Abstract

In this study we deposited Sn-3.0Ag-0.5Cu solder alloy as a bonding material in lead-free soldering by utilizing inkjet printing to improve the electrical interconnections of solar cell modules. Sn-3.0Ag-0.5Cu solder was successfully printed to bond thin-film solar cell modules. The improved interface wetting behavior between the adhesive surface of the aluminum electrode and lead-free solder joints in silicon thin-film solar cell modules was investigated with respect to reflowing at 240°C for 30 s by using an optical microscope and mean contact angle. The results show that the peel strength of the Sn-3.0Ag-0.5Cu solder alloy is better than that of silver paste when the dot spacing of solder droplets is lower than 200 µm (a density of over 50 µg/mm2). The findings also show that the contact resistance of the solder alloy is better than that of silver paste when the dot spacing of solder droplets is lower than 100 µm. This results in a low power loss of solar cells of 1.1%, and a good photovoltaic conversion efficiency of over 8.3%. This study thus demonstrates the feasibility of decreasing the efficiency loss of solar cells by employing the proper spacing of lead-free solder droplets by inkjet printing.

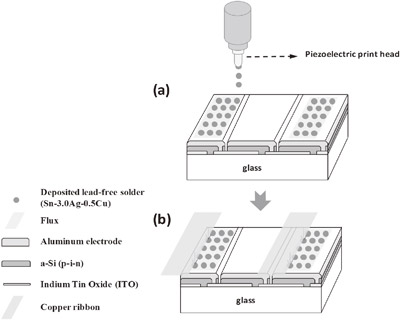

Figure 4. Schematic illustration of bonding processes of Sn-3.0Ag-0.5Cu solders for thin-film solar cell modules by utilizing the inject-printing method. (a) Deposition of Sn-3.0Ag-0.5Cu solder on the aluminum electrode of a thin-film solar cell substrate. (b) The connection of the aluminum electrode and the copper ribbon by re-melting the lead-free solder with a temperature of 250°C for 60 seconds.

Fullsize Image