Featured articles

- |<

- <

- 1

- >

- >|

-

Volume 76 (2019) Issue 2 Pages 141-149Simulation of Grain Coarsening of Block Copolymer Cylindrical Microdomains Which Are Perpendicularly Oriented by Using the Phase Field Crystal Model Read more

-

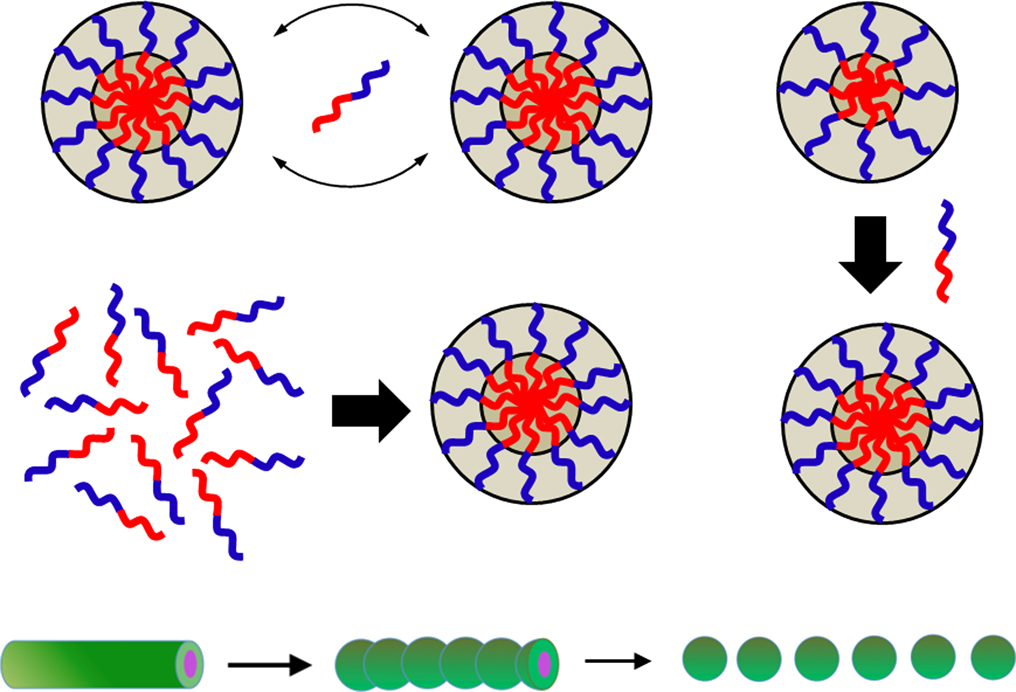

Volume 76 (2019) Issue 1 Pages 3-22Kinetics of Block Copolymer Micelles Formed in Solution Read more

-

Volume 76 (2019) Issue 1 Pages 61-67Synthesis and Properties of Stereoblock Copolymers Composed of Lactide and ε-Caprolactone Read more

