformation-induced crack closure due to the strain-induced transformation of the retained austenite. Moreover, it is known that the stability of the retained austenite was affected by not only its carbon concentration but also its morphology26,27,28) and surrounded matrix.26,27,28) In the TM and the TBM steels, the retained austenite films were located at the martensite and bainitic ferrite lath, block, and packet boundaries, and the fine retained austenite existed as MA constituent surrounded by hard martensite at the triple junctions of the prior austenite grain boundaries. The filmy and fine retained austenite was considered to have high stability against the strain-induced martensitic transformation. Thus, austenite can remain until the crack tip reaches it, and the relaxation of stress concentration due to the strain-induced transformation of the retained austenite at the crack tip suppressed the propagation of fatigue cracks. Therefore, it was considered that the TM and the TBM steels exhibited a higher fatigue strength than that of the TBF steels. In particular, the TBM steels exhibited a level of fatigue strength similar to that of the TM steels, although the TS of the TBM steels was lower than that of the TM steels.

Variations in fatigue limit as functions of (a) initial volume fraction of retained austenite (fγ0) and (b) initial carbon concentration in retained austenite (Cγ0) in ultrahigh-strength TRIP-aided steels. (Online version in color.)

The mechanical properties of the low alloy TRIP-aided steels with a chemical composition of 0.2C-1.5Si-1.5Mn-0.04Al (mass%) have been investigated by Baik et al.,29) and they have reported that the TS and ductility of the TRIP-aided steels were improved by the addition of 100 ppm of nitrogen. It was concluded that the improvements in both TS and ductility might be caused by the increase in the volume fraction of retained austenite. The reason is the delay in the ferrite and/or bainite transformations during cooling from the intercritical annealing and austempering treatment due to the AlN precipitated in the matrix, the refinement of the microstructure due to the pinning effect of AlN precipitation at the grain boundaries, and the strengthening of the matrix microstructure due to the solid solution hardening. In this study, similar effects were expected to be obtained because approximately 0.03 wt% and 0.06 wt% of AlN were precipitated in steels B and C, respectively (Fig. 4). In addition, carbon concentration to the retained austenite during isothermal treatment was expected to occur efficiently because TM, TBM, and TBF steels exhibited a fine retained austenite. According to the observed microstructure (Fig. 3) and the analysis of the characteristics of the retained austenite (Table 2), the refinement of the microstructure and the increase in carbon concentration in the retained austenite were achieved by the addition of nitrogen, and those factors increased the fatigue strength of steel B, with 100 ppm of nitrogen. However, a large amount of coarse AlN was precipitated in the nitrogen-added TRIP-aided steels (Figs. 4, 5) because 0.5 mass% of aluminum was also added to the TRIP-aided steels. Thus, it was considered that the refinement of the microstructure due to the pinning effects of the AlN precipitation and the strengthening of the matrix because of the solid solution strengthening were not sufficiently obtained. In steel C, with 200 ppm of nitrogen, the large size of AlN might act as a stress concentration site, accelerating the fatigue crack initiation. In addition, the fatigue crack propagation was also accelerated due to the coalescence of cracks initiated at the coarse AlN or AlN/matrix interfaces. The effects of nitrogen addition on the fatigue properties of the TRIP-aided steels are summarized in Fig. 12. It was concluded that the addition of 100 ppm of nitrogen improved the fatigue strength due to the improvement in carbon concentration and the refinement of the microstructure, whereas the addition of 200 ppm of nitrogen deteriorated the fatigue strength due to the precipitation of a large amount of coarse AlN.

Illustration of effects of refinement of microstructure, increase of initial carbon concentration in retained austenite (Cγ0) and precipitation of AlN on change in the fatigue limit (ΔσW) in TRIP-aided steels.

The effects of the microstructure and nitrogen addition on the fatigue properties of the ultrahigh-strength TRIP-aided steels were investigated to improve their mechanical performance regarding their application to automotive structural parts. The results are summarized as follows.

(1) TM and TBM steels exhibited high fatigue strength in comparison with TBF steels. This may have been caused by three factors: (i) the fine and uniform martensite and/or bainitic ferrite matrices, (ii) the existence of stable retained austenite along the lath, block, and packet boundaries and MA constituent, and (iii) the increase in tensile and yield strengths due to the low temperature of the isothermal transformation treatment.

(2) The fatigue strength of ultrahigh-strength low alloy TRIP-aided steels was improved by the addition of 100 ppm of nitrogen. The suppression of the crack propagation could be achieved by the refinement of the martensite and bainitic ferrite matrices due to the precipitation of AlN and by the effective relaxation of stress concentration at the crack tip because of the volume expansion associated with strain-induced transformation of the retained austenite.

(3) The increase in nitrogen content from 100 ppm to 200 ppm deteriorated the fatigue properties of the TRIP-aided steels. This may have been caused by the promotion of crack initiation and propagation due to the coarse AlN, which acts as a stress concentration site, even though the TRIP-aided steels with 200 ppm of nitrogen achieved a refined microstructure.

The authors gratefully acknowledge the financial support obtained through grants from The Iron and Steel Institute of Japan (2012).