2019 年 88 巻 4 号 p. 548-558

2019 年 88 巻 4 号 p. 548-558

The objective of this study was to clarify the effects on quality when exporting small amounts of fresh fruits and vegetables by mixed loading. When exporting small amounts of multiple varieties of fruits and vegetables, it is essential to reduce transport costs by using reefer containers for mixed cargo. A lot of research has been conducted on the distribution and storage technology of fruits and vegetables. However, conditions and techniques have primarily been examined only for single items, and research on transporting mixed cargo has not been done. In this study, we used a new reefer container with only marginal internal temperature variability (set to 0°C), and exported fruits and vegetables by sea as a mixed cargo. Subsequently, the fruits and vegetables exported by sea were compared by sensory evaluation with those exported by air. Satsuma mandarins, onions, salad onions, Welsh onion leaf blades, and lettuces were almost the same quality when shipped by sea as by air without any specific treatment. Other items such as tatsois and Welsh onion stems required film, plastic bags, and other packaging to reduce fresh weight loss when exporting by sea. These results suggest that fruits and vegetables can be exported by sea with similar quality to that by air. However, it is necessary to consider the storage temperature, packaging material and conditions, and item selection.

The combined value of fruits and vegetables exported by sea and by air from Japan has risen rapidly from ¥13.3 billion in 2012 to ¥36.6 billion in 2017 (Ministry of Finance Japan, 2018). More than 80% of the exported fresh produce is shipped to Hong Kong because this destination does not require testing to be performed in Japan and offers easy quarantine and other procedures. The next most common destinations are Taiwan and Singapore. While exports to destinations such as Hong Kong and Taiwan have been pursued aggressively because of their relative proximity, exports to Singapore and other parts of Southeast Asia have increased recently.

Currently, fruits and vegetables exported from Japan are shipped by sea and by air. However, because aircraft have a smaller shipping capacity than ships, improvements are necessary in the technologies used to export fresh produce by sea to handle rising export volumes. Shipping by sea is also considerably cheaper than that by air and is therefore helpful in maintaining price competitiveness. In the future, improvements in the distribution technology for fruits and vegetables would help in not only maintaining freshness, but also reducing food loss during the distribution process, which could help to address the problem of global hunger (Abass et al., 2014; Porat et al., 2018).

In general, exporting from Japan to Southeast Asia by sea takes approximately two–three weeks, including time for customs procedures in Japan and at the destination. Therefore, exporters need to maintain the freshness of fruits and vegetables over a long period. When storing fruits and vegetables, storage temperature reduction and respiration reduction are important for maintaining quality (Caleb et al., 2012). In addition, temperature reduction helps to suppress the discharge of ethylene, which can greatly improve the storability of fruits and vegetables (Begheldo et al., 2008). The use of temperature control and packaging materials is necessary to reduce fresh weight loss (Ji et al., 2012; Nunes and Emond, 2007). Moreover, the composition of the surrounding gas environment can affect storability (Mditshwa et al., 2018; Singh, 2010).

However, the optimal temperature and humidity conditions for storing fruits and vegetables differ depending on the stored item (Gross et al., 2018). Further, with low-temperature storage, there is a risk of freezing; this can damage the cell membranes of fruits and vegetables, thereby greatly reducing their quality (Morris and Clarke, 1981). Therefore, the lowest temperature at which freezing does not occur is desirable for storage. Even so, some tropical fruits and vegetables such as mangos and pineapples are damaged by chilling injury even when they are not frozen (Pan et al., 2017; Vithana et al., 2018), and such items require higher storage temperatures.

Studies on the export technology for fruits and vegetables such as persimmon (Fahmy and Nakano, 2016), grapes (Acevedo et al., 2007), mango (Sivakumar et al., 2011), okra (Dhall et al., 2014), and strawberry (Hikawa-Endo and Sone, 2017) have examined factors such as the temperature during export, presence or absence of packaging, and gas environment inside cages. However, all these studies examined shipments of single items. When shipping by sea, the maximum utilization of the space inside a container lowers shipping costs, which implies that the container should be almost full. However, the fruits and vegetables produced in Japan are mostly exported in small amounts of multiple varieties. Therefore, except for items that can endure long-term storage, such as apples and tangerines, it is difficult to secure sufficient quantities of a single item to fill a 20- or 40-foot marine container. To solve this problem, we believe it is necessary to study methods of mixed loading of items so that as many fruits and vegetables as possible can be exported under the same shipping conditions. The mixed loading of fruits and vegetables is a shipping technique that could be widely applied to small-volume exports worldwide and not just to shipments from Japan.

Based on this background, we tested the mixed loading of fruits and vegetables exported by sea from Japan to Singapore, and compared the quality of these items to those exported by air to clarify how mixed loading affects the quality of fruits and vegetables. Recently, several manufacturers have developed reefer containers with improved internal temperature control. We used one of these containers set to 0°C for the mixed-loading test, and evaluated quality via sensory evaluation.

