2013 年 30 巻 p. 221-235

2013 年 30 巻 p. 221-235

The development of nanotechnology for advances in various sectors like health, consumer products has paved way for possible applications in agriculture and food industries. Antimicrobial agents (e.g., silver, titanium dioxide), nano-bio pesticides (hydrophobic silica), smart delivery systems (polymeric nanoparticles) provide promising enhancement or alternatives to the conventional crop protection strategies, which are primarily based on applying chemicals in solid, liquid or suspension forms. Nanotechnology approaches in food industry can impart properties such as resistance to gas penetration, increased tensile strength and enhanced absorption of nutrients leading to novel food packaging and processing materials. Despite these features, the usage of nanotechnology is still limited, owing to the lack of proper toxicity evaluation data. Understanding the risks and taking appropriate measures to mitigate them will significantly enable nanotechnology advances targeting to agriculture and food industries. In this paper, we have reviewed some of the recent research and development efforts that have been carried out in nanotechnology for its potential applications in agrifood sector. More specifically, nanotechnology approaches mediated by particle technology advances are reviewed.

With the global population exceeding 7 billion and an annual growth rate of 1%, there is an increasing demand for food throughout the world. Inflation of food price, climate changes and supply chains are other issues that the agrifood sector faces (ObservatoryNano, 2010). These challenges are the drivers for the farmers and the scientific community to delve into options for maximizing the yield of the crops. Recent report by Food and Agricultural Organization shows that 70% more food needs to be produced by 2050 (FAO, 2009). The major hindrance in accomplishing this goal is the pests and other pathogens that destroy the crops and reduce the resource-use efficiency. For instance, it has been shown that the estimates for potential losses occurring to rice crops due to animal pests and pathogens are 37 and 25 % respectively (Oerke, 2006). Advent of foreign pests is one of the possible reasons for major destruction in the crops with the most recent example being a disease called citrus greening. This disease, which led to a huge loss of $3.6 billion in Florida so far (Hodges and Spreen, 2012) is caused by a bacteria (Candidatus Liberibacter asiaticus) and spread by an insect (Asian citrus psyllid), originated in China (USDA, 2007). With devices to diagnose such new pests, farmers will be able to take proactive measures before the onset of the disease. Also, diagnosis of pests and pesticide residues helps the farmers and the food manufacturers to ensure that the product meets the criteria for the quality and safety before despatch (Grunert, 2005). Although analytical methods like gas chromatography and high performance liquid chromatography are available to monitor the pesticide residues, there is a need to develop easier, faster, online and accurate methodologies without requiring much sample pretreatment. Biosensors are such devices which can not only detect the pests and the pesticide residues, but are also capable of doing it more accurately and faster than the conventional devices with much smaller sample sizes.

While timely detection of the pests helps in addressing the existing issues partially, a comprehensive solution is achieved only by combining effective diagnosis techniques with efficient crop protection strategies. Usage of pesticides is imperative for any crop treatment; however, the rates at which they are sprayed currently, owing to the evaporation and runoff, leads to accumulation and consequently becomes detrimental to the environment. The adverse effects caused by the pesticide residues calls for an efficient treatment method which can minimize the usage of pesticides and also prolong its efficacy in the crops. Smart delivery systems are modalities which can encapsulate an agrochemical and release it in a controlled manner without compromising the environment. Nanotechnology approaches for crop treatment can lead to effective and efficient solutions. For example, the remote sensing property offered by many biosensors could improve the average farm profits by $31.74/ha (Tenkorang and Lowenberg-DeBoer, 2008) by spatially targeting and channelizing the application of the agrochemical in the field. The importance of nanotechnology extends to food packaging and processing materials. Nanoparticles can enhance the packaging material properties such as resistance to gas and moisture penetration, better tensile strength etc. Additionally, nanotechnology approaches for enhancing the absorption of nutrients into the body can lead to interactive food processing materials.

The following sections highlight some of the pioneering nano-bio based technologies and their applications in the agrifood sector.

Nano-bio sensors are devices which utilize the principle of biological selectivity along with the processing power of the optoelectronics to analyze target compounds. Biosensors can be used to detect a variety of compounds such as phenols (Munteanu et al., 1998), volatile organic compounds like benzene (Ikariyama et al., 1993) and pesticides (Oroszlan, 1993) besides pathogens (Costello et al., 2000). Typically, biosensors are tagged with enzymes, anti-bodies or any other biologically active systems to impart biorecognition properties to the sensor. The signal generated by these biological systems can be in the form of electric potential/current/resistance, optical properties such as luminiscence, heat or changes in the mass of the reactants or products etc. (Fig. 1). The biosensors expected to grow to $16.8 billion market by 2018 (Business Wire, 2012) are also applicable in many other industries like healthcare, environmental, and food processing.

Components of a biosensor (adapted from Rana et al., 2010).

