2023 Volume 91 Issue 7 Pages 077005

2023 Volume 91 Issue 7 Pages 077005

A new combination of styrene acrylic rubber (SAR) and sodium carboxymethylcellulose was developed as a water-borne binder for LiCoO2 composite electrodes operating at high voltages. Four novel SAR-based latex binders were synthesized with butyl acrylate or 2-ethylhexyl acrylate monomer and styrene via copolymerization with low and high crosslinking degrees. Composite electrodes prepared using lower-crosslinking-degree SAR binders became more stretchable and flexible. Surface analysis using electron microscopy and X-ray photoelectron spectroscopy revealed that the cycled LiCoO2 electrode was covered with approximately 10-nanometer-thick decomposition products when a conventional poly(vinylidene fluoride) binder was used. The electrodes with SAR-based binders with low cross-linkage formed a stable passivation surface during the initial cycle, and further continuous electrolyte decomposition was successfully suppressed. This passivation improved the cycle stability of LiCoO2 electrode up to 4.5 V, i.e., 87.1 % capacity retention, even after 100 cycles and suppressed self-discharge performance at 45 °C.

Functional binders are vital for composite electrodes formed on metallic foils using powder electrode materials for rechargeable batteries.1 Poly(vinylidene fluoride) (PVdF), is widely used in lithium-ion batteries as a binder for both positive and negative electrodes. This is because PVdF has an excellent electrochemical stability and is partially swollen by the electrolyte solution, which facilitates Li+-ion movement between the active material surface and electrolyte.2–4 However, the adhesive strength between the PVdF-composite electrode layer and current collector is relatively weak, and its delamination is a concern.5–8 In addition, N-methyl-2-pyrrolidone (NMP) is required as a solvent to dissolve PVdF for electrode processing, which is harmful and toxic.9 Aqueous binders have been developed to replace conventional PVdF for NMP-free processes owing to their low cost and environment friendliness.10–12 Styrene butadiene rubber (SBR) and sodium carboxymethylcellulose (CMC) have been applied to graphite negative electrodes as aqueous binders and/or thickener. Other water-soluble binders such as polyacrylic acid, sodium polyacrylate,13,14 glycogen, amylopectin,15 polyglutamic acid lithium,16 xanthan gum,17 carboxymethylcellulose,18 have been applied to silicon electrodes for high-capacity negative electrodes of LIBs with enhanced electrochemical performances compared with those of electrodes using PVdF binders.

For the positive electrode, PVdF remains the primary binder, and alternative binders have not yet been introduced on a large scale. Several studies have been conducted on the use of aqueous binders for positive electrode materials. CMC binders have been applied to positive electrode materials, and their electrodes have been reported to exhibit higher cycle performance than PVdF binders.19 Previously, we focused on mixed binders of conventional SBR (SBRstd, in which std denotes standard unmodified SBR) latex and CMC dispersed and dissolved in water.20 When applied to the active material of LiCoO2 powder, no apparent difference in capacity retention was observed between the binders at an upper voltage limit of 4.2 V. However, when the upper cutoff voltage was set at 4.5 V, the difference in capacity degradation among binders increased. Dahn et al. reported that the main cause of capacity degradation above 4.2 V was an increase in the interfacial resistance on the LiCoO2 surface owing to electrolyte and LiCoO2 surface degradation.21,22 Additionally, we previously prepared SBR-based latex binders with various crosslinking densities and functional groups.23–25 When modified SBR/CMC binders were used, the electrodes exhibited charge–discharge performances superior to that of PVdF. Particularly, when using SBRlow (latex binder with a low crosslinking density) or SBRCN (latex binder with added nitrile groups), the capacity retention of the LiCoO2 electrodes was improved owing to the improved interfacial chemistry via surface coating with the binder.