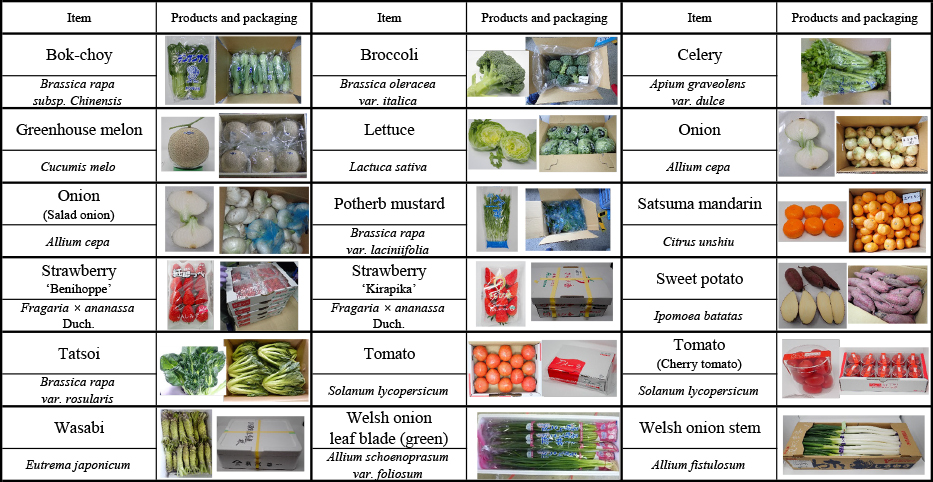

Eighteen kinds of fruits and vegetables were used for the export test (Fig. 1). The fruits and vegetables were selected based on the interest expressed by produce buyers in Singapore. The selected fruits and vegetables were bok-choy, broccoli, celery, tatsoi, onion, salad onion, and Welsh onion leaf blade (JA Topia-Hamamatsu, Hamamatsu, Japan), greenhouse melon (Melon Growers Association Clown Melon Branch, Fukuroi, Japan), lettuce (JA Ooigawa, Fujieda, Japan), potherb mustard, and Welsh onion stem (JA Enshu-Chuuou, Iwata, Japan), Satsuma mandarin (Maruhama-Kankitsu Co-op., Hamamatsu, Japan), strawberry (‘Benihoppe’ and ‘Kirapika’, JA Shimizu, Shizuoka, Japan), sweet potato (JA Fujinomiya, Fujinomiya, Japan), tomato, and cherry tomato (Sunfarmers Co., Ltd., Oyama, Shizuoka, Japan), and wasabi (JA Shizuokashi, Shizuoka, Japan). Two main varieties of strawberry are grown in Shizuoka Prefecture, and the local buyer often indicates the preference in the export order. Therefore, we used both varieties in the test.

Fruits and vegetables used for the export test and packaging conditions.

All samples used in the sea-shipping test were shipped by the producers on February 8, 2018, transferred that night, and received the next morning. The samples used in the air-shipping test were shipped by the producers on February 25, 2018, transferred that night, and received the next morning.

