2017 Volume 58 Issue 8 Pages 1150-1154

2017 Volume 58 Issue 8 Pages 1150-1154

Ultra-high-molecular-weight polyethylene (UHMWPE) is used as a bearing material in total joint prostheses. One of the criterion that determines the strength of medical UHMWPE is its tensile properties. However, its compressive properties, which play an important role in determining the durability of the contact surfaces of prostheses, have not yet been considered. In this study, we examined the effect of gamma and electron beam irradiation treatment on the compressive properties of medical UHMWPE. The compressive properties (Young's modulus and proof stress) of the gamma-irradiated specimens were higher than those of the nonirradiated specimens. The plastic flow pressure of the electron-beam-irradiated specimens was higher than that of the nonirradiated specimens. The inhibition of plastic deformation of the noncrystalline structure due to electron beam irradiation is considered to have increased the plastic flow pressure. The electron beam irradiation treatment was found to be effective for the surface enhancement of medical UHMWPE. An electron spin resonance signal was clearly observed in the irradiated UHMWPE specimen. These results indicated that dangling bonds were probably formed in the irradiated UHMWPE.

This Paper was Originally Published in Japanese in J. Japan Inst. Met. Mater. 80 (2016) 192–196.

Ultra-high-molecular-weight polyethylene (UHMWPE) is used as a bearing material in artificial joints. The crosslinking of UHMWPE enhances the material life, and hence, crosslinked UHMWPE is used as a standard material for the cup of artificial hip joints and the tibial insert of artificial knee joints.

Irradiation with gamma rays and electron beams (EBs) is a standard method for crosslinking UHMWPE1). In particular, UHMWPE used for medical purposes is generally sterilized by gamma irradiation or ethylene oxide gas treatment. It is well known that the molecular structure of UHMWPE changes with exposure to gamma irradiation, and consequently, its mechanical properties change2). Furthermore, multiple free radical species3) are generated in UHMWPE over time because of gamma irradiation, and the crosslinking points and oxide ratios produced by the generation of free radical species are expected to undergo complex changes according to the irradiation conditions.

The expected dynamic properties of medical UHMWPE at the time of production are prescribed by standards such as ASTM F648 and ISO 5834 and evaluated by tensile tests4). In the case of artificial joints, the durability of the contact points of joints is an issue, and the compressive properties of the material should be evaluated. In addition, because fractures on the articular surface of artificial joints are caused by local compressive stress, the plastic flow stress, which is obtained by indentation hardness testing, can be used as a standard for analyzing fracture5,6). However, the effect of irradiation on the compressive properties and plastic flow stress of UHMWPE has hardly been evaluated so far.

Therefore, this study examined the effect of irradiation with gamma rays and EBs on the dynamic properties, including the compressive properties and plastic flow stress, of medical UHMWPE.

The test specimens used in this experiment were prepared by machining a molded rod of medical UHMWPE (GUR 1020), as shown in Fig. 1. The gamma-ray source was 60Co, and irradiation treatment was performed at an exposure rate of 8 kGy/h at room temperature in air. EB irradiation was applied using an electrocurtain processor (Type CB/175/15/180L, Iwasaki Electric Co., Ltd.)7) under the following conditions: an acceleration voltage of 170 kV and an irradiation current of 2.0 mA in nitrogen atmosphere (oxygen concentration: 400 ppm or less) at atmospheric pressure. The penetration depth of an EB was estimated to be 230–360 μm8–10) according to the method described by Sato et al.7)

Preparation of specimens from UHMWPE rod.

Doses were set to 25 and 200 kGy, and the irradiated specimens were kept at room temperature and atmospheric pressure in darkness.

2.2 Compression testThe effects of irradiation on Young's modulus and 0.2% proof stress because of compression were examined by a method to obtain the plastic compressive properties (JIS K7181). The dimensions of the test specimens were 10 × 10 × 4 mm, as shown in Fig. 1, and an EB, whose penetration power is less than that of a gamma ray, was applied to the specimen sides measuring 10 × 10 mm. The thickness of the specimens was 4 mm, and the surface region was modified up to a depth of approximately 230–360 μm by irradiation. Therefore, the dynamic properties of the specimens were expected to improve. The compression test was performed using a universal testing machine (LSC-2/200-SP, Tokyo Koki Co., Ltd., load capacity: 2 kN) at a compression speed of 5 mm/min in air at room temperature.

