-

Volume 32 (2024) Pages 92-95Competitive Adsorption of Particles and Surfactants at Liquid–Liquid Interfaces and Its Applications Read moreEditor's pick

To demulsify Pickering emulsions, a common approach involves chemically altering the particles to detach from the droplet surface when exposed to external stimuli like temperature. In this research, the author introduced an innovative technique for demulsifying Pickering emulsions by utilizing the phase transition of a surfactant adsorbed film to trigger an exchange reaction between the particles and the surfactant on the droplet surface.

-

Volume 32 (2024) Pages 135-139Development of Highly Durable Electrocatalysts Using Porous Ceramic Supports Read moreEditor's pick

This study synthesized porous Ir–IrO₂/TiO₂ catalyst supports with low Ir–IrO₂ loading using flame aerosol processing. Annealing at 750°C significantly enhanced electrical conductivity, providing a simple method to optimize these materials for polymer electrolyte fuel cells where improved conductivity and stability are crucial for efficient energy conversion applications.

-

Volume 32 (2024) Pages 54-57Design of Inhalable Combinations Using Cyclodextrin-Metal-Organic Frameworks Read moreEditor's pick

CD-MOF has garnered attention in the field of pharmaceuticals due to its high biodegradability and safety. Particles produced by spray-drying were found to successfully achieve high loading of levofloxacin and a significantly higher delivery rate to the lungs. Aiming for the design of inhalable combination drugs, particles prepared via spray-drying with 4-aminosalicylic acid and isoniazid demonstrated for the formulation of cocrystals, enabling the simultaneous local delivery of drugs with different properties to the lungs.

-

Volume 32 (2024) Pages 101-105Simultaneous Improvement of Strength and Ductility of Pure Zn by Sintering Using Fine Powder Read moreEditor's pick

Zinc is attracting attention as a biodegradable implant material due to its excellent biocompatibility and biodegradability; however, its mechanical properties limit practical use. In this study, fine-grained Zn samples exhibiting several-fold higher strength and substantially enhanced ductility compared to conventional zinc were produced through spark plasma sintering (SPS) of fine Zn particles followed by heat treatment. These exceptional mechanical properties were attributed to the ultrafine grain size and dynamic recrystallization that occurs during deformation at room temperature.

-

Volume 32 (2024) Pages 121-123Performance Enhancement of Organic Semiconductors by Using Crystalline Powder of Organic Salts Read moreEditor's pick

This study focuses on enhancing n-type organic semiconductors' mobility, which typically lags behind p-type semiconductors. The researchers controlled molecular arrangements using crystalline powder of organic salts and developed a novel method for creating metal-free n-type semiconductor polymers, successfully improving overall performance through both crystalline and polymeric approaches.

-

Volume 31 (2023) Pages 27-33Numerical Analysis of Aerosol Behavior in Facemask and Optimization of Microstructure Read moreEditor's pick

In this study, we numerically investigated the collection behavior of submicron particles within the microstructure of a facemask. After obtaining the three-dimensional structure of a commercially available facemask using X-ray CT image analysis, simulations of aerosol filtration through the obtained microstructure were performed. The results showed that when there was a local coarse and dense structure and relatively large pores within the microstructure, particles were more likely to be collected at the surface of the pores, resulting in a high-quality factor.

-

Volume 31 (2023) Pages 52-57Synchrotron X-ray CT Observation of Morphological Evolution of Defects by Pressure-Assisted Sintering Read moreEditor's pick

The mechanical reliability of products must be assured for scaling up and production of complex-shaped components by spark plasma sintering (SPS) of spray-dried granules. The evolution of morphologies of pores and defects, which control the mechanical strength, is investigated by using synchrotron X-ray multiscale tomography during SPS of alumina granules at 1300 °C. While large defects arising from the hierarchical granule packing structure cannot be removed by pressureless sintering, crack-like defects, and branched rodlike defects are almost eliminated by SPS at stresses higher than 30 and 50 MPa, respectively.

-

Volume 31 (2023) Pages 58-64Elucidation of Formation Mechanism of Solid Electrolyte Nanoparticles and High-Speed Synthesis Read moreEditor's pick

In all-solid-state batteries, the particle shape of the solid electrolyte plays an important role in increasing the contact interface and improving flowability. This study investigated the effects of reaction temperature and impact force on reaction time and particle shape in the liquid phase synthesis of Li3PS4 (LPS) particles. By using a hot stirrer, LPS particles were successfully synthesized much faster than conventional synthesis methods. Furthermore, it was demonstrated that the particle shape of LPS was determined by the impact energy during the reaction process.