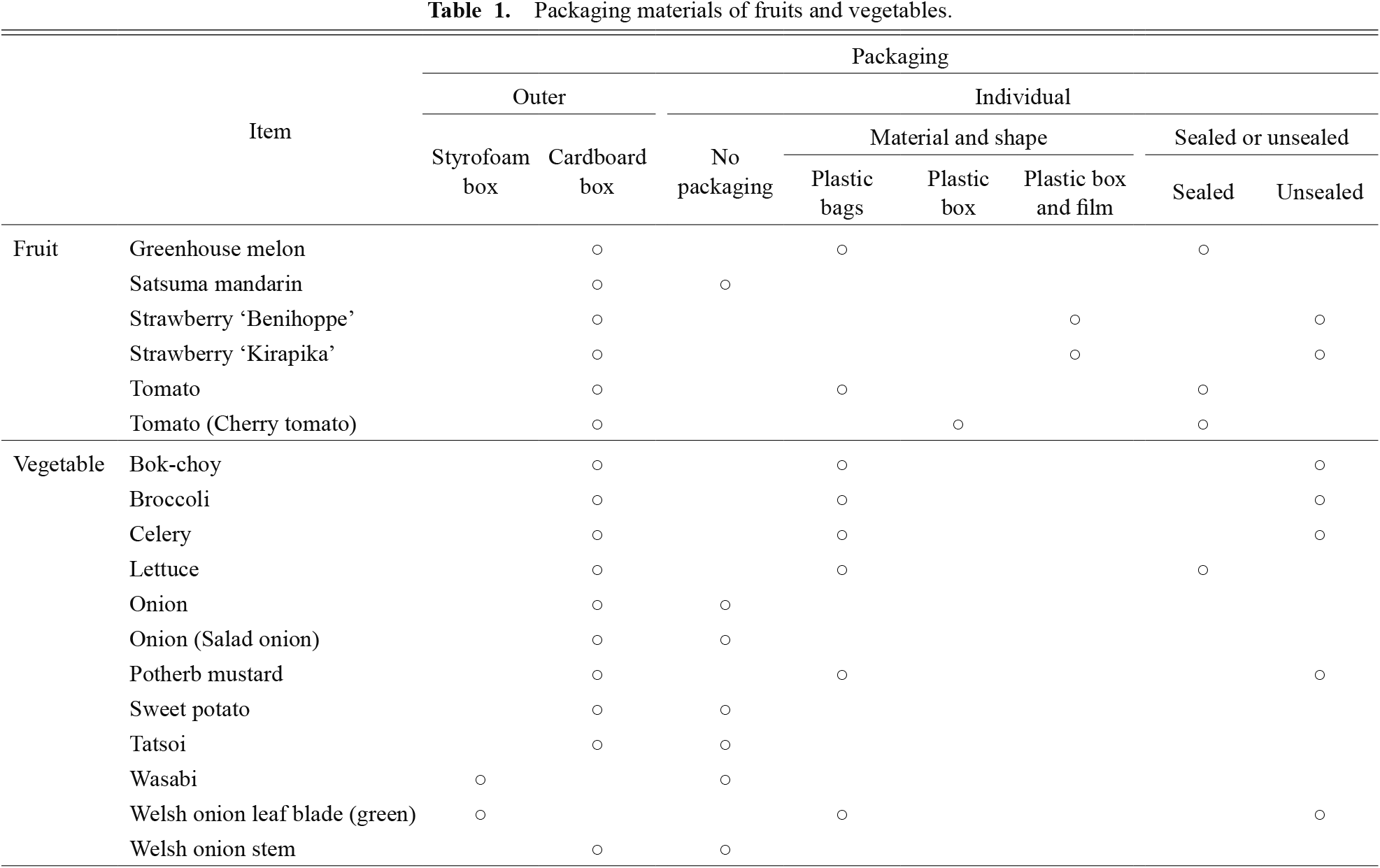

2. PackingThe packing materials of fruits and vegetables are presented in Table 1. Bok-choys were packed in plastic bags, with two stocks per bag, and batches of 10 plastic bags per cardboard box. Broccoli was packed in plastic bags, with 5 kg per plastic bag, and one plastic bag per cardboard box. Celery was packed as one stock per bag, and five bags per cardboard box. Greenhouse melons were packed six per cardboard box with buffer material. Lettuces were wrapped individually in a film, with 10 kg per cardboard box. Onions and salad onions were packed at 10 kg per cardboard box. Potherb mustard was packed at 100 g per plastic bag, and 20 bags per cardboard box. Satsuma mandarins were packed at 10 kg per cardboard box. Strawberries (‘Benihoppe’ and ‘Kirapika’) were placed in plastic trays, with 300 g and buffer material per tray, and covered with film; in addition, batches of four trays were placed in a cardboard box and the boxes were stacked five levels high. Sweet potatoes were packed in cardboard boxes, with 5 kg per box. Tatsoi was packed at 2 kg per cardboard box. Tomatoes were packed at 1 kg per cardboard box, and the boxes were stacked five levels high. Cherry tomatoes were placed in plastic boxes, with 50 g per box. Then, these plastic boxes were placed in cardboard boxes with ten plastic boxes per cardboard box, and the cardboard boxes were stacked five levels high. Wasabi was packed in Styrofoam boxes with moistened newspaper at 2 kg per box. Welsh onion leaf blades were packed in plastic bags, with 100 g per bag, and 30 bags per Styrofoam box. Welsh onion stems were packed in cardboard boxes, with 3 kg per box.

Packaging materials of fruits and vegetables.

Among the fruits and vegetables used in the test, greenhouse melons, tomatoes, and cherry tomatoes discharge large amounts of ethylene (Gross et al., 2018). In general, for shipping purposes, cherry tomatoes are sealed, but greenhouse melons and tomatoes are not packaged using film or other materials. In this test, the greenhouse melons and tomatoes were placed in packaging film (P-Plus, 0.03 × 380 × 270 mm; Sumitomo Bakelite Co., Ltd., Tokyo, Japan) upon delivery for export to protect other fruits and vegetables that are sensitive to ethylene. Other items were not specifically treated for export.

3. Test plan for export by seaFigure 2 shows an outline of the test. The fruits and vegetables were delivered to a refrigerated warehouse set to 5°C near Shimizu Port on the morning of February 9, 2018. In the warehouse, the fruits and vegetables were taken out of their boxes to be photographed and weighed, after which they were repackaged and stored in the same warehouse. After clearing customs on February 13, the fruits and vegetables were mounted on pallets and loaded onto a precise temperature-controlled reefer container (Fresh Keeping Device “futecc”; Denso Corp., Aichi, Japan) set to 0°C. This type of container has two compressors and two inverters that help to minimize internal temperature variations, and the difference in temperature was ± 0.5°C. During loading into the reefer container, the fruits and vegetables were placed on separate pallets. There are various theories about the classification of fruits and vegetables. However, in this study, we defined greenhouse melon, Satsuma mandarin, strawberry (‘Benihoppe’ and ‘Kirapika’), tomato, and cherry tomato as fruits, and the rest as vegetables. Both pallets were covered individually with a polyethylene pallet cover (TM-P-11A; 1200 × 1200 × 1300 mm, Trusco Nakayama Corporation, Tokyo, Japan) to maintain humidity. Fruits and vegetables were loaded onto pallets in order of weight and the loading procedure comprised three steps. The pallets were fixed to the container with a fixture (Ty-Patch 2000; Walnut Industries, Inc., Pennsylvania, USA). The reefer container was loaded onto a cargo ship (WAN_HAI_313), which left Shimizu Port on February 15 and arrived in Singapore on February 26. On February 27, the container with the fruits and vegetables was transported to a refrigerated warehouse set to 4°C near Singapore Port, where the fruits and vegetables were removed from the container. They were then transported in a refrigerated truck to the R&D Center of Mitsui Chemicals, Singapore (hereafter referred to as the R&D Center). Immediately upon arrival, the appearance of the fruits and vegetables was checked and they were weighed. Next, the Satsuma mandarins, onions, salad onions, and sweet potatoes were stored at room temperature (approximately 25°C) and the rest were refrigerated at 4°C. The sensory test was performed the next day.

Outline of the export test. z Fresh Keeping Device “futecc” (Inside dimensions (L5.4 × W2.3 × H2.3 [m]). y Fruits and vegetables were placed on separate pallets, which were covered individually with a polyethylene pallet cover. x Unit Load Device (Inside dimensions: L1.4 × W2.3 × H1.4 [m]).

