2023 年 64 巻 8 号 p. 2000-2005

2023 年 64 巻 8 号 p. 2000-2005

Heavily and simply cold-rolled Cu alloys with ultra-low stacking fault energy exhibit superior strength/ductility balance. The excellent mechanical properties are attained by the formation of a heterogeneous-nano (HN) structure consisting of twin domains, shear bands, and lamellar grains. In this study, using a Cu–Zn system alloy, two specimens with different initial textures were subjected to cold rolling. One has a strong ⟨001⟩ texture along the normal direction (ND) of the rolling surface, and the other has a ⟨111⟩ texture. Then, the effects of the initial texture of specimens on the formation of deformation twins in the early stage of cold rolling were precisely investigated. Also, the microstructure and mechanical properties of the alloys with finally developed HN structure after 90%-cold-rolling were examined. At the early stage of rolling, the mechanical twinning occurred more frequently in the specimen with ⟨001⟩ texture than in the ⟨111⟩ one. The difference in the twinning frequency can be reasonably explained by the significant difference in the ratio of the Schmid factor for twinning partial to the one for the perfect dislocation. On the 90% cold rolling, the ⟨001⟩ specimen exhibited better strength/ductility balance than that of the ⟨111⟩ specimen since the ⟨001⟩ one has a higher volume fraction of the deformation twin domains. It can be concluded that the initial texture of the specimen before the cold rolling plays an important role in the mechanical properties of HN structured materials via the formation of the twin domains.

This Paper was Originally Published in Japanese in J. Japan Inst. Copper 61 (2022) 62–67.

As the miniaturization of electronic devices with securing high performance in recent years, further strengthening of copper alloys comprising these devices is highly required. Grain refinement is one of the methods to increase the strength of metallic materials. Severe plastic deformation (SPD) is the most effective method for grain refinement to the submicron scale—several successful studies about applying SPD methods to copper alloys to attain ultra-fine-grained (UFGed) structures. Miura et al. applied multi-directional forging to Cu–Zn alloy and achieved UFGed structures with an average grain size of 17 nm.1) Qu et al. fabricated a UFGed Cu–Al alloy with an average grain size of approximately 82 nm using equal channel angular pressing.2) However, the SPD methods invented so far are batch processes based on shape-invariant deformation, and thus are difficult to employ in mass production because of the complexity of the process, substantial limitations of product size, and increase in the production costs as well as the cost necessary for the new facilities for SPD methods.

It has recently been reported that extremely high strength can be achieved by heavy cold rolling of copper alloys with ultra-low stacking fault energy.3) The attained high strength is attributed to the formation of a heterogeneous nano (HN) structure consisting of “eye-shaped” twin domains, lamellar grains, and shear bands formed during heavy cold rolling. Watanabe et al. investigated the formation process of the HN structure in detail.4) They showed the twin domains in the HN structure originated from the mechanical twins formed in the initial coarse grains in the early rolling stage. Therefore, the number of deformation twins introduced at the early rolling stage is an essential factor for the volume fraction of twin domains in the final HN structure.

It is reported that the formation of deformation twins strongly depends on the crystallographic orientation against loading direction. Cai et al. investigated the orientation dependence of mechanical twinning through compression tests of pure copper single crystals with different orientations. They showed that specimens with a ⟨001⟩ direction parallel to the compression axis are most prone to twinning.5) Karaman et al. investigated the relationship between the activated deformation mechanisms and crystallographic orientation of a Fe–12.34 mass%Mn–1.03 mass%C alloy during unidirectional tension and compression. They demonstrated that mechanical twinning was the primary deformation mechanism in grains with a [001] direction parallel to the loading direction in compression but those along [111] direction in tension.6) Moreover, in our previous study, it was found that deformation twinning were promoted at the initial rolling stage by subjecting two directional rolling to a Cu–Zn alloy, in which the rolling surface was 90° rotated with a fixing rolling direction.7) The promoted twinning was explained by the formation of deformation twins in the grains having a crystallographical orientation of normal direction (ND) ∦ ⟨001⟩ and transverse direction (TD) // ⟨001⟩ by two directional rolling. In contrast, mechanical twins scarcely occurred in those grains by simple unidirectional rolling.7)

The above experimental results strongly suggest that the initial texture is essential in forming deformation twins. The present study systematically investigated the effects of initial texture on the formation of deformation twins in Cu–Zn alloys during cold rolling. In addition, the influences of initial textures on the evolved HN structure and their mechanical properties are discussed.

