2018 年 87 巻 4 号 p. 516-523

2018 年 87 巻 4 号 p. 516-523

Light is one of the most limiting factors affecting plant growth in greenhouses. Recently, supplementary artificial light has been widely used in greenhouse production in winter or on overcast days when solar radiation is weak. However, plant responses to supplementary artificial light in a Chinese Solar Greenhouse (CSG) and the economic feasibility of the lighting strategy are poorly understood. The tomato, one of the most widely produced and consumed vegetables in the world, was tested in this study. A CSG was divided into three sections, and three treatments were arranged. They were top lighting with HPS lamps (TL), TL plus inter-lighting with LEDs (TL+IL), and control treatment without artificial light, respectively. We showed that supplementary artificial light improved the uniformity of light distribution from the south to north end of the CSG, and increased the average greenhouse temperature by ~1–1.4°C. Tomato yield was increased by 21.8% and 32.9% in TL and TL+IL, respectively, compared with that of the control. The higher yield under supplementary artificial light resulted from a larger number of ripe fruits rather than bigger fruit size. Moreover, fruit quality was improved by supplementary artificial light as indicated by a higher total soluble sugar content. There were no significant differences in total biomass production or total soluble sugar content in leaves, as well as fruits, between TL and TL+IL treatments, but TL+IL further stimulated fruit maturation compared with TL. Although supplementary artificial light confers an advantage in terms of tomato growth, it is not economically feasible as 28.8 kWh electricity was required to increase the tomato yield by 1 kg in the CSG. Therefore, it is important to find solutions to increase the efficiency of supplementary artificial light in the CSG.

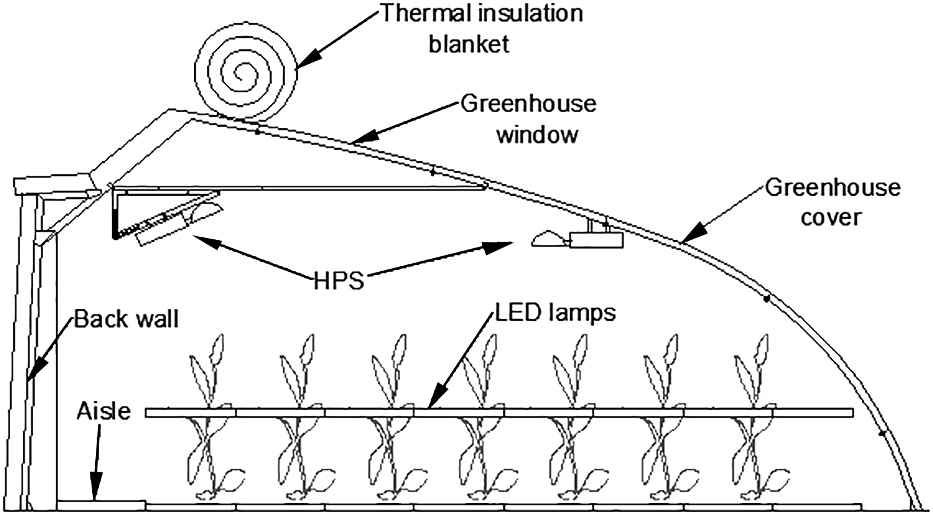

Chinese Solar Greenhouses (CSG) accounted for 26% of total protected cultivation area in China in 2016, playing a pivotal role to guarantee year-round availability of horticultural products in Northern China. A CSG is typically characterized by an arched front roof face to the south side and a thick wall as well as back roof in the north side (Fig. 1). The front roof is often covered by a plastic film during the day with a thermal blanket added at night to maintain the heat inside. Such structures functions well for thermal insulation and with zero heat energy input even during the coldest winters when outside temperatures fall below −10°C (Tong et al., 2013). However, this also results in a heterogeneous light distribution with significantly lower light intensity in the north section of the CSG compared with the middle and south sections, consequently leading to non-uniform plant growth. Our earlier study showed that tomato production in the north section of a CSG was about 30% lower than that in the middle and south sections (Li et al., 2017). Moreover, dust accumulation on the greenhouse cover, as well as the aging effect of plastic cover materials, result in relatively low light transmission in CSGs. More importantly, the frequent occurrence of fog and haze days in northern China caused by increased anthropogenic emissions strongly limits the availability of photosynthetic active radiation (PAR). Therefore, the PAR intensity inside CSGs may not be sufficient for plant growth, particularly in winter or on overcast days, strongly limiting plant growth. For these reasons, many growers have recently tried applying supplementary artificial light in CSGs. However, studies on this approach are scarce. In this context, a detailed study with supplementary artificial light in CSGs is urgently needed. This may not only add information for research into CSGs, but also provide a reference for growers to make informed decisions.

