2023 年 64 巻 7 号 p. 1331-1345

2023 年 64 巻 7 号 p. 1331-1345

Severe plastic deformation drives bulk materials far away from equilibrium and thus opens up a new opportunity to explore hitherto uncharted regions of structure-property correlations with respect to grain size, strain and defect density under extreme conditions. This allows addressing long-standing issues in materials research, such as the validity of “effective temperature” concept and provides a set-screw for exploring the possible levels of defect design and property tuning by deformation processing. As a pre-requisite, basic issues concerning the interaction of defects of different dimensionality during deformation and their interrelation with fluxes of solutes or with segregation fields, resulting in chemo-mechanical coupling effects need to be analyzed quantitatively. In the following review, we address issues related to internal interfaces in severely deformed metals and alloys by highlighting recent observations.

Initial concepts on materials processed by severe plastic deformation (SPD) already indicated the paramount importance of internal interfaces, i.e. grain boundaries (GBs) or hetero-phase boundaries for processing-induced property modifications. Based on the interaction of lattice dislocations with the internal interfaces, a deformation-modified state of the interfaces was suggested to form.1–4) Within the original model, these deformation-modified internal interfaces have been termed as “non-equilibrium” grain boundaries.5) This term, as well as the proposed model, have been intensively and partially controversially discussed in the literature.1,6–8) For the purpose of the present paper, we are not reverting back to this discussion, but acknowledge that severe plastic deformation processing has been shown conclusively to alter the local structure of (a fraction of) internal interfaces as well as of macroscopically averaged properties of different metals and alloys in a consistent manner.4,9–12) For describing the modified internal interfaces, we shall use the term “non-equilibrium interface”5,6) or “deformation-modified interface”8) synonymously.

Aside from the obvious decrease of the grain size in the size range of less than 1 micrometer and the strengthening associated with the grain size refinement, it has been shown that after severe deformation, GBs are characterized by large strains in the grain near-boundary region.10) Moreover, significant magnitudes of the rotational components of strain fields have been observed within the ultrafine - or nanocrystalline grains or at the GBs13,14) that have been interpreted to act to stabilize the microstructure at very high defect densities.14,15) Detailed radiotracer diffusion analyses have shown that the grain boundary self-diffusion rates for substitutional diffusion are strongly accelerated after SPD processing up to more than six orders of magnitude acceleration for pure Ni, as compared to the undeformed material analyzed at identical temperatures.11)

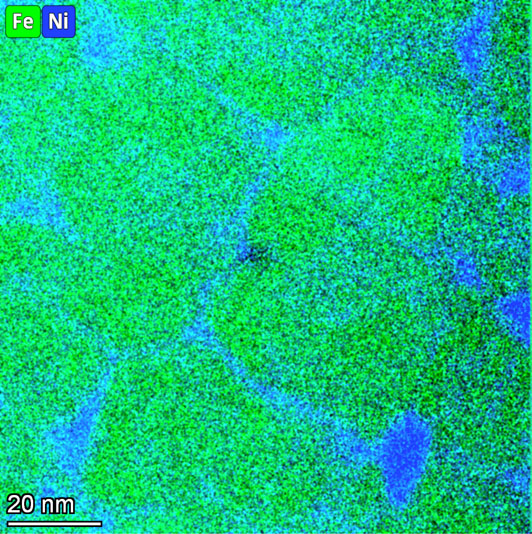

Moreover, for applications of almost any class of materials or type of processing route, constitutional complexity, specifically involving segregation, precipitation or structural transformations at GBs, need also to be considered. Several features that need to be covered for a more complete description are displayed in Fig. 1, such as e.g. the decoration of grain boundaries in a nanocrystalline Fe–Ni alloy by segregation fields. Depending on the specific type of GB, the magnitude of the Gibbsian excess at the GB varies. Triple junctions show a distinct segregation behavior that also displays an intrinsic distribution of the segregation behavior. Dislocation-GB interactions might also lead to local modifications of the atomic structure of the internal interfaces that also affect segregation, precipitation of GB phases and their transformations, leading to full mechano-chemical coupling.17,18) All of these microstructural features affect important properties such as the mechanical strength and ductility through dislocation nucleation and glide, or the stability against detrimental grain growth through the GB mobility.

While local structural details as well as a detailed description of the evolution of such heterogeneous structures of internal interfaces often are still lacking, the observations and results summarized above have important bearings for a wide range of materials behavior that might be addressed by the following questions:

In the following, we shall address these questions by highlighting experimental results for specific model systems that were selected to maximize the transfer of the results towards more generally applicable insight.

Using a mean-field description of an irradiation-modified evolution of solid solutions, a concept of an effective temperature, Teff, has been elaborated.19) The equilibrium configuration of a solid irradiated at a temperature T was found to correspond to that for a non-irradiated solid at a higher temperature, Teff,

| \begin{equation} T_{\textit{eff}} = T(1 + \Delta). \end{equation} | (1) |

The effective temperature was proposed to be defined by the irradiation parameters and materials’ properties19) and the value of Δ in eq. (1) was related to the contribution of ballistic jumps of atoms. Later on, Enrique and Bellon20) found that in the case of short-ranged ballistic jumps Martin’s concept19) applies not only to the driving force but to the fluctuations as well. However, the Teff concept breaks down in the case of finite-ranged ballistic jumps.20)

Recently, this concept of an effective temperature was extended to the case of severe plastic deformation accounting for increased concentrations of non-equilibrium (deformation-induced) point defects and, thus, a ballistically enhanced diffusivity.21–23) The original concept by Martin was found to be applicable to SPD-driven phase transformations, though with some important modifications.22) The SPD processing accelerates the mass transfer in deformed materials and determines the value of Δ in eq. (1). It was concluded that the equivalent diffusion coefficient, applicable to describe the SPD-driven mass transfer at a temperature T, is comparable with the conventional diffusion coefficient at some (elevated) Teff.22) Following these ideas, a further concept of an “equifinal” state (steady-state) was suggested to explain that the grain size, hardness and phase composition of severely plastically deformed materials become independent of their initial state.23) The establishment of a steady state was discussed in terms of a competition between the precipitation and dissolution of precipitates or between amorphization and (nano)crystallization driven by deformation-induced defects.23)

Note that a similar concept of “equifinality” has been developed without involving effective temperature arguments.24) It was hypothesized (providing experimental results for Zr) that as far as a threshold level of accumulated plastic strain for the given deformation route is approached, the material yields in a strain path-independent manner.24)

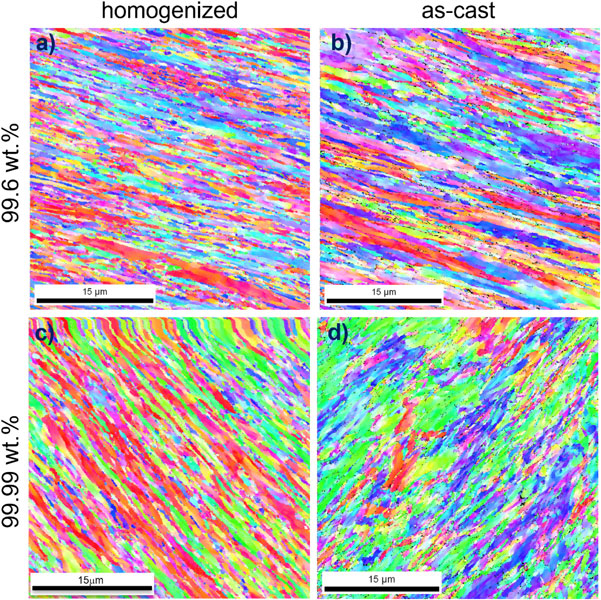

Nevertheless there are prominent cases for which the “equifinality” of the steady-state states seems to be violated, at least partially.26,27) At first glance, the same route of severe plastic deformation via either equal channel angular pressing (ECAP) or high-pressure torsion (HPT) produces, e.g., almost the same microstructures in nominally pure Ni with different initial states, Figs. 2 and 3.