-

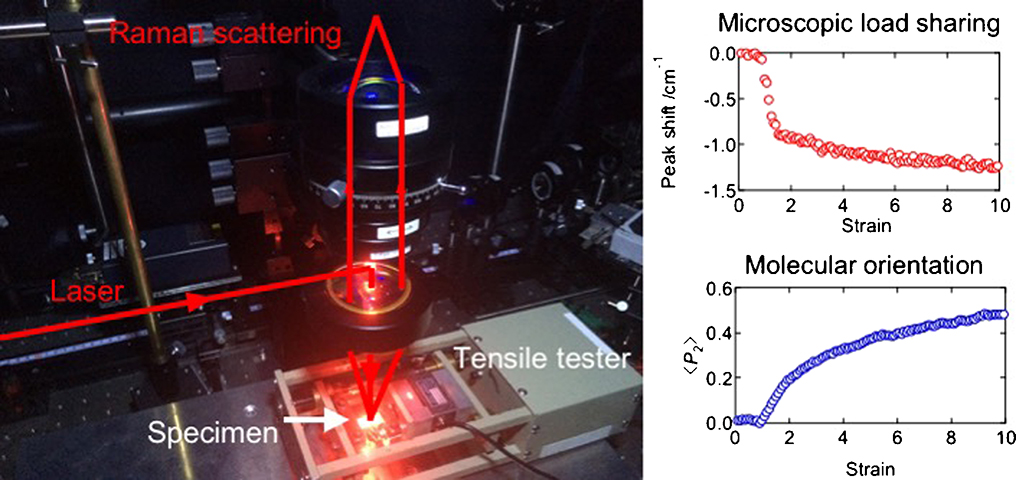

Volume 75 (2018) Issue 6 Pages 497-506Raman Spectroscopic Study of Microscopic Deformation Behavior of Crystalline Polyolefin Solids Read more

-

Volume 75 (2018) Issue 6 Pages 507-514Polymerization and Copolymerization of Olefins by Double-Decker Type Dinuclear Metal Complex Catalysts Read more

-

Volume 75 (2018) Issue 5 Pages 406-420Synthesis of Optically Active Polymers Containing Carbohydrate Units as a Chiral Source and Exploration of Their Functions Read more

-

Volume 75 (2018) Issue 5 Pages 433-443Development of Immunity-Inducing Systems Using pH-Responsive Polysaccharides and Liposomes Read more

-

Volume 75 (2018) Issue 4 Pages 293-336Structural Studies of Polymer Nano-Assemblies in Solution by Scattering Techniques Read more

-

Volume 75 (2018) Issue 2 Pages 143-154Design of Functional Thermoresponsive Polymer Brushes and Their Application to Bioseparation Read more

-

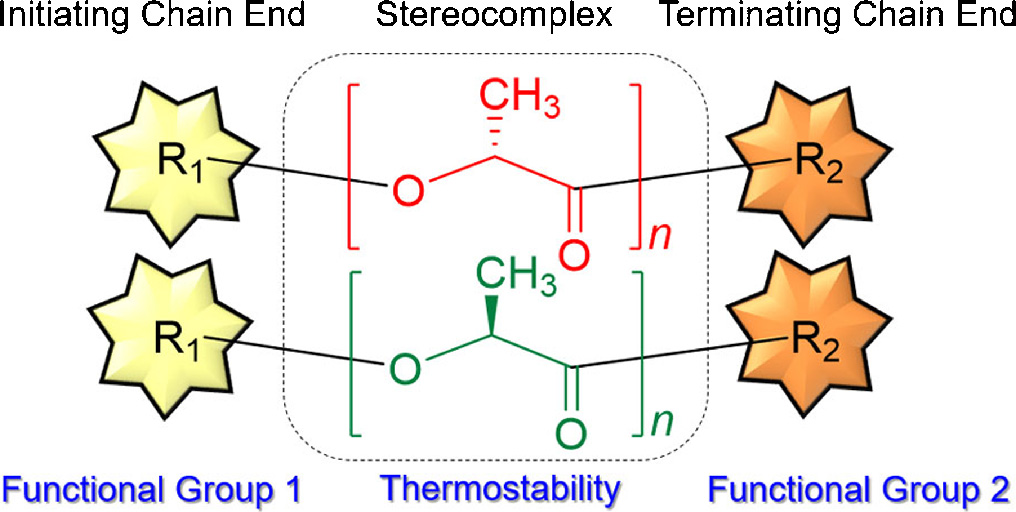

Volume 75 (2018) Issue 1 Pages 9-22Chain End Modification of Polylactide Biomaterials and Investigation of Their Polymer-Polymer Interaction Read more

-

Volume 75 (2018) Issue 1 Pages 23-31Studies on Sandwich Culture by Making Use of Biofunctional Hydrogels as a Three-Dimensional Culture Environment Read more

-

Volume 75 (2018) Issue 1 Pages 42-47Solubilization of a Hydrophobic Prodrug and the Ultrasound Irradiation Effect to TiO2 Nanoparticles-Incorporated Polyion Complex Micelles Read more

- |<

- <

- 1

- >

- >|