2022 Volume 47 Issue 4 Pages 155-171

2022 Volume 47 Issue 4 Pages 155-171

Recent requirements of the pesticide industry have become much severer, and pesticides (formulated products) are required to satisfy higher safety to both human beings and the environment, higher biological efficacy, lower price, and labor-saving. This review explains the outline of basic pesticide formulation technology, followed by recent advances in developing new formulations and application technologies. Labor-saving formulations and application technologies, environmental load reduction technologies, and user-friendly formulations and application technologies are elucidated.

Pesticides are essential for the sustainable food supply, and recent prerequisites of the pesticide industry have become severer. Pesticides are required to satisfy the following conditions.

Candidate compounds cannot satisfy all these requirements simultaneously. Therefore, improving the formulations and application technologies to meet the above requirements for new and existing active ingredients has become imperative.

In this review, the outline of basic pesticide formulation technology is explained. Further, recent advances in the development of new formulations and application technologies such as labor-saving formulations and application technologies, environmental load reduction technologies and user-friendly formulations and application technologies, which have been gathering vast attention, are introduced.

Pesticides are effective at several hundred mg to hundred grams of active ingredient per 10 a. However, uniform application of such small amounts is difficult; hence, pesticide technical materials are usually diluted with suitable solid or liquid diluents for spraying or easy application. This is the first role of formulations. The purposes of such pesticide formulations are shown in Table 1.1–17)

| 1) To make handling and application of the pesticide easy |

| 2) To maximize biological efficacy |

| 3) To improve defects in the pesticide |

| 4) To make pesticides safer for workers and users |

| 5) To reduce harmful effects and impact on the non-target organisms and the environment (To reduce environmental loads) |

| 6) To improve work efficiency that results in labor savings |

| 7) To give various functions to pesticides in order to broaden their spectrum of activity |

Pesticide formulations are classified mainly as solid, liquid, and others. Tables 2, 3, and 4 show formulation types, figure, main components, and application methods for solid, liquid, and other formulations, respectively.4,9,10,12,15)

| Formulation types | Figure | Main components (except A.I.) | Application methods |

|---|---|---|---|

| Dust | Fine Powder: ≪45 µm; ≧ 95% | Mineral carriers | Apply without dilution by duster |

| (usual)Dust | Fine Powder: ≪45 µm; ≧ 95% Mean diameter 10 µm | ||

| DL Dust | Fine Powder ≦ 10 µm; ≦20% Mean diameter 20–30 µm | ||

| Flo-Dust | Fine Powder Mean diameter ≦5 µm | ||

| Dust-granule mixture | Coarse powder–Small Granule, ≦ 1700 µm | Mineral carrier+binder | “ |

| Coarse Granule F | 180–710 µm; ≧ 95% | ||

| Fine Granule | 106–300 µm; ≧ 95% | ||

| Fine Granule F | 63–212 µm; ≧ 95% | ||

| Granule | Small Granule (300–1700 µm; ≧ 95%) | Mineral carrier+(binder) | By hand or by duster |

| Wettable Powder | Fine Powder–Coarse Powder ≦ 63 µm; ≧ 95% | Mineral carrier+Dispersant +Wetter | Spray after dilution with water by sprayer |

| Water Soluble Powder | Fine Powder | Water soluble carrier | “ |

| Water Dispersible Granule Dry Flowable | Fine Granule–Small Granule | Mineral carrier+Dispersant +Wetter Dispersant |

“ |

| Water Soluble Granule | Fine Granule–Small Granule | Water soluble carrier | “ |

| Tablet | Tablet | Mineral carrier+(binder) | “ or by hand |

| Jumbo Formulation | Bubbling Tablet or Water Soluble Package | Mineral carrier+(bubbling agent) | By hand |

(K.Tsuji Sumitomokagaku 1998-I, 79 (1998))

| Formulation | Figure | Main components (except A.I.) | Application methods |

|---|---|---|---|

| Emulsifiable Concentrate | Transparent liquid | Organic solvent+emulsifier | Spray after dilution with water by sprayer |

| Oil Formulation | “ | Organic solvent | Spray before or after dilution with water by sprayer |

| Soluble Concentrate | “ | Water | “ |

| ULV Formulation | “ | Organic solvent or water | Spray without dilution by sprayer |

| Suspension Concentrate, Flowable Formulation | Dispersion in liquid | Water+dispersant+thickener | Spray after dilution with water by sprayer Apply directly from bottle |

| Emulsion, oil in water | “ | Water+emulsifier+(thickener) | Spray after dilution with water by sprayer |

| Microemulsion | Transparent liquid | Water+emulsifier | “ |

| Suspoemulsion | Dispersion in liquid | Water+emulsifier+dispersant | “ |

| Microcapsule, Capsule Suspension | “ | Water+polymer | “ |

| OD | Dispersion in Liquid | Organic solvent+dispersant | Spray after dilution with water by sprayer, Spray directly by sprayer |

| Formulation | Figure | Main components (except AI) | Application methods |

|---|---|---|---|

| Smoking agent | Granule | Heating agent+Burning aid+Regulating agent | Heat A.I. to smoke and float in air |

| Fumigant | Solid, Liquid, Gas | Seal into the closed container | Evaporation |

| Coating formulation, Paste | Paste, Liquid, Powder | Adhesive+Filler+Coloring agent+Surface active agent+Water | Coating formulation or diluted liquid on fruit tree trunk or vegetable stem |

| Injection formulation | Liquid | Organic solvent+Surface active agent | Inject into the pine trunk |

| Aerosol | Pressured container equipped with jet nozzle | Propellant+Solvent+Emulsifier+Stabilizer+Adjuvant | Spray foggily |

| Bait | Granule | Attractant+Filler+Cereal+Binder+Preservative | Attract insect pest and feed |

The international classification was reported in detail. Formulation names used in Japan, their definitions, and their corresponding international formulation codes are shown in the literature.18,19)

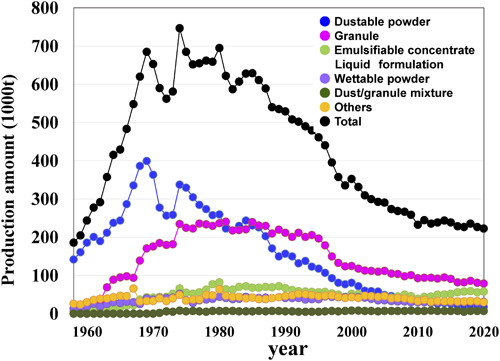

1.3. Transition of production amount of pesticide formulationsThe transition of production amount of pesticide formulations is shown in Fig. 1.20) The ratio of solid formulation in total amount is significant. Initially, the production amount of dust formulation was the highest; however, after 1985, the amount of granule formulation exceeded that of dust formulation. The total production amount of pesticide formulations was the highest at 747,000 t in 1974; after that, it gradually decreased to 353,000 t in 2004, less than half of the highest, and to 223,000 t in 2020. The decrease was mainly attributed to the decreased pesticide use due to the reduction of the acreage planted, a decrease in pesticide usage per unit area due to higher efficacy of pesticides, and the change of formulation types.