The hot-extruded rods of commercial Cu–37.75Zn–0.11Sn (mass%) alloy were used in this study. Two specimens were cut from the rod using a wire electric discharge machine, as illustrated in Fig. 1. These specimens were unidirectionally rolled to a maximum thickness reduction of 90% at room temperature. The definitions of the rolling, transverse, and normal directions of the rolled sheet are described in Fig. 1 and are referred to as RD, TD, and ND, respectively.

Schematic illustration showing the preparation of specimens with different textures. The portion A has a strong ⟨001⟩ texture along the ND and the portion B has a ⟨111⟩ texture.

The textures of the specimens before and after rolling were investigated using X-ray diffraction (XRD). The specimens for the XRD measurements were mechanically polished to half thickness and then polished with a colloidal silica suspension. The X-ray beam was made incident on the mirror-finished plane. Texture measurements were performed using a Cu target (CuKα, wavelength = 0.154 nm8)) operating at 40 kV and 100 mA. The recalculated pole figures (RPFs) and crystal orientation distribution functions (ODFs) were calculated using LaboTex® software.

Microstructural observations were performed using field-emission scanning electron microscopy (FE-SEM). Observations were mainly conducted on the TD plane at the center of the sheet thickness. The specimens for FE-SEM observation were mechanically polished using emery papers and then electropolished using a 30% nital solution {methanol:nitric acid = 7:3 (volume ratio)} at 11 V and 243 K for about 90 s. Crystallographical orientation was analyzed using an electron backscattered diffraction (EBSD) camera equipped with an FE-SEM. The acceleration voltage and data acquisition interval (steps) for EBSD measurements were 20 kV and 500 nm, respectively.

Tensile tests were performed at room temperature with an initial strain rate of $\dot{\varepsilon } = 10^{ - 3}$ s−1. Dogbone-shaped specimens with a gauge part of 5L × 2W × 1T mm3 were cut using an electric discharge machine to parallel the loading axis to the RD of the rolled plates.