Bright-field (a), (b) and dark-field (c), (d) TEM images of HPT processed Ni of high 99.99 wt.% purity with different pre-deformation states, homogenized (a), (c) and as-cast (b), (d).26)

In particular, Ni materials of 99.6 and 99.99 wt.% purity levels were processed starting from either an as-cast state26,27) or after preliminary homogenization treatment at 1373 K with subsequent very slow (step-like) cooling down to room temperature with suitably prolonged intermediate annealings.25,27) The ECAP deformation was performed by subjecting cylindrical samples to 4 passes via the BC route at room temperature in the research laboratory of Dr. R. Lapovok and Prof. Y. Estrin, Monash University, Australia.25,26) In the case of HPT deformation, 4 GPa pressure and 5 revolutions at room temperature were applied to disk-shaped samples using the same custom-built device.26,27) For specific details of the SPD processing the reader is referred to the review by Y. Estrin et al.28)

Although the final microstructures of ECAP-processed Ni of 99.6 wt.% purity were found to be practically independent on the initial state, Figs. 2(a), (b), some subtle differences are indicated for Ni of 99.99 wt.% purity, compare Figs. 2(c) and (d). One may assume a stronger contribution of dynamic recovery processes in the initially as-cast material that prohibits approaching the same final steady-state configuration. A careful comparison of the HPT- 9 processed microstructures, Fig. 3, indicates a slightly smaller grain size, lower dislocation density and more straight GBs in the initially homogenized state of the Ni of higher purity. The same conclusions were drawn for Ni deformed via ECAP processing.26)

Astonishingly, the interface properties and microstructures after post-deformation thermal treatment are significantly different in the samples with different thermal pre-histories.

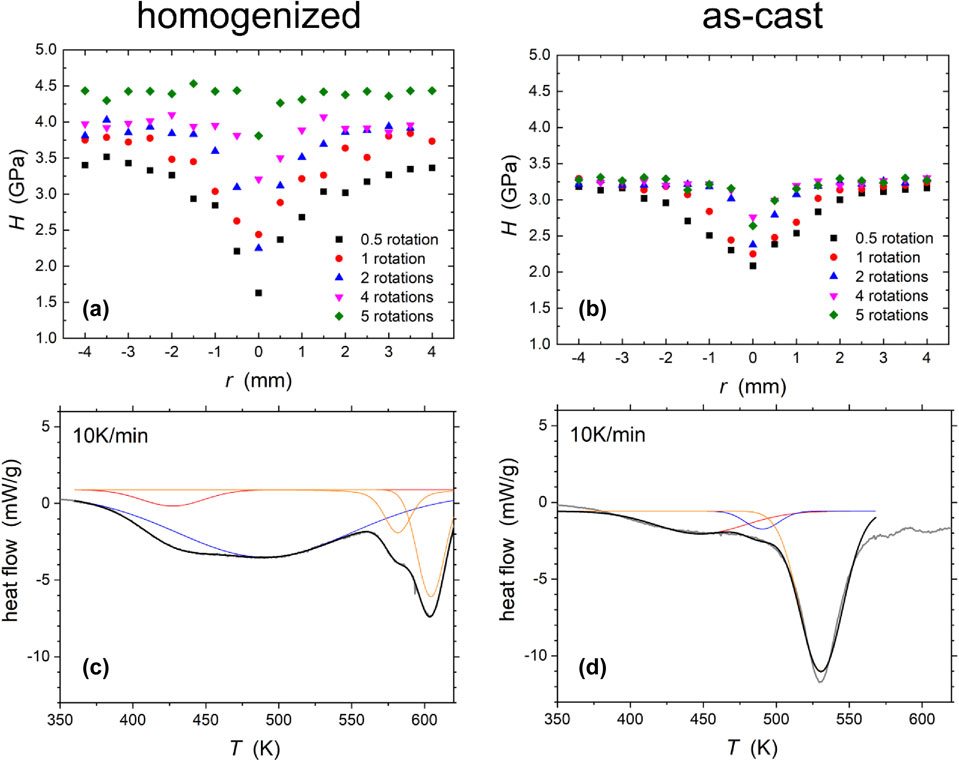

For the Ni material of higher (99.99 wt.%) purity, the impact of the thermal pre-history on the severe plastically deformed state is most pronounced. In Fig. 4, microhardness and heat release during isochronal heating for HPT-processed Ni of the 99.99 wt.% purity are compared for the two different initial states, i.e. as-cast and homogenized ones. The HPT processing of Ni with a solutionized (homogenized) microstructure resulted in an additional increase of the hardness by about 1 GPa, Fig. 4(a), (b). Moreover, the HPT-processed as-cast microstructure is less stable against recrystallization and grain growth, Fig. 4(c), (d). Indeed, the heat release due to recrystallization and grain growth is shifted to lower temperatures by about 100 K, from more than 600 K for the initially homogenized state to somewhat above 500 K for the initially as-cast state. Simultaneously, the concentrations of stored deformation-induced vacancies (heat peaks at about 400 K) are similar for the two cases and dislocation annihilation and re-arrangements (peaks at about 500 K) are more pronounced in HPT Ni processed from the homogenized state.27)

Micro-hardness (a), (b) and heat release (exothermic: down) during isothermal heating (c), (d) of HPT-processed Ni of high 99.99 wt.% purity with different pre-deformation states, homogenized (a), (c) and as-cast (b), (d).

Furthermore, GB diffusion measurements,26) Fig. 5, revealed higher GB diffusion rates and the formation of an interconnected porosity in ECAP Ni of 99.6 wt.% purity if it was deformed in the as-cast state, while no porosity was found in ECAP-processed Ni which was subjected to the preliminary homogenization treatment.25) The generic impact of SPD processing on GB diffusion is considered in more details below, Section 8.

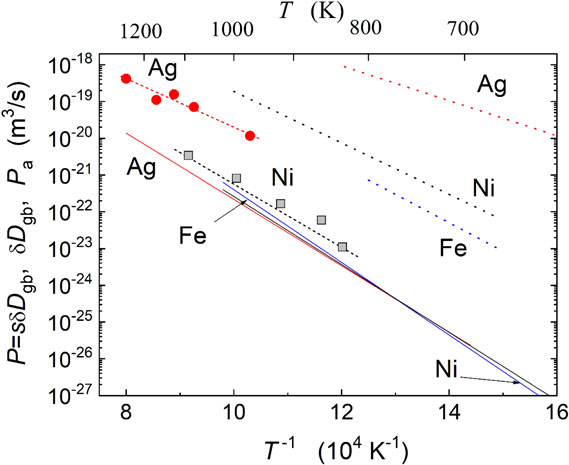

Ni GB diffusion rates measured in ECAP-processed UFG Ni of 99.6 wt.% purity with initially as-cast (red circles) and homogenized (blue lines) states in comparison to the GB diffusion rates in coarse-grained (c-g) polycrystals of 99.999 (5N, dashed line), 99.99 (4N, dotted line) and 99.6 (2N6, dashed-dotted line) wt.% purity levels.