Among them, the decrease in dust formulation was massive. The production amount of dust formulation was 76.3% of that of total pesticide in 1958, and it was the highest at 399,000 t in 1969. However, it decreased to approximately 18,000 t in 2020 (8% of the total production amount of pesticide formulations). This decrease was mainly caused by the drift problem (safety to workers and the environment), spread of seedling-box treatment, its heavy spray work, and high cost owing to its bulkiness.

Granule formulations of herbicides were put to practical use in 1958 in paddy fields. The production amount rapidly increased to 240,000 t (maximum) in 1985, and was maintained at approximately 200,000 t until 1994. The production amount of granule formulations was steadily the highest among all formulations; this is mainly because granules can be formulated for almost all pesticides, applied without dilution, and used steadily for herbicides in both paddy and upland fields. However, the production amount decreased to about 100,000 t from 1995. This was caused by changing the use to 1 kg granule from 3 kg granule, and the spread of direct application of flowable and jumbo formulations.

As for wettable powder, its production amount was 13,000 t in 1958, reached maximum of 52,000 t in 1974, and has been maintained at 30,000 t for almost 46 years until now.

As for emulsifiable concentrate and liquid formulations, the production amount was about 5,000 t in 1958, increased to 82,000 t in 1980, then decreased to about 50,000 t in 1991, 39,000 t in 2010, and 58,000 t in 2020. However, the ratio of its production amount against total production amount was 2.7% in 1958, 6% in 1968, 11.7% in 1979, 16.7% in 2010, and 26% in 2020. This gradually increasing ratio indicates the importance of liquid formulations.

1.4. Importance of formulationsFormulation design is very important to achieve the purposes mentioned above. Firstly, formulation type, recipe, manufacturing method, and formulation properties should be determined. Physicochemical and biochemical properties of active ingredients, and application method should be taken into consideration. As biological efficacy depends on formulation type, recipe, and its properties, these items should be optimized. To commercialize the formulation, biological efficacy, storage stability, safety, handling, and cost requirements should be satisfied. Recently, it has also become desirable to add new high functions to formulations, and controlled release and targeting technologies have become essential. Thus, the research work on formulation and application technology has also becomes crucial.1,3,5,8–17)

1.5. Pesticide delivery system (PDS) and drug delivery system (DDS)To meet the current requirements of the pesticide industry, the concept of PDS is very important. PDS can be defined as a technique or method in which active ingredients are made available to a specified target at concentration and duration designed to accomplish an intended effect to obtain the fullest biological efficacy, and to reduce various harmful effects. The concept of PDS is very similar to that of DDS, but PDS has various difficulties compared with DDS, as shown in Table 5.4,7,13–15,17)

Therefore, PDS is not as easy as DDS, and research pertaining to the formulation and application technologies based on PDS concept should be continuously carried out.

| Features | PDS | DDS |

|---|---|---|

| Target | Open system | Closed system |

| Restriction of raw material and technology | Not allowed for high price | Relatively allowed for high price |

| Delivery vehicle | None | Available (Blood, Body fluid) |

| Influence to environment | Appear | None |

Various improvements in formulations and application technologies have been made according to the recent demands of the pesticide industry and the purposes of formulation. Changes in formulation types have also proceeded, and several new-types of formulations and application methods have been developed.1,2,6–17)

Table 6 shows the problems of conventional formulations, reasons, methods of improvement and new pesticide formulations developed.

| Formulations | Problems | Reasons | Improvement methods | New formulations |

|---|---|---|---|---|

| Emulsifiable Concentrate (EC) | Toxicity, Phytotoxicity Flammability | Organic solvent | Making use of water | Emulsion, oil in water (EW) Microemulsion (ME) Suspension Concentrate (SC) Suspoemulsion (SE) |

| Solidifying | Emulsifiable Granule (EG) Emulsifiable Powder or Gel |

|||

| No solvent | High Concentration EC | |||

| Changing solvents or emulsifier | Improved Recipe | |||

| Wettable Powder (WP) | Dusty | Fine powder | Dispersing in Water | Suspension Concentrate (SC, Flowable) |

| Granulating | Water Dispersible Granule (WG) | |||

| Changing package | Water Soluble Package | |||

| Dust (DP) | Drift | Fine powder | Removing fine particles | DL Dust |

| Granulating | Fine Granule F | |||

| Granule (GR) | Weight | 3 kg/10a | High concentration | 1 kg Granule |

Emulsifiable concentrate (EC) has problems of toxicity, phytotoxicity, and flammability, that are caused by organic solvents and synthetic surface-active agents used in EC.

One of the improvement methods is using water, the safest liquid, instead of organic solvents, which results in emulsion or microemulsion. The other method is solidifying of EC formulation, which results in solid EC (emulsifiable granule or powder). Another way is using safer organic solvents and emulsifiers in formulation recipes.

Wettable powder (WP) results in dustiness at the time of dilution, caused by fine mineral powder used in the WP as a diluent. One of the improvement methods is dispersing WP in water to result in a flowable formulation. The other method is granulating WP, resulting in water dispersible granule (WG). Another technique is packaging WP with water-soluble bag, which results in a water-soluble package.

The dust has a problem of drift, caused by fine mineral powder used as a carrier. One method of improvement is removing very fine particles (less than 10 µm) that result in DL dust (driftless, average particle size>20 µm). Another improvement method is granulating the formulation to fine granules, which results in fine granule F (63–212 µm).