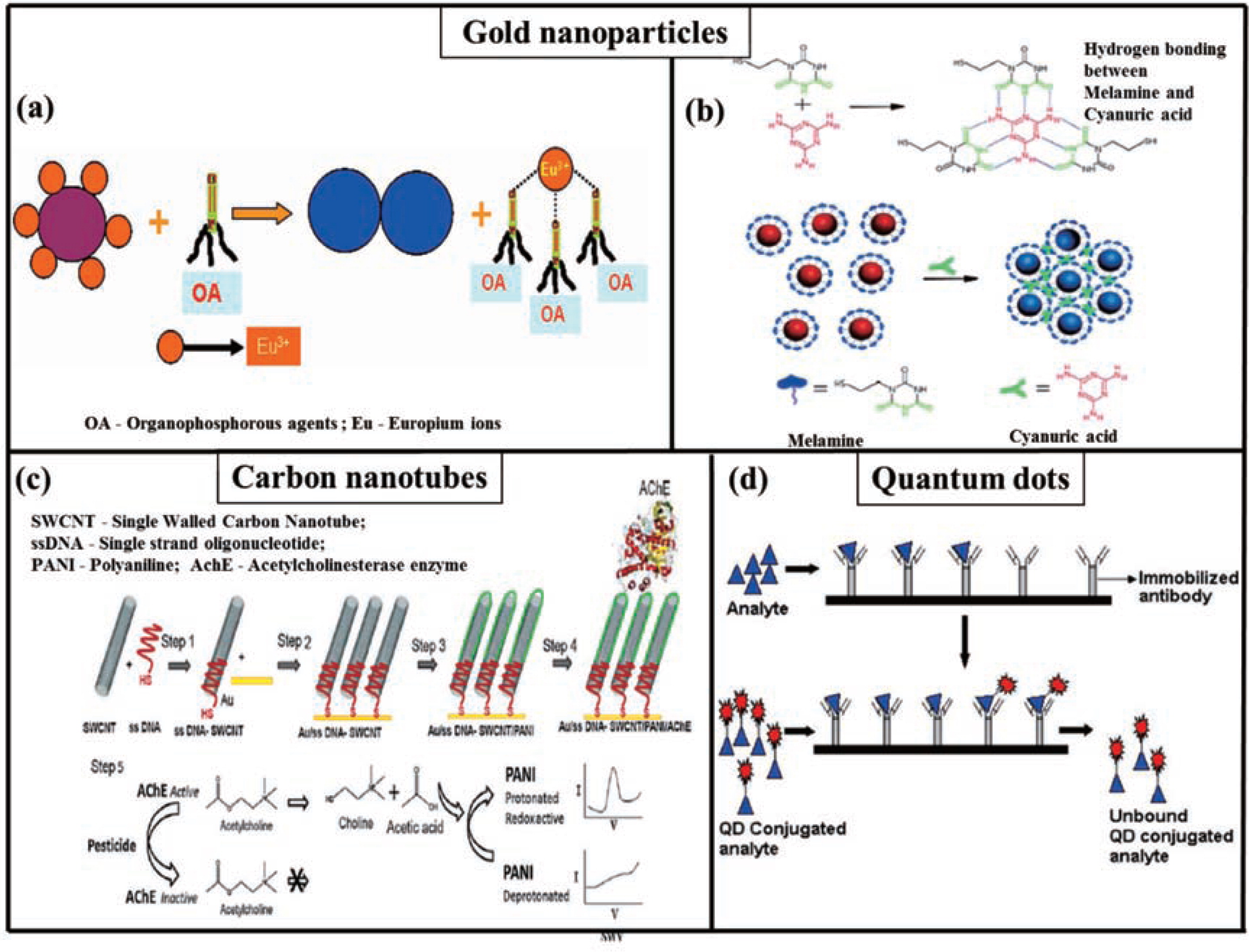

The presence of nanoparticles in a biosensor is expected to improve the overall efficiency of the sensors possibly due to the increased surface for reaction. Typically, the nanoparticles are functionalized by the bioconjugate of the target analyte (Yang et al., 2008). Dye-doped silica, quantum dots (Qdots), and gold are some of the nanoparticles explored for the development of biosensors. Bioconjugated dye doped silica nanoparticles, which is used for the detection of E.coli is shown to be 1000 times more effective in signal amplification than an organic dye. Each silica particle can encapsulate thousands of organic dye molecules and is tagged to a bacterium leading to better signal and enhanced sensitivity (Zhao et al., 2004). Silica matrix is biocompatible, non-toxic and is also optically transparent. In addition, presence of silica shell around the dye is shown to reduce the photodegradation of the dye. However, the major limitation of silica is the lack of inherent spectral properties, which lead to investigation with several other nanoparticles that could address this issue.

Qdots are nanomaterials that possess inherent spectral properties and do not require external fluorophore as in the case of silica particles. This makes Qdots, which have dimensions from 1–10 nm, a strong contender for usage in optical biosensors. The detection of a biomolecule by a Qdot typically depends on the principle of Forster Resonance Energy Transfer (FRET). FRET is an energy transfer between the donor fluorophore and the acceptor chromophore in which the excitation energy of the donor is transferred to the acceptor nonradiatively. The broad absorption spectra of the Qdots allow it to accept energy nonradiatively from a donor chromophore, a biomolecule and reemit the energy corresponding to their emission spectrum. The narrow emission band, broad absorption spectra and extended photostability render Qdots superior to the conventionally used organic dyes.

Schematic of functioning of various biosensors (a) Fluorescence based detection of organophosphorous pesticides using europium tagged gold nanoparticles (Dasary et al., 2008) (b) Colorimetric detection of Melamine in milk using cyanuric acid-gold nanoparticles (Reprinted with permission from (Ai et al., 2009). Copyright (2012) American Chemical Society) (c) Electrochemical detection of pesticides using enzyme activated single walled carbon nanotubes (Viswanathan et al., 2009) (d) Color change of the nanoassembly formed by Qdot nanoprobes and target analyte (Reprinted with permission from (Ho et al., 2005). Copyright (2012) American Chemical Society).

Gold nanoparticles, typically 1–100 nm in size, are used both in optical and electrochemical sensors. The optical properties of gold nanoparticles are shown to vary with their size, shape and agglomeration based on Mie scattering theory (Feldheim and Foss, 2002). While small nanoparticles absorb light in the blue-green spectrum (red color), a red shift is observed when the particles get bigger in size (blue or purple in color). The change in the coloration formed due to the aggregation of gold colloids in the presence of a target analyte forms the basis for optical detection of several target analytes. Gold nanoparticles offer several advantages such as less toxicity than their counterparts (e.g. Qdots), lack of photodecomposition, stability etc. Gold nanoparticles are also used to design a variety of immunoassays for electrochemical sensing of the pesticides and pathogens. For example, Dungchai et al demonstrated amperometric detection of Salmonella typhi (S. typhi) bacteria using gold nanoparticles (Dungchai et al., 2008).

The polystyrene cell wall was immobilized with monoclonal antibodies and a polyclonal antibody conjugated gold nanoparticle was added to bind to these bacteria. Addition of copper enhanced ascorbic acid enables reduction to Copper(0) and further deposition on the nanoparticles. The Cu(II) released in the nitric acid is measured by anodic stripping voltammetry and the current was found to be linearly dependent on the concentration of S. typhi. Table 1 illustrates several nanomaterials used in biosensors and their applications for detection of various pathogens and pesticide residues.

| Nanoparticle | Target Analyte | Method of detection | Detection limit | Reference |

|---|---|---|---|---|

| Dye doped silica | E. Coli | Fluorescence | 1–400 e.coli/g beef sample | (Zhao et al., 2004) |

| Molecular imprinted silica nanospheres with Qdots | deltamethrin (pesticide) | Fluorescence | 0.16 μg/mL | (Ge et al., 2011) |

| Gold | Salmonella typhi | Current | 98 cfu/mL | (Dungchai et al., 2008) |

| Carbofuran and Triazophos | Color | 32 μg/L and 4 μg/L | (Guo et al., 2009) | |

| Salmonella spp | Capacitance | 1.0 × 102 cfu/mL | (Yang et al., 2009) | |

| Organophosphorous pesticides | Fluorescence | 1 μM | (Dasary et al., 2008) | |

| Pathogen (Staphylococcal enterotoxin B) | Color | 0.01 ng/mL | (Yang et al., 2009) | |

| Carbon nanotubes | Methyl parathion and chlorpyrifos | Current | 1 × 10−12 M | (Viswanathan et al., 2009) |

| Zirconium oxide/gold nanocomposite | Parathion | Current | 3 ng/mL | (Wang and Li, 2008) |

| Qdots | Methyl parathion | Fluorescence | 0.1–1 ng/mL | (Chouhan et al., 2010) |

| E. Coli | Fluorescence | 104 e. coli/mL | (Mukopadhyay et al., 2009) |

Usage of pesticides is imperative in any crop treatment strategy. According to a recent report released by United States Environmental Protection Agency (USEPA), the annual usage of pesticides in United States (US) is 1.1 billion pounds (Grube et al., 2011). Typically, pesticides are applied either by spraying or broadcasting. These methods of application lead to pesticides being lost due to run off, evaporation etc. Encapsulation of these pesticides in nanoparticles facilitates controlled and targeted delivery (smart delivery systems), thus reducing the number of applications required (Jurado-Exposito, 1996). Various modalities have been investigated as potential smart delivery systems (e.g. clay, polymeric particles, and silica capsules). A brief review of some of the particle mediated smart delivery systems is presented below.

