2017 Volume 6 Issue 1 Pages A0054

2017 Volume 6 Issue 1 Pages A0054

The development of a robust ionization source using the counter-flow APCI, miniature mass spectrometer, and an automated sampling system for detecting explosives are described. These development efforts using mass spectrometry were made in order to improve the efficiencies of on-site detection in areas such as security, environmental, and industrial applications. A development team, including the author, has struggled for nearly 20 years to enhance the robustness and reduce the size of mass spectrometers to meet the requirements needed for on-site applications. This article focuses on the recent results related to the detection of explosive materials where automated particle sampling using a cyclone concentrator permitted the inspection time to be successfully reduced to 3 s.

The threats of terrorism and criminal bombing are becoming ever more serious problems for all countries. To find hidden explosives, various types of detectors for explosives have been developed.1–3) They are classified into two categories: bulk detection and trace detection. Bulk detection includes X-ray imaging, nuclear quadrupole resonance (NQR), and neutron techniques that are used to determine the shape and size of suspicious objects in luggage, letters, packages, etc. However, bulk detection is not capable of easily identifying what the suspicious objects are. Trace detection, on the other hand, including chemical-analysis methods such as chemical luminescence,4) ion mobility spectroscopy,5–9) and mass spectrometry,10–13) has been applied to the detection of trace contaminants that are present on a passenger’s body, clothes, and luggage. Trace detection permits specific chemicals to be identified, and its selectivity is higher than that of bulk detection. However, it cannot determine the actual amount of chemicals in a suspicious item such as luggage. As mentioned above, the characteristics of bulk detection and trace detection are different. To improve security at important facilities, therefore, the combined use of bulk detection and trace detection is recommended. At current security checkpoints at most airports, not all carry-on luggage is tested by trace detector, although all luggage is examined by X-ray imaging. One of the reasons for this is that the use of a trace detector is not so popular, because its throughput is not sufficiently rapid to permit the method to be applied for all passengers and luggage. Typical test procedures for a trace detector are as follows: a security guard at a security checkpoint wipes the surface of the luggage with a wiping-sheet to collect any contaminants that are adhered to the luggage, inserts the wiping-sheet into the heating unit of the trace detector, and waits to see if the alarm of the trace detector is activated or not. The total analysis time from wiping to detection is typically 30 s per test, when applied to human screening. To shorten this inspection time, we evaluated the use of mass spectrometry because its high separation and high sensitivity might possibility lead to much higher throughput. In the mass spectrometry studies, both vapor or particle detection was used for volatile explosives or less-volatile explosives, respectively. The use of a mass spectrometer for the detection of vapor derived from explosives using various ambient ionization sources such as atmospheric pressure chemical ionization (APCI)11,13) and secondary electrospray ionization (SESI)12) ionized the vapor molecules derived from an explosive has been reported in previous studies. Ewing et al.13) reported on the detection of very low concentrations of vapor (below 25 ppq) produced by an explosive vapor using a laboratory based triple-quadrupole mass spectrometer, but a much higher sensitivity would be needed to achieve the real-time detection of less volatile explosives such as like RDX, and PETN. Many researchers who are involved in the detection of explosive are still seeking a method that is faster and more accurate in this field.

Before starting the development of systems for detecting explosives, we focussed on the development of a highly robust, miniaturized version of a mass spectrometer. A technology for on-site applications would only be acceptable if they met the user’s requirements for usability, size, cost, and related issues.