The fruits and vegetables were delivered to a warehouse at Shizuoka Airport on the morning of February 26, 2018. These fruits and vegetables were produced in the same area and were of the same grade as those used in the sea-shipping test. Inside the warehouse, the fruits and vegetables were photographed, weighed, and then repackaged. After clearing customs, the fruits and vegetables were loaded onto an air-shipping container and flown from Shizuoka Airport to Naha Airport, where they were unloaded and stored in a refrigerated warehouse. They were reloaded late that night and then flown to Changi Airport, Singapore, arriving on February 27. After clearing customs, the fruits and vegetables were transported in a refrigerated truck to the R&D Center. The fruits and vegetables arrived around the same time as those transported by sea and were managed after arrival in the same manner.

5. Measurement of temperature and internal ethylene levels during transportThe temperatures during transport were measured using temperature and shock recorders (G-MEN20; SRIC Corp., Nagano, Japan). The recorders were placed inside the third box of the five-tiers of strawberry boxes during export, both in those by sea and by air. Strawberry boxes were placed directly on the pallet when transported by sea, but were placed at the bottom of the container for air transport. Because the fruits and vegetables were placed on separate pallets for transport by sea, recorders were also placed inside the sweet potato boxes. Temperature readings were taken every 1 min during transport by air and every 10 mins during transport by sea. In addition, when the reefer containers were first opened in Singapore, the ethylene gas levels inside the containers and pallet covers were measured using a gas detector tube (No. 172L; Gastec Corp., Kanagawa, Japan). The gas was measured three times inside the container and each pallet cover at different positions.

6. Appearance and fresh weightThe weight and appearance of the fruits and vegetables were checked when they were delivered to the warehouses at Shimizu Port and Shizuoka Airport and then at the R&D Center. Their appearance was checked by two Japanese assessors with experience in fruit and vegetable quality evaluations. Items with even a small amount of mold or spoilage were classified as “decayed”, and the percentage of decayed units with respect to the total number of units was calculated (Ayala-Zavala et al., 2004). When calculating fresh weight loss, the pre-export weight was considered to be 100%.

7. Sensory evaluationPrevious studies on fruit and vegetable exports (Dhall et al., 2014; Fahmy and Nakano, 2016; Sivakumar et al., 2011) evaluated quality by assessing peel color, ion leakage, texture, chlorophyll content, physiological weight loss, rotting percentage, and other aspects of general appearance and by analyzing certain contents of fruits, such as the total soluble solid, organic acids, and pigments (Gross et al., 2018). However, different freshness indicators and quality evaluations have been used for different fruits and vegetables. Further, quality can vary greatly according to the part of the item examined. In the present study, we needed to evaluate multiple varieties of fruits and vegetables at the same time. Therefore, we decided to assess the overall quality of the fruits and vegetables using sensory evaluations performed by regular consumers.

7.1 Sensory evaluation of appearanceThe appearances of the fruits and vegetables shipped by sea or air were compared using a two-sample preference test (Meilgaard et al., 2007; Sato, 1985). In this test, the items were examined by a 23-person panel, composed of two people in their twenties, 11 people in their thirties, and 10 people in their forties. There were 12 females and 11 males. By ethnicity, there were 10 Japanese panelists, nine Chinese panelists, one Indian panelist, one Caucasian panelist, and two panelists of other ethnicities. The panelists were not given any special training. To assess the fruits and vegetables, each panelist was asked to choose the sample that “looked fresher” and describe the reason for their choice. Each sample was coded with three random digits. The amount of each sample provided was about the same as one package when sold in small quantities at a store. Samples were provided by selecting representative quality, and the decayed samples were excluded from the test.

7.2 Sensory evaluation of taste and preferenceThe same panel outlined in Section 6.1 examined the fruits and vegetables for their suitability to be eaten raw (greenhouse melon, lettuce, Satsuma mandarin, strawberry, tomato, and cherry tomato) using a two-sample preference test (Meilgaard et al., 2007; Sato, 1985). The samples were served as follows. The greenhouse melons were cut into eight radial slices, which were then cut in half. The lettuce was torn into bite-sized pieces. The Satsuma mandarin was peeled and then split into segments. The tomatoes were cut into eight radial slices. The strawberries and cherry tomatoes were served whole. The attributes compared by the panelists were texture, sweetness, sourness, flavor, and overall preference. For the texture, flavor, and overall preference, the panelists chose the samples that felt more preferable according to the two-sample preference test. For sweetness and sourness, the panelists chose the samples that tasted stronger according to the two-sample difference test. The panelists were also asked to give the reasons for their choices.

8. Statistical analysisEach value is expressed as the mean ± standard deviation (SD). The results were compared using the student’s t-test. Angle conversion was applied in advance for the fresh weight test, thereby cancelling out heteroscedasticity. The results of sensory evaluation were evaluated by a two-tailed test (Meilgaard et al., 2007; Sato, 1985). All tests used a significance level of 5%.