-

Volume 31 (2023) Pages 212-216Development of Environmental Catalysts Particles by Utilizing Interconnected Nanoporous Structures Read moreEditor's pick

To enhance the gas purification efficacy of three-way catalysts (TWC), macroporous TWC particles were synthesized using an aerosol process with the assistance of a polymer template particles (polystyrene latex). The results indicated that the large pore size of the macroporous structure facilitated gas diffusion within the structures. On the other hand, the presence of aggregates and nanoparticle structures within the TWC particles reduced this diffusion capability. Therefore, the improved diffusion capabilities of the macroporous structures led to superior CO oxidation performance compared to other configurations.

-

Volume 31 (2023) Pages 172-176Inhibited Structural Expansion of Metal–Organic Frameworks and Control of Adsorption Behaviors Read moreEditor's pick

Several metal–organic frameworks (MOFs) exhibit S-shaped adsorption isotherms due to their structural transition. The unique behavior makes flexible MOFs promising materials to renovate the conventional energy-wasting processes. The use of flexible MOFs in an adsorption column requires molding; however, a typical molding method significantly reduces the adsorption performance. This is mainly because the volume expansion of flexible MOFs upon structural transition is inhibited in molds. This paper aims to compare the adsorption behaviors on the molds with two flexible MOFs that show different ratios of volume expansion and to investigate the effect of the expansion on the adsorption behavior.

-

Editor's pick

Ag clusters have been attracted due to their unique catalytic properties. However, Ag is less thermally stable than other noble metals and thus aggregates easily. In this study, Ag clusters (1~2 nm) were stabilized on the TiO2 surface by strong metal-support interactions (SMSIs) which were induced in a combustion field. As a result, Ag clusters in 20wt%Ag/TiO2 were stable at 350○C for 2 hours.

-

Volume 30 (2022) Pages 52-57Mechanistic Study and Control of Hemolytic Action of Nanoparticles Read moreEditor's pick

Hemolysis assay using red blood cells (RBCs) has been widely used as the simplest cytotoxicity test for nanoparticles (NPs). However, the hemolytic mechanism of NPs is still not well understood. In this study, the author focused on the silica particle properties (size and surface functional group) as well as the exposure environments (solution temperature and addition of proteins) to report the results of (i) the number of silica NPs adhered to an RBC, (ii) the hemolysis assay, and (iii) the silica-induced aggregation/dispersion of RBCs. Consequently, an overall picture of the hemolytic action mechanism of silica NPs was shown.

-

Volume 30 (2022) Pages 72-77Development of Particle Measurement Module by Using Phase Retrieval Holography Read moreEditor's pick

The measurement of fine particles using Gabor holography has been limited to laboratory use due to two problems arising from the measurement principle and the long numerical computation time, making online and inline measurements difficult. In this study, the development of a particle measurement module of a phase retrieval holography using a single-board computer with a graphics processing unit (GPU) has shown that it can be used for online and inline measurements in powder production processes.

-

Volume 30 (2022) Pages 58-64Detect a Slight Change in Powders by Mahalanobis–Taguchi-System (MTS) Read moreEditor's pick

It is important to understand the relationship between the powders’ structure and their functionalities. The Mahalanobis-Taguchi system (MTS) has been utilized because that effective variables which improve accuracy of classification can be visualized. The surface-roughness-related variables were the key to classify into male/female of Japanese beetles larval droppings. Considering that binder concentration in the females’ dropping was higher than in the males, it could be deformed during molding process through the larval gut. The MTS can be the effective way to improve the accuracy of the classification by visualization of the relationship between powder structure and functionalities without individual differences.

-

Editor's pick

Trimeric and tetrameric cyclic aromatic molecules have been synthesized utilizing the flexibility of the Si-Si single bond. The changes in the structure and physical properties of these molecules as a function of temperature have been also reported.

