2016 Volume 65 Issue 11 Pages 881-888

2016 Volume 65 Issue 11 Pages 881-888

Avocado fruit is rich in monounsaturated fat and contains relatively high level of important lipid-soluble compounds such as vitamin E, β-sitosterol and carotenoids. The consumption of avocado fruit is highly related to its potential benefits. However, with the increase of avocado production, short time of maturation and easy oxidation of avocado fruit are the main problem for producers. The production of oil from avocado fruit, thus, is highly promoted. This paper discusses the effects of different extraction methods on chemical composition and yield of oils from avocado fruits.

The avocado(Persea Americana Mill.)belongs to the family of Lauraceae and is a kind of tropical and subtropical fruit. One of its prominent characteristics is its fairly high lipid content(10%–30% of its fresh pulp weight depending on the variety and seasonality)in most commercial avocado cultivars, such as Hass and Fuerte1). The avocado fruit not only is an excellent source of monounsaturated oleic acid, but contains important lipid-soluble antioxidants and phytochemicals with high levels such as carotenoids, chlorophylls, polyphenols, tocopherols, and phytosterols2). Besides, avocado is also a source of other nutraceutics such as dietary fiber, vitamin C, and potassium. The avocado consumption was found to help promote cardiovascular health and may support healthy aging3). Its various nutrients and bioactive phytochemicals providing health benefits make avocado fruit huge potential for applications in cosmetics, food and pharmaceuticals industries. With an increasing awareness of positive health effects, the global demand for avocado fruit continues to increase. The production of avocado is commonly in Mexico, the USA and South American. It also expands to other countries, such as Europe, Australia, and Far East. In 2009 about 3.5 million tons of avocado fruit were produced worldwide4). Most of the avocado fruit is sold and consumed fresh on the domestic and export market. However, the short time of maturation and easy oxidation present in avocado fruit are the main problems for producers. One of industrial processes involving avocado fruit is the production of oil from the fruit. The oil from avocado can be considered a newcomer and have commercial importance in the industry of fats and oils due to its nutrients and health benefits. Avocado oil, thus, has potentially multiple uses as edible/culinary oil, an ingredient in healthcare products and cosmetics. This review provides the relevant literature summary on the chemical composition and extraction methods of avocado oil.