Granule formulation has a problem of weight i.e., 3 kg needs to be applied per 10 a. The method of improvement is to increase active ingredient concentration in the formulation, resulting in the reduced application rate of 1 kg per 10 a.

Table 7 shows recent general requirements in the pesticide industry, methods of improvement, and new types of formulation and application methods.

| Recent requirements | Methods of improvement | New formulations and application methods |

|---|---|---|

| Higher efficacy Higher safety Labor-saving |

Making use of water | Emulsion (EW), Suspension Concentrate (SC) |

| Granulation | Water Dispersible Granule (WG) | |

| Removing fine particle | DL Dust | |

| Higher concentration | 1 kg Granule | |

| Controlled release | Controlled Release Formulations (Microcapsule, Laminate, Granule etc.) | |

| Targeting | Stimuli-responsive Formulations, Seedling Box Treatment, Seed Treatment, Simultaneous Treatment in Rice Transplanting, Low Volume Spray of Solution | |

| Exposure reduction | WG, Water Soluble Package | |

| Application from levee | Jumbo Formulation, Mametsubu Formulation, Flowable for Direct Application | |

| Application from water inlet of paddy field | Oil Formulation | |

| Seedling box treatment | Granules for Seedling Box Treatment | |

| Seed treatment | Seed Treatment Formulation | |

| Simultaneous treatment in rice transplanting | Transplanter with Applicator | |

| Application of pesticides with fertilizers | Fertilizer Containing Pesticides | |

| Making use of biopesticides | Biopesticide Formulation | |

| Physical controlling methods | Adhesive Materials, Trapping | |

| Aerial application | Helicopter, Multi-rotor(drone) |

Controlled-release formulations such as microcapsules are developed for higher safety, labor-saving, and higher biological efficacy.

For labor-saving, there have been developed application methods from levees and water inlets in paddy fields, application at the same time of transplantation, application to the seedling box, seed treatment, direct application of flowable, 1 kg granule, application of pesticides with fertilizers, and aerial application. Corresponding to these application methods, several new types of formulations have been developed, such as jumbo herbicides, water-surface spreading formulations, and fertilizers containing pesticides.

For higher safety, water-based formulations, WG, seedling-box treatment, DL dust, and seed treatment are considered.

In the next section, labor-saving formulations and application technologies, environmental load reduction technologies, and user-friendly formulations and application technologies mentioned below are explained in more detail.

Labor-saving methods for the application of pesticides are:

Hereinafter, typical formulations and application techniques for labor-saving will be described.

2.1. Jumbo formulationDue to only a few successors and the aging of agricultural families,21) the jumbo formulation was launched for the first time in 19949,22) in response to the increasing social demand from farmers. It can be easily apply from the levee of rice paddy field without direct entering into the paddy field, even for the elderly and women. The jumbo formulation was an innovative labor-saving application in the paddy fields in those days. The development of the jumbo formulation was triggered by the proposal of development for throw-in type formulation (later named jumbo formulation) by Japan Association for Advancement of Phyto-Regulators in 1990.23) After this proposal, various jumbo formulations have been researched and developed by many pesticide companies24–33) and launched. “JUMBO” is a registered trademark of the Japan Association for Advancement of Phyto-Regulators34) and is a general term for throw-in type formulation applied in the paddy field for herbicides. The characteristics of the jumbo formulation are the followings; ①Farmers require no sprayer. ②It can be easily applied by hand. ③No drift occurs, and ④It is safe for surrounding crops.

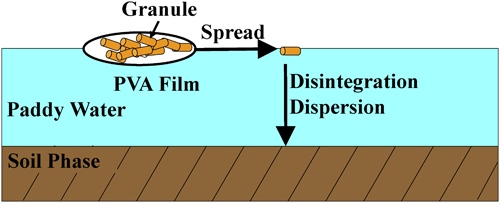

Currently, there are roughly two types of jumbo formulations: a bubbling tablet type35) and a package type in which granules are packaged in a water-soluble bag. A package-type jumbo formulation, particularly consisting of granules, packaged in a water-soluble bag, which are floating and spreading on the water surface (hereinafter referred to as jumbo formulation floating and spreading on the water surface), has an excellent spreading property on the water surface. Figure 2 schematically shows the concept of the formulation design for jumbo formulation floating and spreading on the water surface. The formulation is designed with the concept of “when the jumbo formulation floating and spreading on the water surface is applied into the paddy field, after the water-soluble bag dissolves and breaks, the granules spread on the water surface quickly and widely, and disintegrate and disperse in the paddy-water in a short time.”22) Screening of buoyancy agents and water-surface spreaders is important for the formulation design of granules with excellent water-surface spreadability. Using cork and vermiculite as buoyancy agents and α-olefin sulfonate, α-sulfofatty acid salt and oleylmethyl tauride salt as water-surface spreaders, granules having an excellent water-surface spreadability can be obtained.22,36) There are many other examples of technology development using water-surface spreaders and the buoyancy agents.37–40) Typical example showing an excellent floating property on the water surface and disintegrating and dispersing properties in the water were reported, when jumbo granules were treated in a beaker containing tap water.22) According to this report, approximately 30 sec after the granules treatment, no sedimented granules were observed and the granules started to disintegrate and disperse in water, and 5 min later, it was found that the cloudy fine particles were dispersed in water.22) In another experiment, 90% or more of the active ingredients were already distributed in the suspension, within 10 min after the granules were added.22) For jumbo formulations that apply 10 bags per 10 a, for example, when applied in a standard size of paddy field (30 m×100 m), the applying time is about 4–5 min.22,41) After the application of jumbo formulations, the concentration of the active ingredients in the paddy-water is found to be usually uniform in 1 to 3 days.22,41)

Jumbo formulations have been developed so far for early-stage and one-shot herbicides. There has been also a high demand for jumbo formulations for a middle-stage herbicide, but the growth of rice is more than that in the application timing of early-stage and one-shot herbicides, and then there is almost no wind on the water surface. Initially, it was considered difficult to develop the middle-stage jumbo formulations due to poor spreadability on the water surface. However, recently some jumbo formulations for the middle-stage herbicide have been registered and research and development have still been advanced.