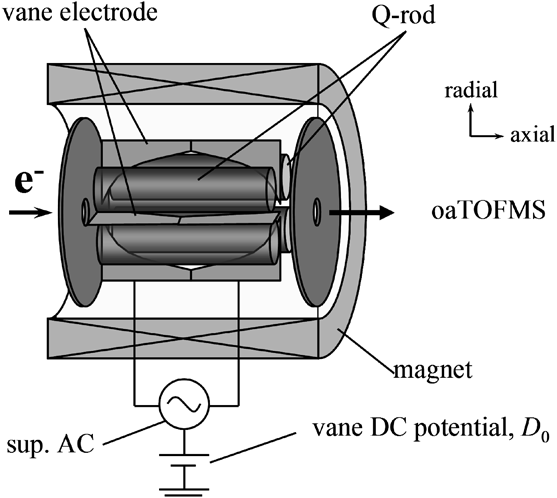

Although it was not specifically designed for detecting explosives but was originally designed for an environmental applications, i.e., monitoring dioxin precursors, we developed the counter-flow introduction APCI14,15) depicted in Fig. 1. The direction of the high-speed air opposite the electric field can avoid overlapping the secondary ionization (ion–molecular reaction) area and the NOX abundant area. Because ions are first generated by Corona discharge they do not perturb the NOX abundant area, ions that are generated first have more chances to react with target molecules like explosives. This less-overlapping configuration improved the ionization efficiency for negative ions by about 3 times. As another advantage of this configuration is that it extended the maintenance frequency to typically every 6 months; our conventional APCI ion source required irregular maintenance between a few hours and a week under this condition. We conclude that the high speed air flow prevents the deposition of dust around the tip of the needle electrode, which makes the Corona discharge much more stable. The robust ionization source has been a key technology and is deployed in our mass spectrometers for on-site applications.

Miniaturization of mass spectrometer was made for on-site applications. We aimed to develop a miniature mass spectrometer that meets, not only size requirements but also has sufficient sensitivity and selectivity for detecting explosives for purposes of trace detection. Since an ion trap has intrinsic characteristics such as small dimension, and less-strict vacuum conditions, we developed several types of linear ion trap mass spectrometers, such as an axially resonant excitation (AREX) linear ion trap mass spectrometer,16,17) and a wire type linear ion trap.18)

The AREX linear ion trap depicted in Fig. 2, inserted in a set of vane lenses between each quadrupole rod, produces ab electrostatic potential that is approximately harmonic along the central axis of the quadrupole field. After ions with a specific m/z are resonantly oscillated in the axial direction, they are mass selectively ejected in the axial direction. At a high scan rate of 11 Th/ms, the AREX achieved a high ejection efficiency of more than 60%, which is more than three times higher than a conventional mass selective axial ejection method from a linear trap using a fringing field. In contrast, CID excitation in a conventional linear ion trap is in a pseudo-harmonic radio frequency potential that destabilizes fragment ions whose m/z is less than 1/4 that of the precursor ions. ECD was achieved in an axial magnetic field of about 0.2 Tesla superimposed along the AREX linear ion trap mass spectrometer. We observed that sequential ECD/CID inside the trap improved the sequence coverage for a peptide.

In another linear ion trap, the wire type linear ion trap shown in Fig. 3, a set consisting of a trap wire lens and an extraction wire lens positioned orthogonally to each other was placed between the quadrupole rods. The trap wire lens confines the ions inside the trap, and the extraction wire axially extracts ions from the trap. The ions are resonantly excited in the direction perpendicular to the trap wire lens by applying a supplemental alternating current to the excitation lenses. Excited ions with a large motion pass over the trap wire lens, while unexcited ions remain trapped inside. Ions that have passed over the trap wire lens are then extracted by the extraction wire lens. The characteristics of mass-selective ejection with a direct current extraction field were investigated by both simulations and experiments. A mass resolving power of m/Δm=1300 was achieved at a scan rate of 500 Th/s. The dependence of ejection efficiency on trap wire lens bias was measured, and an ejection efficiency of 20% at a scan rate of 500 Th/s was achieved by optimizing the DC bias on the trap wire lens.