Although SBR/CMC waterborne binders exhibit good positive electrode performance, as mentioned previously, they often result in poor initial Coulombic efficiency at the first cycle owing to oxidation of SBR, leading to a low energy density owing to the anode/cathode imbalance during full-cell fabrication. This oxidation is due to electrochemical oxidation of the double bonds in the butadiene portion of SBR.24 Therefore, we have developed a novel acrylic rubber (AR) binder which is free from –C=C– double bonds.26 The present study serves as a continuation of our investigation into AR-type binders via the process of copolymerization with styrene, where we replace the unsaturated butadiene unit of the SBR with saturated acrylate monomers. Herein, a series of new styrene acrylic rubber (SAR) latex were synthesized via the copolymerization of butyl acrylate, 2-ethylhexyl acrylate, and styrene with a focus on the different molecular structure and crosslinking density of acrylic acid. The effect of different monomers and crosslinking in the novel SAR/CMC binders on the electrochemical performance of LiCoO2 was studied in comparison with conventional PVdF and affordable SBRstd/CMC binders in the high-voltage region up to 4.5 V.

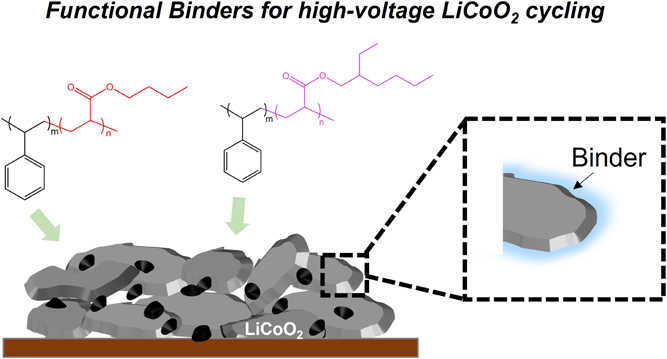

The aqueous dispersions of all SAR-based latex binders depicted in Fig. 1 were provided by NIPPON A&L INC. All SAR-based binders were prepared using emulsion polymerization. SARB is copolymer of butyl acrylate monomer and styrene monomer. SAR2EH is copolymer of 2-ethylhexyl acrylate monomer and styrene monomer. The degree of crosslinking is adjusted by changing the crosslinker; high and low molecular-weight crosslinkers were used for low- and high-degree of crosslinking, respectively. These are also called SARB(high), SARB(low), SAR2EH(high), and SAR2EH(low) depending on the degree of crosslinking. These are also called SARB(high), SARB(low), SAR2EH(high), and SAR2EH(low) depending on the degree of crosslinking. LiCoO2 was supplied by Nippon Chemical Industrial Co., Ltd. Acetylene black (AB; Denka Black Li-400, Denka Co. Ltd.), CMC (CMC#2200, Daicel Miraizu Ltd.), and PVdF (Polysciences Co.) were used in their original form. NMP (purity >99.0 %, Kanto Chemical Co., Ltd.) and a 1.0 mol dm−3 LiPF6 ethylene carbonate (EC) and dimethyl carbonate (DMC) solution (volume ratio, EC/DMC = 1/1; lithium battery grade, Kishida Chemical Co., Ltd.) were also used as received. Deionized water (DI) with a conductivity <1.0 µS cm−1 was obtained using a purification system (Purelite, PRA-0015, Organo).

Chemical structures of the monomers and resultant polymers used in this study.

LiCoO2, AB, styrene-acrylic rubber (SARx), and CMC were thoroughly blended in a mass ratio of 80 : 10 : 0.5 : 0.5 (corresponding to 87.9 : 11.0 : 0.55 : 0.55 wt%) with DI water. A mixture with LiCoO2, AB, SBRstd, and CMC in a mass ratio of 80 : 10 : 0.5 : 1.5 (corresponding to 87.0 : 10.9 : 0.5 : 1.6 wt%) was also prepared using DI water. For comparison, LiCoO2, AB, and PVdF were thoroughly mixed in a mass ratio of 80 : 10 : 10 by adding an adequate amount of NMP as the solvent. It should be noted that a larger quantity of binder was required for the PVdF-based electrode to achieve sufficient mechanical stability, compared to the SAR and SBR-based electrodes. The resulting homogeneous slurries were coated onto aluminum foil current collectors using the doctor blade method and dried under vacuum at 80 °C. The mass loading of LiCoO2 ranged between 3.5 and 3.9 mg cm−2. The obtained electrode sheets were cut into circles with a diameter of 10 mm for battery evaluation in the non-aqueous Li cell. Galvanostatic charge–discharge tests were performed using R2032-type coin cells assembled in an Ar-filled glove box (Miwa). A lithium metal foil, cut into circles with a diameter of 10 mm, served as the counter electrode, and a porous polyolefin sheet was used as the separator. Galvanostatic delithiation–lithiation tests on LiCoO2 electrodes were performed at 25 or 45 °C with a current density of 20 mA g−1 in a voltage range of 3.0–4.5 V.