2.2. Mametsubu formulationMametsubu formulation, which is one-shot herbicide for a rice paddy field applying 250 g per 10 a is on the market. This is a bean-shaped formulation with a particle size of about 3 to 8 mm.42) The formulation is granulated from a floating porous carrier and active ingredients etc.42) When this is applied to the paddy field, the mametsubu granules float and spread quickly on the water surface, and disintegrate and disperse in the paddy field, and then a stable herbicidal effect is exhibited.43)

The characteristic of the mametsubu formulation is that it can be applied in various ways because of its large granular size. The mametsubu formulation is the formulation floating and spreading on the paddy-water surface; farmers can apply it from the levee without entering the paddy field. For example, it can be applied by hand, dipper, power sprayer, unmanned helicopter, radio control boat and multi-rotor (drone) etc.44). Water inlet application is also possible.44) It is also used as a jumbo formulation by packaging mametsubu granules by 25 g per pack in a water-soluble bag and applying 10 packs per 10 a.44) When the mametsubu formulation containing pyrimisulfan was applied, a uniform concentration of the active ingredient was exhibited 3 days after application.45,46)

2.3. 1 kg GranuleDevelopment of herbicide granule for rice paddy field that can be applied by hand began in 1955, and in 1959 granule applying 3 to 4 kg per 10 a was registered.47) Granule was mainly used as herbicides for paddy field weeds, and application of 3 kg per 10 a was widely used. However, for labor-saving by reducing application quantity as well as the compact quantity of manufacture, distribution, and storage in a warehouse; 1 kg granule applying per 10 a has been developed since 1990 and launched.48,49) The granule diameter of 1 kg granule is mainly 1.2 mm, which is larger than that of 3 kg granule, so that a flying distance of 15 m can be obtained by the application from the levee of paddy field with a knap-sack type power spreader without entering the paddy field (30 m×100 m, standard size).47) Since the quantity of 1 kg granule is reduced to be 1/3 and the granule size is larger, the number of granules per 1 g is lesser than that of 3 kg granule.47) The number of granules per unit area of 1 kg granule is about 1/8 in compared to that of 3 kg granule.47) In order to obtain superior herbicidal efficacy, it is necessary that formulation recipe showing superior releasing behavior of active ingredients from the granules into paddy-water should be established. The 1 kg granule is composed of active ingredients, surfactants, binders, carriers etc. In the case of a poorly water-soluble solid active ingredient, the active ingredient is ground by a jet mill or wet ground with a bead mill or the like to reduce the particle size further to improve the releasing property into the paddy-water. The surfactants are compounded as a disintegrating agent of the granule, release enhancing agent of the active ingredient in paddy-water, and the granulation improvement agent. Polymers such as modified starch, carboxymethyl cellulose, and calcium lignosulfonate are used as the binder. As carriers, clay, calcium carbonate, bentonite, etc., which are crushed and pulverized natural minerals, are used.50,51) The 1 kg granule for herbicide used for paddy fields have been on the market since 1993,47) and since then, the development of 1 kg granule for fungicide and insecticide has also been active.

2.4. Flowable for direct applicationRecently flowable for direct application, that is, undiluted herbicide flowable formulation, has been developed. A three-way mixture of ‘pyributicarb+benzofenap+bromobutide’ was the first flowable used as a paddy herbicide showing an excellent dispersion by a broadcast spraying into the paddy-water.49) In 1990, the Japan Association for Advancement of Phyto-regulation started to establish an effective application method from the paddy levee to ensure good dispersion with cooperation of many agrochemical companies.49) and since then, the labor-saving herbicide flowable formulation with spraying the undiluted solution in a bottle as it is by hand has been developed and launched.52) The formulation has a good dispersion in water, and the agrochemical active ingredients are spread evenly in the paddy-water. In addition, to avoid phytotoxicity, the surface tension of the formulation is adjusted to 40 mN/m or more so that the active ingredients do not adhere to the rice plant.53) A method of adjusting the pH of flowable formulation to 7.0 or higher, and the formulation viscosity at 20°C to the range of 300 to 800 m Pas, which contains urea, a surfactant and/or a protective colloid,54) and a method of using porous powder, a surfactant and/or a protective colloid,55) are described. Since the spraying method was mainly by hand spraying, the package was mostly a 500 mL bottle, but recently, spraying in a paddy-water inlet showing an excellent dispersion, spraying with rice-transplanting simultaneous applicator, spraying by radio-controlled helicopter and boat56); furthermore, a spraying method using a multi-rotor (drones) have been developed and relatively large packaging such as a 2 L bottle has been increasing.56)

Herbicide flowable formulation comprises herbicides, wetting agents, dispersants, thickeners, antifreeze, defoamers, preservatives, others (pH regulators, solvents, salts, etc.), and water.57) The particle size of the herbicide active ingredients is determined by the biological effect and the phytotoxicity to rice, and is usually about 1 to 5 µm. The water solubility of the herbicide applied to this formulation is preferably 100 ppm or less from the viewpoint of storage stability of the herbicide, and the melting point of the herbicide technical material is preferably 60°C or higher. Anionic surfactants such as polyoxyethylene arylphenyl ether sulfate, polyoxyethylene aryl phenyl ether phosphate and nonionic surfactants such as polyoxyethylene arylphenyl ether, polyoxyethylene polyoxypropylene block polymers, alkylpolyglucosides etc., used as wetting agents, are described.56) As dispersants, anionic surfactants such as sodium lignin sulfonate, and sodium formaldehyde condensate of alkylnaphthalene sulfonate are described.56) Inorganic bentonite and white carbon (inorganic substances), and xanthan gum and welan gum (organic substances) etc. are described as thickeners.56) Ethylene glycol, propylene glycol, etc. are used as antifreeze.56) As defoaming agents, a silicone-based emulsion having excellent both foam destruction and suppression properties, is used. While benzoisothiazoline-based preservatives, sorbic acid, and benzoic acid, etc. are used as preservatives.56)

