2025 Volume 6 Issue 1 Pages 79-90

2025 Volume 6 Issue 1 Pages 79-90

Urban road projects are crucial for sustainable development but often face challenges such as cost overruns, delays, and inefficiencies. Lean construction principles, focusing on waste reduction and value enhancement, offer a solution to these issues. However, successful implementation relies on understanding diverse stakeholder perspectives involved in the construction industry, which can vary significantly. This study investigates stakeholder views on leanness assessment parameters for urban road projects in Addis Ababa, Ethiopia, through a questionnaire survey. A mixed-method approach was used, combining qualitative and quantitative data, including a Likert scale-based pairwise survey of stakeholders such as clients, contractors, and consultants. The survey results were analyzed using the Analytical Hierarchy Process (AHP) and Hierarchical Clustering on Principal Components (HCPC) to identify key parameters influencing lean outcomes. AHP ranked leanness parameters, including Quality, Time, Sustainability, Safety, Cost, and Risk, and HCPC grouped stakeholders and identified patterns of consensus and divergence. The analysis revealed risk management, quality control, sustainability enhancement, cost efficiency, time management, and quality improvement as top priorities across stakeholders in different clusters. It was observed from the cluster analysis that client stakeholders preferred quality management over other parameters, whereas the stakeholders from construction and site management preferred more cost and time over other parameters. These findings provide actionable insights for fostering collaboration, enhancing decision-making, and embedding sustainability in lean construction, advancing the understanding of stakeholder engagement, and promoting more efficient, sustainable urban infrastructure development.

The construction sector is a cornerstone of economic development, providing critical infrastructure and supporting social progress. Urban road construction, in particular, is integral to the development of cities by enhancing mobility, connectivity, and access to essential services1). However, urban road projects in many developing countries, including Ethiopia, often suffer from significant inefficiencies, delays, cost overruns, poor resource utilization, and sustainability challenges.

These issues result from fragmented project delivery processes, limited adoption of advanced management practices, and misalignment of stakeholder expectations. Addressing these challenges requires a shift toward lean construction, a methodology that emphasizes process improvement, minimization of waste, and the delivery of value to stakeholders2).

Lean construction principles, derived from lean manufacturing, aim to eliminate non-value-adding activities while optimizing the flow of resources and processes3). In urban road construction, leanness refers to the extent to which construction activities are streamlined to reduce time delays, cost deviations, material wastage, and environmental impacts. However, the success of lean construction is highly dependent on the active involvement and alignment of diverse stakeholders, including project owners, contractors, consultants, engineers, and policymakers. These stakeholders often have differing perspectives and priorities regarding leanness assessment, influenced by their roles, experiences, and project objectives. For instance, contractors may prioritize cost and time efficiency, while policymakers may emphasize environmental sustainability and long-term infrastructure values4). These variations can lead to fragmented decision- making, miscommunication, and suboptimal project outcomes. An understanding of stakeholders’ perspectives on leanness assessment parameters is therefore essential to foster consensus, identify priority areas for improvement, and implement lean principles effectively.

To address this critical gap, this study adopts a data-driven analytical approach that integrates the Analytic Hierarchy Process (AHP) and Hierarchical Clustering on Principal Components (HCPC). AHP, developed by Thomas Saaty, is widely recognized for its ability to structure complex decision-making problems and prioritize criteria based on pairwise comparisons5). In this study, AHP is used to capture and quantify stakeholders’ subjective judgments regarding leanness assessment parameters, such as cost deviation, time overruns, resource efficiency, process flow optimization, and environmental sustainability. In addition to AHP, HCPC clustering is employed to uncover patterns and degrees of stakeholder alignment or divergence. This dual- method approach will provide a comprehensive understanding of stakeholders’ priorities and facilitate data-driven decision-making to enhance leanness in urban road projects.

This research contributes to the body of knowledge in lean construction, stakeholder management, and sustainable urban development in several ways. First, it provides a structured framework for understanding and analyzing stakeholders’ perspectives on leanness assessment using the AHP in urban road projects. Second, it identifies critical parameters influencing leanness in urban construction and highlights areas of alignment or divergence among stakeholders by applying HCPC to uncover patterns in stakeholder responses. This enables a deeper understanding of stakeholder groups and their perspectives. Third, the study emphasizes the role of data-driven approaches in decision-making, offering a comprehensive understanding of how leanness is perceived in urban road projects and how these insights can inform strategies to improve project outcomes.