The solvent uptake and solubility of the polymer binders were determined by measuring the mass change during immersion of pure polymer films (3-millimeter-thick) in an EC/DMC solvent mixture. Scanning electron microscopy (SEM) was used to examine the surface morphology of the electrodes (JCM-6000, JEOL, Ltd.). Hard X-ray photoelectron spectroscopy (HAXPES) spectra were obtained using a Scienta Omicron photoelectron energy analyzer (R-4000) at BL46XU in SPring-8, Japan. Electrodes that underwent electrochemical testing were carefully extracted from the cycled coin cells, rinsed with DMC, dried at room temperature in an argon-filled glove box, and transferred to an instrument without exposure to air. The binding energies were calibrated using the C 1s peak from the sp2 carbon of AB (284.6 eV) as a reference, and the integrated peak intensity was normalized to the same peak after baseline correction.

We confirmed the synthesis of SARB(high), SARB(low), SAR2EH(high), and SAR2EH(low) binder via the copolymerization of three different monomers. The binder films were mixed at a ratio of 95 : 5 (m/m) with the SAR-based binder and CMC at a size 1.0 cm width, 1.5 cm length, and 50 µm thick. Tensile testing of the binder films was performed to investigate their physical properties (Fig. 2). As shown in the figure, the PVdF film exhibits the highest tensile stress and reaches irreversible deformation after only a small elongation of ∼2 mm. The SARB(low) and SAR2EH(low) binders with lower degrees of crosslinking show higher elasticity and flexibility than do those with higher degrees of crosslinking. In addition, regardless of the degree of cross-linking, SARB with butyl acrylate is slightly more extensible than SAR2EH with 2-ethylhexyl acrylate.

Tensile test on PVdF, SARB(high), SARB(low), SAR2EH(high), and SAR2EH(low) films.

The adhesive strength between the aluminum current collector and the composite layer containing the binder and other materials was examined by a 90° peel test using adhesive tape. The results are summarized in Table 1. The PVdF electrode displayed a lower average load of 0.03 N cm−1. Notably, even though the electrode with SAR/CMC binder contains only 1 % binder, significantly less than the 10 % found in the PVdF electrode, its value surpasses 0.27 N cm−1, greatly exceeding that of the PVdF electrode. Thus, SAR binders exhibit superior adhesive strength compared to PVdF. In particular, the SARB(low) electrode shows the highest value potentially attributable to enhanced mechanical stability (Fig. 2), indicating a significant improvement in mechanical strength. It is assumed that this improvement in the mechanical strength of the electrode contributes to the improvement in cycle performance.

| Binder | SARB(high) | SARB(low) | SAR2EH(high) | SAR2EH(low) | PVdF |

|---|---|---|---|---|---|

| Average load (N cm−1) | 0.35 | 0.42 | 0.27 | 0.36 | 0.03 |

The solvent uptake and solubility of these binders in the solvent were tested by soaking the binder films in the EC/DMC solution.23 Table 2 indicates that all the binders were insoluble in the EC/DMC solution, with more than 96 % residue. Composite electrodes made of these polymer binders exhibited enough mechanical stability when in contact with the electrolyte solution. SARB(high), SARB(low), SAR2EH(high), and SAR2EH(low) exhibit solvent uptakes of 39, 56, 40, and 42 %, respectively. The previously reported PVdF and CMC films exhibited only 20 and 4 % solvent uptake, respectively.23 This indicates that the electrolyte affinity of the SAR/CMC polymeric binders in the composite electrodes is dominated primarily by SAR, with the SARB(low) binder exhibiting the highest solvent uptake. High solvent uptake is one of the properties that promotes effective swelling of the composite electrode, improving Li+ ion accessibility, rate performance, as well as facilitating passivation layer formation through electrolyte decomposition at the interface. Furthermore, SARB(low) demonstrates an advantage of high flexibility in the tensile testing discussed earlier and is anticipated to exhibit improved electrochemical properties in the cell testing detailed in the subsequent section.