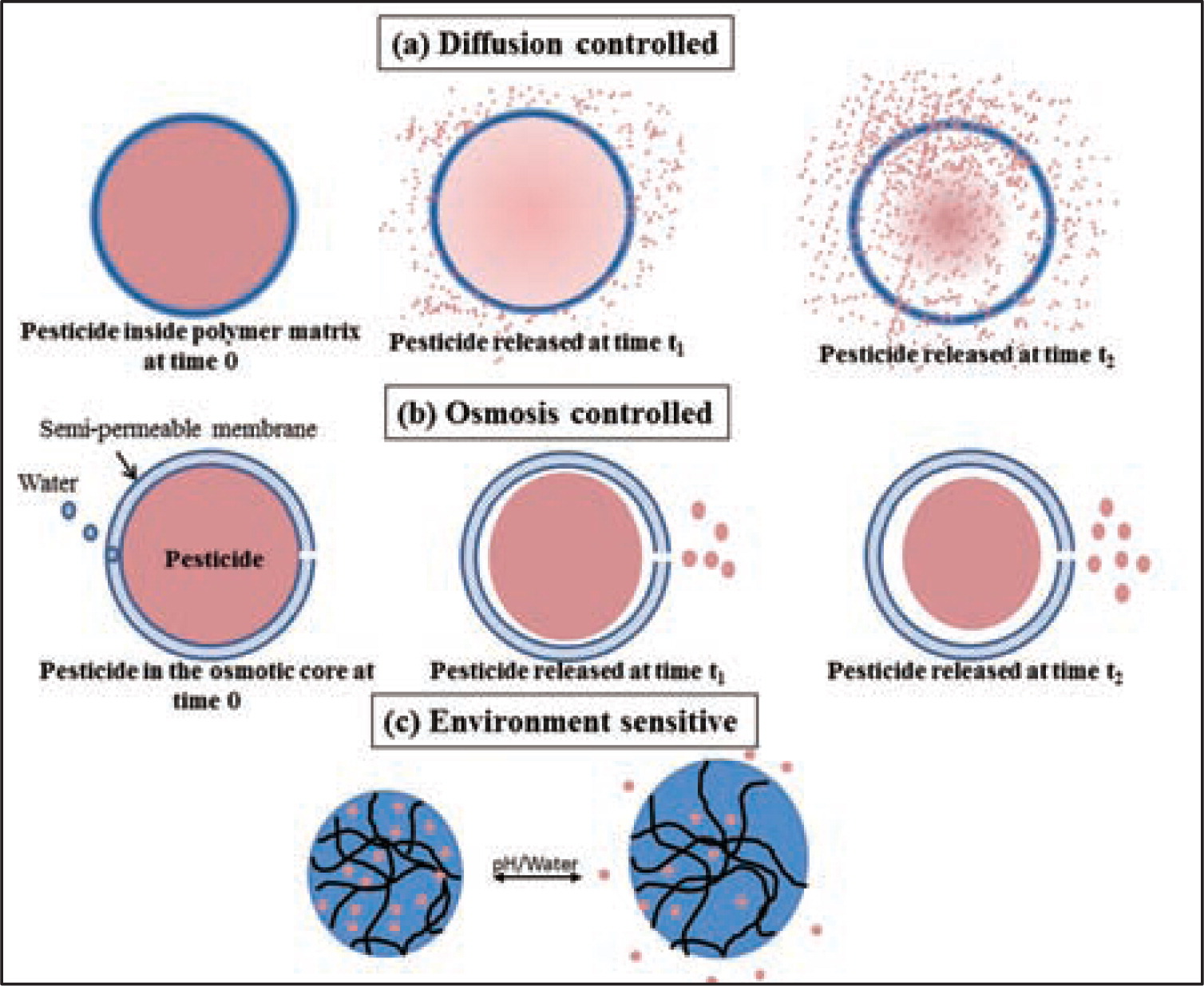

2.2.1 Polymeric particlesEncapsulation of agrochemicals such as pesticides, semio-chemicals (attractants and repellents) in polymers are well-studied. Various methodologies, such as solvent extraction, complex coacervation, insitu polymerization etc., are used for the encapsulation of these chemicals in the polymers. The release of the active ingredient from the polymer can be controlled by varying the pore and the particle size of the polymer. There are several mechanisms by which an active ingredient is effectively released into the environment. As illustrated in Fig. 3, primarily, the release of the active ingredient is driven by either (a) Diffusion (b) Osmosis or (c) Environment which includes changes in the pH, surrounding solvent, temperature, ions etc. Diffusion occurs when the active ingredient passes through the polymer, either through the pores of the polymer matrix (macroscopic diffusion) or between the polymeric chains (microscopic diffusion) typically driven by the chemical potential or concentration gradient of the active ingredient. The other mechanism for release which is osmosis occurs when the pesticide is present inside an osmotic core surrounded by a semi-permeable membrane. The entrance of water into the core drives the release of the pesticide into the surrounding environment. Similarly, environment sensitive delivery devices are designed based on the principle that the polymer matrix responds to a change in the surrounding environment like pH, solvent etc., and swells. The swelling of the matrix forces the release of the active ingredient into the environment (e.g. release of active ingredient from a hydrogel). Several polymeric nanoparticles are designed for efficient release of agrochemicals. One of the most widely explored polymeric materials is chitosan. Chitosan is a biodegradable polymer and the derivatives of naturally available chitosan can self-assemble to form nanoparticles. Biodegradability and biocompatibility of such polymers, renders them potentially safe for agrifood applications. For example, chitosan nanomicelles have been studied for the encapsulation and release of bioactive food factors (Zhang et al., 2006). Similarly, the pesticide Bifenthrin was encapsulated in polymers such as Poly (acrylic acid)-b-poly (butyl acrylate), Polyvinyl alcohol (PVOH (Liu et al., 2008).