2.5. Granules for seedling-box treatment (Nursery box granule)With the rapid spread of mechanical transplanting by a rice transplanter in the 1970s, the method of raising seedlings using a seedling box for paddy rice became widely used.58) In the latter half of the 1970s, outbreaks of rice leaf beetle and rice water weevil began to be seen nationwide, and as effective measures to control them, a seedling-box application became widespread.58) Since the seedling-box application is performed in the vicinity of the target rice seedling, this application is extremely labor-saving compared to the paddy-water or submerged application, and no drift to the environment, as well as no exposure to the farmers, have almost occurred.59) Moreover, the amount of pesticide application for seedling-box application is less than that for the paddy field application.57) Currently, the application timing of the seedling-box application is roughly divided into three categories: (1) seeding time, (2) greening stage, (3) several days before transplantation to transplanting day, and as formulation types, granule is usually applied as 50 g per seedling box. Although, suspension concentrate and water dispersible granules that are diluted with water and poured are defined, but at present, the granule is widely employed.58,60) Seedling-box-applied granules for a long-lasting residual efficacy have been developed, and are rapidly becoming widespread.58,61) The systemic active ingredients are used in this granule, and the formulation needs to have a long-lasting residual efficacy as well as prevent phytotoxicity. For this purpose, the technology development of controlled-release formulation is necessary. As a sustained-release technology for granules, the formulation technology for suppressing the release of the active ingredient by using a carrier such as zeolite easily adsorbing the active ingredient, and also the formulation technology for suppressing the infiltration of water into the granules by using a water-repellent substance such as resin and wax are described.61) These sustained-release technologies are relatively effective for the active ingredients have an extremely not so high solubility in water. They are easy to manufacture, and the manufacturing cost is relatively low among the sustained-release technologies.61) For active ingredients having high solubility in water and low maximum permissible concentration of phytotoxicity, there is a method for coating granules containing the active ingredient with a water-insoluble film, and as the water-insoluble film, resins such as vinylacetate and polyurethane and wax are used.61) Recently, a wax matrix granule, a controlled-release formulation, in which an active ingredient is dispersed in the wax used as a continuous phase, has been developed.62) Since the active ingredient incorporated into the wax continuous phase is gradually released from the surface of the granules into water, a long-lasting efficacy can be expected, and the seedling-box-applied formulation containing dinotefuran having high solubility in water as the active ingredient is often used.62) As factors for controlled release, the types of waxes and oil-absorbing substances,63) and the like are described. Furthermore, to avoid initial phytotoxicity and ensure efficacy at the required time, the release pattern of the active ingredient shouldn't be a mere sustained- release type but a so-called limited-timed release type. By this method, the active ingredient having strong phytotoxicity can be applied at the seeding time, and the active ingredient can be efficiently released according to the growth of rice and the time required for control. As an example, coated granule of metominostrobin was reported.64)

2.6. Simultaneous application with rice transplantingIt is a method of applying pesticide formulation at the same time as rice transplanting. Several methods by simultaneous application with rice transplanting have been put into practical use as a result of the development of 1 kg granule that can ensure sufficient efficacy and safety to rice.65) As rice transplanter-mounted herbicide applying devices, herbicide dropping devices for flowable and herbicide granule applying devices are described.66) Using a sprayer linked to these rice transplanters, pesticides can be applied uniformly, and the labor and time for applying herbicides can be significantly reduced. The formulation used in this device is devised so that even if it is applied at the same time as rice transplanting, it exhibits a control efficacy until the same time as the existing one-shot herbicide, and it does not cause phytotoxicity to the seedlings at the time of rice transplanting.

2.7. Granule resurfacing after submerged applicationGranule resurfacing after submerged application, which is composed of active ingredient, water-soluble potassium chloride as a carrier, a water-soluble binder, surfactant, and other additives, has been put into practical use.67,68) After the granules are applied into the paddy fields, they sink down on the bottom soil first, then potassium chloride dissolves, and granules resurface and diffuse the active ingredient into the water.67) This formulation was first developed as cycloprothrin 2% granule for controlling rice water weevil.67)

2.8. Surf formulationSurf formulation in which the active ingredient such as etofenprox spreads over the entire paddy field together with the solvent by dropping an oil formulation spreading on the water surface into several places in the paddy field has also been put into practical use. The formulation consists of an active ingredient, a surfactant, and a solvent, and the production method is the same as that for EC, in which the active ingredient and the surfactant are added to the solvent, and the mixture is stirred and mixed until uniform.69) As application methods, treatment in the paddy-water from the levee,70) treatment in a paddy-water inlet71) and application of a 50 mL bottle made of polyvinyl alcohol in which the oil formulation is filled, 4 to 10 bottles per 10 a from the levee, etc. are described.69)

2.9. Fertilizers containing pesticides (Pesticides-Fertilizer combination)As a high-performance fertilizer, fertilizer mixed with pesticides has been developed. The first purpose is labor-saving so that pesticides and fertilizers can be applied simultaneously. Currently, fertilizers containing pesticides such as fungicides, herbicides, and plant growth regulators have been put into practical use. All fertilizers containing pesticides listed in the Fertilizer Handbook (6th edition) are granular formulations.72) There are two main technical proposals for producing granular fertilizer containing pesticides. One is a method of impregnating the existing granular fertilizer with pesticides or coating pesticides on the fertilizer surface (addition method), while the other comprises mixing and kneading pesticides together with fertilizer, and then granulating (kneading method).73) However, the former method is widely used.73)

2.10. Aerial application (manned/unmanned aircraft)Japan Agricultural Aviation Association was established in 1962, and pesticide applying by crewed helicopters became widely used as an efficient and economical method.74) The aerial control business decreased due to environmental issues, the decrease in the area of paddy rice planting, and the spread of seedling-box-applied granule for long-lasting residual efficacy after reaching its peak in 1988.9,74) An unmanned helicopter was put into practical use in 1991, where a small amount of liquid formulation was basically sprayed.9) Furthermore, in 2006, the positive list system was enforced, and aerial control was reviewed in response to measures against the drift of sprayed pesticides, and the use of unmanned helicopters expanded.9) In 2008, a drift-reducing spraying device was put into practical use.9) Recently, the rapid technological development of industrial multi-rotors called drones has been progressed in various fields. In the agricultural field, it is an aerial application technology that the operation under the guidelines has started since 2016.75) The loading capacity of the pesticide formulation is 4 to 16 kg on the multi-rotor, and the total weight is 12 to 45 kg.76) The multi-rotor is more compact than the current industrial unmanned helicopter having a total weight of about 100 kg, and the multi-rotor has a high loading capacity of the pesticide formulation per the weight of the aircraft.76) However, it is an issue for the future that the downwash of the multi-rotor is weak and the multi-rotor is easily affected by crosswinds due to its light weight, and the battery capacity is about 10 min.76) Disease and pest control by multi-rotor were carried out in the paddy rice, soybean, etc. in 2018 at 31,000 ha (based on the investigation of the Ministry of Agriculture, Forestry and Fisheries).76)

DL dust was developed considering the advantage of dust formulation and improvement of its drawbacks; drift phenomena at the time of application.