| Binder | SARB(high) | SARB(low) | SAR2EH(high) | SAR2EH(low) |

|---|---|---|---|---|

| Solvent uptake (%) | 39 | 56 | 40 | 42 |

| Solubility (%) | 4 | 3 | 3 | 3 |

The charge–discharge curves of the LiCoO2 with the different binders in Li cells are shown in Fig. 3. The voltage was set to 3.0–4.5 V to observe the effect of the binder on the cycle stability during high-voltage exposure.20 A reduction in CMC content is positively correlated with enhanced cycling properties (Figs. S1 and S2 in Supporting Information). Figure S3 shows SEM images of the top-view of the pristine electrodes with each binder before cycling; no significant differences in homogeneity were observed among the electrodes with PVdF, SBRstd, and SAR binders. Thus, a content of 0.5 wt% CMC was found to be optimal in this study. All electrodes prepared using SBRstd, SAR, and PVdF binders exhibit first cycle reversible capacities of ∼175 mAh g−1. The PVdF electrode shows a lower capacity during cycling owing to the increased polarization. The polarization behavior of the charge and discharge for the electrode with the SAR-based binder exhibits negligible change until the 50th cycle.

Charge and discharge curves of LiCoO2//Li half-cells with (a) PVdF, (b) SARB(high), (c) SARB(low), (d) SAR2EH(high), (e) SAR2EH(low), and (f) SBRstd binders. The cells are cycled at 20 mA g−1 at 25 °C and filled with 1 mol dm−3 LiPF6 in EC/DMC as an electrolyte.

Figure 4a shows the variation in the discharge capacity of the LiCoO2 electrodes. The discharge capacity of the PVdF electrode decreases from 172 to 148 mAh g−1 after 50 cycles. The initial discharge capacities of the electrodes with SBRstd and SAR binders are slightly larger than those of the PVdF electrode, and they remain higher even after 50 cycles. Figure 4b presents a comparison of the capacity retention ratio as an indicator of long-term stability. The capacity retentions after 50 cycles for SBRstd, SARB(low), SAR2EH(low), SAR2EH(high), SARB(high), and PVdF are 94.9, 94.0, 92.7, 90.9, 88.8, and 85.9 %, respectively. The improved capacity retention of the SAR/CMC electrode can be attributed to the interfacial chemistry, namely a surface film on the active materials and the enhanced adhesive strength between the composite layer and aluminum foil (Fig. 2).20,24,26 The surface layer and passivation are discussed later with surface analysis data. Figure 4c shows the variation in Coulombic efficiencies during 50 cycles of LiCoO2 electrodes with different binders. The first cycle Coulombic efficiencies, crucial for full cell performance, are 96 % for PVdF, 92–94 % for SAR, and 91 % for SBR electrodes, respectively. The relatively low value of Coulombic efficiency in the first cycle for the SBRstd/CMC electrode is owing to irreversible oxidation of butadiene (C=C bonds) at potentials above 4.2 V vs. Li+/Li in the SBR structure.23–26 After the 2nd cycle, the Coulombic efficiency increases, and all the electrodes reach nearly the same average Coulombic efficiency of 99 %.

(a) Discharge capacities, (b) capacity retention, and (c) Coulombic efficiencies of LiCoO2//Li half-cells cycled at 25 °C with different binders.

Figure 5 presents a comparison of the discharge rate capabilities of the five LiCoO2 electrodes. During charging and discharging at a current density of 20 mA g−1, the discharge capacity is ∼175 mAh g−1, regardless of the binder. At a current density of 640 mA g−1, the electrode with PVdF exhibits a discharge capacity of 53 mAh g−1, whereas SAR2EH(high) and SARB(high), which had higher crosslinking, exhibit discharge capacities of 82 and 92 mAh g−1, respectively. By contrast, the electrodes using SAR2EH(low) and SARB(low), which had lower crosslinking, exhibited greater discharge capacities (121 and 120 mAh g−1, respectively). This outcome displays a trend similar to the solvent uptake presented in Table 2, thus implying that the strong affinity between the electrodes and electrolyte solution promotes efficient lithium-ion distribution throughout the composite electrodes, thereby enabling a high-rate discharge.