Schematic of controlled release modalities from a polymer matrix.

Kaolin, a white, non-swelling, plate-shaped alumino silicate mineral, is widely used in agriculture as a bio-pesticide and a repellent. The mechanism of this technology is speculated to be the desiccation caused by the inert dust which was first observed by Maxwell (Maxwell, 1937). These clay particles protect plants against various pests and insects (Daniel et al., 2005, Eigenbrode et al., 2006, Glenn et al., 1999) by masking the visual cues. Another clay that has shown potential in agricultural applications is three layered, swelling clay called Montmorillonite (MMT). While the naturally available MMT clays are hydrophilic, their high cation exchange capacity makes it possible for modification with a cationic surfactant to render them hydrophobic (de Paiva et al., 2008). Encapsulation of various pesticides has been accomplished in both hydrophilic (Mishael et al., 2002) and hydrophobic MMT clays (Celis et al., 2005). By encapsulation, the efficiency of the insecticides diazinon and chlorpyrifos has been shown to improve from 4 weeks in the commercial formulation to as high as 20 weeks using the MMT clay (Choudary et al., 1989). On similar lines, preliminary experiments in our group with MMT clays indicate that the efficiency of insect repellent could be increased from 2 days to few weeks (unpublished results). Given that these clays are abundant and environmentally benign, they provide a greener alternative to the conventional crop protection strategies.

2.2.3 Silica particlesRecent development in the health care industry for encapsulation of various drugs in the mesoporous silica particles (He and Shi, 2011) has paved way for a similar application in agricultural industry. Surface functionalized hydrophobic silica can act as an insecticide by getting adsorbed into the cuticular lipids of insects and causing death of insects by desiccation (Mewis and Ulrichs, 2001). A similar effect was shown recently by Debnath et al against rice weevil Sitophilus oryzae (Debnath et al., 2011). Water soluble pesticide validamycin encapsulated in porous hollow silica nanoparticles (PHSN) with a loading capacity of 36% is shown to last for 800 min as opposed to instantaneous release of free validamycin (Liu et al., 2006). Encapsulation of the pesticides inside the hollow silica spheres has also been shown to protect them from environmental factors such as ultraviolet degradation (Li et al., 2007).

2.2.4 Magnetic nanoparticlesThe effective usage of magnetic nanoparticles for imaging and targeted delivery of the drugs has stimulated interest in their application for agricultural purposes. For example, carbon coated iron nanoparticles have been investigated in pumpkin plants which showed signals of varying magnetic strengths in different parts of the plant (Gonzalez-Melendi et al., 2008). The advantages of magnetic nanoparticles lie in the fact that they can be tagged with different substances based upon the application and can be concentrated in a localized area. Ferrofluids are another kind of magnetic material containing a mixture of iron oxides or other ions like Manganese and nickel along with a stabilizer typically a surfactant and carrier liquid. Pintilie et al monitored the catalase activity in Maize as a function of concentration and concluded that the enzyme activity exhibits a maximum before decreasing with further increase in concentration (Pintilie et al., 2004). Similar results were reported in a study conducted in pumpkin plants using magnetic nanoparticles coated with tetramethylammonium hydroxide (TMA-OH) (Zhu et al., 2008). The reason for this trend is speculated to be the oxidative stress generated by the excess iron consequently affecting the process of photosynthesis and metabolism. The highly localized nature of the magnetic nanoparticles will be of interest in studying the local treatment of the plants in greenhouse. Given the inhibitory effects of high concentrations of these particles on the metabolism of the plants, proper selection of the concentration ranges for design of these delivery systems is important.

2.2.5 Nano-Titanium dioxide (TiO2)TiO2 which is a well-known photocatalyst is widely studied for possible enhancement of photosynthesis. For example, Su et. al showed that suitable concentrations of nano-anatase TiO2 can improve the oxygen evolution in spinach plants (Su et al., 2007), supporting the study performed by Yang et al (Yang et al., 2007). The possible reasons stated for this phenomenon are the increase in light absorbance and energy transfer among the amino acids. Similar results were demonstrated with nano-TiO2 on wheat plants (Moaveni et al., 2011). Given the importance of photocatalytic activity of TiO2, various studies have been conducted to improve it. For example, Krishna and coworkers have reported that TiO2 in combination with water soluble fullerenes has been shown to enhance the degradation of an organic dye indicating an increase in the photocatalytic activity (Krishna et al., 2006). A similar effect was achieved with silver doped TiO2 nanoparticles (Behnajady et al., 2008). Increased photoactivity is attributed to the scavenging of the photo-generated electrons, which could consequently increase the generation of hydroxyl radicals. Some of the recent patents based on smart delivery systems are listed in Table 2.