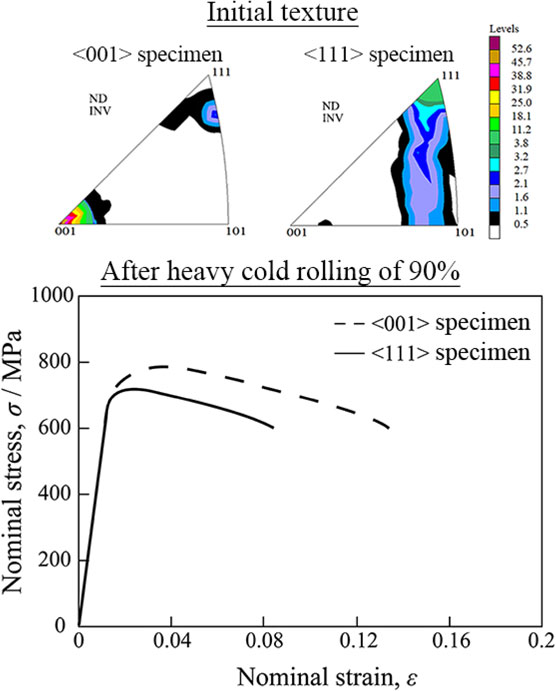

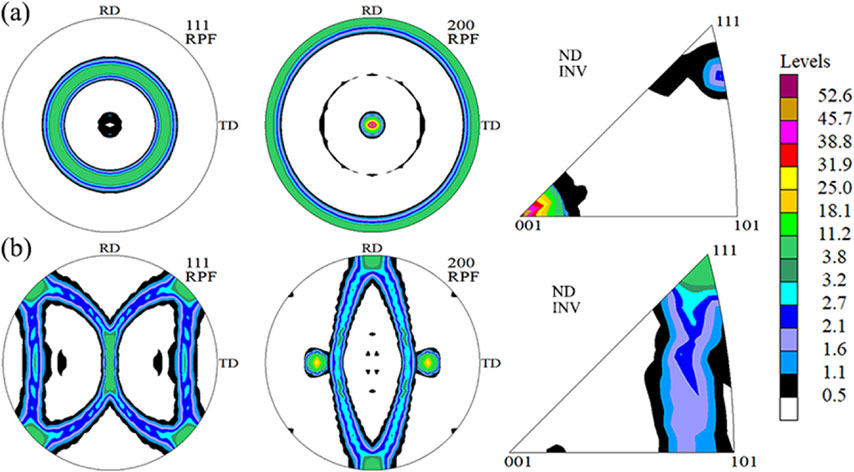

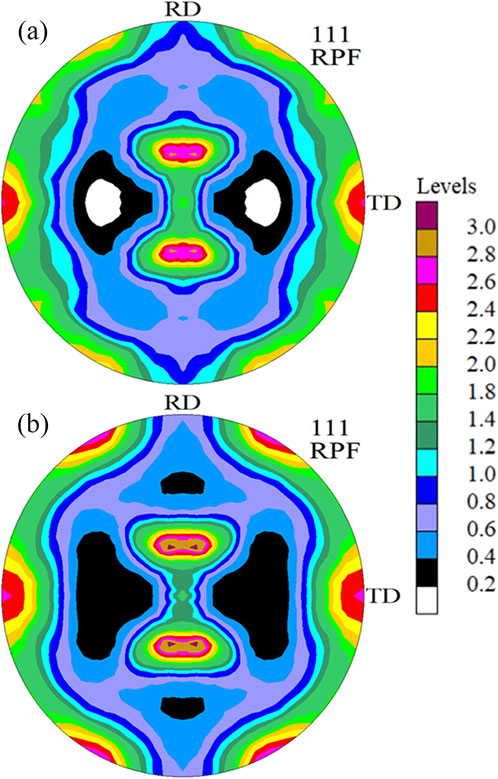

The initial textures of the specimens are shown in Fig. 2. The specimen indicated as portion A in Fig. 1 exhibits a strong ⟨001⟩ texture on the ND plane (Fig. 2(a)). On the other hand, the specimen indicated as portion B, in which the cutout direction is inclined at 35° from the extrusion direction, possesses a relatively substantial accumulation of ⟨111⟩ components on the ND plane (Fig. 2(b)). Hereafter, the former and latter specimens are referred to as the ⟨001⟩ and ⟨111⟩ specimens, respectively.

{111} and {200} pole figures and inverse pole figures of ND plane of (a) ⟨001⟩ and (b) ⟨111⟩ specimens.

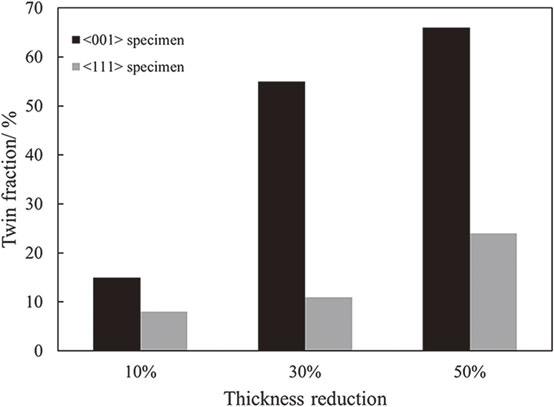

Figure 3 shows the band contrast maps of two specimens after cold rolling to 50% reduction. Red lines on the map indicated the twin boundaries (Σ3 grain boundaries). In both specimens, deformation twins are formed in the initial coarse grains. The ⟨001⟩ specimen comprises denser twin boundaries than the ⟨111⟩ one. For quantitative evaluation, the ratio of the number of twinned grains to the whole grains was determined in the specimens cold-rolled to 10, 30, and 50% thickness reductions. The results are summarized in Fig. 4. At the initial stage of rolling (10%), the ratio in the ⟨001⟩ specimen was more significant than that in the ⟨111⟩ one. After a 30% reduction, the difference in values between the two specimens increased. After a 50% reduction, the ratio in the ⟨111⟩ specimen increased notably. However, the difference in the values between the two specimens appeared unchanged. Not all twin boundaries could be detected by the EBSD analyses because cold rolling introduces high densities of lattice defects and crystallographical orientation change among the twins. Therefore, the ratio of grains containing twins should be underestimated. However, because EBSD analyses were conducted on both specimens under identical observation conditions (such as acceleration voltage and step size), indeed, the fraction of twinned grains in the ⟨001⟩ specimen was relatively higher than that in the ⟨111⟩ one.

Band contrast maps of the (a) ⟨001⟩ and (b) ⟨111⟩ specimens cold-rolled to 50% reduction. The red lines indicate twin boundaries.

The twin fraction of ⟨001⟩ and ⟨111⟩ specimens cold-rolled to 10%, 30% and 50% reduction.