Rate performance of LiCoO2 electrodes employing various binders. (a) Charge–discharge profiles of LiCoO2//Li half-cells utilizing PVdF and SAR binders. (b) Discharge capacities assessed at different discharging rates, ranging from 20 to 640 mA g−1, while the charging rate was fixed at 20 mA g−1 throughout the experiments.

To evaluate the battery performance further, the LiCoO2 electrodes with different binder polymers were fully charged to 4.5 V and subjected to self-discharge tests. The self-discharge reaction is a combination of chemical lithiation and electrolyte oxidation as follows: LixCoO2 + y Li+ + y (electrolyte species) → Lix+yCoO2 + y (oxidized electrolyte products)+. To prevent this, passivation of the charged LiCoO2 particle surface is important.27 Following the initial five charge–discharge cycles to ensure surface passivation, the LiCoO2//Li half-cells were fully charged to 4.5 V and maintained in open-circuit conditions. Subsequently, after a 7-day storage period at 25 °C, the sixth discharge cycle was executed to assess the remaining capacity. As shown in Fig. 6, after 7-day storage, all the electrodes with SAR-based binders exhibit higher Coulombic efficiencies than does the PVdF electrode. This suggests that the SAR binder suppressed the self-discharge and electrolyte decomposition processes when LiCoO2 charged at 4.5 V was exposed to the electrolyte.27 This is consistent with the previously reported results for electrodes using SBR-based binders.25 Among SAR-based binders, SARB(low) exhibits the highest Coulombic efficiency of 93 % in the sixth cycle, as shown in Fig. 6b. Even when tested at 45 °C, which accelerates the self-discharge, SARB(low) demonstrates the highest Coulombic efficiency at the sixth cycle (Fig. S4). This could be attributed to the effective passivation of LiCoO2 particles modified with SARB(low), which showed the higher elasticity and solvent uptake as described previously. This will be discussed further in the next section.

Self-discharge tests for LiCoO2 electrodes employing various binders at 25 °C. (a) Charge–discharge profiles for the sixth cycle and (b) Coulombic efficiency. The cells undergo cycling in 1 mol dm−3 LiPF6 solution in EC/DMC at a current density of 20 mA g−1 in a voltage range of 3.0–4.5 V; subsequently, they are stored at 25 °C for 7-days following the sixth charging process. Cycling resumes after the 7-day storage period.

SEM images were used to identify the difference in electrode performance and surface chemistry. Figure 7 shows the SEM images of the PVdF electrode and the electrode using the SARB-based binder surface before and after 50 cycles. Figure S5 also shows the SEM images of the surface of the electrode with the SAR2EH binder before and after 50 cycles. The electrode with the PVdF binder was covered with thick decomposition products after 50 cycles. This was not observed in the SAR binders, and no significant differences were noted among them.

SEM images of LiCoO2 electrodes with (a) and (d) PVdF; (b) and (e) SARB(high); (c) and (f) SARB(low), before and after 50 cycles at 25 °C.

To examine the surface layer formed on LiCoO2 in more detail, HAXPES measurements were conducted on the pristine and 50-cycled electrodes as well as on the electrode soaked for one day in the electrolyte. Each spectrum was calibrated and normalized to the sp2 carbon (284.6 eV) derived from AB to allow comparison of binding energies and intensities.23 Generally, HAXPES provides information at a depth of several tens of nanometers, which is deeper than that provided by soft X-ray photoelectron spectroscopy (SOXPES or lab-XPS).28–32

Figure 8 shows the Co 2p HAXPES spectra of the electrode before and after 50 cycles with different binders. The Co 2p3/2 and Co 2p1/2 peaks appear at 779 and 794 eV.23 Among the pristine and electrolyte-soaked electrodes, the signal derived from the active material, LiCoO2 (Co 2p), is the weakest for the electrode with the SARB(low) binder. This observation suggests that the SARB(low) covered the LiCoO2 particle surfaces more uniformly. However, in the electrodes after 50 cycles, the signal intensity derived from LiCoO2 decreases for all binders compared with the pristine and electrolyte-soaked samples, thus suggesting that the electrodes were covered with a deposited layer of several nanometers in thickness. In particular, when PVdF was used, the photoelectron intensity of Co 2p decreased, presumably resulting in a thicker deposition layer, which is consistent with the SEM results in Fig. 7.