| Carrier | Application (Patent number) | Reference |

|---|---|---|

| Clays | Pesticides (# 6261997) | (Rubin et al., 2001) |

| Anionic herbicides (# 7030062) | (Nir et al., 2006) | |

| Pesticides (# 0127435) | (VanVoris et al., 2006) | |

| Fertilizer (Sulfur) (# 6749659) | (Yu et al., 2004) | |

| Pesticides (# 0215705) | (Cataldo et al., 2010) | |

| Polymers | Pesticides (# 6638994) | (Crooks et al., 2003) |

| Fungicide (# 7452546) | (Botts et al., 2008) | |

| Essential oils (# 0268780) | (Markus et al., 2009) | |

| Agrochemicals (# 0261043) | (Greiner et al., 2008) | |

| Silica | Pesticides (# 0254082) | (Toledano et al., 2008) |

| Pesticides (# 0015236) | (Margadassi et al., 2010) | |

| Insect repellent (# 0244056) | (Santra, 2011) | |

| Agrochemicals (# 7537803) | (Wang et al., 2009) |

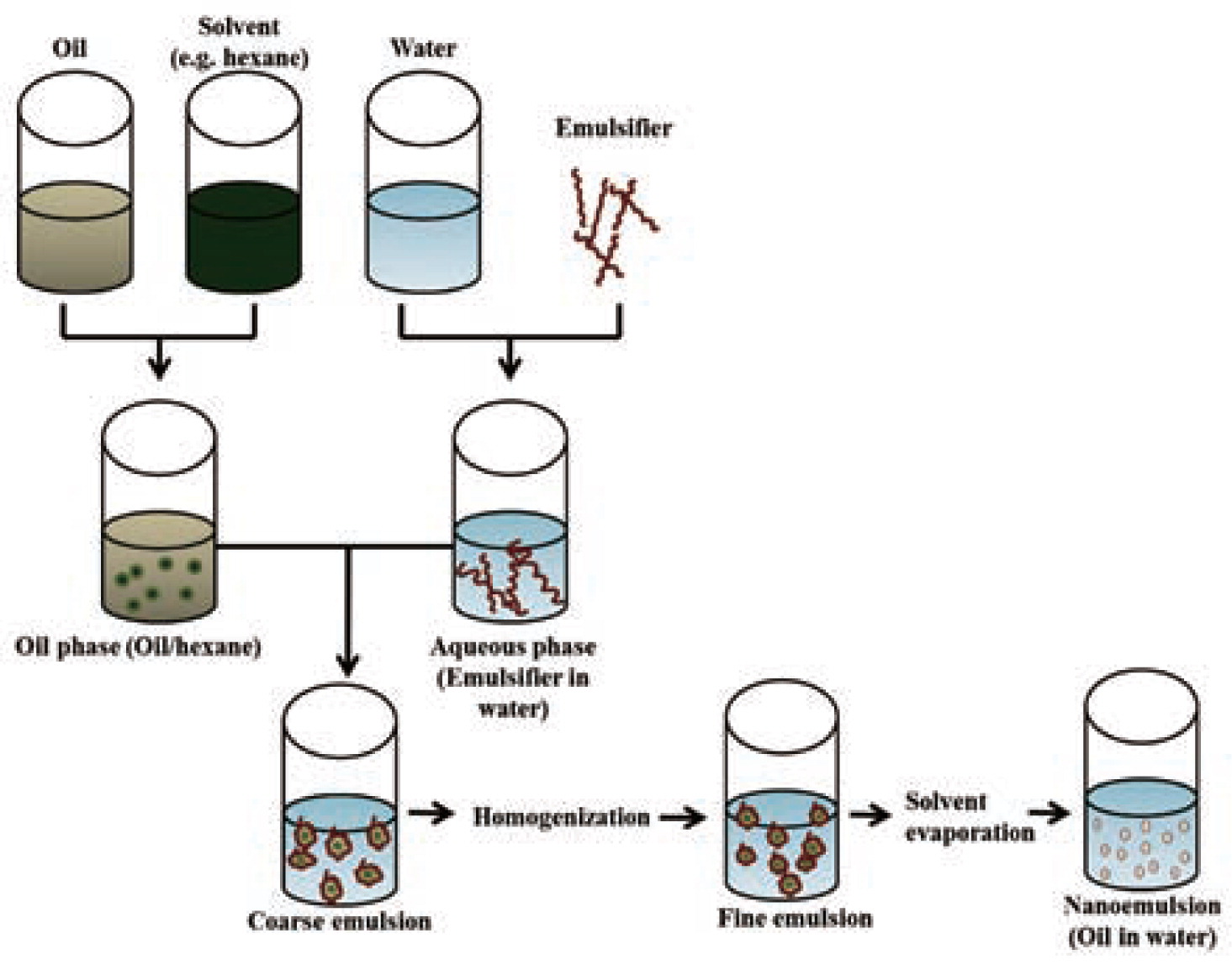

Nanoemulsion can be defined as non-equilibrium colloidal system comprising multiple phases, simplest being oil and water, which is visibly translucent and kinetically stable. The particle size diameter of the nanoemulsion is typically in the region of 20–200 nm (Solans et al., 2005). Nanoemulsions have a wide range of applications in pharmaceutical, skin care and cosmetics industry to name a few. In agricultural applications, nanoemulsions can be used to disperse both hydrophilic and hydrophobic pesticides depending upon the need. By enabling dispersion of hydrophobic pesticides in water, usage of toxic organic solvents can be minimized, in addition to increasing the bioavailability of the active ingredient (Nicolaos et al., 2003). The smaller size of the droplets in the nanoemulsion enables uniform spreading on the plant leaves and also improves internalization in insects (Ebert et al., 1999). Nanoemulsions can be produced by both high energy (mechanical processes) and low energy (addition of surfactants) processes (Fig. 4). The surfactants in the emulsion might lower the surface tension and enable better wettability and penetration of the droplets into the leaves (Tadros et al., 2004). Wang and coworkers demonstrated that the nanoemulsion of a water-insoluble model pesticide β-cypermethrin was highly stable and did not form a precipitate when diluted from the concentrated solution (Wang et al., 2007). Similarly, a study on the neem oil nanoemulsions concluded that the larvicidal effect increased with decreasing droplet size (Anjali, et al. 2012). The increased bioavailability of the nanoemulsions could be explained by the higher surface area (smaller size of the droplet), leading to better adsorption of the target entity (McClements and Li, 2010). Banner MAXX® (fungicide) and PrimoMAXX® (plant growth regulator) are examples of nanoemulsions in agricultural applications.

High energy process of nanoemulsion preparation (adapted from (Troncoso, 2012)).