These results suggest that SPD processing cannot be characterized simply by an effective ‘ballistic’ temperature; the similarity of the final microstructures does not guarantee the same properties and especially the same thermal stability. Thus, the heat treatment of materials before severe plastic deformation processing is a further parameter for tuning the macroscopic properties of materials and needs to be taken into account.

Furthermore, a strong reduction of the phase transformation pressure and the appearance of new phases which are not observed under hydrostatic loading are further examples against, at least the universality of, the effective temperature concept.29,30)

As a generally accepted view, it is often stated in literature that diffusion is significantly enhanced in nano-crystalline materials with respect to that in coarse-grained polycrystals due to a largely increased density of grain boundaries serving as short-circuits for the atomic transport. This is typically true, especially for metallic materials for which GB diffusion is faster than bulk diffusion31) since the increased density of GBs increases definitely the total diffusion flux. However, does the diffusion rate along general high-angle GBs depend on the grain size, too? This makes the problem even more tricky (for a given GB coverage by impurity elements). In this respect, the issue of chemically identical GB compositions is of paramount importance. It is known that a materials’ purity plays a key role in determining the rates of GB transport and the purer the material, the faster the GB diffusion and the lower the corresponding activation energy are.34) For a material with a given total impurity content, the GB coverage by a strongly segregating impurity will decrease with decreasing grain size,35) simply because the same amount of an impurity element has to be distributed over a larger number of corresponding GB sites. Following these reasonings, an increase of the GB diffusivity with decreasing grain size (“GB purification by nanostructuring”) has been suggested36) at a given nominal purity.

Apart from these purity issues, there is no direct relationship of the GB diffusion coefficients and the grain size in a polycrystalline material, as it will be shown below. Generally, several models may be suggested to account for a hypothetical “dependence” of GB diffusion coefficients on the grain size (in a nominally high-purity material):

In the following, we will scrutinize these hypothetical concepts using the experimental data available.

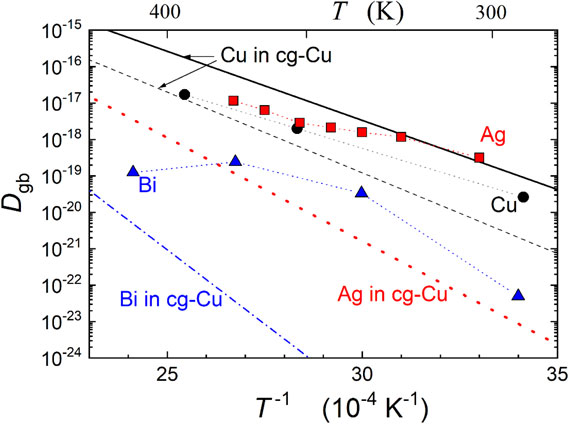

Pioneering measurements,37–39) as reviewed, e.g., by Gleiter,40) indicated an enhancement of the GB diffusion coefficients with decreasing grain size. In Fig. 6, the most reliable diffusion coefficients measured for high-purity polycrystalline Cu (lines) are compared with the results of early diffusion measurements for nanocrystalline Cu (symbols).

Self-diffusion of Cu37) and solute diffusion of Ag38) and Bi39) in nanocrystalline Cu (symbols) in comparison with their diffusivities in coarse-grained material (cg-Cu)34,42,43) (straight lines). GB self-diffusion of Cu in coarse-grained samples was measured in the materials of the purities 5N (dashed line) and 5N8 (solid line).34)

While self-diffusion of Cu in nanocrystalline copper is found to be in line with the independent results for very pure coarse-grained copper material,41) the diffusivities of strongly segregating solutes as Bi or Ag seem to be significantly enhanced, Fig. 6. However, the results of tracer diffusion measurements might be affected by contaminant microstructure characteristics which are related to the processing routes of the nanocrystalline materials.

Potentially, residual porosity, especially interconnected (percolating) porosity, can strongly affect the atom transport and hinder reliable measurements of the GB diffusion rates. Using the radiotracer technique, diffusion of Fe,44,45) Ni,46) and Ag47) in a nanocrystalline γ-Fe–40%Ni alloy was carefully measured, Fig. 7.

Temperature dependencies of Ag,47) Fe44,45) and Ni46) diffusion along boundaries between the nano-grains (solid lines) and along boundaries between the grain agglomerates (dashed lines) in nano-γ-FeNi in comparison to Ag (filled circles) and Ni (squares) GB diffusion in coarse-grained γ-FeNi of the same composition.48)

Relatively deep penetration profiles were obtained, which allowed to quantify the diffusion rates in materials with an inherent coexistence of different diffusion short circuits. In fact, the boundaries between the nanocrystalline grains were found to co-exist with interfaces between agglomerates of nano-grains, dislocations, low-angle GBs, triple junctions, internal surfaces in pores, etc.7) As a result, a multi-level hierarchy of diffusion paths might co-exist in real nanocrystalline materials that has to be taken into account in the analysis. A theoretical framework has been elaborated44,46,47) which showed that a careful discrimination of the contributions is possible and it provides a consistent picture, as shown in Fig. 7.

The results clearly indicate that self-diffusion of both, Fe and Ni along the nanocrystalline grain boundaries (grain size of about 100 nm44)) proceeds with similar rates as in a coarse-grained polycrystal of the same composition (grain size above 50 µm48)). All elements diffuse significantly faster along the interfaces between the grain agglomerates (dotted lines in Fig. 7), which was related to an increased excess volume at those interfaces.46) Astonishingly, the diffusion rates for Ag diffusion along relaxed high-angle grain boundaries in the coarse-grained material, red circles in Fig. 7, exceed those for Ag diffusion along the nano-GBs, red line in Fig. 7, by about two or even more orders of magnitude. The reason is that Ag GB diffusion coefficients, Dgb, were extracted in the case of the nano-crystalline material, while the triple products, P = sδDgb, were obtained for the coarse-grained material. Here s is the segregation factor and δ the GB width (known to be about 0.5 nm for FCC metals36,49)). The difference in the two data sets corresponds to the segregation factor s which can be estimated by setting the GB diffusion rates in nanocrystalline and coarse-grained materials of the same composition as equal.47) Only by accounting for the hierarchy of the short-circuit paths in the nanocrystalline material it becomes possible to perform reliable diffusion analysis and derive the correct GB diffusion parameters.47)

Thus, the diffusion studies for nanocrystalline Fe–Ni alloys confirm that the GB diffusion coefficients do not depend on the grain size down to the 100 nm scale.

In order to investigate this phenomenon further, grain boundary diffusion in nanocrystalline Cu samples produced by spark plasma sintering with grain sizes of about 35 and 44 nm were measured by the radiotracer method using the 63Ni isotope.52)

The measured diffusivities53) turned out to be comparable with those determined previously for Ni GB diffusion in well-annealed, high purity, coarse-grained polycrystalline copper,50) substantiating the absence of a grain size effect on the kinetic properties of GBs in a nanocrystalline material down to grain sizes of 35 nm, Fig. 8. Simultaneously, the analysis predicted that if triple junction diffusion of Ni in Cu is enhanced with respect to the corresponding GB diffusion rates, this enhancement is less than by a factor of 500 within the temperature interval from 420 K to 470 K.52)

Grain size, d, effect on GB diffusion in FCC materials. Ni GB diffusion was measured in coarse-grained polycrystalline Cu,50) d = 100 µm (red solid line), ultra-fine grained Cu,51) d = 300 nm (red circles), Cu52) with the grain size of d = 35 nm (red squares), d = 45 nm (red triangles up), d = 55 nm (red triangles down), coarse-grained γ-Fe–40%Ni alloy,48) d = 50 µm (blue dash-dotted line), and nanocrystalline γ-Fe–40%Ni alloy,46) d = 100 nm (blue solid line). Fe diffusion has been measured in nanocrystalline γ-Fe–40%Ni alloy,46) d = 100 nm (black solid line). Tm is the melting point of the corresponding material.