(1) Lean construction

Initially developed by the Toyota Production System (TPS), lean production was introduced to build environment to address inefficiencies inherent in traditional construction processes. Key principles of lean construction include eliminating waste, improving quality, and ensuring continuous improvement throughout the project lifecycle6). In the context of urban road projects, lean construction has significant potential to address common challenges such as cost overruns, schedule delays, and resource wastage. According to Sacks et al., urban road projects often experience delays due to inefficiencies in material procurement, design changes, and contractor coordination7). The adoption of lean methods, including Last Planner Systems (LPS), Value Stream Mapping (VSM), and Just-in-Time (JIT), helps in streamlining workflows, minimizing waste, and optimizing the use of resources. By focusing on value creation and stakeholder satisfaction, lean construction enhances project performance and contributes to the sustainability of urban infrastructure.

The stakeholders in urban road projects can be broadly categorized into internal and external groups. Internal stakeholders include project managers, contractors, engineers, and designers, while external stakeholders encompass government bodies, local communities, and environmental organizations. Each group brings a unique set of expectations and concerns, which can influence the project’s success or failure. Odjelua et al. stress that stakeholder expectations need to be understood and integrated into the decision-making process to ensure project success8). Misalignment between stakeholders can lead to conflicts, project delays, and inefficiencies, undermining the potential benefits of lean practices.

A study by Fischer et al. highlighted that different stakeholders often prioritize different aspects of the project, such as cost, time, quality, and environmental impacts9). Leanness assessment parameters refer to the criteria used to evaluate the degree of lean practices applied to a project. These parameters include metrics related to cost performance, time efficiency, resource utilization, quality control, and environmental sustainability10). The accurate identification and prioritization of these parameters are essential to measure the effectiveness of lean construction strategies and their alignment with project goals.

In urban road construction, several parameters influence leanness, including cost deviation, time overruns, material waste, and energy consumption. Cost and time overruns are particularly problematic in developing countries, where economic and logistical challenges may exacerbate inefficiencies. Koskela emphasized that lean construction can mitigate these issues by improving communication, enhancing process transparency, and reducing uncertainty in project delivery11). A widely used tool for assessing leanness is Value Stream Mapping (VSM), which identifies waste across various stages of the construction process, from design through to project completion. Sacks et al. argue that VSM is particularly effective in mapping material, energy, and information flows, allowing for the identification of inefficiencies and areas for improvement. In urban road projects, the application of VSM can reduce material waste, optimize scheduling, and improve overall resource allocation7).

Various researchers propose the use of AHP in construction projects to assess leanness parameters and guide decision-making. However, it often requires a large amount of subjective input, making it essential to account for stakeholder perspectives. While AHP facilitates the systematic prioritization of leanness parameters based on stakeholder preferences, additional analysis is needed to better understand the variability in these perspectives. In this regard, HCPC clustering provides a means to analyze patterns and group stakeholders based on their responses. HCPC clustering, which combines hierarchical clustering with Principal Component Analysis (PCA), helps identify underlying trends in stakeholder opinions and highlights areas of alignment or divergence12). In construction management, HCPC clustering has been used to analyze stakeholder perceptions in areas such as risk management, quality assurance, and project performance. Guerra et al. demonstrated how HCPC could reveal distinct stakeholder groups based on their responses to project variables, thus enabling more effective stakeholder management and communication13). The use of this combined methodology can provide a powerful tool for understanding stakeholder perspectives on leanness and offers a detailed picture of how different groups prioritize leanness parameters.

(2) Challenges and gaps in leanness assessment in developing countries

While lean construction has been widely studied and implemented in developed countries, its application in developing countries presents unique challenges. Mengistu et al. note that the construction industry in developing nations often suffers from issues such as corruption, lack of collaboration and benchmarking, lack of skilled labor, inadequate project management practices, and limited access to technology14). Several studies indicate that the adoption of lean principles in developing countries faces considerable challenges and gaps. One of the most prominent barriers is the limited technological adoption and lack of understanding of lean methodologies among construction professionals in these regions. According to Sarhan et al., many construction firms in developing countries rely heavily on traditional practices, and the lack of training in modern tools limits the awareness of lean’s potential benefits15).