Co 2p HAXPES spectra of the LiCoO2 composite electrodes with different binders after (a) no cycles without electrolyte soak, (b) no cycles but electrolyte immersion, and (c) 50 cycles. The cells are cycled in the voltage range of 3.0–4.5 V at 20 mA g−1 and 25 °C, using 1 M LiPF6 in EC/DMC as an electrolyte.

Figure 9 shows the C 1s spectra of the electrodes before and after 50 cycles and on the electrode soaked in the electrolyte for one day. For the electrode after 50 cycles using PVdF, the –O–C– (286.8 eV) and –CH2COO– (285.3 eV)-derived peak intensities rise above that of the C–C peaks (284.6 eV) and may be attributed to polycarbonate produced by the anodic degradation of EC and DMC.23,33,34 By contrast, for the SAR binder, the peak intensities derived from the decomposition products of the electrolyte components before and after cycling does not change significantly. This indicates that decomposition of the electrolyte solvent during cycling was suppressed.

C 1s HAXPES spectra of LiCoO2 composite electrodes incorporating different binders after (a) no cycles without electrolyte soak, (b) no cycles but electrolyte immersion, and (c) 50 cycles. The cells are cycled in the voltage range of 3.0–4.5 V at a current density of 20 mA g−1 and 25 °C, utilizing a 1 M LiPF6 in EC/DMC as the electrolyte.

The F 1s spectra of the electrode before and after 50 cycles with different binders are shown in Fig. 10. For comparison, the electrode immersed in the electrolyte for one day is also shown. The peak observed at ∼688 eV is possibly ascribed to fluorine in PVdF or LiPF6, whereas the intermediate component located at ∼686.6 eV might be associated with LiPF6 decomposition intermediates,35 such as LixPFy, LixPFyOz, and LiF. For the pristine electrode, only the signals derived from the PVdF binder (C–F) are identified. After 50 cycles, the peak intensity of the electrolyte decomposition products (LixPFy, LixPFyOz, and LiF) increases compared with the pristine electrode when PVdF and a SAR-based binder with a high crosslinking degree are used. In contrast, when a SAR binder with a low degree of crosslinking is used, the peak intensity derived from the electrolyte decomposition products is nearly the same for the electrode before and after 50 cycles. This may be attributed to the increased flexibility of low crosslinking binders, which potentially allows them to cover the surface of the active materials more efficiently.

F 1s HAXPES spectra of the LiCoO2 composite electrodes with different binders after (a) no cycles without electrolyte soak, (b) no cycles but electrolyte immersion, and (c) 50 cycles. The cells are cycled in the voltage range of 3.0–4.5 V at 20 mA g−1 and 25 °C, using 1 M LiPF6 in EC/DMC as an electrolyte.

The HAXPES results show that when PVdF and a SAR-based binder with a high degree of crosslinking were employed for the high-voltage operation of LiCoO2 electrode, anodic decomposition of electrolyte proceeded over cycling, and the decomposition products gradually deposited on the active materials surface increased. However, when a SAR-based binder with low crosslinking was used, a stable passivation layer was formed during the initial cycle, and the direct contact between LiCoO2 and the electrolyte was suppressed by the passivation layer. Therefore, the successive deposition of electrolyte decomposition products was also suppressed. The difference between the SARB binder with butyl acrylate and SAR2EH binder with 2-ethylhexyl acrylate was not significant for the LiCoO2 electrode, and the effect of the degree of crosslinking seemed more pronounced in the high-voltage cycle tests.