In Fig. 8 the diffusion rates of Ni along Cu GBs are compared for different grain sizes, ranging from 35 nm52) to 300 nm54) and finally to more than 100 µm.50) All data sets agree well, substantiating the absence of a “grain size effect” on GB diffusion. The same is seen to be true for the fcc Fe–Ni alloy, Fig. 8.

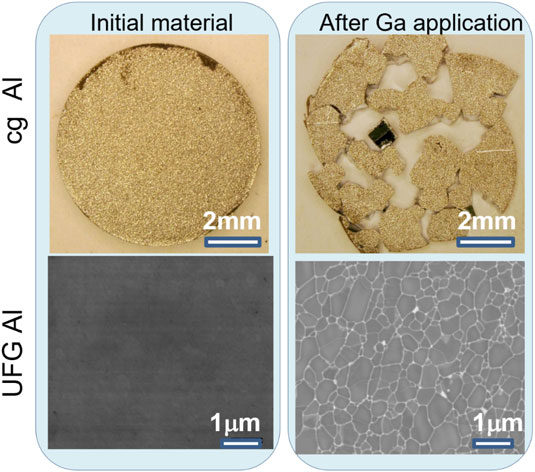

In the presence of certain liquid-metals, such as gallium, bismuth or mercury, many ductile polycrystalline metals including aluminum, nickel and copper fail by catastrophic brittle fracture through so-called “Liquid-Metal Embrittlement (LME)”,55–58) see Fig. 9, upper raw.

Catastrophic failure of coarse-grained polycrystalline Al after exposure to liquid Ga (upper raw) and sustainability of UFG Al produced via HPT processing (5 GPa + 5 revolutions at room temperature) with GB poisoning by Ga (bottom raw). Adapted from Ref. 59).

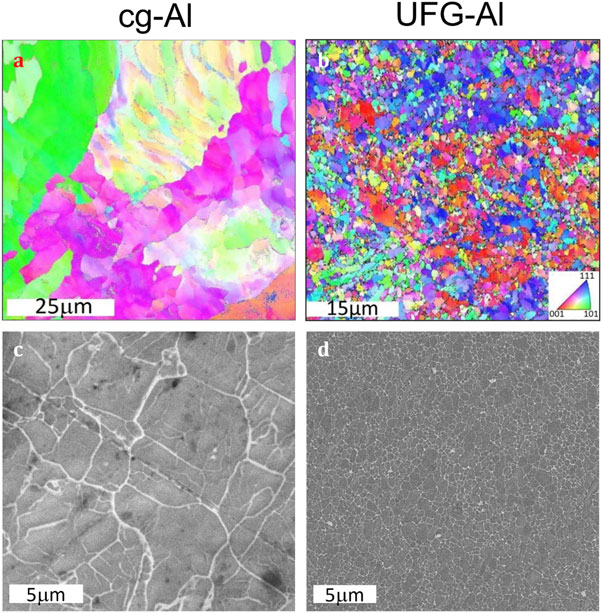

This phenomenon presents a challenge in a wide range of processes with high technological importance (welding, brazing, soldering, galvanizing, heat treatment, hot working, etc.) and it is particularly important in nuclear reactors in which liquid metals are used as coolants or as spallation targets.60) As accepted in the literature, the embrittlement phenomenon is due to the formation of a liquid film along GBs of the polycrystalline host metal.61) Thus, it might be expected that SPD-induced modifications of the structure of GBs and near-boundary regions could also affect LME. Applying liquid Ga on one side of a disc-shape sample and monitoring its appearance on the opposite side in a Scanning Electron Microscope (SEM) in-situ, a strong enhancement of the penetration rate after SPD processing by a factor of about 20 was observed.62) Remarkably, the fast Ga penetration along the GB network of the UFG Al (1050 alloy), Fig. 10, did not result in a complete disintegration of the polycrystalline structure, as in the case of the coarse-grained material, Fig. 9, bottom raw. Yet, strong embrittlement still followed from the Ga penetration. The liquid Ga penetration was studied by a first appearance method directly in SEM, Fig. 11. Predominant Ga penetration along triple junctions and high-angle GBs is seen, still low-angle GBs and dislocation cells contribute to Ga penetration at later stages, too, Fig. 11.

EBSD maps of (a) cast coarse-grained and (b) HPT-deformed 2N6 Al with Ga decoration as a result of Ga penetration from opposite side (c), (d). Adapted from Ref. 59).

SEM micrographs of coarse-grained (a), (b), (c) and UFG (d), (e), (f) Al in as-prepared states (a), (d), after the first appearance of penetrated Ga (b), (e) and after longer waiting times (c), (f). The black arrows in (f) illustrate the areas on which the Ga layer has spread over the surface after 24 h. The EDS analysis performed along the red line indicated in (b) is shown in (g). Adapted from Ref. 59).

Moreover, the penetration process of Ga along the GB network in severely deformed (HPT-deformed) Al was studied using dilatometry, atomic force microscopy (AFM) and scanning electron microscopy (SEM) including electron-backscatter diffraction (EBSD). Unexpectedly, two-stage length changes were observed which are explained by a superposition of two opposite trends with different time constants – which is (i) a net expansion of the sample as a result of liquid metal penetration-induced Ga segregation at Al GBs and, (ii) a compression of the sample due to precipitation of Fe-rich precipitates facilitated by Ga wetting of Al GBs. In total, a net shrinkage of the HPT-processed sample was measured as a result of Ga application, whereas the Ga effects on coarse-grained samples are significantly less pronounced by, at least, one order of magnitude.

The appearance of new grains as a result of liquid metal-induced recrystallization and the formation of Fe-rich precipitates were also observed. These phenomena also contribute to the observed shrinkage of the sample after Ga application. Indications for the existence of GB sliding events promoted by the formation of a quasi-liquid Ga-rich film along Al GBs were found. Presently, it is not clear whether the small grain size alone or its special state induced by HPT-processing influence the observed dilatometric changes more pronouncedly, although an enhancement of the kinetics of liquid Ga penetration is obvious for severely deformed samples.