Schematic diagram showing a cross section of a Chinese Solar Greenhouse (CSG), and the layout of HPS lamps and LEDs.

Light is the driving force for plant growth. A rule of thumb estimating the effects of light on production states that for most greenhouse crops, a 1% reduction in light will reduce production by 1% (i.e. the one-percent rule) (Marcelis et al., 2006). To obtain higher production, therefore, supplementary artificial light is often considered in greenhouses in northern countries (Heuvelink et al., 2006). Conventionally, high-pressure sodium (HPS) lamps are used in commercial greenhouses as a supplemental lighting source above the crop canopy. Plants are known to benefit from even light distribution over the crop canopy (Li et al., 2014b, 2016; Trouwborst et al., 2011b). In the high-wire cultivation system with high plant density, most of the supplemental lighting can only be intercepted by the upper part of the plant canopy (Trouwborst et al., 2010). Interlighting is a recently developed supplemental lighting technique to overcome this problem, which increases production in the order of 10–20% in Venlo-type glasshouses (Hovi and Tahvonen, 2008; Hovi et al., 2004, 2006; Pettersen et al., 2010). Light emitting diodes (LEDs) have been widely applied as a suitable light source for interlighting as the emittance of near infrared (NIR) radiation can be neglected. A disadvantage of LEDs is the lack of radiation heat in the plant heads, which lowers the benefit of additional heating, unlike heat released from HPS lamps that maintains an acceptable development rate (Dueck et al., 2017). Therefore, a hybrid system which combines the advantages of HPS and LEDs could have great potential in greenhouse crops.

Plant acclimation depends to a large extent on the prevailing light conditions (Li et al., 2014b). Under supplemental lighting conditions, apart from increased biomass production, the higher light intensity often leads to an acclimation of the leaf morphology which characterized by thicker leaves as indicated by a lower specific leaf area (SLA) (Poorter et al., 2010). Acclimation under high light intensity also includes changes in physiological properties such as increased chlorophyll content and soluble sugar content in leaves (Tewolde et al., 2016; Trouwborst et al., 2010). Moreover, high light intensity conditions may lead to higher levels of photosynthate availability for fruit growth as fruit is the most important storage organ (or sink) for fruit vegetables (Osorio et al., 2014).

Supplementary artificial light improves crop production and product quality (Heuvelink et al., 2006). In real world production, economic turnover is the decisive factor that needs to be considered. However, there is limited information available to analyze the economic feasibility of applying supplementary artificial light in CSGs. This study aimed to investigate plant growth and production in response to supplementary artificial light in CSGs and evaluate whether supplementary artificial light is cost-effective. The tomato, often seen as a model plant (Kimura and Sinha, 2008) and also one of the most widely produced and consumed vegetables in the world (Heuvelink, 2005), was tested in this study. Moreover, the tomato is a high light-demanding crop and often grows under inadequate light conditions (Heuvelink and Buiskool, 1995; Li et al., 2015; Matsuda et al., 2011).