Another significant challenge is leadership and management commitment, which is critical for successful lean implementation. Researchers such as Singh et al. emphasize that, without proactive leadership and strategic management support, lean practices are often perceived as unnecessary, leading to poor adoption rates16). Cultural resistance to change also plays a significant role in impeding the adoption of lean principles in developing countries. Scholars like Salem and Zimmer stated that the entrenched reliance on traditional construction methods and a lack of motivation to adopt new approaches contribute to the slow progress of lean implementation in these regions17). Similarly, Olamilokun et al. highlight management and skills gaps as major hindrances, particularly in small and medium-sized enterprises in Nigeria that often do not have the resources to invest in lean training programs18). For instance, Ethiopian urban road construction projects face additional challenges related to resource constraints, political instability, and a lack of standardized processes19). The absence of a robust framework for leanness assessment further complicates efforts to optimize project performance. Existing studies often fail to account for the specific contextual factors that influence the implementation of lean practices in developing countries. This research aims to fill this gap by providing a data-driven analysis of stakeholder perspectives on leanness assessment parameters, tailored to the Ethiopian context.

The methodology flow chart of the research is shown in Fig.1. The details steps are as follows.

(1) Data collection

In order to analyze the patterns of stakeholders’ perspectives on leanness assessment in urban road projects of Ethiopia, data were collected through a stakeholder survey considering urban road projects in Addis Ababa, Ethiopia, a rapidly growing city facing significant infrastructural demands and sustainability challenges. As the capital city, Addis Ababa serves as a hub for economic activities, but its road infrastructure is often constrained by inefficiencies, poor planning, and limited adoption of lean practices. Hence, the questionnaire survey was prepared and distributed to stakeholders in Addis Ababa City Roads Authority (AACRA) in May 2023.

The number of respondents was selected using a purposive sampling approach based on their role in urban road construction. The stakeholders in the construction industry were internal stakeholders, including project managers, engineers, contractors, design teams, supervision teams, road asset directors, and engineers involved in the planning, execution, and administration of urban road projects. The survey targeted 75 stakeholders and 65 completed surveys were received, achieving a response rate of 87%. The respondents’ distribution reflected the composition of the Addis Ababa roads authority stakeholders; therefore, the sample members are proportional to their representativeness in the group analyzed in this study. From the resulting number of respondents, the members were classified by organization relationship in three categories as clients, contractors and consultants, with each category further classified based on their departments, such as design and procurement, planning and control, construction and site management, and health and safety. The distribution of the respondents by their role and department are shown in Fig.2.

The original questionnaire survey was designed to gather information on five topics: background information, factors affecting road project delivery, waste during road infrastructure delivery, performance evaluation for road infrastructure delivery, and lean construction approach for road infrastructure projects. However, for this study, only data on the background information of the respondents and the factors affecting road project delivery were used. The latter question collected data on the stakeholders’ perspectives by pairwise comparison of the importance of leanness assessment factors or parameters. The question asked the respondents to judge the relative importance of one factor or parameter over another using a scale from 1 to 9, where 1 represents both factors or parameters as equally important, and 9 represents that one factor or parameter is extremely more important than the other factor or parameter.

(2) Details of survey design and approach

The selection of leanness assessment parameters was guided by a review of existing literature and consultation with subject matter experts in lean construction and urban road projects. Considering the project performance, AACRA uses six indicators in different phase of road projects with different level of concern (Fig.3). These indicators were analyzed to observe if they reflect the lean construction principles and method. After consideration, all six parameters available were used for leanness assessment. The parameters emphasize waste minimization and value optimization of urban road projects by improving cost-time efficiency, quality, safety, and sustainability while minimizing risk-related issues.

The key parameters considered in this study were: Cost Performance as “cost,” which evaluates how effectively cost is managed and affect the leanness of the projects; Time Efficiency as “time,” which measures how well a project meets deadlines and avoids delays; quality management as “quality,” which focuses on adherence to quality standards and minimizing defects; sustainability as “sustainability,” which evaluates the project’s impact on the environment, such as waste generation, energy consumption, and pollution; and Risk management as “risk,” which focuses on measuring how different stakeholder groups perceive their involvement in decision-making and overall project satisfaction. The contextualization of the leanness assessment is presented in Fig.3. These parameters formed the basis of the questions in the survey and were framed as parameters to be prioritized for leanness assessment based on stakeholder preferences.

This study adopted a mixed-methods approach to investigate stakeholder perspectives on leanness assessment parameters in urban road projects in Addis Ababa, Ethiopia. AHP and HCPC were utilized to conduct a comprehensive analysis of stakeholder preferences, priorities, and patterns. This approach helps to assess how different stakeholders prioritize leanness parameters and identify distinct clusters of stakeholder perspectives, providing insights into the underlying factors that influence leanness in urban road projects.