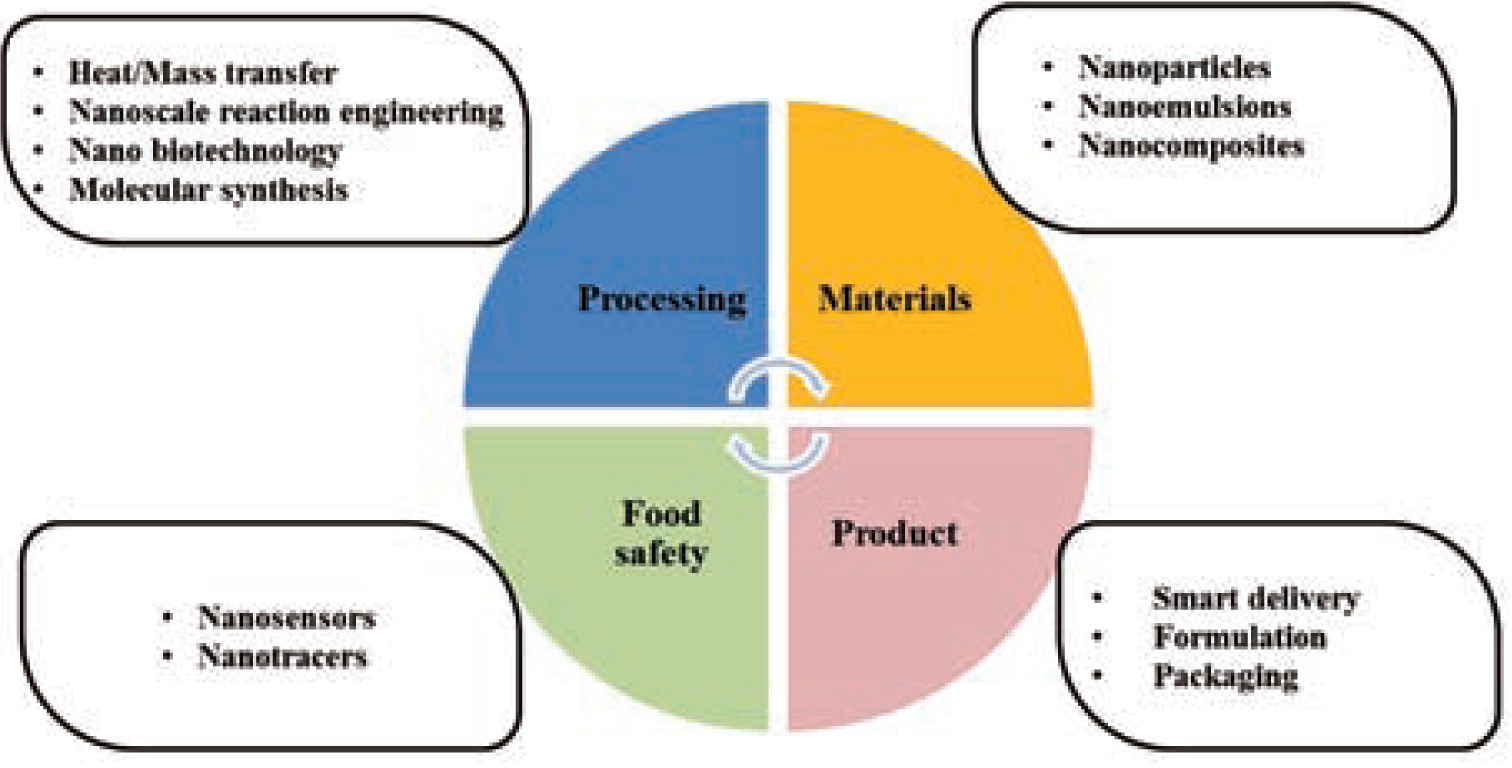

Food industry finds increasing applications of nanotechnology in areas such as for food safety, processing, novel packaging materials and sensors as illustrated in Fig. 5. Examples of nanoparticles that have generated wide interest in this area e.g. nanocomposites and nanosensors (packaging) and nanoemulsions and nanocapsules for efficient delivery of nutrients (food processing) are described in following section.

Applications of Nanotechnology in food sector (adapted from (Weiss, 2006)).

Improvement in the lifestyle of the people demands for multifunctional food packaging options. Owing to this, there has been a significant effort by the industry to explore smart packaging material. As a result, the market for smart food packaging is estimated to skyrocket to $ 23.5 billion by 2015 (Marketsandmarkets, 2011). This section reviews the set of nanoparticles with great potential for usage in smart food packaging materials.

3.1.1 NanocompositesThe nanocomposites, expected to be a $3.8 billion annual market by 2015, is the fastest growing market within the polymers. Nanocomposites are typically made of polymers and a nano-additive, which can be nanoclays or any other nano-reinforcement material such as chitosan, cellulose, carbon nanotubes etc. The presence of nano-additives offer advantages such as increased resistance to moisture and gases, and improved tensile strength properties.

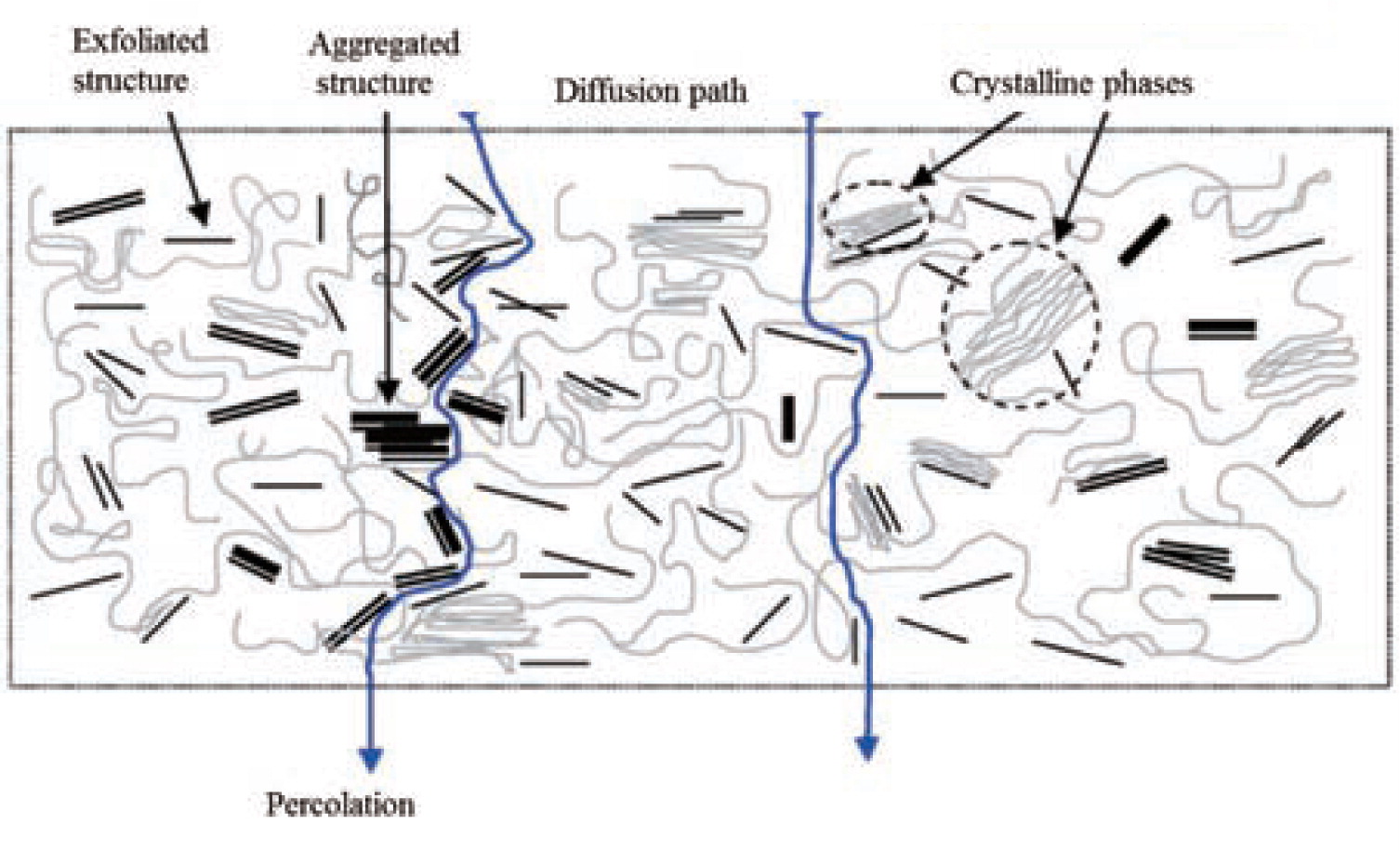

3.1.1.1 NanoclaysOne of the promising materials for smart packaging, nanoclays provide the well-needed resistance to water vapor and gas transmission. This phenomenon has been exploited for packaging of food which is sensitive to moisture, carbon dioxide and oxygen (Lan et al.,2001). Nanoclays are typically montmorillonite clays which are organically modified for enhanced dispersion properties in polymer matrices. When the clay is intercalated into polymers or vice-versa, the resulting nanocomposite has better tensile strength and barrier properties (Maul, 2005). The possible interactions between polymer and clay can be either intercalation, which is penetration of polymer into the layers of the clay or exfoliation involving delamination of clay (Adame and Beall, 2009, Alexandre et al., 2009; as shown in Fig. 6). The presence of tortuous path in the nanoclays-polymer composite, which was initially proposed by Nielsen and further studied by other authors (Adame and Beall, 2009, Mirzadeh and Kokabi, 2007), is postulated to be the cause of barrier properties. It has been shown that the relative permeability decreases with increase in sheet length because of the increased tortuosity (Bharadwaj, 2001).