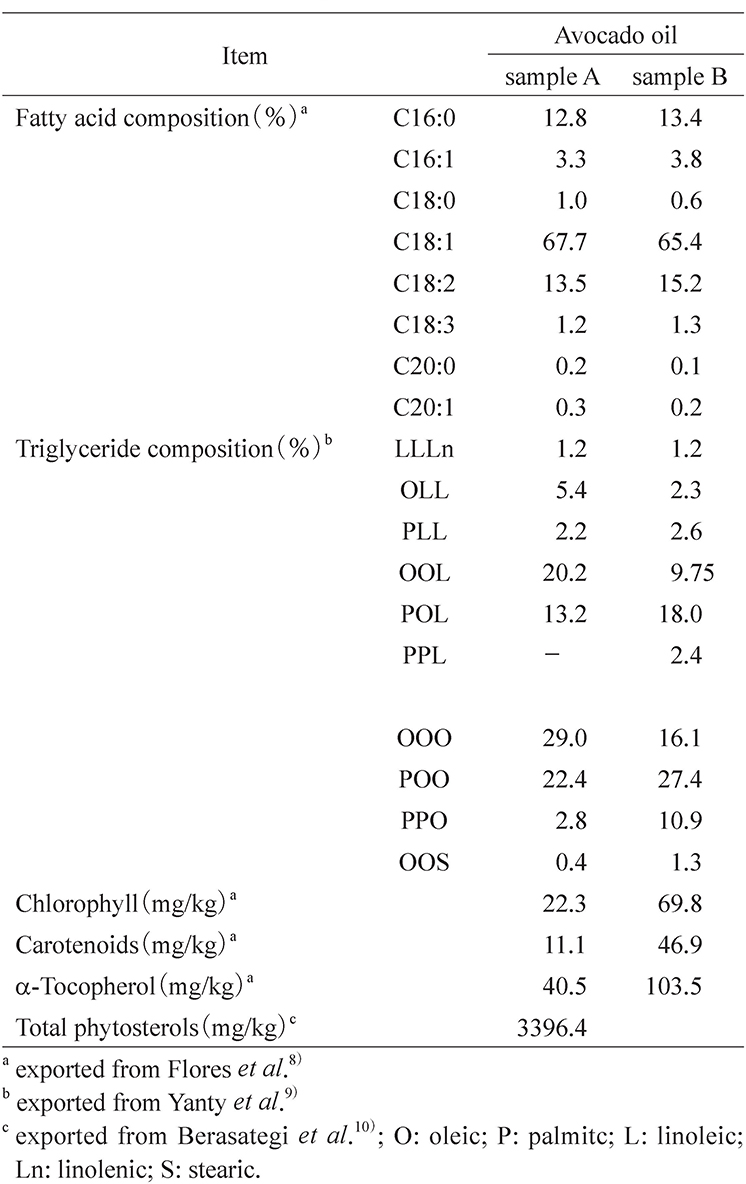

The lipid extracted from the mesocarp of the avocado fruit rather than the seed. Avocado seed contains little oil(about 2%), and its seed oil even has some toxic factors(i.e., hepatotoxic agents)that cause some metabolic alterations in growing fats such as enhancement of liver lipogenesis, increase in hepatic-lipids amount in liver, and elevation of enzymes level involved in lipid biosynthesis5). Thus, most commercial avocado oil extracted from the flesh. The chemical composition in the mesocarp of avocado fruit is depended on the cultivar and harvesting time. For example, in Fuetre and Bacon cultivars, the lipid content is 18.7% and 21.8%, respectively6). Total lipids extracted from the mesocarp include neutral lipid, glycolipid and phospholipid. Among the total lipids content, more than 95% is neutral lipids(of which 87% were triglyceride). Table 1 gives triglyceride composition, total fatty acid composition of avocado oil and its lipid-soluble compounds. The fatty acid composition can be changed depending on variety, ripening stage, geographical growth location as well as extraction method1),7). Avocado oil is characterized by the fact of having a high content of monounsaturated fatty acid(oleic acid, >50%), which is similar to olive oil. Palmtic acid is a main saturated fatty acid and linoleic acid is a main polyunsaturated fatty acid present in avocado oil8). Also the triglyceride profile of avocado oil can be distinctly different from various cultivars. For example, the dominant triglyceride of avocado located in Malaysia were POO, followed by POL, OOO and PPO, while major triglyceride of Hass avocado variety imported from Australian were OOO, followed by POO, OOL and POL9). The triglyceride composition may vary by extraction methods. However, till now there is little information on the comparison of triglyceride profile of avocado fruit by various extraction methods.

In addition to the lipids, lipid-soluble antioxidants and bioactive phytochemicals are rich in the avocado oil(Table 1). Especially, carotenoids(mainly lutein), tocopherols(mainly vitamin E)and phytosterols(mainly β-sitosterol)are three of the most important lipid-soluble compounds, which have positive health outcomes. For example, lutein is considered as beneficial for the improvement of eye diseases such as age-related macular degeneration and cataracts11),12). Phytosterols can reduce plasma or serum total cholesterol and LDL-cholesterol by competing with cholesterol in the intestine for uptake in hypercholesterolemic people13). High concentration of chlorophylls is also found in virgin/crude avocado oil. It contributes to the appearance(emerald-green color)and health profile of avocado oil. However, a high level of chlorophylls can cause negative effect on oxidative stability of crude avocado oil due to its easy photo-oxidation when it exposes to light and oxygen. The concentration of pigments including chlorophylls and carotenoids increases in the oil with increasing the proportion of skin added to avocado pulp during oil extraction. Wong et al.14) reported lutein concentration and total chlorophyll concentration in the oils extracted by cold pressed extraction procedure increased from 1.13 to 3.21 μg/g and 7.3 to 27.5 μg/g as the amount of skin(increasing from 0 to 100%)added to the ripened avocado flesh.

