2024 Volume 73 Issue 11 Pages 1361-1375

2024 Volume 73 Issue 11 Pages 1361-1375

The increasing global population and the rise of health-conscious consumers have led to a growing demand for innovative foods and functional ingredients. Hairless canary seed (Phalaris canariensis L.), which has recently obtained regulatory food approval from Health Canada and the United States Food and Drug Administration (US-FDA), has the potential to meet these demands due to its unique nutrient profile and characteristics. Canary seed stands out among cereals and pseudo-cereals (gluten-free cereals) as it has the highest protein content and is gluten-free. Additionally, it contains significant amounts of tryptophan, an amino acid typically lacking in cereals. It is considered a true cereal grain that can be processed into flour, starch, and oil for various food and non-food applications. This article provides a comprehensive overview of the chemical composition, functional properties, and biological activities of canary seeds. It also explores the processing methods for incorporating these seeds into food and cosmetic products. Furthermore, suggestions for future research directions are presented to enhance the utilization of this plant. Overall, it is evident that Phalaris canariensis holds considerable potential as a sustainable crop that can be further developed.

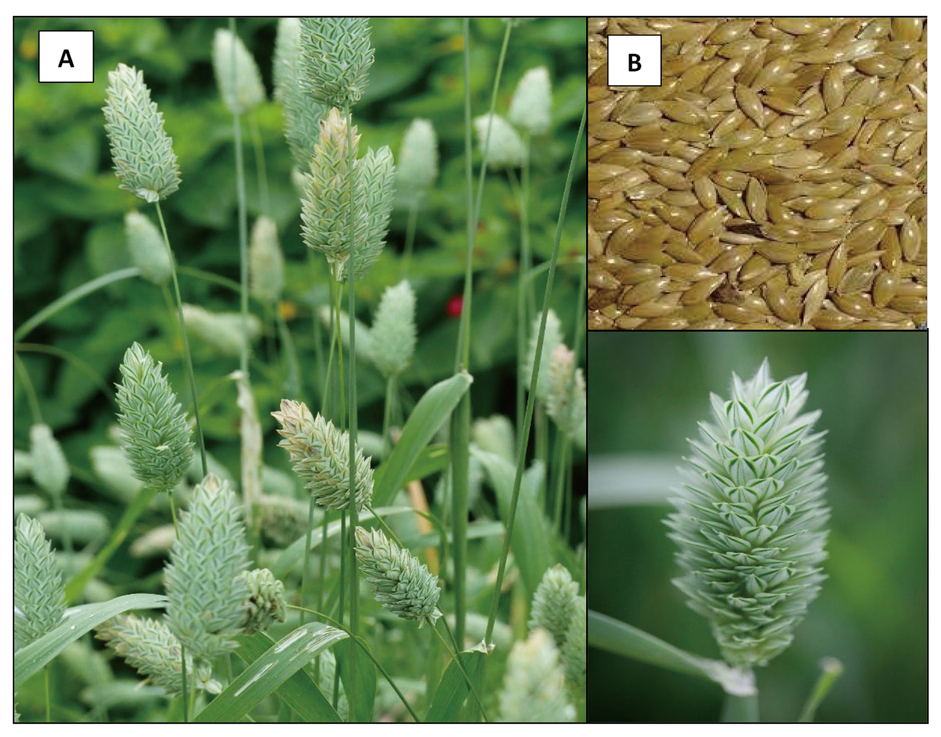

In the course of time, humans have been actively involved in the domestication and cultivation of plants in search of novel ingredients and alternative sources of functional foods. Phalaris canariensis L. (Fig. 1) , an exceptional plant, has exhibited remarkable potential, resulting in a rapid increase in publications focusing on this plant and its constituents. It is considered as a pseudo-cereal plant that produces white oval-shaped panicles with green veins, which eventually yield small elliptical seeds of approximately 4 to 5 millimeters in length and 1.5 to 2 millimeters in width1) .

(A)Glabrouscanary seed(P. canariensis L.), (B)Canary seed(P. canariensis L.).

Canary seed, scientifically known as Ph. canariensis L., is a highly cultivated cereal crop in many regions of the North American hemisphere. This versatile cereal has gained popularity due to its adaptability and has become an important part of agricultural practices in various areas. The south-western provinces of Canada, where there is an important and intensive production, which is the principal grower and exporter of canary seed in the world2) ,3) , it is also grown in North America4) ,5) , North Africa and Asia6) ,7) . Three varieties in Canada are distinguished, which are authorized as grain for human consumption (CDC Maria, CDC Togo and CDC Bastia) 8) . Canary grass crops have the potential to produce an impressive amount of seed per hectare. This could range from 1,000 to 1,500 kg9) . The nutritional composition of the seeds consists of gluten-free protein (8.8-24%) 10) ,12) which is considered to be the highest protein content in cereals and pseudocereals, fatty acids (13% SFA, 31% MUFA and 56% PUFA) , carbohydrates (48-61%) and dietary fiber (6-20%) 5) ,13) ,14) .