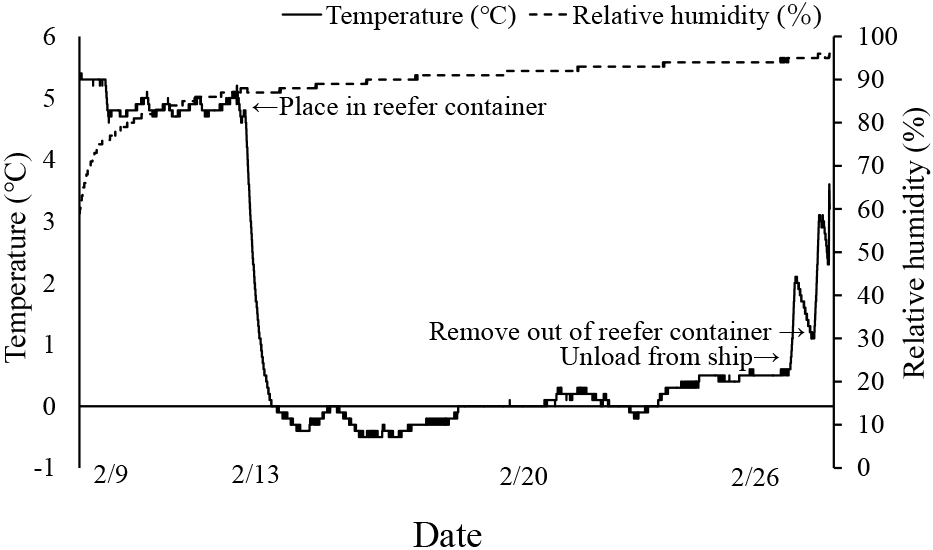

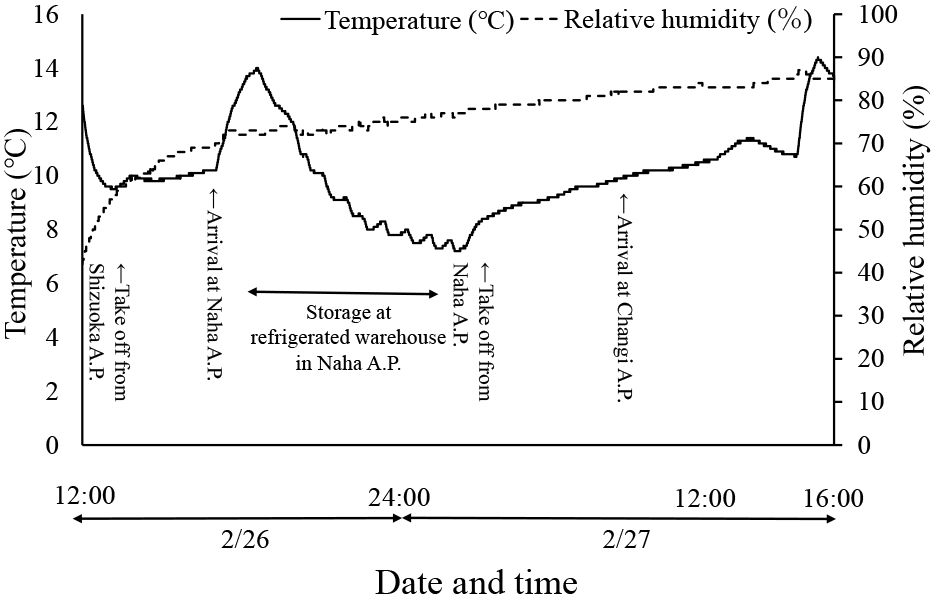

The changes in temperature and humidity inside the shipping box during the export test are shown in Figures 3 and 4. Only data from inside the strawberry box are shown because the readings from the fruit and vegetable pallets shipped by sea were not considerably different.

Temperatures during export by sea. Data were collected using a recorder inside the strawberry box.

Temperatures during export by air. Data were collected using a recorder inside the strawberry box.

During transport by sea (Fig. 3), the temperature inside the pallet was maintained at around 5°C up until it was loaded into the reefer container. Inside the container, the temperature took approximately 12 h to drop to approximately 0°C and stayed at 0°C ± 0.5°C until the container arrived at Singapore Port. When it arrived in Singapore, the reefer container’s electrical source was cut off temporarily when it was unloaded from the ship. During this time, the temperature rose to 2.1°C. When electricity was restored, the temperature inside the container fell to 1.1°C. The cargo was then removed from the container inside a refrigerated warehouse and transported to the R&D Center in a refrigerated truck. During this time, the temperature remained below 4°C. The humidity was approximately 65% when the cargo was delivered, and then it gradually increased to 90–95% after it was loaded onto the reefer container.

In contrast, during transport by air (Fig. 4), the maximum and minimum temperatures were 14.4°C and 7.2°C, respectively. The humidity was initially 40% and gradually rose to approximately 80% at the end of the transport test.

Although a minimum temperature of −0.5°C was reached during transport by sea, when the fruits and vegetables arrived in Singapore none of them showed signs of freezing. Among the fruits and vegetables used in this test, celery, broccoli, and lettuce have high freezing points of around −0.4°C, depending on the variety and conditions (Whiteman, 1977). Freezing did not occur in this test. However, mixed loading may involve fruits and vegetables in various conditions. Therefore, the risk of freezing can probably be reduced by setting the temperature to approximately 0.5°C.

During transport by sea, the humidity was kept sufficiently high to create an appropriate environment to avoid moisture loss. However, high humidity can encourage the growth of mold and other microorganisms. Changing the gas composition to increase CO2 levels can be used to control mold growth (Saltveit, 2018a). Hence, modifications to control the gas environment during shipment by sea, such as the use of modified-atmosphere packaging, could be effective. During transport by air, the humidity reached a maximum of around 80%. Because of the short transport time, this level of humidity had only a marginal impact, but a slightly more humid environment is desirable to prevent moisture loss.

2. Ethylene gas concentration in the reefer containerEthylene gas levels were measured inside the reefer container during transport and in the pallets when the container was opened inside the refrigerated warehouse after arriving in Singapore by sea. Ethylene gas was not detected in either the container or the pallets. However, the gas detector tube we used had a measurement range of 0.2–50 ppm and a detection limit of 0.05 ppm. These results indicate that even under the shipping conditions used in this test, in which pallet covers can easily be filled with ethylene gas, the ethylene gas concentration was less than 0.05 ppm.