Fatty acid composition, triglyceride composition and levels of minor compounds of avocado oil.

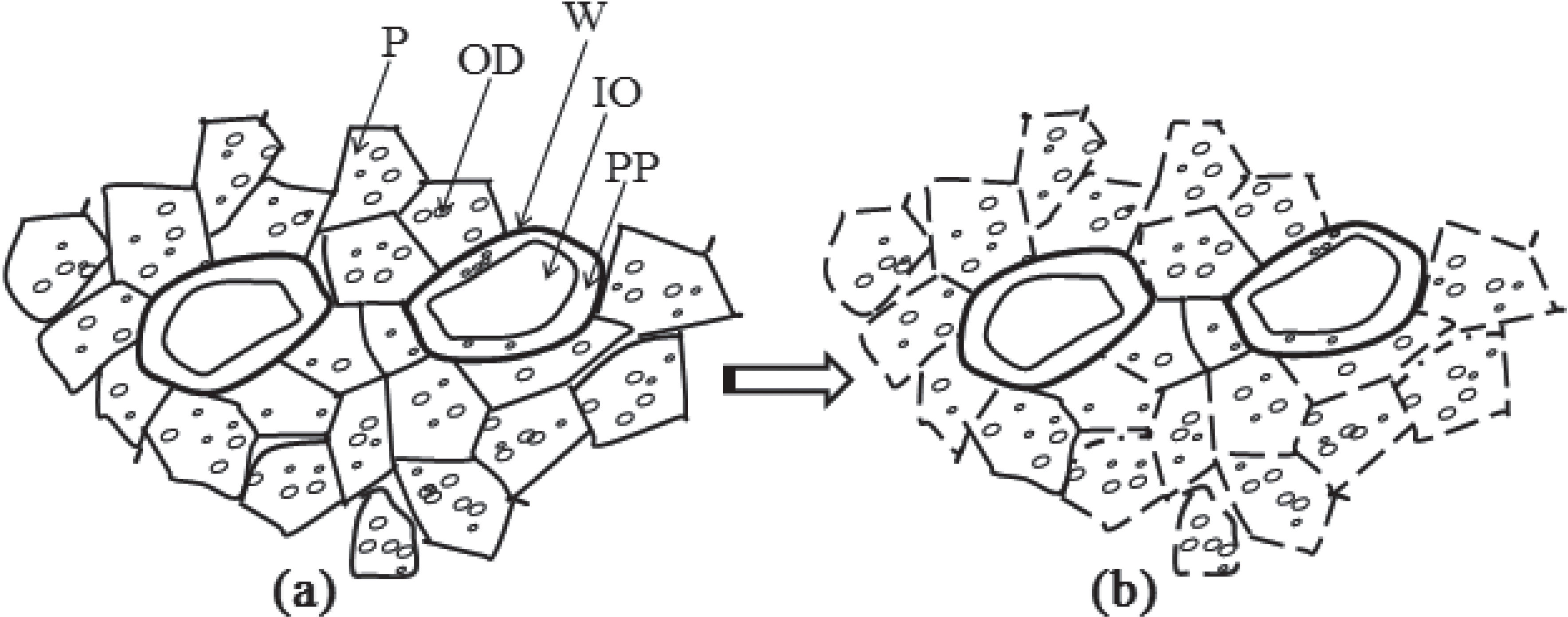

Several investigations focus on the production technology of avocado oil, with the purpose of adding economic value and attaining a suitable product for various applications. Generally, crude oil could be obtained by techniques of centrifugation, pressing and solvent extraction. In addition to extraction process used, the pretreatment of oilseeds and/or oily fruits is one of important factors affecting oil extraction yield. Lipids are primarily found in avocado mesocarp that composed of numerous parenchyma cells and evenly scattered idioblasts(Fig. 1a). The parenchyma cells contain finely dispersed oil emulsion, and the idioblasts are filled with one large oil sac15),16). The idioblastic oil cells have an average diameter of 75 μm and thicker cellular walls compared to the parenchyma cells. The primary walls of the parenchyma cells can be degraded by the activity of cellulase and polygalacturonase during ripening, but the suberized walls of the idioblastic cells remain intact due to the immunity of the activity of these enzymes15) as shown in Fig. 1. To increase the release of oil from the cellular bodies and enhance oil extraction, extraction processes assisted with mechanical, enzymatic and thermal pretreatments are used to rupture the structure of the emulsion and the cell walls. Various extraction methods for recovering oil from avocado fruit are summarized in Table 2.

Sketch illustrating avocado mesocarp cells during ripening. (a)Unripen mesocarp cells; (b)Ripen mesocarp cells; P, parenchyma cell; W, wall of idioblast; OD, oil droplet; PP, protoplasm, IO: idioblastic oil sac.

Overview of various extraction methods for crude avocado oil.