Tomato seeds (Solanum lycopersicum, ‘Ruifen882’) were sown into 50-cell plug trays, and seedlings were transplanted to a CSG after two weeks of germination. The CSG had an area of 600 m2 (60 m×10 m) and was located in Shunyi district, Beijing, China (40°26' N, 116°52' E). Plants were grown in mixture substrate bags filled with soilless medium composed of 1/3 peat, 1/3 vermiculite, 1/3 perlite by volume from August 2016 to January 2017. Plant density was 3.75 plants·m−2 and nutrient solution was provided with a drip irrigation system. The nutrient solution recipe was 110.4 N, 32.3 P, 83.6 K, 122.0 Ca, 48.4 Mg, 2.8 Fe, 0.5 Mn, 0.05 Zn, 0.02 Cu, 0.5 B, and 0.01 Mo, in mg·L−1, with mean pH of 5.8 and mean EC (electrical conductivity) of 1.8 dS·m−1. Plant rows were in the north to south orientation. The distance between rows alternated between 60 and 90 cm, resulting in a double row followed by a path. Pollination was conducted twice a week with vibrate pollinators (SC-99; SUCA, Taiwan, China) and all side shoots were removed once they appeared. Throughout the experimental period, 4 to 5 fruits were maintained on each truss. Air temperature and relative humidity in the greenhouse were recorded every 10 min by a data logger (HOBO U14-001; Onset Computer Corporation, Bourne, MA, USA) which was placed in the middle of the compartment at a height of 1.5 m. An aluminum foil cover was applied to avoid the influence of heat from the direct irradiance on the sensor. Light intensity inside and outside of the CSG was monitored at 10 min intervals by pyranometer (model CMP3, Kipp and Zonen, Delft, The Netherlands).

Light treatmentThe CSG was divided into three compartments for three treatments: control, top lighting (TL) and top lighting plus interlighting (TL+IL). TL was supplied by high pressure sodium lamps (HPS, 600 W, 220 V, Agrismart, Shanghai, China) which were mounted on the frame of the greenhouse, while interlighting was supplied by one-layer LEDs which were installed between rows (Fig. 1). The light spectrum of LEDs was a mixture of 90% red (640 nm dominant wavelength) and 10% blue (450 nm dominant wavelength). Irradiance was emitted from both sides of the LED lamps with a PAR intensity of 70 μmol·m−2·s−1 at 20 cm from the lamps. The PAR intensity of HPS lamps was 120 μmol·m−2·s−1 at 1 m below the lamps, measured by a light quantum sensor (LI-1500; LI-COR, Lincoln, NE, USA). The photoperiod of the interlighting LEDs was from 6:00–20:00. The photoperiod of the HPS was automatically controlled according to natural irradiance such that the lamps turned on when the natural PAR intensity was below 300 μmol·m−2·s−1 and turned off when it exceeded 400 μmol·m−2·s−1. Application of HPS lamps started from Oct. 19, 2016 to Jan. 16, 2017, while application of interlighting LEDs started from Nov. 23, 2016 when plant height reached to 1.5 m until Jan. 16, 2017. Two electricity meters (DTS2626; RMDNB Co. Ltd, Shanghai, China) were installed in the two lighting treatments, respectively, to record electricity consumption.

Growth measurementsRipe fruits were harvested three times (Dec. 22, 2016, Jan. 3, 2017, Jan. 16, 2017) during the experiment. The accumulated fresh weight of ripe fruits was considered to be the fruit yield. Five ripe tomato trusses from each treatment were selected and their fresh and dry weights were determined to calculate the dry matter contents (DMC, dry weight/fresh weight). Dry weight of ripe fruits was the product of DMC and fresh weight of ripe fruits. Destructive harvest measurements were taken at the end of the experiment. Four plants were randomly selected from each treatment. Fresh and dry weight of stems, leaves (including regularly removed leaves during the experiment) and fruits were determined, and the stem length and leaf number were recorded. Dry weights of leaves and stems were determined after being placed in a ventilated oven (DHG-9620-A; Bluepard, Shanghai, China) for two days at 80°C, while dry weights of fruits were determined for 5 days at 105°C. Plant total biomass was the sum of the dry weight of plant organs produced during the experiment. Dry matter partitioning and dry matter contents of plant organs were calculated simultaneously.