-

Volume 29 (2021) Pages 47-50Personalized Manufacturing of Pharmaceuticals Using One-Pot Powder Processing Equipment Read moreEditor's pick

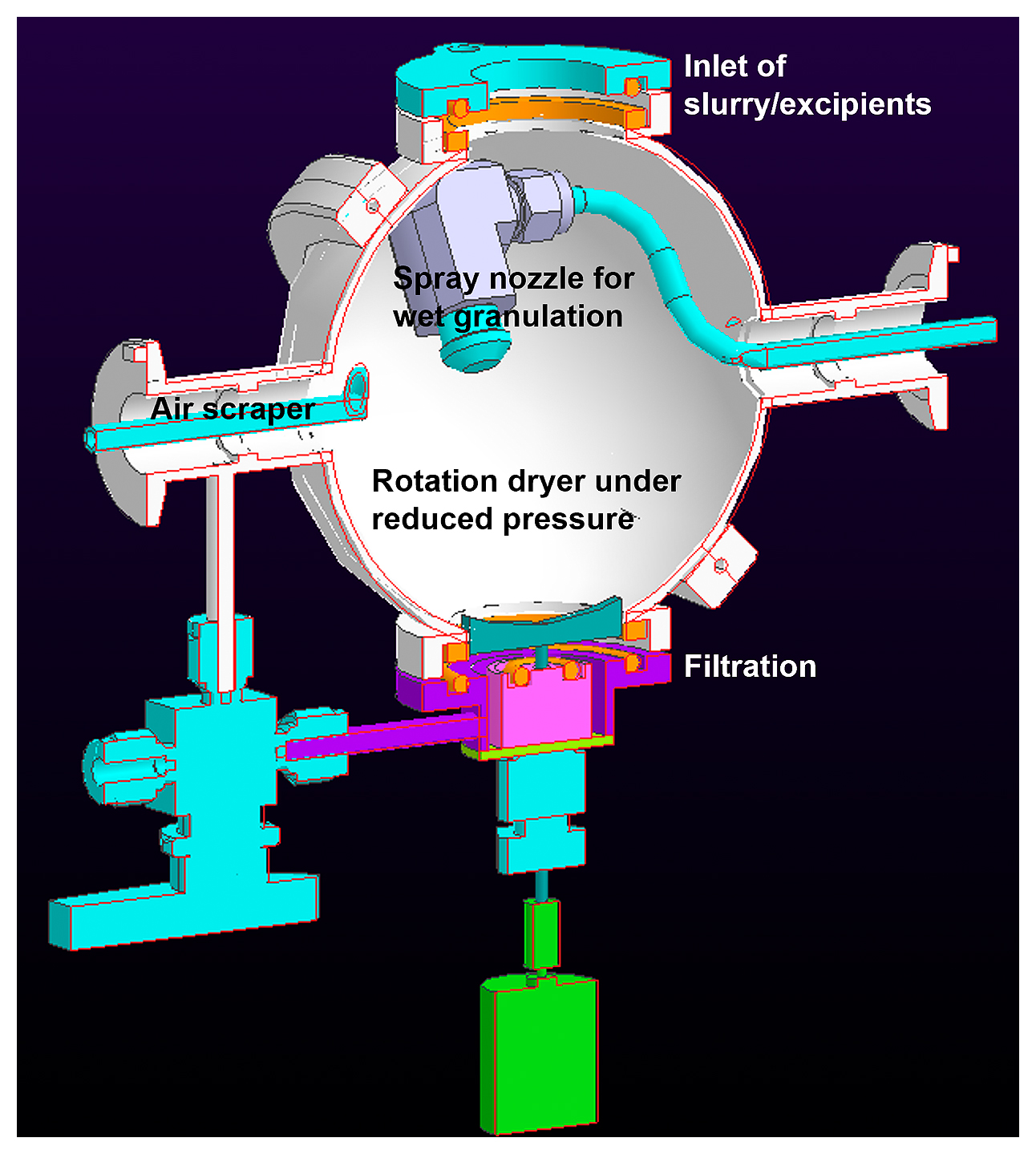

It would be essential to make the manufacturing process as efficient as possible to achieve personalized manufacturing of pharmaceuticals in the future. We have developed a one-pot processing system that integrated powder processing operations in addition to filtration and drying. This table-top equipment was designed to perform the processes of filtration, drying, powder mixing, and wet granulation in a single operation.

-

Editor's pick

In Discrete Element Method (DEM), it is common to reduce the particle stiffness artificially from the original material property to reduce the computational cost. When this method is applied to simulate cohesive particle flows, it is necessary to prevent the excessive energy dissipation caused by the prolonged contact duration, which can make the particles become more cohesive than the original ones. In this article, a new method to scale the viscous damping coefficient according to the reduction of the particle stiffness is proposed to replicate the both static and dynamic flows of the original cohesive particles at the same time.