The increasing prevalence of chronic diseases over time has made it important to develop food-derived bioactive peptides that have the potential to help improve medical conditions (health and well-being) . Studies have highlighted the future bioactivity of canary seed proteins to produce bioactive peptides with beneficial health effects, such as antioxidants, antihypertensive and antidiabetic property11) ,15) . Mason et al.16) reported that canary seed has a chelating activity superior to that found in oats and wheat. These health advantages could be explained by the presence of different bioactive substances, including proteins and polyphenols.

This paper presents a summary of the latest advancements in chemical constituents, functional properties and biological activities of canary seeds. The processing of seeds for food and cosmetic formulations will also be studied. Orientations for future research on how to better use this plant are also suggested.

Phalaris canariensis L., an annual grass growing in the Mediterranean area17) , Canary seeds belongs to the family Poaceae (Gramineae) , subfamily Pooideae and the tribe Agrostideae. This places annual canary seeds in the same subfamily with wheat, barley (Hordeum vulgare L.) and rye (Secale cereale L.) in the tribe Triticales, or oats (Avena sativa L.) in the tribe Aveneae, but in a different tribe18) (Fig. 2) . Canary seeds is a herbaceous plant, about 60 to 100 cm high, with many tillers and an erect habit. It has glabrous pods, blunt ligules 6-8 mm long, flat glabrous leaves 20-40 mm long by 5-10 mm and large compact oval-shaped panicles that firmly contain the seeds17) . Canary seed is a decorticated or husked grain of cereal (the hulls remain attached to the grain after the harvesting process) and once hulled, the hull-free grains are called 〝groats〟15) . It is a self-pollinated diploid plant (2n=12) that produces small-grained elliptical grains with lengths and widths of about 4.0 to 5.1 mm and 1.5 to 2.0 mm respectively. It has a genome size of 3800 Mpb19) . The weight is about 7 mg, with a medium specific weight of 70 kg per hectoliter20) . This crop thrives on nutrient-rich clay soils with a neutral to slightly acidic pH with good moisture retention due to its shallow rooting depth7) . Annual canary seed is generally sown in May, it can take between 95 and 110 days to mature2) .

Taxonomicconnections among cereal grains.

Annual canary seeds (Ph. canariensis L.) , is the only one of the following species to have been commercially important in the past. Phalaris brachystachys, a direct ancestor of annual canary seeds, Phalaris paradoxa, and Phalaris minor are considered weeds in the agricultural sector, while the other Phalaris, Ph. arundinacea, Ph. aquatica and Ph. angusta are used as vegetation for animals21) .

Properties of starch morphology, including shape and size, as well as the degree of crystallinity have been summarized in Table 1. The morphology of canary seed starch (Fig. 3) was commonly analyzed using scanning electron microscopy (SEM) . The form of starch showed a polygonal structure with sharp borders and uniform size3) ,4) ,11) ,22) . In addition to polygonal structures, oval-shaped granules have been observed, which are probably granules in growth.4) . Canary seed starch surfaces have been reported to be smooth with the appearance of protein and lipid residues on the external side of the granules3) ,4) . The observed variation in granule size and/or shape could be related to genotype, environmental factors, extraction techniques and botanical origin23) .

Morphology, X-ray diffraction pattern, and degree of crystallinity of canary seed starch.

Due to the small and consistent starch particle size (2.2 - 2.6 μm) 22) ,24) , the extraction of starch from this grain could have potential industrial, in food applications as a substrate for flavors and/or small bioactive molecules in chewing gums and encapsulated products20) ,24) ,25) and in cosmetics as thickeners and/or stabilizers to improve the texture, consistency and stability of skin and body care products24) ,25) . Inside the granules there is a dynamic interaction between the outer amylopectin chains, water molecules and each other, resulting in the formation of double helices and crystal23) , the latter is systematically arranged in granules according to 3 polymorphisms (Type A / B / C) 26) . Type A and B polymorphs are distinguished on the basis of the arrangement of the double helices in the amylopectin and their level of hydration27) . A and B are combined to form Type C26) . According to X-ray diffraction, canary seed has starch (type A) characteristics, which is typical of the majority of cereal11) . Irani et al. reported a degree of crystallinity equal to 27%, which falls in the range of crystallinity degree of native starch (15 and 45%) 24) . However, Batista et al. found a degree of crystallinity outside the previously mentioned range equal to 52.98%4) . The degree of crystallinity is critical as it affects the digestibility, pasting properties and temperature characteristics associated with starches24) ,28) .