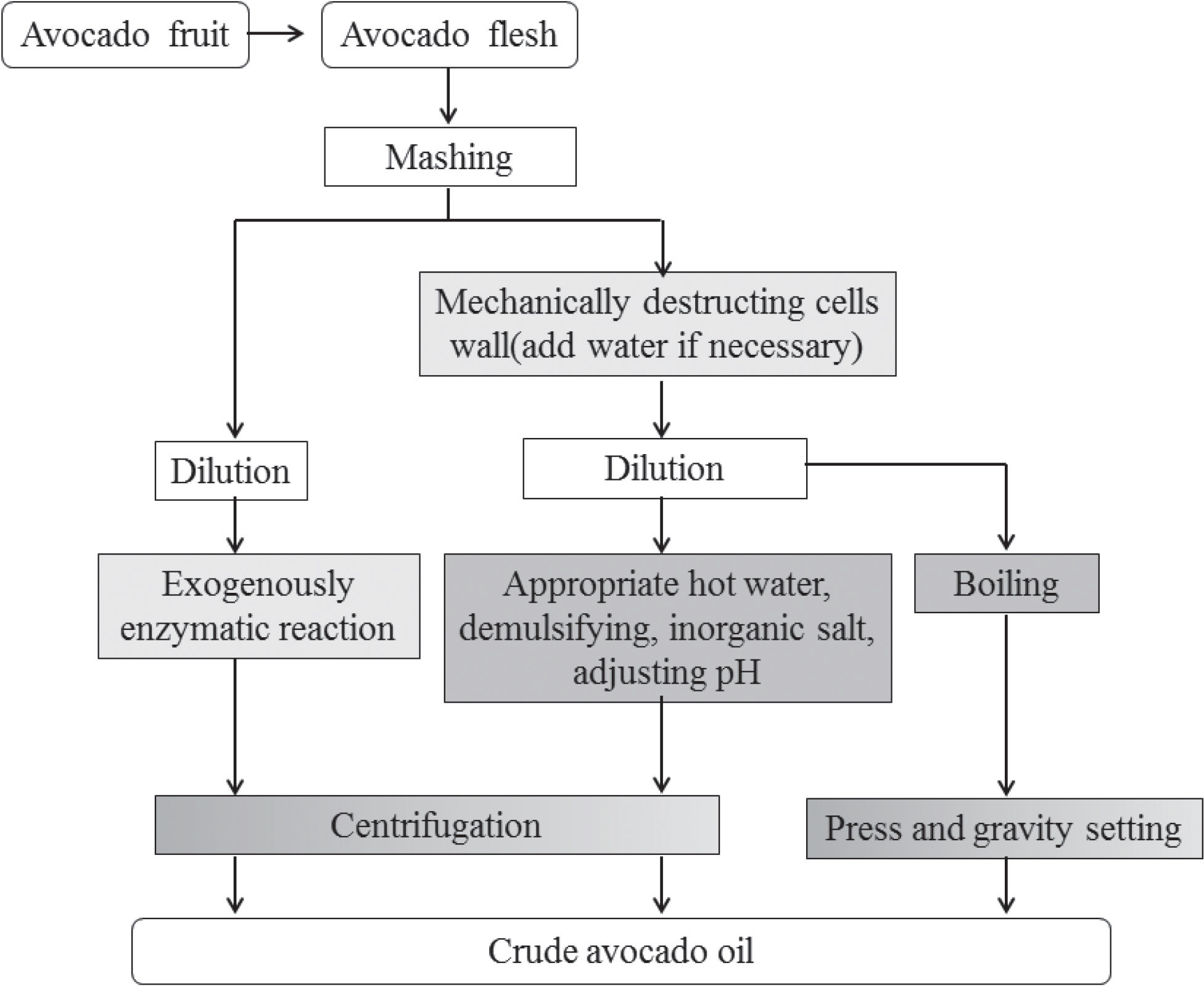

The water or aqueous extraction is a traditional process used to recover oil from plant resources. Water separation of avocado oil is performed by enzymatic or mechanical destruction of tissue cells contained lipids followed by centrifugation or gravity setting to separate the oil from the oil-water emulsion. According to destroying way of cells wall and the driving force of separating oil layer, aqueous separation methods can be mainly divided into three groups: (1)enzymatically assisted centrifugation separation, (2)mechanically assisted centrifugation separation, and(3)mechanically assisted hot water separation methods, as showed in Fig. 2. According to the first method, the extraction of oil from avocado fruit is primarily accomplished by degrading tissue cells wall with exogenous enzymes and using centrifugation-force separating oil from three phases(aqueous, oil and fruit residues). While in the second and the third methods, the destruction of cells wall is by mechanical force. One of outstanding advantages of aqueous separation technique is that it does not need to remove a large quantity of water from fresh pulp, compared to solvent and pressing extraction process. The aqueous separation technique is practicable due to its simple operation and low cost, compared to other oil extraction methods(like organic solvent extraction). Besides, the benefit of utilizing centrifugal force to separate lies in yielding a higher quality product with higher purity, which greatly simplifies the subsequent refining process.

Flow-chart of aqueous separation technique for the production of crude avocado oil.

In enzyme-assisted centrifugation technique, prior to centrifugation, endogenously cellulitic and the added exogenous enzymes together hydrolyze and degrade the cellular walls, favoring the release of oil from the cells. The added exogenous enzymes can be pectinases, α-amylase, proteases, celluloses and pectolytic enzyme. Many factors including enzyme type and concentration, enzymatic reaction temperature, reaction time and dilution ratio of paste to water are considered as important factors affecting oil extraction yield. It has been reported that extraction yield from avocado paste was greatly improved more than 25 folds by enzyme-assisted centrifugation compared with non-enzyme assisted centrifugation17). Freitas et al. evaluated the profitability of enzymatically-assisted aqueous extraction technology by using payback period and internal rate of return as criteria25). To reach a higher productivity, oil content in avocado pulp and extraction yield are required greater than 10% and 60%, respectively, when considering raw material price, plant capacity, enzyme price and selling price. They concluded that this process is economically attractive.