For producing portable mass spectrometers used in the illicit drug detection applications, we developed a mass spectrometer with discontinuous sample gas introduction.19,20) The study was intended to produce a mass spectrometer that was sufficiently compact that it would be portable and be used in an onsite analysis. The development of a small mass spectrometer required the use of a compact pump whose displacement was small, thus decreasing the sensitivity of that spectrometer. To obtain a high sensitivity with a small mass spectrometer, we integrated some novel techniques: a highly sensitive ionization source and the efficient extraction of sample vapor. The low-pressure dielectric barrier discharge ionization (LP-DBDI) source made it possible to increase the conductance between the source and the mass analyzer, compared with ambient ionization sources, thus enhancing the efficiency of ion transfer from the ionization source to the mass analyzer. We also developed a vacuumed headspace and probe heating methods for efficiently transporting the sample vapor to the ionization source. The sensitivity was also further enhanced by using a discontinuous sample gas introduction technique. A prototype portable mass spectrometer using those novel techniques was found to be sufficiently sensitive to permit the detection of 0.1 ppm methamphetamine, 1 ppm amphetamine, 1 ppm 3,4-methylenedioxymethamphetamine, and 10 ppm cocaine in a liquid. These size reduced mass spectrometers could make on-site mass spectrometry possible.

We started the development of a high-throughput explosive detection system using these component devices in 2007. We first developed a high-throughput portal system for detecting triacetone triperoxide (TATP) vapor emitted from passengers and luggage, as shown in Fig. 4.21,22) The portal system consists of a push-pull air sampler, a counter flow introduction APCI ion source, and a wire-type linear ion trap mass spectrometer. TATP signals were clearly obtained within 2 s after the subject passed through the portal system. By optimizing the shape of the nozzle that controls the air flow of the vapor sampler, TATP vapor could be detected at a high throughput, i.e., 1200 persons/hour. The false-positive rate of the detection portal system for TATP was evaluated by a field test performed at a train station. A multimarker logic to determine was adopted, and no false-positive alarms were obtained for over 3000 passengers during the field test. Moreover, acetone, which is an inflammable liquid, could be detected from the passengers during the field test. We therefore concluded from these results that this detection portal system would be useful for detecting dangerous chemicals that have high vapor pressure (such as TATP and inflammable liquids). The detection limits of the vapor portal were between the sub-ppb and ppb level, which is not sufficient to permit explosive vapors such as TNT, and RDX to be detected.