Compared to other types of starch, the chemical structure of canary seed starch has been relatively understudied. A study of the molecular characteristics of canary seed starch has been executed by Irani et al.29) and Heydary et al.30) . They found that it has an ellipsoidal shape with a random coil pattern, a molecular weight of 8,830-24,600 kDa, a coil radius ranging from 2.647-4 nm, a coil volume between 77.684 - 267.5 nm. Research shows that the size of a polymer coil in dilute solutions is influenced by two critical factors: the molecular weight of the polymer and its thermodynamic interaction with the solvent. The increase in volume of the coil is driven by the increasing molecular weight of the polymer30) ,31) .

With the ability to control temperature and the presence of sugars, canary seed starch allows for precise customization of its molecular and rheological properties, tailoring it to specific and targeted applications (lactose or sucrose) to improve the starch characteristics30) ,32) .

The process of fractionating raw materials is an essential stage in the production of both food and non-food products. Its primary objective is to separate the various components of a raw material on the basis of their physical, chemical or biological properties. This separation allows the extraction of specific fractions such as starch, protein, fiber and oil, each of which has different properties that are desirable for specific applications in the food and industrial sectors12) ,25) .

Fractionation can be performed on a wide range of feedstocks, including cereals, legumes, algae, micro-organisms and many others33) . It can be carried out at different scales, ranging from the laboratory to industrial, using various separation and purification techniques such as wet milling32) ,34) , sieving, centrifugation, alkaline extraction24) ,25) , filtration12) , chromatography35) , as well as new advanced extraction technologies such as ultrasonic extraction36) , microwave-assisted extraction37) , pressurized water extraction (PWE) and enzyme assisted extraction (EAE) 33) .

Alkaline extraction has been found to be effective in separating starch and protein from cereal grains25) . Abdel-Aal et al.12) evaluated three different wet milling technologies in a different sequence by changing the solvent sequence, using ethanol (E) , water (W) and alkaline (A) extractions to determine which of the three methods produced the highest yield of starch, protein, fiber and oil fractions from canary seed. They concluded that the sequential ethanol-alkali-water (EAW) extraction was the most efficient, with high purity of starch (92%) and protein (75%) . As designed, the process was optimized for starch recovery and purity12) . Therefore, there is a need to find an appropriate extraction method to maintain the physicochemical, rheological, functional and structural properties especially of starch and protein of canary seeds. Further research is needed to extract the components of canary seeds by trying clean extraction methods, which consist in reducing the volumes of solvents needed, thus reducing waste and solvent release to the environment, as well as the extraction time38) .

Starch is mainly synthesized by plants, it is also synthesized by some cyanobacteria39) . Qualitatively, starch is a remarkable renewable biomaterial, because it is plentifully available, market demand, the absence of toxic substances, the ease of extraction, its high purity compared to wheat starch and its biodegradability for various food related and non-food-related enterprises32) ,33) . A study by Batista et al.4) on the parameters associated with the fermentation of canary seed starch showed that both fermented and non fermented starches had acceptable characteristics for the production of biscuit. They found that both starches exhibited usable characteristics for cookie production, suggesting the applicability of both products in the food industry. In addition, other studies have shown that canary seed flour has been used in the production of distilled alcoholic beverages42) , bread, pasta and porridge43) . The most important component of the grain is the starch, accounting on average for about 60% of the total components of canary seed4) . Canary seed starch has demonstrated a large variation in chemical composition (Table 2) . It contains two different types of glucose polymers: straight-chain amylose and branched-chain amylopectin. Irani and Abdel-Aal demonstrated an average amylose in the range 16.2-22.5% in canary seed starch compared to 22.7-25.6% in wheat starch35) ,22) . The variation observed in amylose percentage can be attributed partly to genotype and partly to external factors32) .

The percentage of moisture found in canary seed starch was in the range of 10.6% to 12.8%22) ,24) . Achouri et al., investigated the moisture content of canary seed flour, they reported a varied content in the range of 8.29% to 8.94%12) ,16) . These moisture levels were below 13%. This level is within safe limits for storing cereals without affecting their quality24) . Other important components of canary seed for example (lipids, proteins, fiber and ash) have also been highlighted (Table 2) . The remarkable compositions and intrinsic properties of canary seed have elevated its status as a highly sought-after crop in the fractionation industry, with great promise for various applications25) .

The literature that studied the canary seed flour and starch chemical compositions: grain flour has reported protein content ranging from 8.8 to 23.7%10) ,12) ,25) ,44) ,45) , lipid contents from 6 to 8.7%10) ,12) ,25) ,44) ,45) , fiber from 6 to 20%12) ,25) ,44) ,45) and ash from 2 to 2.46%10) ,12) ,25) ,44) ,45) . However, these same components exist in small quantity in starch: protein contains 0.1 to 0.5%22) ,24) ,32) ,40) , lipid content ranged from 0.02 to 0.45%, fiber content ranged from 0.03 to 0.07%24) , and ash content ranged from 0.17 to 0.22%22) ,24) ,32) .Thus, these remaining components are generally present in minimal amounts in canary starches and might have an insignificant impact on the functionality of the starch.