In mechanically assisted centrifugation method, cells in avocado flesh containing oil droplets are ruptured by mechanical force(such as grinding by a mortar or pestle), and the oil released by centrifugation force. The particle size of ruptured cells is considered as more important factor than other factors(such as pulp concentration, heating temperature, electrolyte concentration and centrifugal force)for oil extraction from the slurry26). To ensure high oil yield, parenchyma and idioblastic cells of avocado fruit can be intensely ruptured, producing particles with small size. However, the degree of fine grinding is required to well control. Because the oil released from the cells is easily emulsified with water and other cellular substrates, resulting in difficult separation of oil from the mixture during centrifugation process. To prevent or reduce oil emulsification, a certain amount of demulsifying agent added to the slurries, adjusting pH value of the slurries and appropriate heating are included before centrifugation process. Bizimana et al.19) reported oil recovery was higher at pH 5.5(71.45%)than that at pH 4.0(65.77%). In addition, the addition of inorganic salts(NaCl, CaCO3 and CaSO4)promoted the separation of oil from water18),19). It should be pointed out that the endogenously lipoxygenase activity may still present in the crude avocado oil extracted by the mechanically assisted centrifugation method without appropriate heating. This enzyme can degrade unsaturated fatty acids, which influences oil quality and nutritional properties of unsaturated fatty acids. Expect moderate heating before the centrifugation processing, additional treatments are developed to decrease the lipoxygenase activity in the crude oil. One of treatment for solution to this issue is the utilization of electric field treatment. Ariza-Ortega et al.27) reported that, from a nutritional point of view, the changes in unsaturated fatty acids were negligible by observing Fourier transform infrared spectrograms of electric field-treated crude avocado oil, suggesting electric field technology is a suitable method to minimize the oxidation of unsaturated fatty acids for preserving the oil quality.

According to the mechanically-assisted hot water separation method, avocado fruits are subjected to mechanically mashed, then oil is released from slurries by boiling water and subsequent pressing, the oil layer is then separated by gravity setting. As mentioned, avocado fruit itself not only contains endogenously pectolitic and cellulitic enzymes, but also has lipolytic enzymes. The endogenously lipolytic enzymes cause oil hydrolysis and oxidation especially under their optimal temperature conditions, resulting in decreasing the quality of crude avocado oil18). The fine-grounded slurries, thus, are diluted or treated with hot water to allow easy release of oil from the slurries and inactivation of lipolytic enzymes. Bizimana et al. reported that a inverse linear relationship(R2=0.999)was obtained between heating temperature from 75 to 98°C, and thus a higher heating temperature with short time was chosen to minimize the chances for heat damage to the oil and to increase process efficiency19). In the process of hot water separation method, the diluted slurries are generally heated at a higher temperature(100–105°C)to separate the oil part20). The diluted slurries also can be homogenized using a blender prior to the heating28). However, quiet high temperature(105°C)is not enough to break down water-in-oil emulsion. Proteins and carbohydrates existed in avocado fruit can improve the emulsion stability, leading to a harder break-down of the linkage between oil and these components during heating. To make it easier to break down the emulsion, homogenization pressure is employed prior to heating. Hamzah found that homogenization pressure from 7 kg/cm2 to 71 kg/cm2 significantly increased extraction yield, iodine value and free fatty acid of crude avocado oil, but there was no remarkable increase in extraction yield, iodine value and free fatty acid of crude avocado oil when the homogenization pressure increasing from 71 kg/cm2 to 176 kg/cm2 21).

3.2 Pressing extractionPressing refer to oils are extracted by pressing or squeezing oily materials with screw press or hydraulic press. Pressing technology commonly used to squeeze oil from oilseed materials(like sesame)with relatively high oil content. Compared with oilseeds, avocado pulp contains higher moisture(about 77%)and its cellular contents are different. Water content of fruit pulp can significantly affect the oil yield. Pretreatment methods of avocado pulp, thus, can be different prior to pressing. The pretreatment approaches include(1)slicing and dying of avocado flesh, (2)microwave-oven drying and(3)the addition of solid additives. Traditional dying procedures such as oven-drying and sun-drying are time consuming to dry the slices to 4%–5% water content, accompanying with a relatively high risk of poor oil quality. In contract, microwave-oven drying process not only shortens the drying time, but also serves as a function of inducing cells structure disruption. Factors, such as quantity of samples, the intensity of microwave energy and time of microwave exposure, affect the oil extraction yield. Moreno et al.7) reported that the oil extraction yield reached its lower level(less than 30%)when the energy was more than 2 kJ/g. A high temperature(>100°C)is accompanied by this high microwave energy, resulting in severe transforming the structure of idioblastic oil cells. Such transformed structure has a negative effect on the oil extraction yield. When the highest oil extraction yield by microwave-assisted squeezing was obtained at the optimized energy(1.89 kJ/g), the idioblastic cells became empty with no major changes.