In order to test the impact of severe plastic deformation on the poisoning effect, the Al 1050 material was subjected to SPD using HPT with a hydrostatic pressure of 4 GPa and 5 revolutions. The deformation was performed at room temperature and almost homogeneous grain refinement with an average grain size of about 1.4 µm was obtained. Additionally, Al–Ga alloys were synthesized via HPT deformation. To obtain an Al-alloy with low Ga concentration (5 wt.%), Al was severely deformed first. Subsequently a droplet of Ga sufficient to wet the sample surface of the Al disc was applied, 19 which then permeated into the UFG-Al sample. A sample with higher Ga content was prepared by repeating twenty times the HPT process (4 GPa, 2N) followed by Ga exposure after each HPT process. The Ga concentration was monitored by EDX. Remarkably, the maximum Ga amount was found to be about as high as 30 wt.%! after SPD-processing the Al–Ga alloy which corresponds to about 150% of the maximum solubility of Ga in coarse-grained Al. Even more remarkable is the fact that the Al–Ga alloy with a high Ga content partially showed a structural integrity as indicated in Fig. 9. It should be noted that the scale bars in Fig. 9 are different to allow the observation of the microstructure at different scales corresponding to the grain size. However, catastrophic failure due to the disintegration of the material after Ga penetration was not observed for the HPT-processed material, despite the enormous amount of Ga incorporated. This result clearly indicates that the process of severe plastic deformation involves modifications of the structure of internal interfaces as well as near-interface regions which serve to modify the thermodynamics of wetting, absorption and solubility in addition to modifying the kinetics of atomic transport along the grain boundaries. It should be emphasized at this point that these results also indicate that a concept based on an effective temperature for describing the states that are attainable during SPD does not hold as the measured amount of Ga that went into the (over-saturated) solution is higher than the absolute maximum of the equilibrium Ga solubility in Al at any temperature below the melting point of Al.63) Moreover, the increase of GBs in Al after SPD processing alone, allowing for an enhanced solubility for Ga at GBs, also cannot explain the observed high solubility since the fraction of atomic sites situated in or at GBs was less than 1%, i.e. clearly too low to account for the measured solubility enhancement. Moreover, these results indicate that the atomic structure of internal interfaces and most probably also near-interface regions are significantly modified by the interactions between pre-existing and/or deformation-induced defects. The processes during the deformation under high applied (hydrostatic) pressure are complex and so far have eluded direct in-situ analysis. Yet, post-deformation analyses indicate the importance of interactions of GBs with dislocations and, most probably, also with excess vacancies supported by strain analyses showing zipper-like features located at GBs.10,11)

Additive manufacturing (AM) is a very promising fabrication method to produce functional parts with a shape on demand,64) however it seems that it has nothing in common with typical SPD processing routes. Nevertheless, the AM techniques use rapid melting/solidification of powder with laser or electron beam heating, resulting in a microstructure with a high density of residual defects. Furthermore, moving interfaces during the rapid solidification of multi-component alloys feature often non-equilibrium segregation due to solute trapping,65) a phenomenon also well known for SPD-processed materials.6,66)

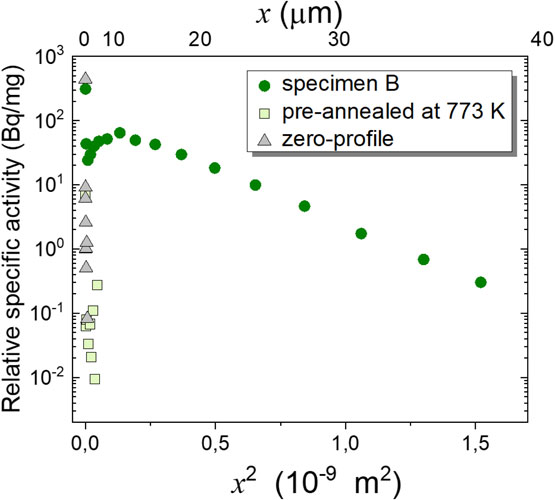

Very recently, grain boundary tracer diffusion was measured in an additively manufactured equiatomic CoCrFeMnNi high-entropy alloy.67,68) The radiotracer experiments were performed at a relatively low temperature of 500 K, at which no measurable tracer penetration would be observed in annealed coarse-grained polycrystals69,70) of equal composition.

Since additive manufacturing is known to induce cracks and pores in the material,71) the tracer penetration in the as-printed state was monitored, too, triangles in Fig. 12, the so-called “zero-profile”. This method allows discriminating surface-like diffusion along inter-connected porosity and solid state diffusion along internal interfaces.54) Figure 12 substantiates the absence of any artifacts resulting from inter-connected porosity in the 3D-printed alloy.

Penetration profiles measured for Ni diffusion in 3D-printed equiatomic CoCrFeMnNi alloy without annealing (zero-profile, triangles), after annealing at 500 K for 3 d (filled circles), and after pre-annealing at 773 K for 1 h followed by repeated diffusion annealing at 500 K for 3 d (squares).

The tracer diffusion experiment at 500 K has been repeated after pre-annealing of the sample at 773 K for 1 h.68) As a result, no tracer penetration was resolved in such case (squares in Fig. 12). Note that the annealing at 773 K for 1 h does not introduce any significant changes of the microstructure of the CoCrFeMnNi alloy in terms of grain size, GB distribution and their character, dislocation density or local strains.68) These tracer experiments substantiate that in the as-printed state the process of additive manufacturing had induced a ‘non-equilibrium’ state of the general (random) high-angle grain boundaries, as it was often observed for a fraction of the GBs in SPD-processed materials.6,8)

Accurate TEM studies72) revealed a strong segregation of Mn atoms (and partially of Ni) to GBs in the as-produced AM CoCrFeMnNi alloy, see Fig. 13. Note that there is no GB segregation in this alloy in its coarse-grained equilibrium state.69,70) Figure 13 summarizes the observations. During the AM process the CoCrFeMnNi alloy has experienced high thermal stress which manifests as dislocation networks. The red line in the HAADF image indicates a high-angle GB. An enrichment of Mn and Ni is accompanied by a depletion of Fe, Co and Cr at both sub-boundaries (dislocation networks) and high-angle GB. That such a microstructure is actually thermally stable is demonstrated in Fig. 14. The segregation is enhanced; however the grain size has remained stable.

Thus, in the studies of Choi et al.67,68) the existence of non-equilibrium GBs featuring remarkably enhanced diffusion and a strong segregation of a constituting element (Mn) were for the first time identified and analysed. The diffusion enhancement disappears after annealing at a relatively low temperature of 773 K, while the non-equilibrium segregation of Mn remains, being accompanied by a further phase decomposition with precipitation of Cr-rich nano-particles.68) These features and a depletion of Co and Fe were found at both, high-angle GBs and dislocation walls. The heterogeneous chemistry was generated during the processing and the heterogeneity was not homogenized after a heat treatment at 823 K for prolonged annealing treatments,72) see Fig. 14.

The non-equilibrium state of GBs in additively manufactured materials has been related to defect generation and fast GB migration during rapid solidification.68) A model of non-equilibrium segregation induced by rapid solidification during additive manufacturing was recently proposed.73,74)

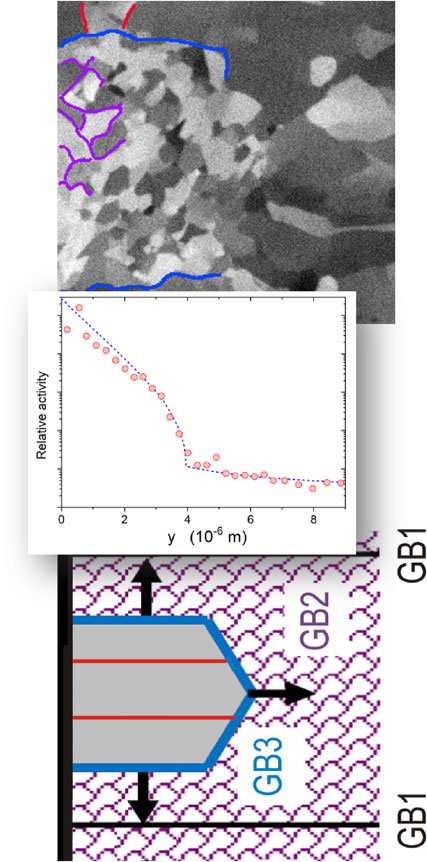

The impact of recrystallization and grain growth on grain boundary self-diffusion in ultrafine-grained (UFG) Ni prepared by high-pressure torsion was studied in Refs. 75, 76). Two Ni materials of low (99.6 wt.%) and high (99.99 wt.%) purity levels were compared and the kinetic properties of stationary and mobile grain boundaries were examined in detail. Unusual concentration profiles with characteristic “kinks” were measured for Ni self-diffusion in 99.99 wt.% pure Ni, which undergoes recrystallization and grain growth during the diffusion annealing treatment, Fig. 15 (central panel).