Yield and chemical composition of canary seed(starch and flour).

The increasing global demand for protein has grown dramatically over the past century, due to exponential growth in world population46) . According to the Food and Agriculture Organisation (FAO) , the world’s population is expected to exceed 9.7 billion by 2050, as well, it has alerted that among the alarming concerns in the future is protein, which will be a limiting macronutrient. And it declared that protein for every citizen should be a basic right, in sufficient quantity, and of adequate quality47) ,48) .

Canary seed stands out among cereals and pseudo-cereals (gluten-free cereals) due to its exceptional protein content as shown in Fig. 4. This characteristic serves as a fundamental indicator in the development of canary seed as a potential substitute for protein sources in human consumption, as well as its applicability in the food industry12) ,15) ,49) ,50) . Canary seeds are a major source of plant protein, having a protein content ranging from (15-24%) compared to other cereals of the same family (Fig. 4) . In contrast to wheat, the absence of gluten-like is considered to be one of the most crucial qualities11) ,12) . Several studies showed that the amino acid composition of the seeds is unique. About 78% of the total protein present in canary seed is represented by prolamine and glutelin, which are the major storage proteins18) . Several studies have consistently reported that canary seed proteins contain a particularly high concentration of tryptophan, an essential amino acid. This amino acid is essential for various biological processes and is significant for human nutrition51) . In this context, and to satisfy the human population’s need for tryptophan, canary seeds offer encouraging prospects for meeting the recommended daily intake of tryptophan (estimated at 250-425 mg or 3.5-6.0 mg/kg body weight) 15) . The potential of canary seeds proteins to produce bioactive peptides with health benefits such as antioxidant, antihypertensive and antidiabetic activity has been demonstrated in a number of studies11) ,15) . Other studies have shown an impressive range of antimicrobial, immunomodulatory, anticancer, anti-inflammatory, mineral-binding, opiate, antilipidic activities that may affect the cardiovascular, gastrointestinal, immune and endocrine systems of the human body52) ,53) . In addition, the accumulation of these peptides in body tissues is less likely to cause serious side effects, making them better alternatives to conventional drugs in the prevention and treatment of lifestyle diseases53) .

Comparisonof protein content in canary seed and other cereals.

In addition to their nutritional value, proteins have physicochemical properties that make them advantageous in food applications, such as emulsification, gelation, foaming, fat and water retention capacities, film formation, and food viscosity15) ,54) .

In summary, the increasing demand for protein and the need to address current and future food crises has become a major research focus. It is essential to explore sustainable alternatives to meet this growing demand for protein, considering both nutritional and environmental aspects. By prioritizing the search for alternative protein sources, we can ensure food security while minimizing the environmental impact associated with conventional protein production47) .