(3) Analytic Hierarchy Process (AHP)

AHP is a multi-criteria decision-making tool that decomposes complex problems into simpler hierarchies. In this study, AHP was used to determine the relative importance of each leanness parameter from the perspective of stakeholders involved in urban road projects. The AHP process included the following steps:

・ Problem Structuring: The problem in this study was “prioritizing of leanness assessment parameters.” It was structured into a hierarchical model with the overall goal of prioritizing leanness assessment parameters at the top level. The next level comprised the different leanness parameters (cost, time, quality, safety, sustainability and risk) and the third level stakeholder categories (clients, contractors and consultants) as shown in Fig.4.

・ Pairwise Comparisons: The responses of stakeholders were collected in a pairwise comparison of leanness parameters, using a 1-9 scale (1 indicating equal importance and 9 indicating extremely more importance of one parameter over the other).

・ Calculation of Weights: Based on the pairwise comparisons, an eigenvector analysis was employed to compute the relative weights of each leanness parameter. This step involved converting pairwise comparison data into a normalized set of weights that reflects the relative importance of each parameter.

・ Consistency Check: The consistency of stakeholder perspectives was assessed using the consistency ratio (CR). A CR value less than 0.1 was considered acceptable, indicating that the respondents’ judgments were consistent20).

Using AHP, first the general weights were calculated for each leanness parameter which was utilized for comparison and discussion purposes.

(4) Hierarchical Clustering on Principal Components (HCPC)

HCPC combines PCA with hierarchical clustering was used to identify patterns and clusters within data. This method helps to group similar responses of the stakeholders based on underlying patterns and principal components, offering a comprehensive view of stakeholder perspectives on leanness parameters. For HCPC, the pair-wise comparison data representing stakeholders’ perspectives on leanness parameters (cost, time, quality, safety, sustainability, and risk), which originally range from 9 to 1/9, were converted into equal interval data sets from 8 to -8 for data normalization.

HCPC was then performed on the normalized data by the following steps:

・ Principal Component Analysis (PCA): PCA was applied to the response data of stakeholders regarding leanness parameters to reduce dimensionality while retaining the most significant variables. This step identified patterns in the data by transforming the data into a set of principal components, which represent underlying trends and correlations.

・ Hierarchical Clustering: After dimensionality reduction, hierarchical clustering was employed on the principal components to group stakeholders with similar responses into clusters. The Euclidean distance metric was used to measure similarity, and the ward.D2 method was applied to form clusters.

・ Cluster Analysis: The output from the HCPC analysis was visualized using a dendrogram to identify the distinct clusters of stakeholders, each with unique patterns of preferences and priorities concerning leanness assessment parameters

(5) Interpretation of results

In the final step, the interpretation of results was conducted. The HCPC analysis provided the result of each leanness parameter (cost, time, quality, safety, sustainability, and risk) within each cluster, ranging from -8 to 8. These values were then converted into their original pairwise scale, ranging from 9 to 1/9. By applying the AHP weighting method to each cluster, the weights of each leanness parameter in each cluster were identified. Subsequently, the respondents’ data were placed back to each respective clusters to characterize each cluster and identify the stakeholders within them.

(1) Characteristics of respondents

The dataset of 65 respondents were organized into categories based on organization and their respective departments. It was observed that in the organization category, the 65 respondents were 80% clients, 9.2% of contractors, and 10.8% of consultants. On the other hand, respondents’ distribution with respect to departments it was observed that, out of 65 respondents, 61.6% were from construction and site management, 16.9% from design and procurement, 16.9% from planning and control, and 4.6% from health and safety.

The questionnaire also gathered information about the number of years of experience for each of the 65 respondents. The classification per year of experience in the road sector of less than 5 years corresponded to 12.3%, between 6 to 10 years to 40%, between 11 to 15 years to 24.6%, between 16 to 20 years to 20%, and greater than 21 years to 3.1%. The analysis of results shows that, when observed by the Organization, Clients are the major group of respondents with 80%. The survey was conducted in the Addis Ababa City Road Authority (Ethiopia), which is the main client of the road construction projects; hence most respondents were from the client organization. The Consultants and Contractors are external organizations that contribute to theproject’s conclusion.

The respondents’ composition influences the results of the perspectives in the weighting of important factors, by reflecting the clients’ proportion in the data set. The results of weighting are calculated in the following subsections. The results can also be observed in the category of Department where the respondents were from. The Construction & Site Management corresponded to 61.5% of the total respondents. The smallest group was from the Health & Safety Department with 4.6%.