Partially recrystallized microstructure (upper panel), measured penetration profiles of Ni diffusion (central panel), and suggested model (bottom panel).75) Three families of high-angle GBs are distinguished: ‘nonequilibrium’ GBs (GB1), relaxed high-angle boundaries (GB2), and recrystallization ‘front’ (GB3) with different kinetic properties.75) Adapted from Ref. 75).

This behaviour was found to be related to specific kinetic properties of the GBs which encompass the recrystallized areas (blue lines in Fig. 15, upper panel) and consume numerous defects of the UFG matrix during their motion. Accounting for a hierarchy of stationary and moving fast diffusion paths, a model of self-diffusion in recrystallizing material (Fig. 15, bottom panel) was elaborated and successfully applied to process the diffusion data.75,76)

Figure 15 (left panel) shows the existence of a residual fraction of the ultra-fine grained matrix surrounded by recrystallized areas, the corresponding GBs are highlighted by violet lines. This behaviour was explained in terms of a solute redistribution in front of the moving boundary.75,76) Moreover, specific deformation-induced defects14) contribute further to the high stability of nanocrystalline (ultra-fine grained) structures and these features are analysed in more detail below.

SPD materials contain many different sorts of defects which are introduced during processing.78) They can be classified by their dimension starting from 0-dimensional defects such as vacancies and interstitials, dislocations such as 1-dimensional defects and grain and twin boundaries as 2-dimensional defects. All of them are contributing to a complex mechanical or mechano-chemical interplay when alloys are also considered that finally lead to the observed ultrafine-grained or nanocrystalline structures. While their production by top-down approaches such as HPT, ECAP or accumulated rolling has become standard, their stability is still a major concern with regard to applications as structural materials, since the high density of defects provides a significant driving force for grain growth. This in view, their characterization, especially using imaging techniques, is of importance and can even be complicated since the individual defects are often ‘invisible’ as in the case of vacancies or dislocations when imaging conditions are not appropriate. However, their strain signatures contributing to intensity in terms of diffraction or phase contrast can be used to analyze their impact. While it is state of the art to visualize defects such as dislocations, grain and twin boundaries in the scanning electron microscope (SEM) using electron backscatter diffraction (EBSD) or using diffraction/phase contrast in the transmission electron microscope (TEM), rotational defects are hardly considered in experiments.79–82) The aim of this section is to recall examples of disclinations which are actually stabilizing elements in SPD materials inhibiting grain growth.13,15)

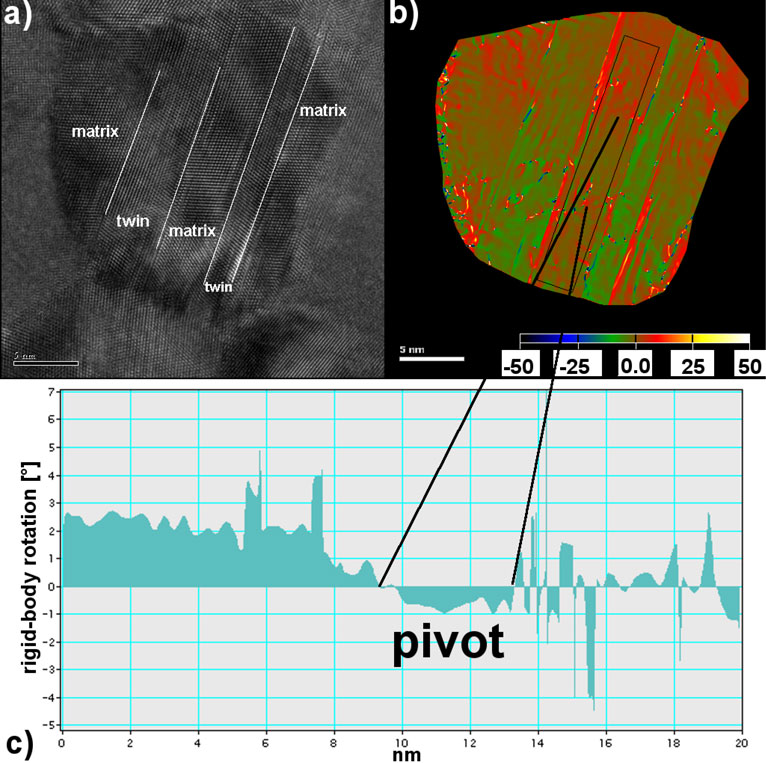

7.1 Examples for mechanical stability provided by disclination dipolesIn the following we provide evidence for the existence of rotational defects (disclinations) in metals and (high entropy) alloys. We show that the defects are located in the grain interiors as well as along such GBs. High resolution TEM was used to provide structural information which was further used to perform quantitative strain analyses83) using the geometric phase analysis (GPA).84) Figure 16(a) shows a lattice image of a nanocrystalline Pd grain containing deformation-induced twins as indicated by the lines.77) Figure 16(b) shows the corresponding color map of the in-plane rotation ωy. The results are extracted from the central matrix region as indicated by the black frame and displayed in Fig. 16(c). This profile reveals unambiguously the existence of rotational gradients between top and bottom of the deformed nanograin. Two turning points are observed as indicated by arrows in the profile a ‘pivot’-like distribution. The strain energy stored in such a deformed Pd grain (Fig. 16(a)) was estimated to be about 4 J/g.77,85)

(a) Lattice image of a deformation-twinned nanocrystalline Pd grain. (b) Colour map of the in-plane rigid-body rotation ωxy. (c) Profile of the rigid-body rotation measured from top to the bottom along the central matrix segment as indicated by the boxed area. Figure adapted from Refs. 77 and 15).

Such structures have been observed frequently not only in metals but also in high entropy alloys as the next example shows (Fig. 17). Here we observe again deformation twins as a result of the deformation process producing rotational gradients between top and bottom of the investigated nanograin. A pivot region can also be seen, again located roughly in the middle of the profile. The profile corresponds to the white boxed area. The third example reveals that such rotational gradients or disclinations also exist along GBs.

(a) Lattice image of nanocrystalline grain showing multiple twins in a high entropy alloy (Al0.3CoCrFeNi). The inset shows an enlarged view of the boxed region. (b) Colour map of the in-plane rigid-body rotation ωxy. (c) Profile of the rigid-body rotation measured from top to the bottom along the central matrix segment as indicated by the white boxed area.