Leaf morphology and chemical measurementsTen leaf discs with a diameter of 1.6 cm were randomly collected from leaf number ten (leaf number one is defined as a leaf length longer than 10 cm at the top of canopy) and their area and dry weight were determined to calculate specific leaf area (SLA, leaf area/dry weight). Similarly, three leaf discs were randomly collected from each leaf and six leaves were selected as six replicates. These samples were used for measuring chlorophyll content. Ethanol was used as a solvent and the absorbance was measured at 665, 649, and 470 nm using a UV-Vis spectrophotometer (UV-1800; Shimadzu, Kyoto, Japan). The chlorophyll concentrations were calculated using the equations derived by Wellburn (1994). The leaf samples for total nitrogen and soluble sugars were collected before sunrise on the day two months after light treatment. Collected leaf samples were covered by aluminum foil and immediately plunged into liquid nitrogen and stored at −80°C until analysis. The samples were lyophilized (STELLAR 53/85; Millrock, Kingston, NY, USA) for two days and powdered with a grinder (Scientz-48; Scientz, Ningbo, China) before measuring leaf total nitrogen and soluble sugar (fructose, glucose, sucrose and maltose). The total nitrogen content was determined using an elemental analyser (vario PYRO cube; Elementar, Hanau, Germany). The leaf soluble sugars were extracted with 80% ethanol in an 80°C water bath. The supernatants were dried with a Pressure Blowing Concentrator (MTN-2800D; Autoscience, Tianjin, China) and dissolved with distilled water (Milli-Q Reference; Merck, Shanghai, China). The solutions containing soluble sugars were determined with UPLC (Aquirty H-class UPLC; Waters, Milford, MA, USA) equipped with a refractive index detector (RID) as described by Yin (2010) with modifications.

Fruit quality measurementsDuring the second harvest (Jan. 3, 2017), eight ripe fruits were randomly selected and each fruit was evenly cut into four sections lengthways. One section was stored at −80°C until analysis. Fruit soluble sugar contents were determined by UPLC (Aquirty H-class UPLC; Waters, Milford, MA, USA) as described above when analyzing the contents in leaves.

Leaf photosynthesis measurementsDiurnal variations in leaf photosynthetic rates were measured using a LI-6400 portable photosynthesis system equipped with a clear leaf chamber (LI-COR, USA). Photosynthetic rates were measured at leaf number five in the control and top lighting treatments during the day between 7:00–19:00 at one hour time intervals. Air inlets were connected with a buffer bottle to achieve a steady-state greenhouse CO2 concentration. The air flow was 500 μmol·s−1, the leaf temperature was maintained at 25°C, and relative humidity was between 50–70%.

Statistical analysisTreatment effects on plant growth parameters were evaluated by one-way ANOVA (analysis of variance) using SPSS (Version 19.0; IBM, Armonk, NY, USA), followed by Fisher’s protected least significant difference test (LSD) at 95% confidence.

The daily PAR integral substantially decreased from late autumn to winter and was maintained at around 10 mol·m−2 inside the greenhouse (Fig. 2A). The greenhouse transmission was 54%. PAR intensity was unevenly distributed inside the CSG. Specifically, the natural PAR intensity in the north section of the CSG was only 60% of the south section, while the PAR intensity from HPS lamps was the opposite, with 60% higher in the north section compared with the south section (Fig. 2B). TL and TL+IL treatments increased the daily PAR integral by 24.4% and 35.5% during the experimental period, respectively (Table 1). Moreover, both lighting treatments increased average greenhouse temperature by ~1–1.4°C compared with the temperature of the control (Table 1).

Daily light integral (DLI) inside and outside of the CSG during the experiment (A), which ran from Aug. 28, 2016 to Jan. 16, 2017. (B) The distribution of natural light and artificial light inside the greenhouse. HPS lamps were turned off to measure distribution of natural light; a greenhouse cover blanket was fully applied when measuring the distribution of light intensity of HPS. Error bars show means ± SE (n=4).