The term “DL’ stands for “drift less.” The physical properties of DL dust and dust formulation are shown in Table 8. For the fineness of both dust formulation and DL dust, more than 95% of the particles passes through the 45 µm sieve. The average particle size of dust formulation is about 10 µm, and that of DL dust is more than 20 µm. The percentage of particles less than 10 µm in DL dust is less than 20%, while that of dust formulation is about 50%. As for the drift index, DL dust is less than 20%, while dust formulation is about 50%.77–80)

| Items | DL Dust | Dust | |

|---|---|---|---|

| Fineness | 300 Mesh ≦ 45 µm |

≧95% | 98% |

| Average particle size | ≧20 µm | App.10 µm | |

| Percentage of particle ≦10 µm | ≦20% | App.50% | |

| Apparent specific gravity | 0.7–1.1 | 0.45–0.65 | |

| Drift Index | ≦20 | App.50 | |

・Physical properties of DL Dust formulation is from specification of ZEN-NOH (1985)・Regarding physical properties of Dust formulation, those of a commercial product are described.

Dust formulation is obtained by mixing and pulverizing of technical ingredients and various components such as carriers, coagulants, and improvers of physicochemical properties such as flowability and dispersibility. As for the carriers of DL dust, cut clay is usually used, in which average particle size is more than 10 µm, and particles less than 10 µm are removed by sieving.

The concentration of active ingredients in dust formulation and DL dust is very low, and a premix of components is used for mixing.

3.2. Fine granule F (microgranule F)Fine granule F was developed to improve the drift of dust formulation through the enlargement of particle size. The percentage of particles between 63 and 212 µm is more than 95%. Therefore, particle size is 3–10 times larger than that of DL dust, and drift preventive effect is very high. Fine granule F can be sprayed by a conventional knap-sack type power spreader attached with a boom type blower head. As sprayed particles are almost invisible, this formulation is used with visual safety.81,82) Fine granule F was formulated mainly by coating method, but the particle size was smaller than the usual granule, and smaller particles are easily exfoliated during the drying process. As formulation cost was high, and application efficiency was worse, this formulation was not used initially widely, and DL dust was used widely as an easy, efficient, and drift preventive formulation for the paddy field.

After the positive list system was enforced on May 2006, concern about pesticide residue in plants and drift to neighboring plants became large. Fine granule F was reevaluated as a drift preventive formulation, and various efforts were carried out to improve formulation cost and application efficiency.

3.3. Drift preventionTo prevent drift, various kinds of application equipment and nozzles are being developed. The classification of pesticide application equipment is shown in Table 9.10,83,84)

| Formulation | Application type | Application equipment | Note |

|---|---|---|---|

| Liquid Formulations | Walking | Manual spreader (knap-sack type, shoulder-slung type) Power sprayer (knap-sack type, portable, self-propelled type) Speed sprayer (self-propelled type) |

High volume spraying (equal to or more than 100 L/10 a) |

| Riding | Boom sprayer (tractor-mounted type, tractor-pulled type, riding management machine-mounted type), Speed sprayer (self-propelled type), Riding, rice transplanter mounted with flowable formulation dripping device | High volume, low volume spraying (boom sprayer adaptive to 25 L/10 a) | |

| Outdoor | Sprinkler | High volume spraying | |

| Indoor | Cold fog machine (stationary, unmanned traveling type) | Low volume spraying | |

| Power sprayer (unmanned traveling type) | High volume spraying | ||

| Radio control | Industrial unmanned helicopter (liquid sprayer) Unmanned multicopter, Drone (liquid sprayer) |

Low volume spraying, about 0.8 L/10 a | |

| Granule Formulations | Walking | Manual granule applicator (knap-sack type, shoulder-slung type) Power granule applicator (knap-sack type, self-propelled type) |

Application weight, about 1–3 kg/10 a |

| Riding | Boom-type applicator (riding management machine-mounted type), Rice transplanter mounted with granule applicator to transplanting part | ||

| Radio control | Industrial unmanned helicopter (granule applicator) Unmanned multicopter, Drone (granule applicator) |

||

| Fine Granule F | Walking | Power spreader (knap-sack type, attached with a boom type blow head) | Application weight, about 3–4 kg/10 a |

| Dust Formulations | Walking | Manual duster (apron type), Power duster (knap-sack type) | Application weight, about 3–5 kg/10 a |

| Riding | Power duster (tractor-mounted type) | ||

| Smoke Generator | Indoor | Smoke machine | Fumigation |

Power sprayers are used widely for the application of liquid formulations. This consists of a pump to apply pressure to spray liquid and nozzles to minimize spray liquid particles through small holes at high speed. From conventional nozzles of a power sprayer, spray particles are obtained, whose average particle size is 60–80 µm, and show good biological efficacy but tend to drift easily. Drift is due to small particle size. Therefore, drift can be prevented by the enlargement of particle sizes. Two kinds of drift preventive nozzles are developed for conventional boom sprayers. A single head spray nozzle gives flat spray, whose average particle size is about 300 µm. Double head spray nozzle gives from front and back of the boom, spray particles whose average particle sizes are 350 µm and 250 µm, respectively.

These nozzles prevent drift to 1/10 of that of conventional nozzles and give biological efficacy equal to conventional ones.85)

Two kinds of drift preventive nozzles for speed sprayers are also developed.86) One type shows 350 µm of spray particle diameter and backward tilt angle 0° (spray angle 50°) , and another type shows 250 µm of spray particle diameter and backward tilt angle 15° (spray angle 50°). These two nozzles prevent drift significantly and show both adhesion performance of spray liquid and biological efficacy equal to conventional ones.

New formulations and application methods are also developed, which do not cause any drift. They are mametsubu formulation, jumbo formulation, pack formulation, seedling-box application, and seed treatment.

A new technology of low volume spray also spreads in Hokkaido. In low volume spray, spray pressure is lower, and particle size of spray liquid is relatively large, which results in small drift. Spray volume into a definite area is also small. Therefore, spray work is efficient and labor- saving. Low volume spray is significantly suitable for large scale farm management.

