Abstract

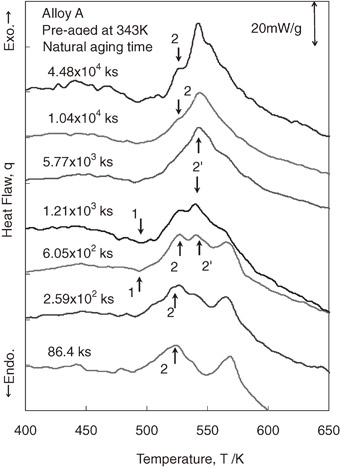

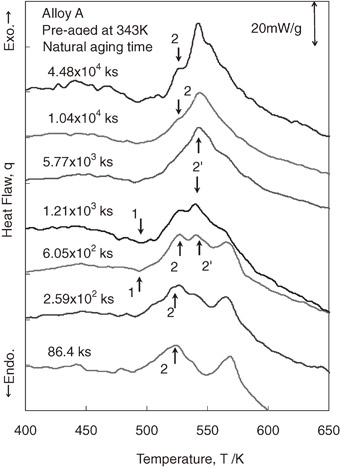

In the present paper, the effects of natural aging on the bake hardening behavior of four Al–Mg–Si alloys, i.e., Alloy A (Al–0.6Mg–0.6Si) (mass%), Alloy B (Al–0.6Mg–1.0Si), Alloy C (Al–1.0Mg–0.6Si) and Alloy D (Al–1.0Mg–1.0Si), were investigated by means of Vickers hardness test, tensile test, differential scanning calorimetry analysis (DSC) and transmission electron microscopy (TEM). Two kinds of nanoclusters, i.e., Cluster(1) and Cluster(2) were controlled with the multi-step aging process. As the results, it was found that Cluster(1) formed during natural aging caused the decreased bake hardening response even though the pre-aging was conducted before natural aging. The decrease of the bake hardening response with increasing the natural aging time was markedly higher in the later stage of bake hardening than in the early stage. Exothermic peaks of Peak 2 and Peak 2′ were observed in all of four alloys pre-aged at 343 and 363 K. Peak 2′ became larger with the natural aging time. The size distribution of the β″ precipitates became wider with the natural aging time for Alloy A heated up to the temperature of Peak 2′. This is well understood by the following model. The transition from Cluster(2) formed during pre-aging to β″ occurs preferentially at the early stage of bake hardening or during heating up to the temperature of Peak 2. Then the growth of β″ is inhibited by the presence of Cluster(1) at the later stage of bake hardening. The secondary nucleation of β″ occurs just after the dissolution of Cluster(1) into the matrix during heating up to the temperature of Peak 2′. The combined formation of Cluster(1) and Cluster(2) by the multi-step aging essentially affects the BH response and the β″ precipitates in Al–Mg–Si alloys.