Conditions inside the Chinese Solar Greenhouse (CSG) with different light treatments.

TL and TL+IL treatments improved tomato yield by 21.8% and 32.9%, respectively, compared with the yield of the control (Table 2). Moreover, both supplementary lighting treatments significantly increased the number of ripe fruits, while the fresh weight of single fruit remained similar among treatments (Table 2). Plant total biomass production was increased by 61–66% under supplementary artificial light treatments compared with that of the control (Table 3). This mainly resulted from a significantly heavier dry weight of leaves as well as fruits (Table 3). There was no significant difference in biomass production between the two supplementary lighting treatments. Dry matter partitioning to fruits under supplementary lighting treatments was significantly higher than that of the control, while dry matter partitioning to leaves in the TL treatment was significantly lower than that in the other treatments (Table 3).

Effects of supplementary lighting on tomato yield, ripe fruit number per plant and single fruit fresh weight.

Effects of supplementary lighting on plant dry weight, dry matter partitioning and specific leaf area.

Both lighting treatments significantly decreased the SLA of the upper canopy leaves (Table 3), indicating that leaves were thicker under supplementary lighting compared with the control.

Leaf photosynthesisLeaf photosynthetic rates changed with the diurnal variation in PAR intensity during the day (Fig. 3). On a clear day, HPS lamps were turned on during the morning and afternoon (Fig. 3A), and correspondingly, net leaf photosynthetic rates were higher than the control during these periods (Fig. 3B). In the early morning and late afternoon when solar radiation was weak, there was no carbon gain under control treatments as indicated by the negative net photosynthetic rates (Fig. 3B).

Photosynthetic active radiation (PAR) (A) and net photosynthetic rate (B) under control and top lighting (TL) with HPS on a clear day (Dec. 6, 2016). Error bars show means ± SE (n=4).