The years of experience can reflect the cumulative knowledge that the employee gained in the road sector. The continuity influences the respondents’ knowledge of the important factors for leanness assessment parameters, and consequently their perspectives of importance for each factor. The respondents with less than 5 years of experience can be considered as new or fresh in the dynamic of the projects. On the other hand, the respondents with more than 21 years of experience have participated in many projects as client, consultant, or contractor. The overall result of this analysis shows that a larger number of respondents (40%) had 6 to 10 years of experience in the same work position. The interval can be considered as a step further from the respondents that have less than 5 years of experience and are new in their job role. The majority of the respondents had between 6 to 20 years of experience (84.6%), being considered mature and knowledge about the project dynamic related to their respective working position independent of Organization of Department classification. The smallest portion (3.1%) have more than 21 years of experience. This group can be considered as highly experienced individuals, that are close to retirement.

(2) Assessment of weights from prioritization of leanness parameters - general respondents

The results for prioritization of leanness parameters can be calculated by using an AHP matrix in pairwise comparison. The results of the AHP analysis revealed the relative importance of the leanness assessment parameters according to the general group of stakeholders’ judgments. Aggregation of pairwise comparisons from all respondents using geometric mean was performed to construct a single aggregated comparison matrix as shown in Table 1. The table illustrates the pairwise comparison matrix used to derive priority weights.

To ensure the reliability of the AHP results for aggregated judgment in group decision-making, the Consistency Ratio (CR) was calculated for the whole data set. The overall consistency of the combined data is calculated and its CR value was 0.007, indicating a high consistency in the aggregated pairwise matrix. This is within the acceptable threshold of 0.1, confirming that the priority weights derived from the pairwise comparisons are reliable and reflect logically coherent judgments provided by the respondents were reliable and consistent.

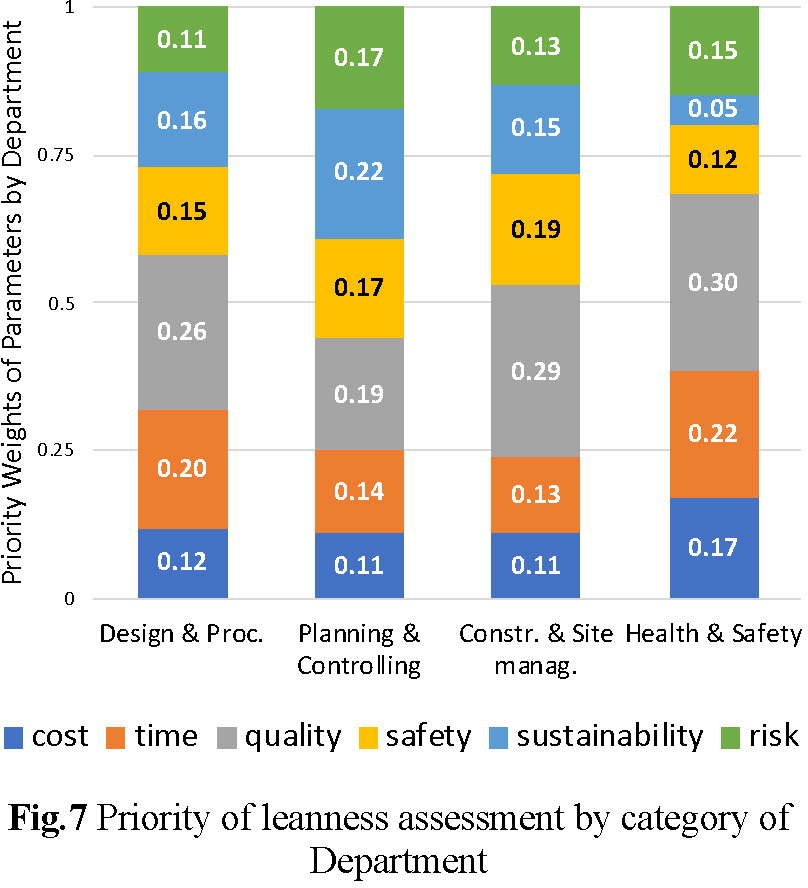

The weights were calculated from the pairwise comparison matrix and the results from the total groups of respondents can be seen in Fig.5. The results by category of organization and department can be seen in Fig.6 and Fig.7, respectively.