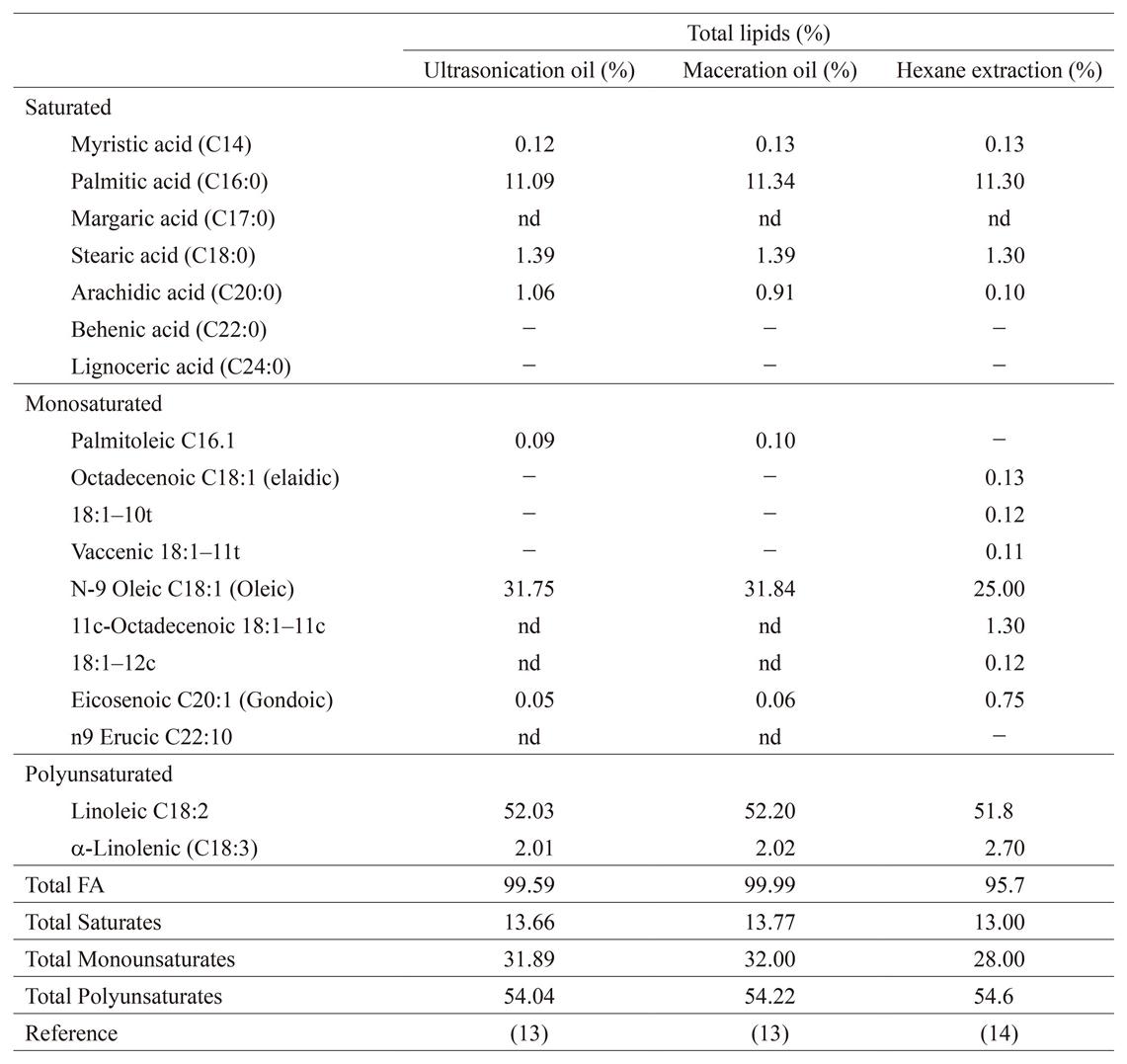

6.2 Lipids compositionCanary seed contains about 6-8.7% of fats (Table 2) 1) ,16) . The fatty acid composition is represented as follows: 13% SFA, 31% MUFA and 56% PUFA (Table 3) 13) ,14) . Due to the presence of significant amounts of 6-linoleic and 9-oleic acids, canary seed oil is classified as a 〝low palmitic acid and high oleic and linoleic acid oil〟13) ,15) . Previous epidemiological studies and clinical studies have shown that replacing SFA with PUFAs and MUFAs reduces combined cardiovascular risk, mainly by lowering LDL cholesterol and reducing inflammation55) ,56) .

Fatty acid composition of canary seed oil extracted using various methods.

a. Saturated fatty acids

The most common saturated fatty acid was palmitic acid, ranging from 11.09% to 11.34%, followed by stearic acid which varied between 1.22% and 1.39%. The following saturated fatty acid contents in particular Myristic, Marganic, Arachidic, Behenic and Lignoceric acid are all below 1 gram. The total saturated fatty acids ranged from 13% to 13.77%13) ,14) .

b. Monounsaturated fatty acids

Among the different monounsaturated fatty acids (MUFA) present in canary seed, oleic acid was found to be the most important. The content of oleic acid was found to be 25% and 31.84% as shown in Table 3. This indicates that oleic acid was the predominant MUFA in canary seed, making it a significant component of its fatty acid profile. Oleic acid has a number of beneficial effects, including reducing the risk of coronary heart disease, improving glycemic control, reducing elevated triglycerides and low-density lipoprotein cholesterol levels, assisting with weight loss, reducing feelings of anger and irritability, and raising high-density lipoprotein cholesterol levels55) . Total monounsaturated fatty acids ranged from 28% and 31.89%13) ,14) .

c. Polyunsaturated fatty acids

With values ranging from 51.8% to 52.2%, linoleic acid was found to be the main fatty acid, making up the majority of the composition, alpha-linolenic acid ranged from 2.01% to 2.42% (Table 3) . Total polyunsaturated fatty acids ranging from 54.6% to 55.88%13) ,14) .

With a UFA/SFA ratio of 6.4, canary seed oil is an exceptionally beneficial option for consumers looking to improve their diet and overall well-being. Its high-unsaturated fatty acid content makes it a valuable and beneficial addition to a healthy diet, helping to promote overall health and well-being15) ,55) .