Ethylene gas can cause fruits to ripen and reduce the quality of vegetables (Saltveit, 2018b). Therefore, ethylene gas has become a major problem in mixed fruit loading (Pathak et al., 2017). While there have been many studies on ethylene gas, all of them detected concentrations higher than the detection limit in these measurements (0.05 ppm). Although ethylene gas can affect certain items at the ppb level (Saltveit, 1999), we confirmed that high levels of ethylene gas are not reached even inside a pallet cover used to prevent drying. Therefore, we believe that in this test, ethylene gas had almost no impact on the quality of the stored fruits and vegetables.

Appearance and fresh weightThe assessments of the appearance of the fruits and vegetables immediately after arrival showed that except for sweet potatoes and potherb mustard, the entire batch of all the items transported by air had quality levels that were sufficiently high for commercial sale. Decay was observed in 7.9% of the sweet potatoes and 20.0% of the potherb mustard. Sweet potatoes are susceptible to chilling injury when stored at low temperatures below 8°C (Masuda et al., 2007; Ohashi and Uritani, 1972). Therefore, the decay was assumed to be caused by chilling injury. There are no reports of chilling injury in potherb mustard, and it was thought that the cause of the decay was simply that the shelf life of the potherb mustard was short. Therefore, with mixed loading at 0°C, it is better to avoid items that are susceptible to chilling injury. Further, items with a short shelf life should be exported by air, not by sea. In addition, among the fruits and vegetables selected in this test, chilling injury due to storage at 0°C has also been reported for tomatoes and greenhouse melon (Gross et al., 2018). However, chilling injury was not confirmed for these items in this study. In addition, we transferred some samples to room temperature (25°C), including tomatoes, cherry tomatoes, greenhouse melons, and sweet potatoes because they may succumb to chilling injury even after cold storage has finished. We confirmed their conditions for two days after arrival in Singapore, but no other abnormality occurred.

We also supplied the fruits and vegetables exported by sea and by air to a local buyer. He evaluated all of them as being of salable quality, except for some sweet potatoes and potherb mustard that had decayed. In the future, we plan to obtain evaluations from more buyers.

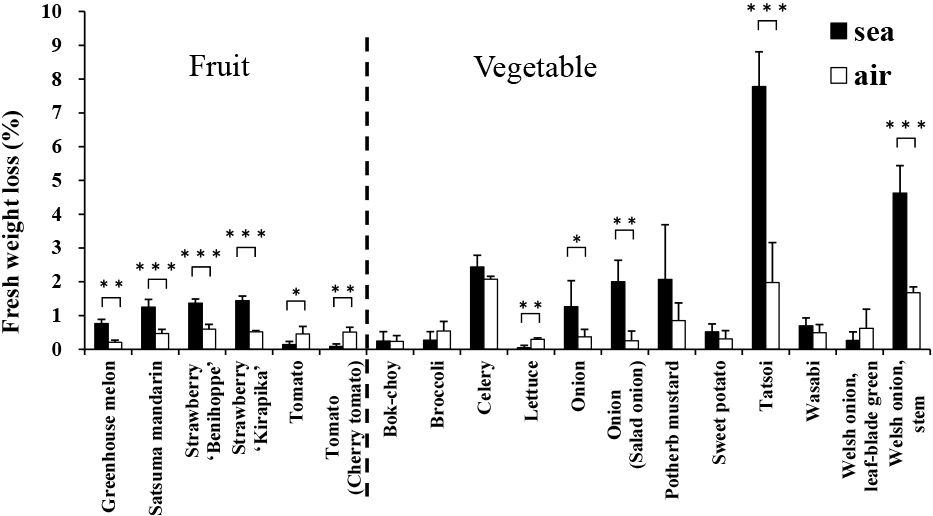

Figure 5 shows the fresh weight loss resulting from transport by sea or air. Fresh weight loss is an indicator closely related to reduced quality of fruits and vegetables (Nunes and Emond, 2007). During transport by sea, the fresh weight loss was slightly high for tatsoi and Welsh onion stems at 7.8% and 4.6%, respectively. While these items did not appear abnormal, showing no signs of decay or discoloration, they did look somewhat dry. The fresh weight loss in the other fruits and vegetables was 3% or less. Generally, when moisture loss exceeds 4–6% of the total fresh weight, it results in visible wilting or wrinkling of the surface of most commodities (Kays, 1997). In terms of fresh weight, transport by sea did not greatly reduce quality in this test.

Differences in fresh weight between sea and air transport. The fresh weight when delivered to the port or airport was considered to be 100% (n = 6). *, **, and *** P < 0.05, 0.01, and 0.001, respectively.

The fresh weight loss in tatsoi and Welsh onion stems was large probably because they were only placed in cardboard boxes without any film or other packaging. In addition to tatsoi and Welsh onion stems, the Satsuma mandarin, sweet potatoes, onions, and salad onions were packed only in cardboard boxes, but these fruits and vegetables did not exhibit significant fresh weight loss. This is probably because these fruits and vegetables have outer skins that reduce the amount of transpiration. Further, all items with sealed individual packaging had a fresh weight loss of 1% or less. These results indicate a strong correlation between fresh weight loss and the type of packaging used on fruits and vegetables.

In the fruits and vegetables transported by air, the fresh weight loss was largest in celery at 2.1%, followed by tatsoi and Welsh onion stems, which showed large amounts of weight loss when transported by sea. However, the fresh weight loss for all these items was minor, and there was hardly any change in their appearance.