Water-based formulations are obtained by emulsifying or suspending pesticide technical materials in water. Water is the safest liquid. Therefore, water-based formulations have various advantages from the safety point of view. On the other hand, they also have some kinds of disadvantages. For example, generally pesticides that are unstable in water cannot be formulated into water-based formulations. But various types of technologies have been developed to stabilize the pesticides that are unstable in water. Each water-based formulation will be discussed in more detail.

4.1.1. Emulsion, oil in water (EW)This formulation is obtained by emulsifying water-insoluble pesticides in the liquid state in water employing suitable emulsifiers. The pesticides, which are liquid at room temperature, can be emulsified as it is in water. Solid pesticides are dissolved at first in water-insoluble organic solvents, then emulsified in water. In this case, water solubility should be lower than 1000 ppm. This formulation includes active ingredients, emulsifiers, thickening agents, antifreeze, preservatives, defoamer, (organic solvents), and water. As emulsifiers, synthetic emulsifiers are commonly used such as the mixture (HLB>14) of polyoxyethylenecastor oil ether and polyoxyalkyleneglycol ether, and water-soluble polymers such as polyvinyl alcohol, and gum arabic, which act as protective colloid, are also used. As thickening agents, acrylic polymers, cellulose derivatives, and xanthan gum are frequently used, as these materials show thixotropic property. Fine mineral powders, such as bentonite, hydrated silicone dioxide, are also applied.

The advantages of this formulation are as follows;

The disadvantage is that emulsion is thermodynamically unstable dispersion. Therefore, it tends to lose its uniformity after keeping for a long time at room temperature through coalescence, coagulation, creaming, and settling to result in phase separation.

4.1.2. Suspension concentrate (SC, flowable)This formulation is obtained by suspending solid water-insoluble pesticides in water. The purpose of this formulation is to formulate pesticides insoluble both in water and organic solvents, into flowable liquid formulation. This formulation contains active ingredients, dispersing agents, wetting agents, thickener, antifreeze, preservatives, defoamer, specific gravity adjuster, and water.

Dispersing agents act as dispersion stabilizers. There are two stabilization mechanisms: static electric repulsion force and steric stabilization. Stabilization by former mechanism involves anionic surfactants such as polyoxyethylene phosphate and polyoxyethylene sulfate. These surfactants adsorb to the dispersed particles to give a negative electric charge, which stabilizes dispersion by repulsion force between negative charges. Polymers and high molecular weight nonionic surfactants form thicker adsorbed layers on the dispersed particles. Water-soluble polymers such as lignosulfonate, polyvinylalcohol, and alkylnaphthalene formalin condensate are often used for steric stabilization. As wetting agents, which make pesticide technical materials wet in water, polyoxyethylene alkylphenylether and polyoxyethylene sorbitan ester are often used. Dispersing agents may also act as wetting agents. Inorganic electrolytes such as sodium chloride and calcium chloride act as specific gravity adjusters to reduce the difference between specific gravities of liquid layer and dispersed particles.

The advantages of this formulation are the same as those of “emulsion.”

The disadvantages are as follows;

This formulation is usually sprayed after dilution with water. Recently, flowable herbicides have been developed, which have good diffusion properties in water and can be applied without dilution by hand from levees of paddy fields smaller than 30 a. In this case, proper surfactants are chosen for active ingredients to diffuse and spread smoothly in the water. The concentration of active ingredients reaches to an even level within 1 day in paddy-water and within 3 days on the soil surface. This flowable application method reduced the labor intensity in applications to approximately 20% compared with conventional granular herbicides.

To avoid sticking to rice and reduce phytotoxicity, surface tension is adjusted to be 36–65 dyne/cm (at 25°C) by selecting appropriate surfactants.

4.1.3. Suspoemulsion (SE)This formulation is a combination of emulsion and suspension. Both solid and liquid technical materials are dispersed in water. Usually, solid technical materials are formulated into SC and liquid technical materials are formulated into EW. When they are sprayed at the same time, they should be tank-mixed before application. It is a great advantage of suspoemulsion that water-insoluble solid and liquid technical materials are dispersed in one solvent, i.e., water. The advantages of this formulation are the same as those of EW and SC. By using suspoemulsion, the number of application and formulation cost is reduced resulting in savings time and money. This formulation is very promising because of its advantages in safety and application, although not so many formulations have not been developed due to the difficulty of developing stable formulations as mentioned below.

In suspoemulsion, generally, two kinds of surfactants are necessary, emulsifier to emulsify oily liquid technical materials and dispersant to disperse solid technical materials. They should be compatible in one formulation. An appropriate surface-active agent may act as both an emulsifier and a dispersant. When adsorption characteristics to solid and emulsion particles are different, stable emulsion or dispersion cannot be obtained. Therefore, the selection of appropriate surfactants is significantly important but considerably difficult. At present, they are selected by trial and error method for each formulation. But easy method for preparation of suspoemulsion by using latexes as emulsion stabilizers was also reported. Alkylglucoside surfactants have been successfully utilized in both phases of a suspoemulsion.

4.1.4. Microemulsion (ME)The microemulsion is a transparent or semitransparent one liquid phase, and thermodynamically stable emulsion system. The particle size of the microemulsion is about 0.01–0.1 µm. Therefore, neither creaming nor settling takes place during storage. This formulation has almost the same advantages as those of emulsion, and there are some other advantages as follows;

There are, however, some drawbacks as follows,

This formulation contains active ingredients, emulsifiers, cosurfactants, and water. When active ingredients are solid, water immiscible organic solvents such as aromatic hydrocarbons are used to dissolve them. The amount of emulsifiers is larger than that in the emulsion. For example, about 20% emulsifiers are necessary to make microemulsion containing 10% of active ingredients. As emulsifiers, combinations of strong hydrophilic (HLB>13) and high molecular weight nonionic surfactants and hydrophobic anionic surfactants are preferable. For example, polyoxyethylenestyrylphenol ether, polyoxyethylene phenylphenol ether, and calcium dodecylbenzene sulfonate are used for microemulsions of pyrethroid and organophosphorus insecticides. Tristyrylphenol based surfactants are also used for the microemulsion of pyrethroids.

4.2. Water dispersible granule (WG, dry flowable)9, 92–96)WG was developed to prevent the dustiness of WP at the time of dilution, and this formulation disintegrates and disperses readily in water after application.