The results for the general group of respondents Fig. 5 show that the highest weight was assigned to Quality (0.26), followed by Time Management (0.20), reflecting the general prioritization of Quality and Time management in project delivery in urban road projects. Sustainability (0.16) and Safety (0.16) were considered the following important parameters to be considered, while Risk (0.11) and Cost (0.12) received relatively lower priority in the general responses. The general answers were the weight of indicators from all answers combined without considering the organization and department. This result reflects that quality prevails over the other parameters being almost 50% of the weight for leanness assessment of road infrastructure projects. It may be due to the reason that client was the major group of respondents and they mostly preferred quality and time in the construction projects more specifically for important projects like urban road projects.

Regarding the results for the weighting when considering the organization classification, clients and consultants gave Quality the highest weight with 0.27 and 0.33, respectively. Clients and Consultants also shared the lowest values for the Cost parameters. However, Contractors considered Time as the most important parameter, giving 0.30 weight to this indicator. This group also considered Sustainability as the indicator with least priority (0.09), which may be due to low awareness of sustainable construction. The results classified by the department found that Quality was the most important parameter for the four departments. However, the lowest weight values were different among the groups. Design & Procurement considered Risk as the lowest, whereas Planning & Controlling and Construction & Site Management considered Cost, which may be due to their involvement in project execution phase. However, Health & Safety considered Sustainability (0.05) to be the least important, which may be due to low awareness of sustainable construction.

The results for both classifications of answers show that Quality, Time, and Safety are three important factors for the respondents. This aligns with lean construction principles, which emphasize minimizing waste, and maximizing the value of the urban roads by aligning with customer’s requirements. The relatively lower importance given to cost efficiency, time, and risk management highlights a potential gap in stakeholder awareness regarding the leanness assessment based on performance evaluation criteria considerations in the construction process. This finding is particularly relevant for projects in developing countries like Ethiopia, where economic factors often take precedence over environmental and social sustainability concerns.

(3) Assessment of weights from prioritization of leanness parameters - cluster groups

The results of prioritization analysis from AHP were analyzed by using HCPC to create groups with high similarities in their perspectives, independent of the classification of organization and department. The calculation of HCPC consists of applying a hierarchical cluster on the principal components selected by performing PCA. The results can be seen in the following subsections.

(a) Determining the principal components for hierarchical clustering - PCA

The first analysis conducted was PCA for selecting the principal components to be used for HCPC. The principal components were observed by using eigenvalues, the scree plot of the values can be seen in Fig.8. The number of principal components retained was 4, accounting for 70.2% of inertia in the dataset. The PCA results revealed the first two principal components (Dim 1 and Dim 2) explained 51.5% of the total variance in the data, with Dim 1 explaining 34.9% and Dim 2 explaining 16.6%. These two dimensions have primarily contributed to explaining variance and can be associated with the relative Cost-Risk, and Quality-Sustainability parameters, as can be seen from the parameter loadings in Fig.9. The parameter loadings also show that Cost-Risk and Time-Risk were most strongly associated with Dim.1, while Quality-Sustainability, Quality-Risk, and Safety-Risk were more closely related to Dim.2, which suggests that these parameters are primary in the context of leanness assessment for urban road projects.

(b) Determining groups with similar responses - HCPC

HCPC was carried out using the principal components selected in the previous section to identify clusters of stakeholders with similar perspectives on leanness parameters. The HCPC used 4 dimensions (70.2% of cumulative variance). Fig.10 shows the dendrogram from the HCPC, illustrating the hierarchical structure of the stakeholder clusters, and Fig.11 presents a factor map of the clusters. The dendrogram was cut, resulting in six clusters grouped by similarity of responses regarding the importance of leanness assessment indicators. The clusters’ nomenclature and details can be seen in Table 2.

The factor map in Fig.11 indicates that clusters 3, 4, and 5 are overlapping when considering only the bi-dimensional space of Dim 1 and 2. The representation cannot express the Dim 3 and 4, that are also used to explain the results, making the results of these clusters overlap in the factor map representation.

(c) Characterization of cluster memberships

The results show six clusters’ groups with members from different organizations/departments and years of experience as indicated in Table 2. Considering the entire dataset (65 respondents), Cluster 4 contained the largest number of people, with 36.9% of the total. The smallest cluster was Cluster 5 with 4.6%.

Considering the Organization classification, as discussed in Section 4(1), the clients are the major group of respondents in the questionnaire survey, being 80% of the total of 65 responses. The presence of Clients also affects the clusters groups that have high number of clients for all six clusters. Among the six clusters, five are a combination of two or more classifications (Clients, Contractors, or Consultants), but Cluster 5 is 100% formed by Clients. Considering Department classification, Cluster 5 also showed a homogeneous result for members’ association with the Department of Construction & Site Management (100%). Another characteristic of Cluster 5 is that the work experience from the Clients in this cluster is from 6 to 10 years for all members.