According to Ben Salah et al.57) , ultrasonic assisted extraction is considered the most suitable method for oil extraction due to its simplicity, cost effectiveness, efficiency and ability to yield sterile oil. Regarding extraction solvents, ethanol has been demonstrated to be a very suitable and sufficient solvent for the extraction of vegetable oil from P. canariensis seeds25) ,58) . Unlike other cereals such as wheat (2%) 25) , barley (2.3%) and sorghum (4.6%) 12) , canary seed is a valuable source of oil.

6.3 Fiber compositionIn addition to proteins and fats, the canary seed also contains an essential element known as dietary fiber. Dietary fiber (DF) is a term used to describe a collection of polysaccharides or oligomers that resist hydrolysis by small intestinal enzymes and instead pass into the colon where they are fermented by the small intestinal fauna59) . Based on its solubility in water, fibers come in two main forms: soluble (soluble dietary fibers (SDFs) ) and insoluble (insoluble dietary fibers (IDFs) ) . SDF helps to improve viscosity, reduce blood glucose and serum cholesterol levels and IDF help to promote food digestion by improving the intestinal peristaltic action, increasing fecal volume and facilitating the rapid elimination of toxins and high-density elements60) . Based on the ethanol-water-alkaline (EWA) extraction method developed by Achouri et al.12) found significant fiber content ranging from 15% to 20%, the separation sequence started with the extraction of oils, fibers, starches and protein. However, lower contents were found in other studies ranging from 6% to 7.3%1) ,25) ,10) . According to Abdel-Aal et al., the bran fraction of grains contains more dietary fiber than the whole grain and white flour fractions10) , and since canary seed is a grain whose bran remains on the grain even after harvest15) , therefore, exploiting these grains entirely may prevent body weight gain61) .

Aromatic and ornamental plants and their antioxidant activity has attracted particular attention because of its role in the development and proceeding of fatal malady linked to oxidative stress. Bioactive peptides from canary seed have been shown to have antioxidant activity by interacting with 〝free radicals,〟 protecting tissues from damage11) . Valverde et al. identified five peptides in the digested prolamine fraction by mass spectroscopy, only one of which (KPQLYQPF) showed antioxidant activity62) . The digested protein fractions of canary seeds generally have a higher antioxidant activity than raw meal due to protein hydrolysis, which enhances their antioxidant potential62) . In terms of antidiabetic activity, the enzyme dipeptidyl peptidase IV (DPP-IV) has an effect on type II diabetes by inactivating incretin hormones, which leads to an increase in blood glucose levels63) . The research by Estrada-Salas et al. found that peptides derived from the enzymatic metabolism of their milk using enzymes such as pancreatin, trypsin and pepsin, exhibited DPP-IV inhibitory activity in pigs, with a dose-dependent relationship64) . In addition, a study by Gutierrez et al.65) has demonstrated the anti-obesity effects associated with a fatty derivative of the canary seed. In order to understand more clearly the effects as well as antidiabetic properties of the DPP-IV inhibiting peptides present in canary seeds, further characterization is required. Regarding antihypertensive activity, innovative ACE inhibitors, utilized to control hypertension, can be associated with serious health problems such as wheezing, loss of taste, rashes and skin irritation and reduced long-term efficacy66) . New studies have discovered that the bioactive peptides present in canary seeds have the potential to reduce blood pressure by inhibiting angiotensin I-converting enzyme (ACE) 5) . Valverde et al.62) found that proteins in the prolamine fraction of canary seed flour exhibited high inhibitory activity against the ACE enzyme, with an IC50 value of 217.4 μg/mL after in vitro digestion with pepsin and pancreatin. These studies highlight the beneficial potential of canary seed in regulating cardiovascular disease.