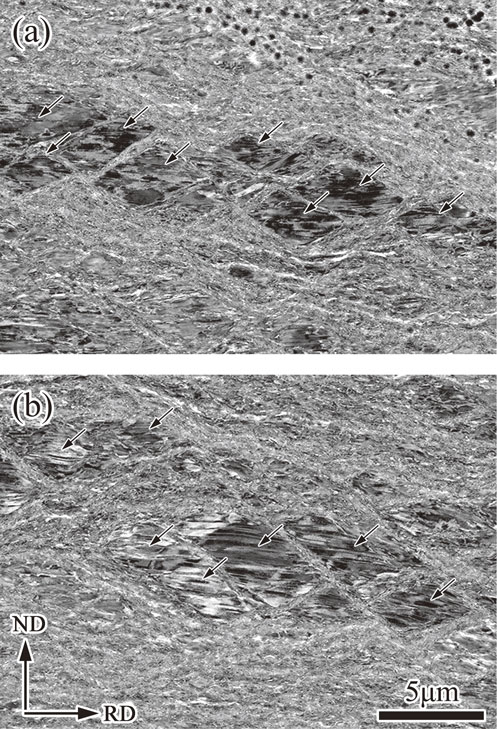

Figure 5 shows the backscattered electron (BSE) images of the two specimens cold-rolled to 90% reduction. Similar to the report by Miura et al.,3) the HN structure with characteristic “eye-shaped” twin domains can be observed in both specimens. The twin domains are indicated by arrows in Fig. 5. The twin domains are surrounded by shear bands and embedded in lamellar grains. Moreover, there are two types of twin domains with crystallographical orientations of i) ⟨111⟩ // ND, ⟨110⟩ // TD, and ii) ⟨111⟩ // ND, ⟨211⟩ // TD. The characteristics of the HN structure are consistent with those in previous studies.4,7)

SEM-BSE images of the (a) ⟨001⟩ and (b) ⟨111⟩ specimens cold-rolled to 90% reduction.

Figure 6 shows the {111} pole figures of the ⟨001⟩ and ⟨111⟩ specimens after 90% cold rolling. The ⟨001⟩ specimen possesses a higher intensity of ND // {111} texture than the ⟨111⟩ one. The volume fraction of ND // ⟨111⟩, RD // ⟨211⟩, or ND // ⟨111⟩, RD // ⟨110⟩ components, which comprise twin domains, were estimated by the analyses of the ODF. The estimates were 24% for the ⟨001⟩ specimen and 21% for the ⟨111⟩ one.

{111} pole figures of the (a) ⟨001⟩ and (b) ⟨111⟩ specimens cold-rolled to 90% reduction.

Figure 7 shows the changes in the inverse pole figure along the ND of the ⟨001⟩ and ⟨111⟩ specimens with an increase in the rolling reduction. Cold rolling causes a rotation of the crystallographical orientation in both specimens. In the ⟨001⟩ specimen, the ND // ⟨001⟩ component decreased during rolling up to 50% reduction, whereas the ND // ⟨111⟩ component increased after 70% reduction, which did not exist before rolling. In contrast, in the ⟨111⟩ specimen, the intensity of the ND // ⟨111⟩ component decreased with increasing rolling reduction and then increased slightly after 70% rolling. The ND // ⟨011⟩ and ND // ⟨111⟩ components became the primary orientation in both specimens after 90% rolling. The former corresponds well to the crystallographical feature of the lamellar grains developed in the HN structure4) and the latter to the “eye-shaped” twin domains, as described in Section 3.3. Thus, the terminal textures in both specimens were almost identical owing to the formation of the HN structure. However, the evolution process is considerably different.

Inverse pole figures along the ND of ⟨001⟩ and ⟨111⟩ specimens cold-rolled to the thickness reduction of 0%–90%.

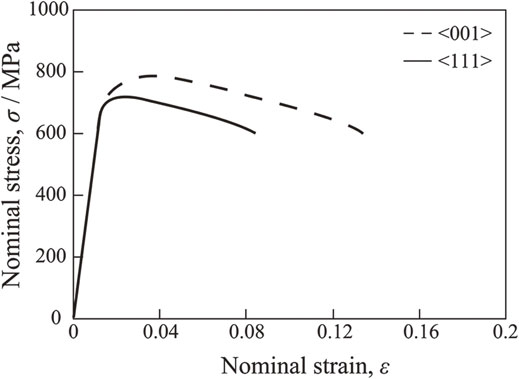

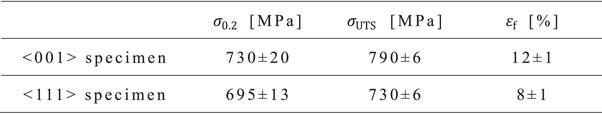

Figure 8 shows the nominal stress – nominal strain curves of both specimens after 90% cold rolling. The values of 0.2% proof stress (σ0.2), ultimate tensile stress (σUTS), and fracture strain (εf) are listed in Table 1. Both specimens exhibit high strength, which can be attributed to the formation of the HN structure.9) However, the strength–ductility balance of the ⟨001⟩ specimen is superior to that of the ⟨111⟩ specimen.