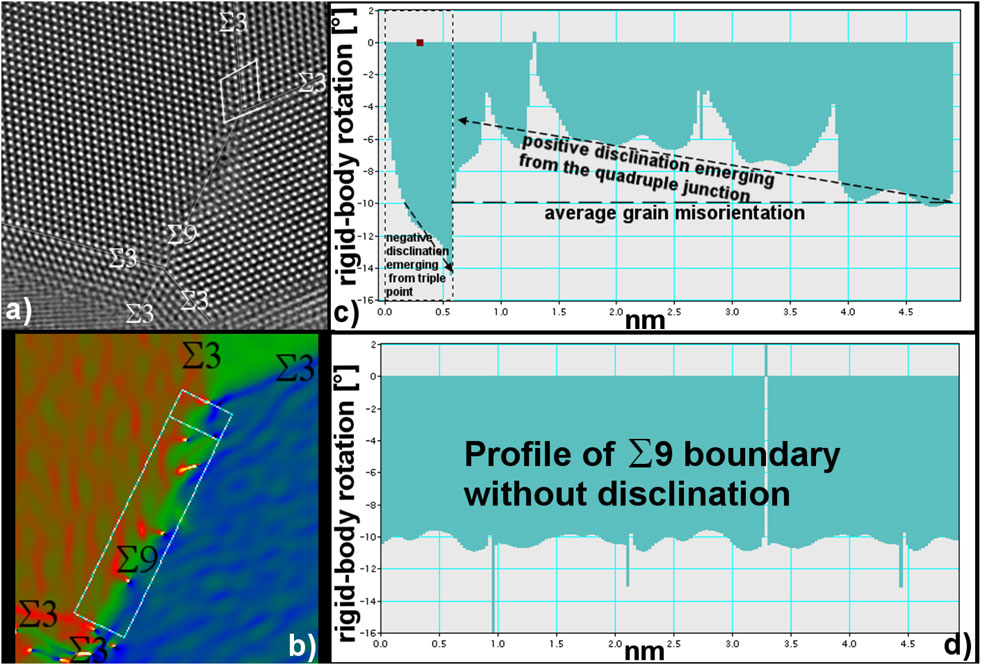

Figure 18(a) shows a triple junction in nanocrystalline Pd. This triple junction consists of two intersecting Σ3 twin boundaries with a Σ9 GB and is connected to a quadruple point via the Σ9 GB. A comprehensive strain analysis of this triple junction using GPA is shown and compared with a molecular dynamics (MD) simulation containing no disclination. Figure 18(c) shows a disclination emerging from the triple junction along the Σ9 GB which is balanced by a disclination of opposite sign emerging from the quadruple point. The same analysis performed on a similar configuration generated by MD simulation but without disclinations is displayed in Fig. 18(d). Since such structures have been observed to be thermally stable over long periods (>1 year) at room temperature, it is thought that the presence of disclination dipoles either at GBs or in the grain interiors are essential for the stabilization of the observed microstructures. Moreover, since deformation is a heterogeneous process not all grains show such deformation features which might lead to a bimodal grain size distribution due to grain growth with patches of deformed nanograins amidst coarse grown grains.15) We conclude the following from the presented examples:

(a) Lattice image showing part of a severely deformed nanocrystalline Pd grain containing a triple junction and quadruple point. (b) Corresponding strain map showing the rigid-body rotation along the Σ9 GB. (c) Strain profile measured along the boxed area. (d) Strain profile of a simulated Σ9 GB used for comparison. Figure adapted from Ref. 13).

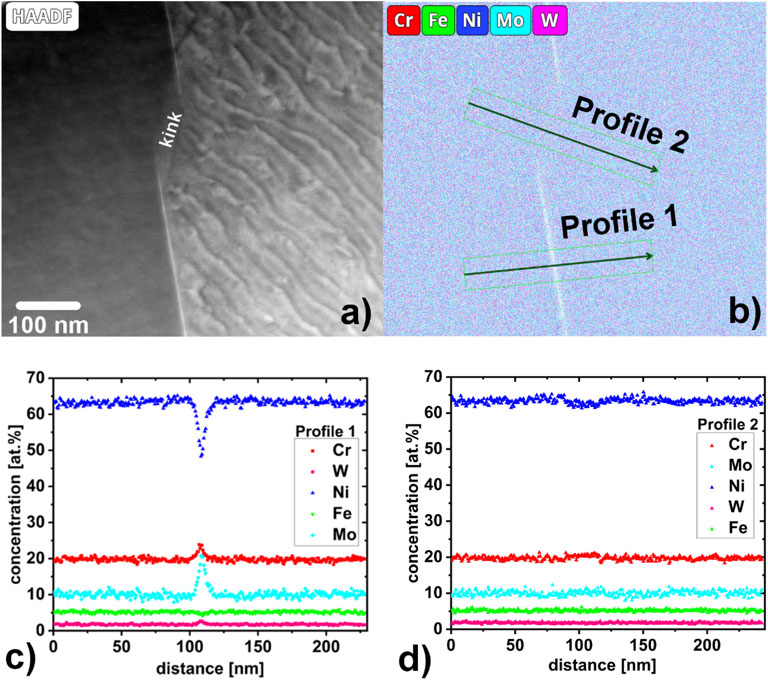

In the previous section mechanical equilibrium was maintained via disclination dipoles which act as stabilising elements against grain growth. However, it is also well known that the thermal stability of ultrafine-grained or nanocrystalline materials can be obtained by the addition of solutes.86–88) The following example shows a high-angle GB in a FeCrNiMoW high entropy alloy which contains a kink (Fig. 19(a)). The corresponding elemental profiles reveal segregation of Cr, Mo and W along the straight GB segments (Fig. 19(c)) while there is no concentration gradient along the kink (Fig. 19(d)). This observation suggests that the GB is actually stabilised/pinned when segregation occurs.

(a) High-angle annular dark-field (HAADF) image showing a high-angle GB in a high entropy alloy (NiCrMoFeW). (b) Elemental map (EDX) of the same area indicating two line profiles drawn across the grain boundary and the kink. (c) Profile 1 reveals segregation of individual elements at the grain boundary whereas profile 2 (d) shows neither enrichment nor depletion.

The ‘non-equilibrium’89) or ‘deformation-modified’7) state of GBs was introduced to describe the response of the internal interfaces to plastic deformation via a transformation of their structure without affecting the macroscopic degrees of freedom of the GBs.90,91) Being analysed first in terms of spreading of GB dislocations,92) a concept of the non-equilibrium GB state as one with an enhanced GB energy, increased GB diffusivity, excess free volume and GB-related elastic strain fields has been elaborated5) and supported via atomistic simulations.93)

GB diffusion was found to represent a unique and extremely sensitive tool to probe the ‘non-equilibrium’ state of interfaces due to an exponential response of the transport rates on the relative changes of interatomic distances along the diffusion path in solids.10,49) First reported for nanostructured Ni11,94) and a Cu–Zr alloy,9) significantly (by orders of magnitude) enhanced tracer diffusion has been measured in severely plastically deformed pure Cu,51,53,54) pure Ti12) and a Cu–Pb alloy.95)

Key experiments to decipher the nature of the diffusion enhancement in UFG materials were performed for ultra-fine grained Ti deformed using 31 ECAP processing at room temperature.12) Significant enhancement of substitutional diffusion of Ag and a retardation of interstitial diffusion of Co were simultaneously measured.12) This behavior was interpreted in terms of a deformation-induced excess free volume at non-equilibrium GBs.