Significant differences in fresh weight loss between sea and air transport were observed for several items. When transported by sea, the fresh weight loss was significantly smaller for tomatoes, cherry tomatoes, and lettuce. All these items were packaged in either film or sealed plastic boxes. When transported by air, the fresh weight loss was smaller for strawberries, greenhouse melons, Satsuma mandarins, onions, salad onions, and Welsh onion stems. Except for greenhouse melons, all these items were shipped in cardboard boxes either without additional packaging or in unsealed packaging. These results again highlight the fact that items sealed in film or other packaging exhibited only marginal fresh weight loss when transported by sea, and in some cases, these items exhibited less fresh weight loss than those transported by air. Even tatsoi and Welsh onion stems, which exhibited large amounts of fresh weight loss when transported by sea, could probably be exported by sea if they were placed in film or other packaging. Only greenhouse melons, despite being unsealed, did not exhibit more fresh weight loss when transported by sea than when transported by air. This is likely because the packaging used for greenhouse melons was a film meant to prevent condensation and this had high permeability.

These results indicate that the type of packaging has a major impact on fresh weight loss when exporting fruits and vegetables, and that even when items are placed in styrene foam or cardboard boxes, sealed individual packaging can significantly reduce the impact of fresh weight loss on quality.

Sensory evaluation of appearance 1. Appearance of fruitsThe upper rows of Table 2 compare the sensory evaluation results for the appearance of the fruits shipped by sea or air.

Comparison of the appearance of fruits and vegetables exported by sea and by air.

Cherry tomatoes, strawberries (‘Benihoppe’), and greenhouse melons were assessed as significantly fresher when shipped by air. All these fruits were only slightly reduced in terms of fresh weight, whether shipped by sea or air; therefore, other factors are thought to have had a greater impact on quality. In particular, cherry tomatoes were assessed to be fresher when shipped by air, even though this mode of transport caused more fresh weight loss. This is because several panelists said that the cherry tomatoes shipped by air had an orangish, bright-red color, whereas those shipped by sea had a slightly purplish, red color. Cherry tomatoes become redder during storage (Fagundes et al., 2015), and because the shipment transported by sea required more time, this characteristic was expressed more strongly. There was no significant difference in tomato by shipping method according to sensory evaluation.

With regard to the strawberries, differences between the shipments transported by sea and air were observed for ‘Benihoppe’, but not for ‘Kirapika’. The amount of moisture loss did not differ between them. Several panelists found that ‘Benihoppe’ strawberries shipped by sea were purplish red compared to those by air. It has been reported that the pericarp color does not change significantly in strawberries, even when stored at 0°C (Sacks and Shaw, 1993). The color change was not confirmed in ‘Kirapika’. Therefore, the change in the color of strawberries due to storage is considered to vary by variety.

Greenhouse melons were packaged in film when shipped by both sea and air, and so exhibited only marginal moisture loss. However, the panelists commented that the stems of melons shipped by sea were slightly more withered, which we consider to be the reason for the difference in the appearance assessments. Luxury Japanese melons (Fig. 1) are harvested with some of the stem still attached. Consumers in nearby countries have gradually learned about this, and some buyers now ask for melons with stems in good condition. Therefore, when shipping melons by sea, some method should be devised to prevent withering of the stems. These results suggest that when shipping fruits such as tomatoes and strawberries by sea, differences in appearance may be observed between varieties.

2. Appearance of vegetablesThe lower rows of Table 2 indicate that among the vegetables, only lettuce was evaluated to be significantly fresher when shipped by sea. While lettuce shipped by sea or air was of extremely high quality levels, the sensory evaluations were probably impacted by the fact that fresh weight loss was lower when shipped by sea.

Broccoli, bok-choy, celery, tatsoi, Welsh onion stems, potherb mustard, and wasabi were evaluated to be fresher when shipped by air. For tatsoi and Welsh onion stems, this was probably because there was clearly more fresh weight loss when shipped by sea. However, significant differences in moisture loss were not observed for broccoli, bok-choy, celery, potherb mustard, and wasabi. The quality of these vegetables was sufficiently high for commercial sale when shipped by both sea and air. However, when compared side by side, the items shipped by air were dark green, whereas those shipped by sea were light green and yellowish. The amount of chlorophyll in many vegetables decreases during storage, leading to a light green color (Sun and Li, 2017). The panelists appear to have made their evaluations based on this color difference. The appearance evaluations did not differ for sweet potatoes, onions, salad onions, or Welsh onion leaf blades. Welsh onion leaf blades were not evaluated differently even though Welch onion a green vegetable. The freshness of Welsh onion leaf blades largely depends on respiration, and the respiration rate is greatly suppressed by low temperature (Ibaraki, 2002). It was thought that the quality of Welsh onion leaf blades did not differ between those transported by air and by sea because exports by sea require a long time, but low temperatures suppress respiration. These results show that changes in the appearance of green vegetables shipped by sea are more likely to be noticed by consumers than those shipped by air.