Nominal stress – nominal strain curves of the ⟨001⟩ and ⟨111⟩ specimens cold-rolled to 90% reduction.

The difficulty of mechanical twinning in a grain can be judged by the Schmid factors of twinning and slip systems under externally given stress condtions.5) The direction of the applied stress, which maximizes the ratio of the Schmid factor of the twinning system to that of the slip system, is favorable for mechanical twinning. Cai et al. showed from compression tests of copper single crystals with various orientations that compression along the ⟨001⟩ direction is the most favorable for forming deformation twins, whereas the ⟨111⟩ direction is unfavorable.5) Although the processing method employed in the present study differs from the above compression tests, analyses of the deformation structure were performed at the half-thickness part of the rolled plate, where the deformation mode would be assumed to be similar to that of compression. Thus, the frequency of mechanical twinning during cold rolling is higher in the ⟨001⟩ specimens, which have a relative higher volume fraction of grains with ND // ⟨001⟩ (Fig. 3 and Fig. 4). Deformation twin domains in the HN structure were originated from twinned grains developed during cold rolling.4) Therefore, it can be reasonably understood that more deformation twins could be introduced in the ⟨001⟩ specimen to evolve a higher volume fraction of twin domains of the HN structure than that in the ⟨111⟩ specimen.

The ND // ⟨111⟩ component increased in both specimens with a rolling reduction from 50 to 70% (Fig. 7). This increment can be attributed to the formation of twin domains, as described in section 3.3. Watanabe et al. systematically investigated the formation process of HN structure. They reported that the twinned coarse grains were subdivided by shear bands to form twin domains with increasing rolling reduction and eventually transitioned to lamellar structures.4) The intensity of the ND // ⟨111⟩ component in the ⟨001⟩ specimen was lower at 90% rolling reduction than at 70% (Fig. 7). This indicates that the volume fraction of the twin domains was smaller at 90% than at 70%. As discussed in Section 4.2, the volume fraction of the twin domains in the HN structure strongly affects the mechanical properties. Moreover, as mentioned in Section 3.4, the evolution of texture during rolling significantly differed between the two specimens. Therefore, it is strongly suggested that an appropriate rolling reduction exists depending on the initial texture to optimize the mechanical properties.

4.2 Effect of initial texture on mechanical properties of heavily cold-rolled specimensAoyagi et al. investigated the deformation behavior of HN-structured materials using a crystal plasticity simulation. They suggested that the tensile strength of HN-structured materials increased with increasing volume fraction of the “eye-shaped” deformation twin domains.10) In the present study, the tensile strength of the ⟨001⟩ specimen, with a higher volume fraction of twin domains, was higher than that of the ⟨111⟩ specimen. This finding is qualitatively consistent with the results reported by Aoyagi et al.

Miura et al. reported that the evolution of deformation twin domains in the HN structure suppressed the formation of a strong rolling texture to improve ductility.11) Thus, the ⟨001⟩ specimen with a higher volume fraction of deformation twin domains possesses a more significant elongation and higher tensile strength than the ⟨111⟩ one. However, the relationship between the ratio of each component structure in the HN microstructure (“eye-shaped” deformation twin domains, shear bands, and lamellae) and ductility has not yet been fully understood, and hence further study is necessary.

As discussed above, the initial texture significantly affected the morphology of the terminal HN structure and the mechanical properties of the specimens because of the frequency of deformation twinning at the early rolling stage. To date, control of the HN structure has been carried out mainly by adding alloying elements to change the stacking fault energy of alloys. However, in the present study, it is revealed that the characteristics of the HN structure can be modified even in an identical alloy by controlling the initial texture and improving the mechanical properties of the alloy. Moreover, depending on the initial texture, optimum rolling reduction exists for the development of the HN structure. Improvement of the manufacturing process based on the knowledge obtained in this study is expected to enhance the mechanical properties of HN-structured materials.

Two specimens with different textures were prepared from a Cu–37.75 mass%Zn–0.11 mass%Sn alloy. The specimens were subjected to heavy cold rolling to investigate the effects of initial texture on the evolution of microstructure and mechanical properties. The results are summarized as follows:

In summary, the initial texture significantly influences the evolution of heterogeneous nanostructure after heavy cold rolling and the mechanical properties. An optimized initial texture can promote the development of the heterogeneous nano structure. Thus, further improvement of mechanical properties can be achieved.

This research was partially supported by a research grant from the Copper Society of Japan for 2020. The authors would like to appreciate the Grant-in-Aid for Scientific Research (Grant No. 20H02461).