The Department classification for the clusters also shows that Construction & Site Management members are high for all six clusters. However, Clusters 3, 4, and 6 showed significant presence of other departments in the groups.

(d) Weight of leanness parameters by clusters

The results for the priority weights from the pairwise comparison of leanness parameters can be seen in Fig.12. The overall results show that Cluster 1 presented the weight of Risk as 0.45. Cluster 2 and 5 considered Quality as predominant with 0.46 and 0.61, respectively. Cluster 6 considered Cost (0.36) and Time (0.32) as high weight value. However, Clusters 3 and 4 showed more balanced values for the weights. The highlight of Cluster 3 can be observed as a low value for Cost (0.04), and Cluster 4 presented Risk as the lowest (0.09).

Cluster 1 presented high importance for Risk (0.45), followed by Sustainability (0.23). The lowest weight value was for Cost (0.02) and Time (0.05). When considering Organization, the cluster consists on Clients (85.7%) and Consultants (14.3%), with 0% of Contractors. The members of this cluster have a range of experience in the job position of 6 to 16 years (6 to 10, 28.6% and 11 to 16, 71.4%). This cluster focus on minimizing issues related to projects risks from construction and operation phases by advocating sustainable practices. The Cluster 2 and 5 showed high values for Quality, however the other weight values contribute to differentiate both.

The Cluster 2 presented Safety with value of 0.27 that, together with quality, accounts for 0.73 of the total weighting. This group can be considered a Quality-Safety focus group. The members of the cluster group are, when considering Organization, 62.5% Clients and 37.5% Consultants. The Department classification shows that this cluster has 75% of Construction & Site Management, 12.5% of Planning & Control, and 12.5% of Health & Safety. The experience in the job position demonstrates that this cluster has most of the member with between 6 and 20 years of experience. This cluster focuses on maximizing the value of urban road projects, aligning customer and end-user requirements and standards for long term benefits of the projects.

However, for Cluster 5 Quality alone consists on 0.61 of the weighting. The other indicators are Cost (0.14) and Sustainability (0.12), and the lowest value for Risk (0.02). The members of Cluster 5 are the most homogeneous. The classification of members shows that 100% are Clients and from the Department of Construction & Site Management. All respondents also showed years of experience as 6 to 10 years (100%).

Clusters 3 and 4 can be considered more balanced when compared to the other four clusters. Cluster 3 shows a slightly higher value for Sustainability (0.25) and lowest value for Cost (0.04), while Cluster 4 considered Quality as highest and Risk as the lowest. From these weights, Cluster 3 can be considered as high Sustainability-low Cost and Cluster 4 as high Quality-low Risk.

The Cluster 3 members are classified as Clients (83.3%) and Contractors (16.7%) when considering Organization. The results for Department consideration show that 58.3% are from Construction & Site Management, 25% are from Design & Procurement, and 16.7% are from Planning & Control. The years of experience shows that most of the group consists in people with 6 to 10 years of experience (41.7%). The lowest values for 11 to 16 (8.3%) and more than 21 (8.3%) years of working experience in the job position. Cluster 4 members are 79.2% of Clients, 12.5% of Contractor and 8.3% of consultants. The Department classification shows 54.2% of Construction & Site Management, 29.2% of Design & Procurement and 16.7% of Planning & Control. The experience of the member of the groups shows that 20.8% are under 5 years and between 11 and 16. The experience between 6 to 10 and 16 to 20 years of experience are 29.2%.

Cluster 6 presented high weight values for Cost (0.36) and Time (0.32). The group can be considered as Cost-Time oriented cluster. The lowest values presented by the cluster were for Safety (0.06), Sustainability (0.04), and Risk (0.05) that presented weights under 0.10. The result for members’ classification of Organization shows that 81.9% of the members are Clients. Contractor and Consultants were both with 9.1% of the cluster. The Department classification shows that all four departments were represented in the cluster. The Construction & Site Management department members were 54.5%, Planning & Control and Health & Safety were both 18.2%. The least represented group in the cluster was the Design & Procurement with 9.1%. The years of experience for the group were 54.5% of 6 to 10 years of experience, followed by 11 to 16 with 18.2%, and the remaining (less than 5, 16 to20 and more than 21) with 9.1%. This cluster reflects a focus on project execution, where cost and time are paramount for success. This cluster may be more inclined to adopt practices that streamline processes, reduce waste, and focus on immediate project delivery.