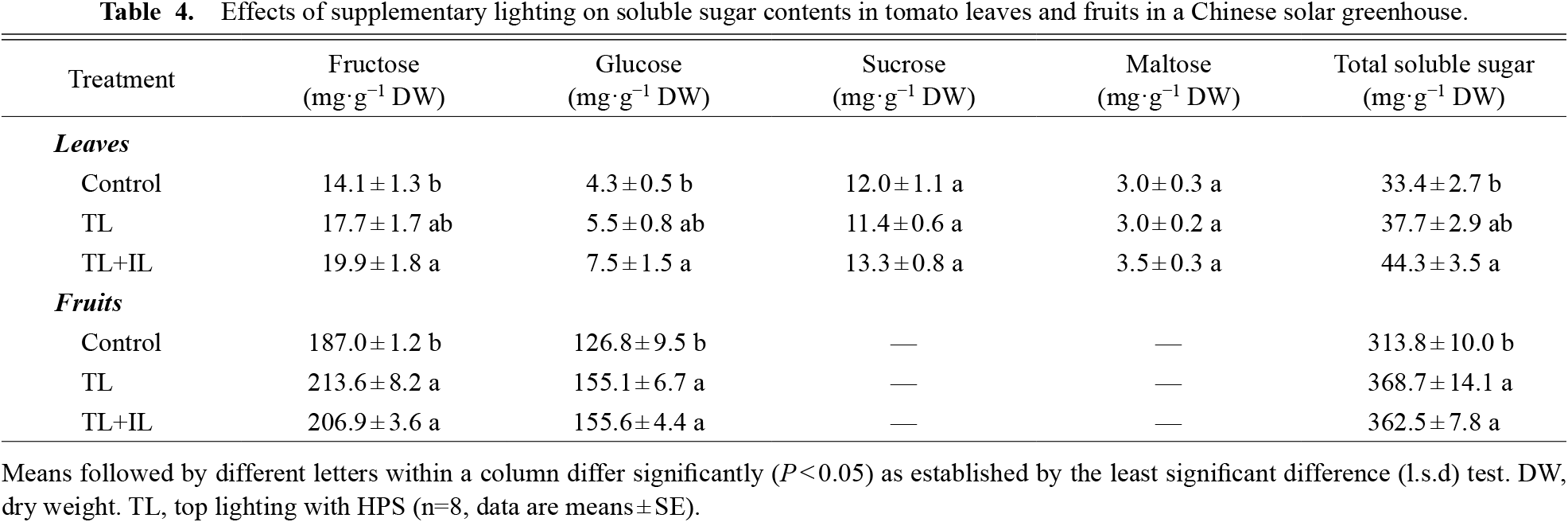

The two lighting treatments significantly increased total soluble sugar contents in leaves compared with the control, and this mainly resulted from a higher fructose and glucose content (Table 4). A similar phenomenon was observed in tomato fruits (Table 4). However, there were no significant differences in soluble sugar contents in leaves or fruits between the two supplementary lighting treatments (Table 4). Although the supplementary lighting treatments increased the total nitrogen content, chlorophyll content, and chlorophyll a/b ratio compared with the control, such differences were not significant (Table 5).

Effects of supplementary lighting on soluble sugar contents in tomato leaves and fruits in a Chinese solar greenhouse.

Effects of supplementary lighting on total nitrogen, chlorophyll content and chlorophyll a/b ratio in tomato leaves.

Electricity consumption levels were 30.4 kWh·m−2 and 42.9 kWh·m−2 in TL and TL+IL treatments, respectively, at the end of the experiment. Corresponding to the yield enhancement in both treatments (Table 2), the electricity utilization efficiency was 28.8 kWh·kg−1 (Fig. 4).

Relationship between tomato yield and electricity consumption under supplementary artificial light. TL, top lighting; TL+IL, top lighting plus intracanopy lighting with LEDs. Error bars show means ± SE (n=4).

Light is one of the most limiting factors affecting plant growth in greenhouses (Pinho et al., 2013). The daily PAR integral from solar radiation inside a CSG was about 10 mol·m−2 during the winter, which markedly limited the growth of tomatoes, as fruiting tomato plants are often source-limited (Heuvelink and Buiskool, 1995; Li et al., 2015). We showed that supplementary artificial light in a CSG significantly increased yield and total biomass production (Table 2; Table 3). To our knowledge, we are the first to systematically investigate the effects of different supplementary lighting strategies on the growth performance of tomato plants in a CSG, and to further explore their electricity utilization efficiency.

Solar radiation was unevenly distributed in the CSG as shown by the PAR intensity in the north section which was only ~60% of that in the south section of the greenhouse (Fig. 2B). This mainly resulted from the shadow cast from the greenhouse back roof and wall which functions for heat storage during the day and heat release during the night (Li et al., 2017). It is clearly recognized that heterogeneous light distribution strongly limits light use efficiency (Li et al., 2014b). In this study, the emission angle of the HPS lamps in the north section was adjusted to face the south section (Fig. 1), which resulted in a higher PAR intensity from artificial light in the north section of CSG compared with the PAR intensity in the south section (Fig. 2B). Therefore, by integrating with natural radiation, our strategy improved the uniformity of PAR distribution in a CSG. In this context, the current lighting system in the CSG could not only compensate for the low PAR intensity available from nature, but also improved the light distribution in the greenhouse. This differs from the existing supplementary lighting system of the Venlo-type greenhouses that mainly aims to increase light intensity. Moreover, the greenhouse temperature was increased by ~1–1.4°C during the experiment due to the application of HPS lamps that emit near infrared radiation, which also positively affects plant growth and development (Särkkä et al., 2017).