In the food industry, the ability of a starch to gelatinize is of paramount importance, precisely in the development of 〝designer starches〟 with specific functionalities and food formulations with improved nutritional composition at present67) ,68) . In the process of gelatinization, starch granules undergo a semi-cooperative or cooperative physical change when exposed to high heat and abundant water. First, the amorphous region (amylose) within the granule absorbs water, resulting in hydration, swelling and disintegration. This causes the crystalline regions (amylopectin) to deform and separate, completing the gelatinization process68) . Various techniques can be used to measure gelatinization, including differential scanning calorimetry commonly referred to as DSC, rapid viscoanalysis (RVA) , rheometric measurement, solid-state nuclear magnetic resonance (NMR) , light/polarized microscopy, small-angle X-ray scattering and X-ray diffractometer69) . As DSC is a very powerful and most widely used technique, it is crucial in the study of starch23) . Its enormous usefulness has been demonstrated in accurately measuring the crystallinity of both native and retrograded starches. DSC has also been very helpful in understanding the kinetics of retrogradation and the influence of various factors. DSC also has the advantage of being user-friendly as it doesn’t require highly skilled operator70) . A number of empirical parameters can be obtained from the analysis, including the onset temperature (To) , peak temperature (Tp) and completion temperature (Tc) of the gelatinization process. In addition, the endothermic enthalpy (ΔH) can be measured, which indicates the degree of loss of molecular organization within the starch granule. These parameters provide a valuable insight into the gelatinization behavior and characteristics of the starch sample under investigation69) . The results of the comparative DSC analysis (Table 4) clearly show that canary seed grains have significantly higher temperatures (To, Tp and Tc) and a wider gelatinization range than wheat starch71) . The ratio of amylose to amylopectin, the amount of amylose present, the structure of the starch granule and the molecular architecture of the crystalline region all influence variations in gelatinization24) . It was found that the gelatinization transition temperature range (Tc - To) of wheat starch was lower (16.7-18.9°C) than that of canary seed starch (19-22.57°C) 14) ,24) ,32) , indicating potential variations in the strength of the starch granule crystalline region, as reported by Banks and Greenwood (1975) . Enthalpy (∆H) represents the energy required to gelatinize a given amount of starch (1st peak) . Moreover, there were differences in enthalpy (∆H) between starches, which can be attributed to variations in the strength of the crystal structure and the double helix structure of the starches24) ,32) .Several studies have shown that the phenomenon of starch gelatinization is dependent on a number of factors which will be the subject of discussion below.

Gelatinization property of canary seed(P. canariensis. L.).

There are various parameters that influence the gelatinization properties of starch, Govindaraju et al.72) ,73) , has reported: the vegetable nature of starch, the relationship between amylose and amylopectin, granule shape and size, the relative crystallinity and the water content. According to a study by Hong et al.74) , particle size was an important factor in the gelatinization mechanisms of starch, where smaller starch granules exhibit reduced thermal stability. Additionally, a previous study found that high temperatures gelatinize the large granules first and then the small granules68) . Furthermore, the internal structure of the amylopectin molecule contributes significantly to starch gelatinization, as noted by Zhu and Li75) . They concluded that changes in the enthalpy of starch fusion and improved heat stability were caused by a more organized structure of amylopectin in starch.

8.2 Effects of moisture on starch gelatinizationOne of the important elements of gelatinization that significantly affects the internal gelatinization property of starch is its water content69) . According to Li et al., when there is an excess of water, a single symmetrical endothermic gelatinization peak appears, which is attributed to the involvement of short amylose chains. Conversely, limited water content can lead to the observation of multiple gelatinization peak69) .

For instance, in rice starches with restricted water content, at 75°C and 90°C two endothermic peaks were observed, and a third peak emerged around 120°C, indicating the presence of amylose-related factors such as the amylose-lipid complex and amylose-amylose interactions (intermediate chains of amylose) 68) ,69) . In studies conducted on canary seeds, two peaks were observed: the first, at around 70°C, representing starch gelatinization, and the second peak, at around 105°C, characterizing the melting of the starch crystal structure, in particular the amylose-lipid complex24) . However, further studies are required to clarify the nature of these peaks in the gelatinization process.

8.3 Effects of salts on starch gelatinizationThe gelatinization and physicochemical properties of starch are significantly influenced by salt ions76) , not only to improve the perception of flavor, aroma, texture and color, but more importantly for its functional role, where it contributes to the development of food products with a specific characteristic77) ,78) . Research suggests that the gelatinization temperature and enthalpy of starch can be increased and/or decreased by the type and concentration of salts32) ,68) ,69) . Wang et al.79) , in their DSC analysis, demonstrated that the addition of salting-out ions such as F- and SO42- resulted in higher gelatinization temperatures and enthalpies for two starches. The opposite, salting-in ions like NO3- and SCN- showed the opposite trend. Shi et al., studied the influence of NaCl on potato starch. The results showed that the addition of NaCl could increase the gelatinization temperature of starch, and decrease the enthalpy of gelatinization68) . Similar studies reported that the peak gelatinization temperature and enthalpy decreased when 0.1 mol/L NaCl solution was mixed with starch. However, increasing the concentration of NaCl to below 4 mol/L led to an increase in gelatinization onset temperature and enthalpy69) . Yang et al.80) examined the influence of K2SO4 on indica japonica, and waxy rice starch and observed that adding K2SO4 up to 0.6 mol/L increased the gelatinization temperature of starch by 10 to 13°C and decrease the enthalpy of gelatinization. Over the years, several explanations have been proposed to explain the effect of neutral salts on starch gelatinization. The most widely accepted mechanism involves two aspects: (I) manufacturing and structure breaking effects on water and (II) electrostatic interactions between salts and starch hydroxyl group69) ,81) . In general, the Hofmeister sequence is followed for the effects of salt on starch gelatinization and retrogradation79) .