In 2010, we started another development of a high-throughput explosive detection system for detecting more comprehensive explosives including less volatile explosives such as TNT, and RDX. This detector consists of an automated particle sampler for collecting contaminants in explosives and an ion-trap mass spectrometer for analyzing them. The automated sampler, which uses a cyclone concentrator and mass spectrometer in this manner enables the rapid detection of explosives’ particles that had adhered to the surface of a synthetic leather sheet within a few seconds.23) Figure 5 shows the experimental setup of the prototype sampler, which consists of an air nozzle (inner diameter: 1.5 mm), evacuation port, cyclone particle concentrator, vaporizer, and a homemade mass spectrometer. A wire type linear ion trap mass spectrometer with counter-flow introduction atmospheric pressure chemical ionization (APCI) records the mass spectrum at a rate of about 4 spectra/s. Explosive particles are wiped off with a sampling probe, which is an aluminium rod with a diameter of 2 mm. This wiping operation was made to cover only the tip of probe with particles from the sample reservoir. Explosive particles are deposited onto a synthetic leather sheet with the sample probe. First, the explosive particles on a sheet are detached by an air jet pulse with a duration of 100 ms. Particles detached by the air jet pulse are collected from the evacuation port and then introduced into the cyclone particle concentrator. The mechanism and structure of the concentrator has been described in the literature,24) and our dimensions are given in the caption for Fig. 5. The pumping speed from the evacuation port into the concentrator is about 80 L/min. Particles accumulate near the bottom of the concentrator as the result of centrifugal wind and gravity forces. The vaporizer, which is placed at the bottom of the concentrator, has a transfer line between the concentrator and the mass spectrometer. Because the vaporizer is constantly heated at about 200°C, the explosives particles that arrive here are converted into vapor. Explosive vapor is then introduced into the mass spectrometer at a flow rate of about 1 L/min. To prevent particles from reaching the spectrometer, a metal filter with a filtration accuracy of 1 μm (Nippon Seisen Co., Ltd., Osaka, Japan) is set inside the vaporizer. Explosive particles wiped off with the sampling probe were deposited onto and directly injected into the vaporizer after removing the cyclone particle concentrator (number of trials, n=20). By comparing the calibration curve and the signal intensity at the direct injections, the amount of TNT contained in a single deposit of particles was estimated to be about 47 ng (C.V. of 24%). The weight of deposited silica (C18) particles with the sample probe was calculated to be about 47 μg by calculating the amount of TNT of 47 ng and mass fraction of 0.1%. In the following, we calculate the amounts of explosive particles from the calculated deposit particle weight of 47 μg and each mass fraction. We investigated the dependencies versus several parameters such as the nozzle gas pressure, angles of gas injections onto the object, distance between the nozzle and objects, pumping speed into the cyclone using the experimental setup. An example for determining the optimum pressure inside the jet nozzle, and the pumping speed are explained in the following. Figures 6(A) and (B) show surface images on the synthetic leather sheet before and after an air jet pulse at a nozzle pressure of 0.05 MPa is introduced. These images were taken with a fluorescence microscope after silica (C18) particles were prepared by doping with the fluorescent dye fluorescein. From the images, we calculated a detachment efficiency of 86.4%. Figure 7 shows changes in detachment efficiency against nozzle pressure. The detachment efficiency increased with the pressure increment and was saturated at more than 80% over 0.05 MPa. Since a higher nozzle pressure might spread the detached particles with a strong air flow and degrade the subsequent collection efficiency into the evacuation port, a nozzle pressure of 0.05 MPa was found to be optimum for this configuration. The detection efficiency reached a maximum value of about 20% when optimal conditions were employed. The cyclone particle concentrator enriches the explosive particles by about 80 times compared to the absence of a concentration process. Figures 8(A) and (B) show mass spectra when explosive particles were directly deposited into the metal filter inside the vaporizer using the setup shown in Fig. 5. In the negative ion mode, strong peaks originating from the explosives were observed. Molecular ions of M− with a peak of m/z 227 were dominantly observed in the TNT mass spectrum of Fig. 8(A). Unlike TNT, adduct ions of [M+NO2]− with a peak of m/z 268 were dominant in the RDX mass spectrum shown in Fig. 8(B). These spectra show that TNT and RDX particles can be vaporized with minimal fragmentation at a temperature of 200°C. We used the intensities of the dominant peaks at m/z 227 and m/z 268 for the TNT and RDX concentration index. Figures 9(A) and (B) show the signal time response after the explosive particles are exposed to an air jet pulse. An air jet pulse was injected at a timing of 1.0 s, depicted as arrows in the figures. The signal for TNT rose in about 1 s and returned to the former level in less than 10 s after the air jet pulse. The time necessary for the transportation of the particles from the sample sheet to the mesh, and the transportation time of the vapor from the mesh to the mass spectrometer are estimated to be about 50, and 100 ms, respectively. In comparison, the signal of RDX increased in 2 s and then returned to the former level in about 15 s. The time response for RDX was slower than that for TNT, which can be explained by the difference of their volatility. The vapor pressure of RDX is much lower than that of TNT,3) which means RDX is vaporized more slowly than TNT with heating. If we take 1 s of data after signal-rising as its explosive’s concentration, detection is accomplished in 2 s for TNT and in 3 s for RDX after the air jet pulse.