Figure 11 shows the charge–discharge tests of LiCoO2//Li half-cells with different binders at 45 °C. The charge–discharge curves and absolute discharge capacities are shown in Fig. S6. In Fig. 11a, the capacity retention over 50 cycles degrade in the order of SARB(low) < SARB(high) < SAR2EH(high) < SAR2EH(low) < PVdF. Among the tested binders, the SARB(low) binder exhibits the highest capacity retention of 89.9 %. We hypothesize that the LiCoO2 particles were effectively coated with the SARB(low) and CMC binders, facilitated by the high flexibility and electrolyte uptake. Thus, the SARB(low) is able to induce the successful formation of the passivation layer in the initial cycle. The surface layer can suppress the electrolyte decomposition even at the higher temperature. Figure 11b confirms the higher Coulombic efficiencies of LiCoO2 electrodes with SARB(low) binder. The initial Coulombic efficiency of the PVdF electrode is 91 %, whereas that of the SAR electrode is in the range of 92–94 %, thus indicating the high anodic as well as temperature stability of the SAR-based binder.

(a) Capacity retention and (b) Coulombic efficiencies of LiCoO2//Li half-cells cycled at 45 °C with different binders.

Finally, Fig. 12 presents the results of charge–discharge test, over 100 cycles, of a LiCoO2//Li half-cell with SARB(low) at 25 °C. Even after 100 cycles, it exhibits a discharge capacity of over 158 mAh g−1 and capacity retention of 87.1 %. This suggests the possibility of using SAR-based binders as the positive electrodes in lithium-ion batteries.

Cycling performance and Coulombic efficiency of LiCoO2//Li half-cells with SARB(low) over 100 cycles. The cell is cycled in the voltage range of 3.0–4.5 V at 20 mA g−1 and 25 °C using 1 M LiPF6 in EC/DMC as an electrolyte.

Unlike conventional PVdF binders, the novel SAR-based binders cover the LiCoO2 surface, which induces superior passivation of the electrode. This suppresses the anodic decomposition of the electrolyte and accumulation of byproducts on the electrode surface. The difference in coating composition, as observed from HAXPES, between SARB-based binders with butyl acrylate and SAR2EH-based binders with 2-ethylhexyl acrylate was not highly pronounced. However, the binder with lower crosslinking degree displayed a thinner decomposition layer, suggesting enhanced coating and passivation due to its flexibility. Moreover, we observed that the lower crosslinking SAR exhibited better adhesion strength, whereas the homogeneity of the composite electrode was not significantly influenced by the binder composition. Notably, among all, SARB(low) binder, characterized by the highest electrolyte uptake and flexibility, demonstrated the best cycling stability. The application of SARB(low) effectively promoted the formation of a protective layer on the active material surface, thus resulting in the a desired passivation completed in the initial cycle. Based on these findings, further investigations are underway on the application of SAR-based binders to different electrodes, electrolytes, and voltages for lithium-, sodium-, and potassium-ion batteries.

The synchrotron radiation experiments were carried out at BL46XU of SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) under proposal numbers 2021B1874, 2022A1657 and 2022B1838.

The data that support the findings of this study are openly available under the terms of the designated Creative Commons License in J-STAGE Data at https://doi.org/10.50892/data.electrochemistry.23294582.

Lu Yin: Conceptualization (Equal), Data curation (Lead), Formal analysis (Lead), Investigation (Lead), Writing – original draft (Lead)

Ryoichi Tatara: Conceptualization (Equal), Investigation (Equal), Methodology (Lead), Visualization (Equal), Writing – original draft (Supporting), Writing – review & editing (Lead)

Shogo Yamazaki: Data curation (Supporting), Investigation (Supporting), Methodology (Supporting)

Rena Takaishi: Conceptualization (Equal), Formal analysis (Lead), Resources (Lead), Writing – review & editing (Supporting)

Eisuke Shiiyama: Conceptualization (Equal), Investigation (Supporting), Resources (Supporting)

Takashi Matsuyama: Conceptualization (Equal), Formal analysis (Lead), Resources (Lead), Writing – review & editing (Supporting)

Satoshi Yasuno: Data curation (Equal), Investigation (Supporting), Methodology (Supporting), Writing – review & editing (Supporting)

Shinichi Komaba: Conceptualization (Supporting), Supervision (Lead), Writing – review & editing (Supporting)

The authors declare no conflict of interest in the manuscript.

L. Yin: ECSJ Student Member

R. Tatara: ECSJ Active Member

S. Komaba: ECSJ Fellow