Increasing light intensity increases crop production when plants are source-limited (Li et al., 2015). We showed that tomato yield was increased by 21.8–32.9% under supplementary lighting at the end of the experiment (Table 2). Considering the yield enhancement and the extra PAR gained from supplementary artificial light, we noted that tomato yield was increased by 0.89% and 1.01% in TL and TL+IL treatments, respectively, with a 1% additional daily PAR integral in CSG. This is in accordance with the rule of thumb that a 1% increment in light results in a 1% yield increase (Marcelis et al., 2006). Yield enhancement under supplementary artificial light treatments mainly resulted from the higher number of ripe fruits rather than the changes in the fresh weight of single fruit (Table 2). Although TL+IL resulted in a significantly higher ripe fruit yield compared with that of TL, there was no significant difference in total biomass production between the two treatments (Table 3). This indicates that intracanopy lighting with LEDs only stimulated fruit ripening. TL+IL treatment did not substantially improve total biomass production compared with TL. This could be caused by two factors. Firstly, the amount of radiation gained from intracanopy lighting accounts for only a quarter of total supplementary radiation. Secondly, severe leaf curling occurred nearby the LEDs in this study, which may have strongly limited canopy light interception (Trouwborst et al., 2010). Such phenomena probably occurred due to the integrating effect of improper positioning of LED lamps, light spectra, as well as the microclimate in the canopy (Marcelis et al., 2014). Dry matter partitioning of fruits under supplementary artificial light was higher than that of the control (Table 3). This is because tomato plants during the fruiting stage are strongly source-limited (Li et al., 2015), while fruits are the most important sink organ, having the priority to use photosynthates (Osorio et al., 2014). This also resulted in higher soluble sugar contents in tomato fruits (Table 4), indicating better fruit quality under supplementary artificial light.

Photosynthesis is the ultimate basis for plant growth and production (Yamori and Shikanai, 2016). We showed that net photosynthetic rates were negative in the early morning and late afternoon in CSG on a clear day in December (Fig. 3B). This indicates that the PAR intensity was lower than the photosynthesis light compensation point during these times. To maintain plant growth, therefore, supplementary artificial light is indispensable (Fig. 3B). Source-sink balance regulates carbon status in plants (Osorio et al., 2014). For a strongly source-limited fruiting stage tomato plant as in this study, supplementary artificial light could increase the source strength, and consequently result in a higher carbohydrate contents in plants (Li et al., 2015). This explains the higher total soluble sugar contents in leaves and fruits under supplementary lighting conditions (Table 4). Plant acclimation highly correlates with the prevailing growth environment (Poorter et al., 2009, 2012). Supplementary artificial light resulted in thicker leaves as indicated by the lower SLA (Table 3), which is a typical strong light induced acclimation trait (Poorter et al., 2009, 2010). Furthermore, plants grown under high light often exhibit an enhancement in total nitrogen and chlorophyll contents, as well as chlorophyll a/b ratio in leaves (Li et al., 2014a; Trouwborst et al., 2011a). In this study, significant differences were not observed in these leaf biochemical properties, but an increasing trend could be observed under supplementary artificial light treatments (Table 5). This probably occurred because the PAR intensity from artificial light was not strong enough to induce leaf physiological acclimation.

It is obvious that supplementary artificial light improves plant growth and production. To decide whether or not to invest in supplementary artificial light in CSGs, reliable yield expectations are needed. We showed that 28.8 kWh electricity was required to increase tomato yield 1 kg under supplementary artificial light (Fig. 4). This is not economically feasible based on the current standard electricity and product prices in China. Actually, utilization of supplementary lighting in vegetable production is generally not economically feasible based on model calculations (Heuvelink et al., 2006). Considering the fact that greenhouse areas equipped with supplementary lighting are dramatically increasing, it is important to find ways to increase the efficiency of supplementary lighting. In a CSG, just adding supplementary artificial light without considering other climatic factors and crop management is unacceptable. In this context, realizing economically feasible production with supplementary artificial light in a CSG has many barriers to overcome.

ConclusionSupplementary artificial light substantially increased tomato yield in a CSG, which resulted from a higher number of ripe fruits rather than bigger fruit size. Moreover, fruit quality was also improved by supplementary artificial light as indicated by a higher total soluble sugar content. Intracanopy lighting with LEDs further stimulated fruit maturation compared with top lighting only. Although supplementary artificial light positively affected tomato yield as well as quality, it is not economically feasible as 28.8 kWh electricity was required to increase tomato yield 1 kg in a CSG.