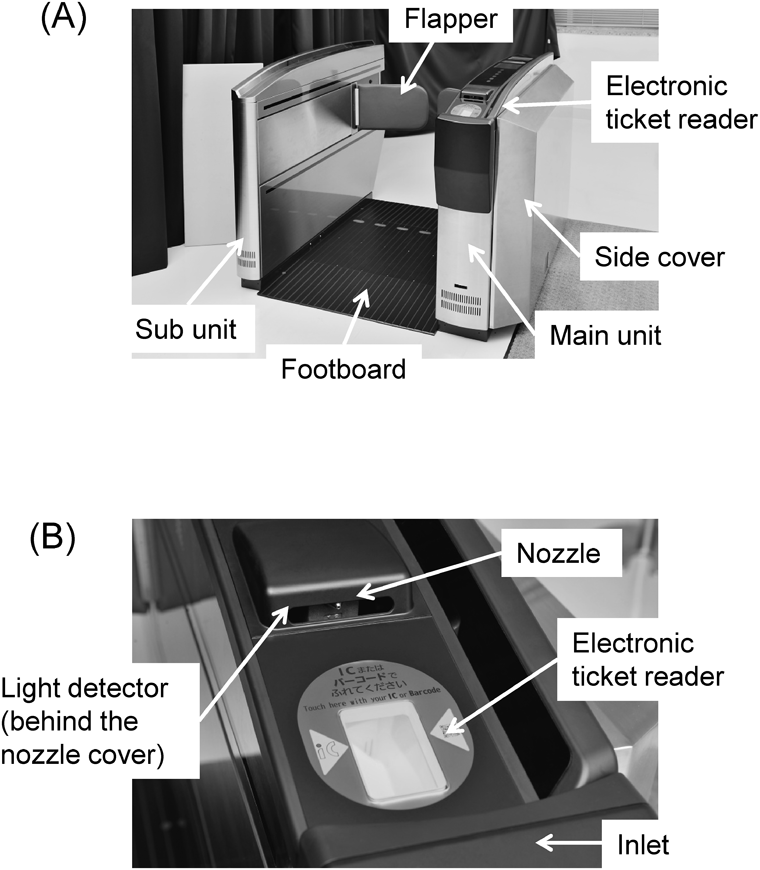

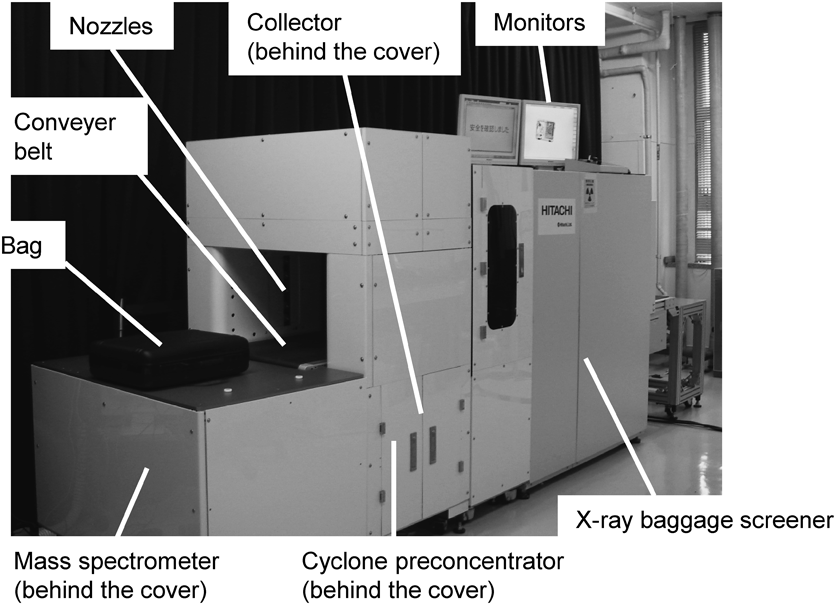

As the next step towards practical security applications of the high-throughput explosive detection system, we installed the automated particle sampler in a commercial boarding gate and baggage screener to check all passengers and baggage boarding an aircraft for traces explosives.25) We designed these prototypes using several parameters such as the nozzle gas pressure, angles of gas injection onto the object, and distance between the nozzle and objects, which we obtained in the sample testing described above. Photographs of boarding gate type are shown in Figs. 10(A) and (B). The prototype is based on a commercial boarding gate used at airports (Nippon Signal, Co., Ltd., Japan). As shown in Fig. 10(A), the boarding gate consists of a main unit, a sub unit, and a footboard. To install the particle sampler and the mass spectrometer in the main unit, the width of the side cover of the main unit is 15 cm wider than that of the original cover. The controllers of the particle sampler and the mass spectrometer are installed in the sub unit. Cables connecting the main and sub units are covered by the footboard. An air compressor (not shown in the figure) is needed to supply compressed air to the boarding gate. However, the air compressor does not always need to be located nearby the boarding gate because compressed gas may be supplied via a long tube. An enlargement of the electronic-ticket (e-ticket) reader is shown in Fig. 10(B). When a passenger places his/her IC-card or e-ticket on the reader, an air jet is emitted from the nozzle. Particles that had adhered to the e-ticket and/or the passenger’s hand are blown by the jet and collected by the inlet. The main challenge to installing the detectors into a gate system is the simultaneous detection of various explosives. We carried out the simultaneous detection of TNT and TATP as an example where the switching of the ionization polarity to detect nitro-compounds (which have strong electron affinity) and peroxides (which have a strong proton affinity) was confirmed. To change the polarity of the ion source and the mass spectrometer, the interval between the negative and positive mass analysis was set to 0.3 s. The simulants of TNT and TATP particles that had adhered to the surface of the plastic card, and the plastic card was tested by the boarding gate set up. The results for detecting TNT and TATP are shown in Fig. 11. The data acquisition frequency in the case of the polarity switching analysis was expanded