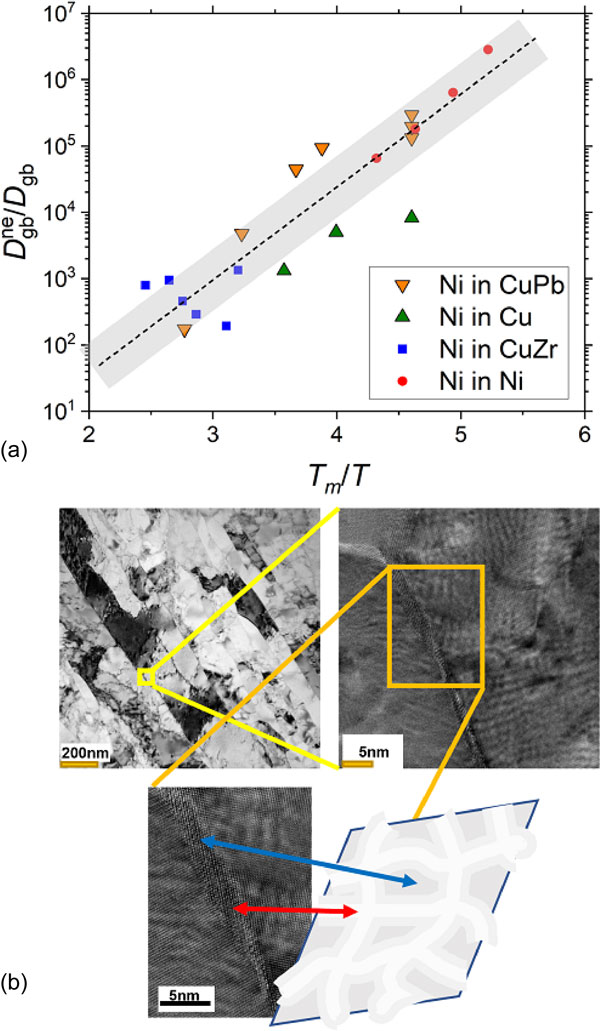

The excess free volume in deformation-modified GBs was quantified for ECAP-processed Ni96) and it was found to be equal to about 10% of the value typical for the excess volume of relaxed high-angle GBs. The measured GB diffusion rate enhancement corresponds to an increase of the GB excess energy density by about 20 to 30%.11) When plotted against homologous temperature, similar enhancements of the GB self-diffusion rates have been observed for different materials after SPD processing, Fig. 20(a), indicating that the modification of the GB structure through severe deformation proceeds rather independently compared with the actual structure of the crystal lattice.

(a) Relative enhancement of GB diffusion along “non-equilibrium” GBs, $D_{\text{gb}}^{\text{ne}}$, with respect to that along general high-angle GBs, Dgb, as they are present in polycrystalline aggregates against the inverse homologous temperature, Tm/T. The data for SPD-processed Ni,11) Cu,54) Cu–0.17 wt.%Zr,9) and Cu–1 wt.%Pb95) are presented. The shaded area correspond to the suggested generic trend. (b) Proposed97) model of non-equilibrium GBs with areas of GB structure in a ground state (dark grey) and a metastable, defected state (light grey). The sequence of snapshots with varying magnification illustrates the corresponding atomic configurations as observed by high-resolution TEM. Note that the schematic pattern of a fraction of a nonequilibrium GB (bounded by blue box) is inclined with respect to the GBs in TEM images where the boundaries are seen almost in “edge-on” projection.

A linear regression of the whole amount of the data results in the following relative enhancement of the GB diffusion along the “non-equilibrium” GBs,

| \begin{equation} D_{\text{gb}}^{\text{ne}}/D_{\text{gb}} = (0.08_{-0.06}^{+0.22})\times \exp \left\{ (3.13\pm 0.3) \frac{T_{m}}{T} \right\}. \end{equation} | (2) |

The corresponding dependence is plotted in Fig. 20(a) as dashed line and the shaded area visualizes the generic trend. Equation (2) is applicable at lower temperatures only, T/Tm < 0.33, since the “non-equilibrium” state of GBs relaxes fast with increasing temperature.11) Figure 20(a) suggests that GBs under external action attain a metastable “non-equilibrium” state characterized by increased diffusion rates. Furthermore, an increased energy and associated elastic strains were prescribed to this state.6) This picture meets an apparent contradiction between the enhanced diffusion rates and a prolonged retention of the high-energy state. Definitely, the relaxation time of the state has to depend on the corresponding diffusion rates.

In order to resolve this apparent contradiction, a consistent model was elaborated.97)

For interstitial grain boundary diffusion on the other hand, decelerated diffusion rates have been observed,12) indicating the importance of deep trap states within the deformation-modified grain boundary. Taking additionally the observed “relaxation times” (i.e. “life times”) of non-equilibrium GBs into account,11) a picture emerges where SPD processing causes relaxed GBs to develop into a more complex structure with an intrinsic heterogeneity of the diffusion rate.97) As long-range diffusion requires a percolating diffusion pathway, a structure as schematically indicated in Fig. 20(b), or more complex variants thereof, might be anticipated. The different regions of the GB “plane” indicated in Fig. 20(b) are distinguished by GB diffusion rates that are either of conventional (dark grey) or enhanced (light grey) magnitude. Structurally, the different diffusion behaviour might be related to different levels of local topological mismatch, i.e. by analogy to the lock-in model described by Fecht and Gleiter,98) the channel-like regions would be characterized structurally by incorporated extrinsic defects (such as disclinations or rotational-type defects, see Section 7.1), higher local strains and enhanced diffusion rates, while the adjacent regions between the channels would be more closely related to the structure and properties of relaxed GBs.97)

SPD applying high plastic strain under at least partial confinement conditions and involving high hydrostatic pressure components yields significant structural modifications of metals and alloys that affect the microstructure (grain size, dislocation density, excess vacancy concentration, distribution of solute elements and precipitates) as well as the local atomic structures of internal interfaces, i.e. GBs and heterophase interfaces. The latter modifications are likely to affect the former. Examples are given by the dependence of GB segregation and GB diffusion on the strain accumulation at GBs; the impact of high applied plastic strain on the severity of GB poisoning or the inhibition of GB migration by rotational defects such as disclinations. Yet, in-depth analyses indicate that such modifications are probably not unique for materials processed by SPD. In fact, GB diffusion measurements on an additively manufactured high entropy alloy indicate a very similar diffusion rate enhancement as found after SPD. Given the importance of the interdependencies between microstructure and its evolution on the one hand and local structural modifications by defect interactions at GBs on the other hand, one needs also to consider this response behaviour concerning the bidirectional feedback loop between materials’ properties and microstructure.

Several prominent features underlying the thermo-mechano-chemical coupling during severe deformation and post-processing heat treatment are to be highlighted.

While strong variations between different GBs and different segments along an interface in a given material already exist, it seems, however, obvious that the present level of in-depth understanding of the intricate relationship between processing-atomic structure-microstructure and resulting macroscopic property is far from being complete. Based on the available results, also highlighted in the present review, knowledge and understanding of the atomistic details of internal interfaces and its relation with the previous thermo-mechanical history and processing pathway seems essential, as already remarked upon in earlier work focused on the description of general high-angle GBs.99) A strong heterogeneity of GB structures, segregation response, precipitation and or phase decomposition along the same boundary (with the same macroscopic degrees of freedom) demands new approaches apart of purely geometric description of the interfaces. In most cases, such level of analysis and understanding is not yet available, but is nowadays within reach of state-of-the-art experimental and modelling methods.

According to the authors’ personal point of view, numerous issues exist that still awaiting to be resolved, such as e.g.:

Financial support from the German Science Foundation (DFG) via research grants WI 1899/44-1 and DI 1419/19-1 is acknowledged. The DFG is further acknowledged for funding our TEM equipment via the Major Research Instrumentation Program under INST 211/719-1 FUGG. The authors gratefully acknowledge partial support by the Münster Nanofabrication and Nanoanalysis Facility (MNF).