-

Volume 29 (2021) Pages 41-46Understanding of the Physical Phenomena Caused by Interactions between Laser and Agglomerated Particles Read moreEditor's pick

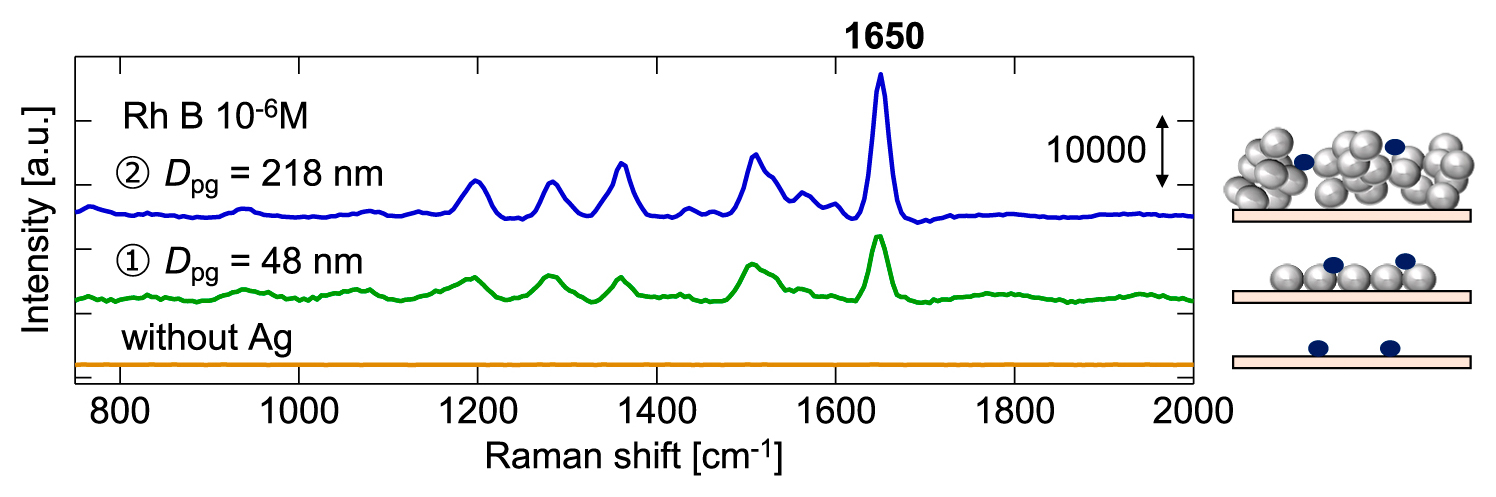

Surface-enhanced Raman scattering (SERS) is expected to be applied to ultra-sensitive analysis in a wide range of fields such as the medical field and the biological field. In SERS, it is known that aggregate structure is important to obtain high electromagnetic field. Since the target molecule is selectively adsorbed between primary particles, the SERS effect is expected to be further amplified in the aggregated particles due to the synergistic effect. In this study, we fabricated a nanoparticle multilayer film by aerosol technique, and obtained extremely high SERS effects.

-

Volume 29 (2021) Pages 62-67Control of Porous Structure in Membrane Manufactured by Drying of Slurry Read moreEditor's pick

Control of properties of porous membrane consisting of carbon-black (CB) and ionomer was investigated, intending the catalyst layer in fuel cell. Slurry in which CB and ionomer were dispersed was coated on the substrate by doctor blading. Porous membrane was manufactured by drying its wetting film. As a result of the measurement of permeability of membrane, it was approximately constant when the specific surface ratio of CB is large, on the contrary, it increased with the membrane thickness when specific surface ratio is small.

-

Volume 29 (2021) Pages 36-40Control of Charging and Motion of Particles using UV Irradiation and Electrostatic Field Read moreEditor's pick

The use of an electric field and ultraviolet enables to control of the charge and motion of particles n in the absence of complicated mechanical and/or pneumatic systems. This article describes a method to charge and levitate the dielectric particles deposited on the insulating plate by an upward electrostatic field and UV irradiation and the effect of photoelectrons emitted from the particles by UV irradiation on the flux and motion of the levitated particles.