The addition of solid additives is another way to reduce avocado pulp's moisture and viscosity and to increase the oil extraction yield. Solid additives are supposed to have a certain hardness and granularity and to be non-toxic, insoluble in oil or water. For example, the squeezing effect was better by adding rice, sorghum rice and grains of sand than that by adding rice husk, sugar and salt22). After sufficient mixing avocado pulp with solid additives, appropriate heating is required for subsequent squeezing. Such heating favors accelerating the disruption of cell walls during the extrusion process, making the decrease of the viscosity of cellular oil to increase the oil extraction yield. Besides, moderate heating favors the inactivity of lipases, which reduces or eliminates the hydrolysis of avocado oil during the squeezing and storage period.

3.3 Solvent extractionOrganic solvent extraction is the most common method to separate oil from oily resources. In the organic solvent method, avocado fruit is sliced, dried and grounded, subsequently oil is extracted with organic solvents. Traditional solvents including hexane and acetone are widely used to extract oils from various sources7),16). Moreno et al.7) reported the extraction yield was 54% by hexane extraction and 12% by acetone extraction, respectively. The action of solvents to the oil cells mainly causes remarkable differences in their extraction yield. The hexane extraction method causes an irregular and rough shape of both idioblastic and parenchyma cells. However, for acetone extraction procedure, the strongest modification(deformation)on the cellular structure was observed and most of the oil held inside the idioblastic cells16). Although a higher oil extraction yield can be obtained by an appropriate solvent, this technique has some drawbacks like environmental pollution and solvent residue in the final products, which limits the use of avocado oil in food and pharmaceutical applications.

Recently, supercritical fluid extraction has been used in separating desired compounds from solid matrices used in pharmaceutical and food industries. The supercritical carbon dioxide(SC-CO2)as a green solvent is biological safety with no solvent residue in the final product, compared with organic solvents used in oil extraction. Besides, differences in SC-CO2 solubility to a certain desired product and other lipid-soluble bioactive compounds can be controlled by operating conditions such as pressure and temperature. For example, lower temperature and lower pressure favor reducing co-extraction of chlorophyll when extracting oil from dried and grounded avocado; the amount of chlorophyll(indicated as absorbance of 0.765)by SC-CO2 extraction was still lesser even at higher pressure(5.4×107 Pa)and higher temperature(81°C), compared with that by hexane extraction(absorbance of 0.876)29). Thus, the level of unsaponifiable matter including chlorophyll in avocado oil could decrease during the SC-CO2 extraction process. On the one hand, the removal of chlorophyll from avocado oil during SC-CO2 process gives better oil quality. On the other hand, the unsaponifiable matter separated from avocado oil is considered as valuable fraction used in the cosmetic and pharmaceutical industries. In consequence, the extraction yield by SC-CO2 is lower than that by hexane extraction because SC-CO2 is more selective and discriminative during the extraction23). The SC-CO2 extraction, thus, serves as double functions of extraction and purification of avocado oil, which exhibits superior advantages in industrial extraction of avocado oil.