from every 0.25 s in the case of only the negative mode to every 0.9 s, but the signals for TNT and TATP were clearly obtained, as shown in Fig. 11. The findings reported herein show that the high-throughput detection for both positive and negative ionized explosives could be performed within 3 s after a passenger places his/her IC-card or e-ticket on the reader. For baggage screening, on the other hand, the trace-explosives detector was combined with a conventional X-ray baggage screener shown in Fig. 12. When a bag is put on the conveyor belt of the automated particle sampler, compressed air jets are emitted from nozzles. The trace analysis is finished, while an X-ray image of the bag is being obtained by the X-ray baggage screener. In both security equipment cases, the simulated TNT, RDX, and TATP particles that adhered to the detection targets were successfully detected. Accordingly, the developed security equipment will be useful tools for improving airport security in the near future.

This article summarizes the development of an MS-based system for detecting explosives. The instrument includes a counter-flow introduction APCI, a miniature mass spectrometer, and an automated sampling explosive detector system combined with these component devices. These developments have been ongoing for nearly 20 years in order to realize on-site mass spectrometry. Counter flow introduction APCI enhances robustness, ion trap development reduces the size of the mass spectrometry, permitting it to meet the requirements needed for on-site application. The detection of explosives at the level of the boarding gate and baggage screener were demonstrated, where the automated particle sampling using cyclone concentrator successfully reduced the inspection time and labour-intensive sampling process.

Mass Spectrometry Society of Japan bestowed the MSSJ AWARD for Technical Development 2016 on the author. This is an invited review of the achievement.

The article is a review of “Development of miniature mass spectrometer and automated sampling explosive detector,” that was awarded by MSSJ AWARD for Technical Development 2016. The author wishes to thank the Mass Spectrometry Society of Japan (MSSJ), co-authors, and many collaborators involved in the research. This work was partially funded by R&D Program for Implementation of Anti-Crime and Anti-Terrorism Technologies for a Safe and Secure Society, and Strategic Funds for the Promotion of Science and Technology of the Ministry of Education, Culture, Sports, Science and Technology, the Japanese Government.