Illustration of diffusion of water through clay-polymer nanocomposites (Alexandre et al., 2009).

Nanocor, a subsidiary of Amcol International Corporation, USA, has developed a nanocomposite called Imperm® that is used as a substitute for glass bottles to store beer and claimed to have a shelf life of around 6 weeks. Oxygen transmission rate (OTR) has been showed to decrease with increased loadings of nanoclays in the composite (Lan et al., 2001). A similar product from Honeywell claims to offer a shelf life of around 26 weeks (Sherman, 2004). Durethan® (Bayer) is another nanoclay product which could reduce the transmission of gases and moisture thus preventing the food from spoilage (McHugh, 2007).

3.1.1.2 Nanofibres and nanotubesNanofibers closely follow nanoclays as an efficient additive in a composite. Cellulose nanofibers (CNFs) are explored for their ability to offer low cost, high tensile materials. These are typically synthesized as nanofibers which are made up of crystalline and amorphous regions. Azeredo et al investigated the effect of nanofibers combined with films made of mango puree (Azeredo et al., 2009) and chitosan (Azeredo et al., 2010). They observed a significant decrease in water vapor transmission rate and increase in young’s modulus at 10% addition of CNFs. Similar results were observed with nanofibers in the presence of chitosan films. The improved barrier to water vapor due to the presence of CNFs is attributed to the increased tortuosity as also postulated in case of nanoclay-polymer composites (Sanchez-Garcia and Lagaron, 2010). Apart from CNFs, carbon nanotubes (CNTs) (Kim et al., 2008) and silica nanoparticles are reported to improve the tensile properties of several polymers (Wu et al., 2002, Xiong et al., 2008) as summarized in Table 3. Xylan is yet another hemicellulose material used for food packaging, which when reinforced with CNF improves the tensile strength and water barrier properties (Saxena et al., 2009).

| Nanocomposite (Nanoadditive/polymer) | Tensile strength of the nanocomposite (MPa) | Percentage increase in tensile strength from pure polymer | Reference |

| CNT/polyurethane | 21.3 | 180 | (Sahoo et al., 2010) |

| CNT/PAN terpolymer | 114.8 | 160 | (Ji et al., 2009) |

| CNT/Chitosan | 73.1 | 170 | (Tang et al., 2008) |

| CNF/Mango puree films | 8.76 | 214 | (Azeredo et al., 2009) |

| Rice straw nanofiber / Chitosan | 193.2 | 355 | (Hassan et al., 2011) |

| Carbon nanofiber/epoxy | 74.4 | 110 | (Sun et al., 2011) |

The most widely studied metal nanoparticle is silver, principally because of its well-known biocidal activity against a wide range of pathogens including gram-positive, gram-negative bacteria and several fungi (Balazs et al., 2004). Surfaces resistant to bacteria are designed by incorporating silver as silver nanoparticles, silver zeolites or silver ions. While smaller silver nanoparticles have better antimicrobial activity (Baker et al., 2005,Panacek et al., 2006) owing to their higher surface to volume ratio, the triangular ones are shown to kill E.Coli better than spherical or rod shaped particles (Pal et al., 2007), possibly due to higher atom-density facets. The antimicrobial activity of silver nanoparticles is successfully tested against E.Coli (Sondi and Salopek-Sondi, 2004), E.coli, S.aureus and P.aeruginosa (Djokic and Burrell, 1998). The biocidal activity of silver nanoparticles grafted on filter paper against E.coli offers promise for food packaging application (Tankhiwale and Bajpai, 2009). Commercial products like Fresh Box from BlueMoonGoodsTM are developed for food storage products based on the antimicrobial properties of silver.

3.2 Food processingNanomaterials exist in the food naturally in the form of proteins, fats etc. Understanding and manipulating such processes lead to smart and interactive food processing materials such as nanocapsules and nanoemulsions. The presence of nanodelivery systems (NDSs) in food could improve the utilization of the nutrients in the body. In this section, we provide insights into some of the NDSs investigated for their usage in food processing.

Nanoencapsulation is the process of packing the materials at nanoscale, typically for controlled delivery purposes. Generally regarded as safe (GRAS) materials and naturally occurring nanoparticles are practiced for delivery of food and other bioactive products. Typically, nanoencapsulation can be carried out by any of the following processes (a) Physical processes (e.g. Spray drying) (b) Physico-chemical processes (e.g. simple and complex coacervation) and (c) Chemical processes (e.g. Interfacial polymerization). Appropriate process for encapsulation is selected depending on the nature of the core material, desired release rate, nature of the substance that has to be encapsulated etc. Examples for nanoencapsulated products include α-lactalbumin, which is a hydrolyzed milk protein as a carrier of nutrients (Bugusu et al., 2009), casein micelles for delivery of sensitive food products (Semo et al., 2007), dextrins for bioactive products and hydrophobically modified starch to encapsulate curcumin (Yu and Huang, 2010). Lipid-based nanoencapsulation can potentially improve the solubility, stability and bioavailability, thus preventing unwanted interactions with other food components. Increase of reactive oxygen species (ROS) such as hydroxyl radical, hydrogen peroxide and superoxide in the body are proven to cause oxidative stress, which in turn can cause pathological disorders such as chronic inflammatory disease and eventually to cancer (Wiseman and Halliwell, 1996). Decrease of this oxidative stress can be accomplished by the presence of anti-oxidants in the body which can inhibit the oxidation by scavenging the ROS. Nano-encapsulation of these anti-oxidants in lipid-based nanocarriers helps in preventing the degradation of food during processing and storage and also helps in reducing the chronic disorders. Nanoliposomes, archaeosomes and nanocochleates are some of the most promising lipid-based carriers for anti-oxidants. Nanocochleates can wrap around micronutrients and has the ability to stabilize and increase the nutritional value of the processed foods (Mannino, 2003). Nano-encapsulated probiotics that could be selectively delivered to certain parts of gastro-intestinal tract might be able to modulate immune responses (Vidhyalakshmi et al., 2009). Examples of nanocapsules in the market include Tip-Top Up bread in Australia which includes fish oil in the capsules (Mazzocchi, 2011), HydraCel, a natural mineral product (≈ 5 nm in size) which reduces the surface tension of drinking water thereby improving the absorption of water and other nutrients in the body (Tonelli, 2011).