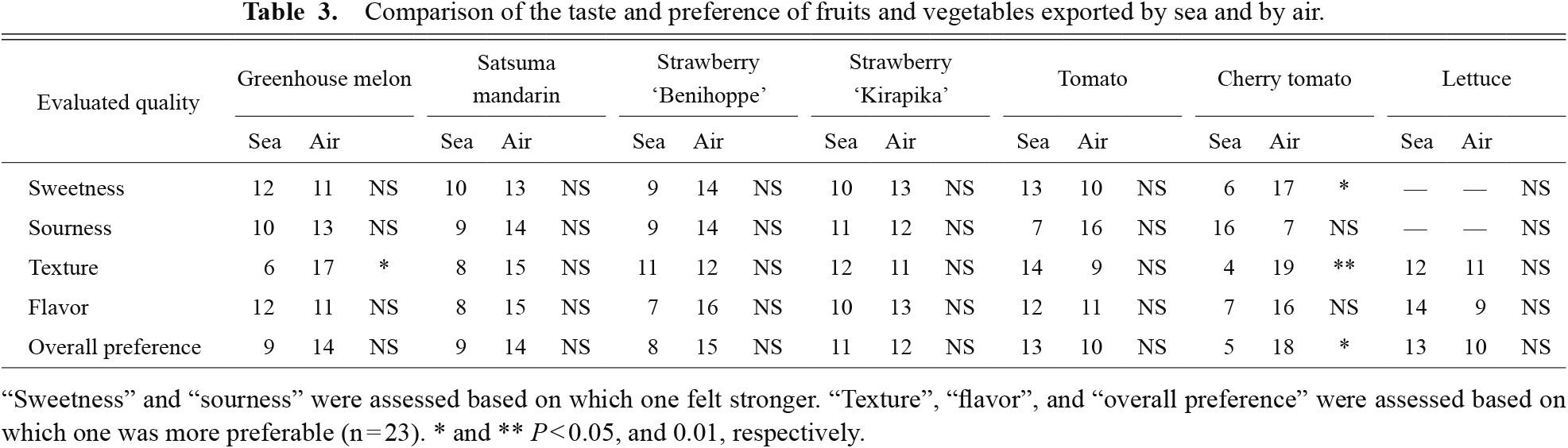

Sensory evaluation of taste and preferenceWe compared the taste and preference of fruits and lettuce, which can be eaten raw, between those shipped by sea and air (Table 3). The panelists rated the texture, sweetness, and overall preference of cherry tomatoes shipped by air to be significantly higher. While the panelists did not mention sweetness, this difference is thought to be because the sugar content of tomatoes declines during storage (Park et al., 2018). Regarding texture, the cherry tomatoes shipped by sea were evaluated by several panelists to be inferior to those shipped by air because the exocarp remained in the mouth. Storing tomatoes at low temperatures can cause low-temperature injury, and the tomatoes soften in a manner that is different from how their hardness decreases during normal ripening (Biswas et al., 2014). Therefore, we considered that the softening of the flesh was the cause of the reduction in texture quality. In the cherry tomatoes shipped by air, we infer that the mesocarp was relatively hard and was integrated with the exocarp, which meant they were masticated together. In the cherry tomatoes shipped by sea, the mesocarp had softened, which meant that the exocarp remained in the mouth, leading to lower texture evaluations. Therefore, it is advisable not to export cherry tomatoes by sea, even if there is no significant abnormality in their appearance. For tomatoes, no differences were observed between any of the items, which suggests that the effects of low temperatures on tomato pericarps differ depending on the variety, the cultivation method, and other factors.

Comparison of the taste and preference of fruits and vegetables exported by sea and by air.

For both strawberry cultivars, no differences were observed between any of the items. While storage reduces the total soluble solids in strawberries (Ayala-Zavala et al., 2004), in this test, shipping by sea or air did not reveal any clearly noticeable differences. The texture of greenhouse melons shipped by air was significantly better. While a difference in the overall preference was not seen, the panelists appear to have evaluated the melons shipped by sea to be slightly overripe. The optimum temperature range for storing melons is 2–5°C, and at temperatures below that, chilling injury occurs (Gross et al., 2018). The main symptoms of melon chilling injury are pitting and surface decay (Gross et al., 2018), but these were not observed in either melon type. Therefore, it was unclear whether the cause of this overripening was because the storage period was too long or due to chilling injury. No clear differences were observed for Satsuma mandarin and lettuce.

The above results indicate that the shipping conditions used in this test did not lead to differences in the taste or flavor of tomatoes, strawberries, Satsuma mandarin, and lettuce. A difference was observed in the texture, but not in the overall preference, of greenhouse melons. The taste of the cherry tomatoes worsened significantly. In the future, we intend to investigate the cause of this deterioration in taste.

ConclusionsStrawberries (‘Kirapika’), Satsuma mandarin, onions, salad onions, and Welsh onion leaf blades exported by sea under the low-temperature conditions used in this test could maintain quality levels similar to the corresponding fruits and vegetables shipped by air, without having to change their packaging. For the other items, fresh weight loss can probably be reduced by placing them in film or plastic bags, which may allow them to maintain quality when exported by sea. However, the film or plastic bags used for export should have suitable properties. Further, the taste of cherry tomatoes shipped by sea was significantly worse than those shipped by air, although no such differences were observed for tomatoes, strawberries, Satsuma mandarin, and lettuce. These results indicate that regarding fruits and vegetables that are currently mostly exported by air, sufficient value can be added by exporting them by sea when factors such as the amount of each item being shipped, shipping cost, and delivery date are considered; however, packaging should be adapted to the temperature and humidity conditions during shipping by sea in a mixed cargo.

We would like to express our sincere gratitude to Fumiaki Yano, Youhei Mochizuki, Ayako Watanabe, and Yasuhide Matsumura of JA Shizuoka Keizairen Co., Ltd.; Masahiro Wakasugi of Amano Kaisoten, Ltd.; Takashi Kodama and Saori Watanabe of NTL Naigai Trans Line (Singapore) Pte., Ltd.; Kazuo Yoshida and Takahiro Hashimoto of Denso Corporation; Reiko Nishime of Mitsui Chemicals Singapore R&D Center; Hirokazu Ikenaga of Mitsui Chemicals, Inc.; and Masaya Kaneko, Shinya Ogai, Hiroyuki Ashizawa, Toshihiko Takeda, and Naoya Nakamura of Shizuoka Prefectural Government for their considerable efforts in helping us conduct this research.