The extractability and oil quality of avocado oil can be affected by factors such as fruit ripeness and pulp moisture and its corresponding dying method. Hydrolytic enzymes such as polygalacturonase and cellulases in avocado fruit degrade the parenchyma cells walls during ripening. As a result, the cell tissue is softened and more paths are created for the solvent accessing in the parenchyma cells. For both SC-CO2 and hexane extraction methods, the oil extraction yield from oven or freeze-dried ripe avocado mesocarp(average yield of 626 and 713.5 g/kg, respectively)is higher than that from unripe one(average yield of 555 and 653 g/kg, respectively)23). High pulp moisture interferes with the oil extraction effect, thus the reduction of water content in fruit pulp is necessary prior to solvent extraction. To lower the fruit pulp moisture, there are two common drying approaches, namely oven-drying and freeze-drying. More brittle and powdery dried material is obtained by freeze-drying method, while a harder structure is obtained for oven-dried material. Such hardness structure probably caused by the denaturation and crosslinking of proteins and the gelatinization of starch which acts as physical barriers around oil cells and increases the mass transfer resistance for solvents transport to the cellular surface7). Mostert et al.23) reported that the oil extraction yield was significantly higher from freeze-dried ripe avocado material extracted with SC-CO2 than from oven-dried ripe avocado material, while the oil extraction yield from freeze-dried ripe avocado material extracted with hexane was higher but not significantly than that from oven-dried material. It seems that freeze-drying is a better choice for the extractability of avocado oil if a higher oil yield is the objective. The quality or oxidative stability of oil extracted from ripe or unripe avocado fruit is highly related to the dying method of the fruit. The lipase enzyme activity might be still present in the freeze-dried fruit material, which leads to the deterioration of oil and the destruction of valuable minor-compounds30). For the industry, however, other factors like the cost and efficiency of drying methods(freeze and oven-drying)and the concentration of minor-compounds(carotenoids, chlorophyll, tocopherols, etc.)in the oil must be taken into account when considering the oil quality and oxidative stability.

3.4 Comparison of various extraction methodsA suitable extraction method depends not only on the oil extraction yield but also on chemical composition and oil quality. Several methods have been proposed to extract oil from avocado pulp and to investigate the efficiency of various extraction techniques. Moreno et al.7) reported that microwave-assisted squeezing and microwave-assisted hexane extractions provided lower chemical properties such as the content of free fatty acids and peroxide value of the extracts than solvent extractions with hexane and acetone. Dramatic differences were observed in the fatty acid profiles of extracted oil processed with various extraction techniques, specifically for palmitic, palmitoleic(cis), oleic(cis), linoleic(cis)and linolenic(cis)acids. This may relate to different solubility of various fatty acids in hexane and acetone. Among these extraction methods, the total trans fatty acids concentration was the lowest with the microwave-squeezing technique. Another study demonstrated that the highest oil extraction yield from the Hass variety was obtained by microwave-assisted hexane extraction(7 g/kg dry weight)compared with hexane(6.5 g/kg dry weight), ultra-turrax treatment assisted hexane(6.4 g/kg dry weight)and SC-CO2(6.3 g/kg dry weight)extractions24). For the fatty acid profiles, stearic acid(C18:0)was only detected in Hass cultivar extracted by SC-CO2 extraction, showing SC-CO2 provided a wider range for fatty acids. Besides, high levels of heavy metals present in the extracted oils are considered detrimental to oil quality. Among the five extraction methods compared, the SC-CO2 and microwave-assisted Soxhlet extractions gave the lowest dissolution percentages of oxidizing metals such as Fe and Cu. From the viewpoint of an industry, microwave-assisted hexane extraction and SC-CO2 present poetical large-scale extraction operation.

Avocado fruit is outstanding for its high content of monounsaturated oil and an excellent source of important lipid-soluble compounds such as tocopherols, carotenoids and phytosterols, which plays a significant role in reducing the risk of cardiovascular diseases and in providing health benefits. With increasing production of this fruit, one of industrial processes is the production of oil from the fruit. The extraction efficiency and quality of avocado oil depend on various extraction methods including conventional and non-conventional extraction methods. The combination of non-conventional pretreatments(like microwave drying of avocado flesh)and extraction processes(like SC-SO2, pressing)shows its advantage in perusing a superior quality avocado oil.

This work was made possible with funding provided by Fundamental Research Funds for the Central Universities(No. XDJK2014B019, No. XDJK2016B034), Chongqing Research Program of Basic Research and Frontier Technology(No. cstc2015jcyjA80013), Guangdong Province Key Laboratory for Green Processing of Natural Products and Product Safety(No. 201609), and the National Natural Science Foundation of China(No. 31501446, No. 31601430).