Nanoemulsions offer many advantages such as high clarity, decontamination of the food packaging equipment etc. The clarity of the nanoemulsions helps in addition of bioactives and flavors in beverages without compromising the product appearance. Single-layer, double-layer and triple-layer nanoemulsions can be produced using alginate and chitosan polyelectrolytes (Choi et al., 2011). Nanosized self-assembled liquid structures, which are expanded micelles (∼30 nm), are used in the targeted delivery of lycopene, beta-carotene, omega-3 fatty acids, co-enzyme Q10 (Garti, 2008). It is claimed that canola active oil from Shemen industries, Israel could decrease the cholesterol intake by 14% by nanoencapsulation of fortified phytosterols (Titoria and Groves, 2009).

Despite the interesting properties, the inconclusive toxicity data on the nanoparticles makes it difficult to achieve unanimous acceptance by consumers. For example, one study concluded that silver nanoparticles when combined with DNA could compromise the replication fidelity (Yang et al., 2009) while Chi et al showed that the silver nanoparticles alone has weak genotoxicity but exhibits significant toxicity when combined with a surfactant such as cetyl pyridinium bromide (Chi et al., 2009). With the increased surface area and other properties such as size, surface chemistry and solubility, the toxicity of the nano-materials might differ from the bulk material significantly (Gattiand Montanari, 2008; Nel et al., 2006). Also, a study conducted by Bermudez and coworkers indicated that there were significant differences in the pulmonary responses to ultrafine TiO2 nanoparticles between rats, mices and hamsters (Bermudez et al., 2004).This study suggests that the sensitivity nanoparticles may vary from animal to animal, thereby indicating the difficulty in generalizing the bio-effects of nanoparticles.. Although considerable research is being carried out to evaluate the nanoparticles, some concerns such as studying single size nanomaterial, administering high dosage, omitting certain biological parameters need to be addressed (Oberdorster et al., 2007). The biokinetics of certain nanomaterials which possess the ability to bind with proteins or other compounds altering their absorption profile (e.g. chitosan) (Alkhamis et al., 2008) are to be evaluated carefully. From the toxicology results so far, it is imperative that a more structured methodology has to be followed for testing of the nanomaterials. Reports from Food and Agriculture Organization (FAO) and World Health Organization (WHO) suggest that factors such as testing systems, dose metrics and clinical studies need to be considered for assessing nanotoxicology (FAO/WHO, 2010). So far, there is not much data available on the genotoxicity of the nanoparticles (Bouwmeester et al., 2009). The persistence of the nanoparticles in the body might lead to chronic effects, which could cause significant damage to the organs. This makes it important to assess the chronic effects of these particles. The other important factor for the assessment of these particles is the effect of surface area. Typically, dosage of nanoparticles is assessed based on the mass or number. However, studies show that surface area is a much better dose metric than mass, especially when comparing between different types of nanoparticles (Brown et al., 2001, Oberdorster et al., 2007). Table 4 summarizes the FAO/WHO recommended indicators to assess toxicology. Characterization of various particle properties relevant to toxicological assessment are discussed in recent publications (Powers et al., 2006, Powers et al., 2007)

| Physicochemical indicators | Biological/toxicological indicators |

| Solubility | Biopersistence |

| Particle size/size distribution | Bioavailability |

| Complexity of composition | Biocorona |

| Surface reactivity | Potential for “Trojan horse” (carriers of contaminants in the body) |

The integration of novel nanoscale materials such as gold, carbon nanotubes, Qdots into engineered systems has led to applications ranging from highly sensitive biosensors, smart delivery systems for maximizing efficiency and bioavailability in agriculture practices to their role in improving barrier properties of packaging materials, preventing contamination and delivering nutrients effectively in food products. The increased public awareness from the recent pests outbreaks in food and related health implications will necessitate stringent controls and more sensitive methods of detection, prevention and remediation-giving impetus to development of better food and crop protection technologies. Future nano-biotechnology developments would include low cost, portable, real time pathogen detection tools that can be rapidly applied in field settings, food storage and transportation facilities; remediation of pollutants and pathogens; controlling spread of pathogen using non-fouling agents and disinfectants; and more efficient crop protection delivery systems, materials and modalities.

The authors acknowledge the partial financial support of the Particle Engineering Research Center (PERC) and the Center for Particulate and Surfactant Systems (CPaSS) at the University of Florida, the National Science Foundation (NSF Grant EEC-94-02989, IIP-0749481) and the CPaSS Industrial Partners. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect those of the National Science Foundation.

Aarthi Narayanan

Aarthi Narayanan received her B.Tech. in Chemical Engineering from Sri Venkateswara University, India in 2006 and Masters of Science in Environmental Engineering from University of Miami, USA in 2010. She joined Particle Engineering Research Center (PERC) at the University of Florida as a Research Staff in 2011. Her work at PERC is focused on modification of clays and controlled release of agrochemicals.

Parvesh Sharma

Parvesh Sharma received his B.Sc. and M.Sc. in Chemistry from St. Stephen’s College, Delhi University. He completed his Ph. D. in the area of analytical coordination Chemistry from Department of Chemistry, Delhi University in 1998. He joined the Chemistry Faculty; St. Stephen’s College, Delhi University and taught for 7 years. He is currently working as Research Assistant Scientist in Particle Engineering Research Center at the University of Florida, Gainesville, USA. His areas of interests include development of engineered particulates for medicinal and agricultural applications, non-invasive imaging, multimodal-multifunctional nanoparticles, controlled release formulations, nanotoxicology, and applications of surfactants/polymers in industrial processes.

Brij M. Moudgil

Dr. Brij M. Moudgil is a Distinguished Professor and Alumni Professor of Materials Science and Engineering at the University of Florida. His current research interests are in particulate materials based systems for enhanced performance in bioimaging, nanomedicine, photocatalytic degradation of hazardous microbes, polymer and surfactant adsorption, dispersion and aggregation of fine particles and nanotoxicity.

Dr. Moudgil received his B.E from the Indian Institute of Science, Bangalore, India and his M.S and Eng.Sc.D degrees from Columbia University, New York. He has published more than 400 technical papers and has been awarded 14 patents. He is a member of the U.S National Academy of Engineering.