8.4 Effects of sugars on starch gelatinizationSugars, including natural sugars or sweeteners, represent another factor that can significantly impact the properties of the host food system and the gelatinization properties of starch69) , the extent of the changes in thermal properties depends on various factors, such as the botanical origin of the starch, the quantity, molecular weight and intrinsic properties of the sugars82) . For example, sucrose has been shown to raise the gelatinization temperature of starch more than other sugars83) . It is generally known that sugars increase the gelatinization temperatures of starch and modify the enthalpy of gelatinization66) ,69) ,84) .

Due to the widespread interest in starch gelatinization, many explanations have been proposed as to how various additives affect the temperature and process of gelatinization85) . Many hypotheses have been suggested in the literature as potential underlying mechanisms. Firstly, water deficiency, for example, sugar, due to its hydrophilic nature, can cause water to compete with starch and reduce the availability of water, reducing the potential for water to react with starch molecules and ultimately increasing the gelatinization temperature of starch86) . Secondly, sugar/starch hydrogen bonding interactions taken into account. A study by Allan et al.83) , compared the effects of 19 different carbohydrates and demonstrated that the concentration, stereochemistry and molecular flexibility of the sugar influence intermolecular interactions with the starch in the amorphous regions. These interactions limit the mobility of the amorphous regions and raise the gelatinization temperatures. However, the evaluation of the literature still reveals the lack of comprehensive and sufficient information regarding the effect of sugars and temperatures on the gelatinization properties of canary seed starch.

8.5 Pasting properties of starchPasting is a process that follows gelatinization, it summarizes continuous transformations of starch that occur at high temperature, it includes intensive swelling of the granules and leaching of the amylose molecules87) ,88) ,89) . Various techniques can be employed to measure starch pasting, RVA being the most well-known instrument for viscosity measurement due to its speed, sensitivity, reproducibility, and requirement of a small sample sizes88) ,90) . Evaluating the pasting properties of starch is crucial for determining their suitability in different foods and other related products91) . Table 5 presents the starch pasting properties of different canary seed cultivars as determined by RVA and DSC. The pasting temperature ranges were extremely close, showing linearity between the studies performed. The maximum viscosity, finale viscosity, recoil viscosity, breakage viscosity and pasting temperature of various canary seeds starches were reported within the ranges of 2070-2525 cP, 3700-4647 cP, 1630-2783 cP, 410-784 cP and 84.3-88.8°C, respectively.

Pasting properties of canary seed(P. canariensis L.).

Generally, pasting temperatures vary from one starch to another, influenced by factors such as amylose content, amylose leaching, degree of crystallinity, granules size23) , surface distribution of lipids in starch granules and internal starch lipids (unsaturated fatty acids) 14) . In addition to the intrinsic factors, proteins are an important extrinsic that affects adhesive properties92) . The properties of canary seed starch were compared to wheat starch, with the maximum viscosity and pasting temperature of canary seed starch being higher than those of wheat starch (p>0.05) 93) .

Hairless canary seed flours possess distinctive nutritional qualities, primarily attributed to their high levels of non-gluten protein (24%) , dietary fiber (20%) , bioactive peptides with antioxidants, antihypertensives, and antidiabetic properties, polyphenols, and unsaturated fats (primarily linoleic acid at 51.8% to 53.39%) . The small particle size (2.2-2.6 µm) , high purity, and strong gelling properties of canary seed starch make it an excellent candidate as a non-conventional starch source for various applications, including fat replacement, cosmetics, and pharmaceutical products. The growing demand for natural health products and non-conventional starch provides opportunities for the hairless canary seed industry to flourish.

To maximize the advantages of canary seed flour and starch, several key issues need to be addressed. More studies are required to evaluate the safety, side effect, and efficacy of extracts and bioactive peptides. Firstly, research into alternative extraction methods can significantly increase the yield and purity of canary seeds starch. Furthermore, a comprehensive characterization of the physicochemical properties of canary seed starch is essential. This includes studying its rheology, retrogradation, gelation and stability during freezing and thawing. It is also important to study the non-starch components, such as lipids and proteins, present in canary seed starch. In order to gain a better understanding, the chemical and molecular structures of amylose and amylopectin in canary seed starch should be studied. Analyzing the internal molecular structure of canary seed starch in relation to its physicochemical properties provides valuable information. Comparative studies using other starch sources such as wheat, rice and potato as references can help to identify potential benefits of using canary seed starch. This research will facilitate informed decisions about its use in different industries.

Considering the application of chemical, physical and enzymatic modifications or combinations thereof in future research on canary seed starch may further enhance its functionality and versatility. The exploration of advanced technologies such as nuclear magnetic resonance, atomic force microscopy and other improved characterization techniques open up new possibilities for the study of canary seed starch. By addressing these key issues, we can effectively maximize the use of canary seed flour and starch, leading to innovation, improved applications and a deeper understanding of this valuable resource.