The advantages of this formulation are as follows;

WG can be formulated by various methods. Commercial water dispersible granules are formulated mainly by spray drying, pan granulation, high speed mixing, and extrusion methods. Recently extrusion method has become more popular.

4.3. Pesticide microcapsule (CS)Microcapsules are typical controlled-release formulations. The controlled-release formulations have the following various advantages;

Microcapsules (MCs) are small particles (1–1000 µm), composed of core material and an outer wall. The wall isolates the core material from the environment and protects it from environmental degradation and interaction with other materials. The core materials are designed to be released in a controlled fashion as required.97–108)

The general advantages of pesticide microcapsules are the same as those of the controlled-release formulations described above. An MC does not necessarily have all of the above advantages. Therefore, the MC’s proper design is crucial to obtain the desired characteristics according to the purpose of the application.

In order to be biologically effective, the pesticide must be released from the MC. There are two mechanisms for release.

The release behavior described above is controlled by factors such as particle size, wall thickness, type of wall materials, wall structure (porosity, degree of polymerization, crosslinking density, additives, etc.), type of core materials (chemical structure, physical state, presence or absence of solvents), and amount or concentration of core materials.

Many pesticide microcapsules are available at present, but research and development work on microencapsulation of pesticides has grown significantly in recent years. This growth has to do with the fact that a lot of advantages mentioned above can meet the current demands of the pesticide industry, that is, safer formulations and application methods, which are more labor-saving and environmentally friendly.

Some examples of functional MCs are explained.

Fenitrothion MCs for cockroach control (SumithionⓇ MC for cockroach control) were developed. Polyurethane was used as the wall material and they were prepared by interfacial polymerization.98,100,102,103,105,107,108)

Long-lasting residual activity was obtained and could be caused mainly by the trampling mechanism; the cockroaches broke the MCs when they contacted them. If trampling is the mode of action, biological efficacy depends on the MCs’ strength. It was found that the trampled percentage of MC by contact with cockroaches can be controlled by D/T, where D is a mass median diameter, and T is a wall thickness. D/T is known to be a parameter of MC strength. When the value of D/T is set properly, both initial and residual efficacy are good.

When the cockroaches trample the MCs, AI comes out from the MCs and kills the target insects. These MCs are activated only when the cockroaches make contact with them. Discussion of the physical strength of the MCs was also reported, where relationship between D/T and P50, pressure at which 50% of the MCs were broken, was explained by modifying the theory of destruction of an empty sphere with a thin wall.98,100,102,107,108)

Fenitrothion (KareitⓇMC) and fenobcarb (BaktopⓇMC) microcapsules were developed for termite control, and the action mechanism was reported to be the biting of MCs in soil by worker termites.9,98,102,107–109)

There are reported fenitrothion and pyrethroids (fenvalerate and fenpropathrin) MCs for agricultural uses whose mode of action was breaking of MC.9,98–100,102,107,108) It was found that the efficacy of MC depends on the D/T ratio, the parameter of the strength of MC, and fish toxicity and mammalian toxicity were found to depend on the D×T, the parameter of the release rate of AI into water from MC. Therefore, both fish toxicity and mammalian toxicity are controlled by the diffusion of the AI into water.

Pyriproxyfen microcapsule (PlutoⓇ MC) was developed to control the mulberry scale on tea during dormancy (from January to March). This formulation is a self-burst type.99–101,110) This formulation keeps proper microcapsule size during dilution by water and spray application. This results in drift reduction in the tea fields and reduces the risk of toxicity to the silkworm greatly. After the spray, liquid sticks on the tea trunk, dilution water evaporates, and microcapsules themselves collapse by their weight to release AI, which remains stably on the tea trunks for a long time. Therefore, dormant spray of this formulation shows good control efficacy against the mulberry scale for a long time. This method is a new labor-saving technique for farmers.

Recently research works on nanoencapsulation of pesticides are being progressed, and several papers have been reported. This technology aims to reduce the indiscriminate use of conventional pesticides and ensure their safe application. The purpose of research is mainly the development of nanoencapsulated pesticides that have slow releasing properties with enhanced solubility, permeability, and stability.111)

Nanoencapsulated pesticide formulations are able to reduce the dosage of pesticides and human exposure to them, which is environmentally friendly for crop protection. But cost benefit analysis and safety considerations are very important.

It is reported that water-based mPEG-PLGA nanoparticle formulation containing metolachlor shows enhanced water solubility of hydrophobic metolachlor and contains no organic solvent and surfactant, which represent one of the most important sources of pesticide pollution.112) Absorption of nanoparticles into rice roots suggested a possible transmitting pathway of the metolachlor formulation and increased utilization of metolachlor. This nanoparticle showed higher effect than non-nano forms on Oryza sativa, Digitaria sanguiralis.

The research work was reported on pyraclostrobin loaded lignin-modified nanocapsules. Lignin-modified nanocapsules show improved bioavailability to pathogenic fungi, lead to improved mobility and less residue in the soil, and provide excellent control in tomatoes against soilborne fungal diseases.113)

In order to meet the recent requirement of the pesticide industry, various new formulations and application technologies have been developed.

In this article, the outline of pesticide formulations was explained, and then recent advances in development of new formulations and application technologies were elucidated, such as labor-saving formulations and application technologies, environmental load reduction technologies and user-friendly formulations.

The requirement of the pesticide industry will increase in the future, and in order to meet such requirement, various kinds of new, functional and high technologies should be developed. In this process, the concept of PDS will become more important, where controlled-release and targeting technologies are essential.

Recently various high technologies such as IT, ICT, IoT, and AI are making huge progress in various fields, and these technologies can be applied to agricultural field including formulation and application technologies. Among them, sensing technologies have considerably advanced and drones are widely used in agriculture. By using these technologies, new formulation and application technologies that accord with PDS can be developed, especially from targeting, labor-saving and user and environmentally friendly points of view.

It is also highly desirable to develop smart formulation and application technologies in future, that have sensing, processing, and actuating functions. Then pesticide application will become very efficient, safe, and labor-saving.

In this work, we received scientific and technical information from Dr. Yoshida (The National Agriculture and Food Research Organization) and Dr. Miyahara (The Japanese Society of Agricultural Machinery and Food Engineers). We would like to express our sincere gratitude here. We would like to thank also Editage (www.editage.com) for English language editing.