The analysis of stakeholders’ perspectives on leanness factors enriches the understanding of the importance of leanness in road projects. In this research, six groups were identified and demonstrated the plurality of opinions from Addis Ababa City Roads Authority stakeholders. The results clarify that although there is a large number of Clients in the dataset, their opinions are not homogeneous. There are different understandings of important factors related to the leanness approach. The analysis of general respondents’ responses of weights in section 4(2) shows that quality and time are the highest values, hiding the contrast of stakeholders’ perspectives evidenced in the cluster analysis.

The results for the weights from cluster analysis also demonstrated that Addis Ababa City Road Authority stakeholders do not consider cost as an important factor in leaness projects. In general, indicators such as risk and quality showed higher values than cost, except for cluster 6; contradicting the idea that developed countries professionals understand as priority cost-time related issues.

Overall, the results suggest that a holistic approach to leanness assessment in urban road projects is required, one that takes into account the different priorities of various stakeholders. Quality management was demonstrated as central, but it is also crucial to integrate with Cost and Time optimization, Safety and Sustainability consideration, and risk management to ensure the long-term sustainability and effectiveness of the projects.

This study investigated stakeholders’ perspectives on the importance of leanness assessment parameters for urban road projects in Ethiopia by utilizing AHP and HCPC clustering for a better understanding of the various dimensions of leanness assessment and lean construction in the context of urban road infrastructure development.

The AHP results indicate the stakeholders’ priorities for leanness parameters. Stakeholders in urban road projects prioritize quality management above other leanness parameters. These findings reflect the core challenges of road construction, where project managers and contractors are often under pressure to meet quality standards and requirements. However, Cost was considered less important by many stakeholders, suggesting a gap in the recognition of efficiency, leanness, and sustainability aspects of urban road projects. This gap is particularly critical in the context of developing countries like Ethiopia, where economic constraints did not receive adequate attention.

The use of HCPC clustering showed distinct stakeholder groups. The result revealed six distinct groups of stakeholders with varying degrees of focus on different leanness parameters. Stakeholders were associated with different groups, with Cluster 1 as risk-focused, Cluster 2 as quality and safety-focused, Clusters 3 and 4 as balanced decision makers, Cluster 5 as quality-focused, and Cluster 6 as efficiency- oriented. Four clusters showed a distinct preference for one leanness parameter over the others. Two of the other clusters, Cluster 3 and Cluster 4 showed a more balanced preference of leanness parameters. This clustering analysis highlights the divergence of priorities among stakeholders and the challenge of aligning these diverse perspectives in a unified approach to lean construction.

However, these findings can be effectively utilized by integrating stakeholder priorities across different project phases, for example. When observing the stakeholders perspectives on planning and design phase about the importance of leaness indicators, the result of cluster analysis can identify the factors that are being prioritized by the stakeholders. From this, specialists can be assigned to strengthen the prioritized factors by listening to the stakeholders and addressing their concerns and the reasons for choosing a specific priority among the leanness parameters. To bridge these sometimes competing priorities, a collaborative and inclusive approach is essential. This can be achieved by using data-driven decision-making, integrating stakeholder perspectives into phase-specific lean strategies, and ensuring that road authorities develop adaptive policies that align with stakeholder-specific priorities.

The results underscore the necessity for a holistic approach to leanness assessment that considers not only the traditional factors of cost and time but also Quality, Safety, Sustainability, and Risk. To optimize leanness in urban road projects, it is crucial to integrate economic efficiency with environmental and social sustainability, ensuring that all relevant stakeholders’ concerns are addressed. Stakeholders focused primarily on cost and time efficiency should be made aware of the long-term benefits of resource optimization and environmental considerations, while stakeholders who prioritize risk, quality, and sustainability should recognize the importance of cost control and timely project delivery for the overall success of the project.

Stakeholder representatives must be involved early in the decision-making process to ensure that the projects meet both economic and social expectations. Policymakers and construction firms should prioritize stakeholder engagement as a core component of project planning and decision-making processes. In doing so, they can help foster a greater sense of ownership and collaboration among all parties involved, leading to more sustainable and efficient urban infrastructure projects, and would be beneficial for urban road construction projects, especially in cities with rapidly growing populations, such as Addis Ababa.

This study was supported by a scholarship for road asset management from the Japan International Cooperation Agency (JICA). The authors would like to thank the Addis Ababa City Road Authority (AACRA) in assisting for collecting survey response.