Figure 2 shows the stress–strain curves obtained from the compression test results. The test was stopped when the test specimens experienced buckling deformation, and then, the specimens were forced out of the compression end plate after the maximum load was reached. Because all the specimens showed linear trends in the range of 3–10 MPa, their Young's moduli were evaluated as the slope within this range.

Stress-strain curves of gamma and electron beam irradiated UHMWPE.

An indentation test was performed to examine the effect of irradiation on the plastic flow stress. The dimensions of the test specimens were 50 × 50 × 10 mm, as shown in Fig. 1, and the side measuring 50 × 50 mm was treated by irradiation. A ball bearing measuring 28 mm in diameter was pressed on to the treated side at a specified load of 1.8 kN and a test speed of 5 mm/min in air at room temperature. The indenter was held in position for 1 min after the load reached the specified value, and then, the specimen was removed from the testing machine, following which the diameter of the indentations was measured using a Vernier caliper. The indenter was pressed into one side of the test specimens at five points such that the indentations did not interfere with each other, as shown in Fig. 1.

The plastic flow stress6) was calculated by dividing the load by the area obtained from the diameter of the indentation. The depth of the indentation was found to recover to approximately 50% of the maximum depth immediately after the test.

2.4 Radical measurement by electron spin resonanceFree radicals are generated in UHMWPE in response to gamma or EB irradiation, which cleaves C–C and C–H bonds. To confirm the presence of dangling bonds in UHMWPE, electron spin resonance (ESR) analysis was performed using an ESR spectrometer (JES-FA200, JEOL Ltd.). The samples to be analyzed were collected from the irradiated surface of the test specimens as the sample dimensions became smaller than 8 × 2 × 2 mm. The collected samples were placed in a quartz sample tube and subjected to ESR measurements with X-band (frequency: 9.45 ± 0.05 GHz) at a magnetic field modulation of 0.1 MHz at room temperature. The microwave power was 1.0 mW, and the measurement range of the magnetic field was 317–327 mT11).

2.5 Statistical evaluationA statistical test was performed to determine the difference in the average of the dynamic properties between nonirradiated and irradiated specimens. First, homoscedasticity was tested by performing an F-test. If variances were assumed to be equal, the result of Student's t-test was accepted, and, if variances were assumed to be not equal, the result of Welch's t-test was accepted. The level of significance was 5%.

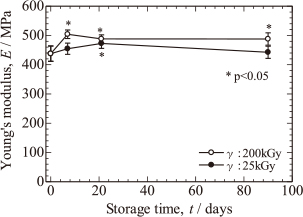

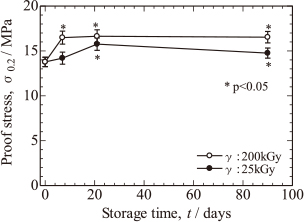

Figures 3 and 4 show the relationship of the storage time after gamma irradiation with Young's modulus and 0.2% proof stress, respectively. The storage times were denoted as Day 0 (nonirradiated), Day 21, and Day 90. Each plot shows the average value, and the error bars indicate standard deviations. Asterisks are included in the upper or lower parts of the error bar of each plot to denote cases where a significant difference (p < 0.05) was found between the average values of the nonirradiated and irradiated specimens.

Young's modulus vs. storage time of gamma irradiated UHMWPE.

Proof stress vs. storage time of gamma irradiated UHMWPE.

Young's modulus of all specimens increased after gamma irradiation. Furthermore, Young's modulus increased by up to 8% at a dose of 25 kGy and by up to 15% at 200 kGy, which clearly shows the effect of the dose.

The results for the 0.2% proof stress are similar to those for Young's modulus. The 0.2% proof stress increased by up to 14% at a dose of 25 kGy and by up to 21% at 200 kGy. At 25 kGy, the 0.2% proof stress attained its maximum value at Day 21 and then decreased until Day 90, whereas at 200 kGy, the stress remained almost constant within the storage times considered in this experiment.

Similar to Figs. 3 and 4, Figs. 5 and 6 show the relationship of the storage time after EB irradiation with Young's modulus and 0.2% proof stress, respectively. Again, the storage times were denoted as Day 0 (nonirradiated), Day 21, and Day 90. No marked changes were found after EB irradiation, and no statistically significant differences were found in Young's modulus and 0.2% proof stress.

Young's modulus vs. storage time of electron beam irradiated UHMWPE.

Proof stress vs. storage time of electron beam irradiated UHMWPE.

Figure 7 shows the relationship between the storage time after irradiation and the plastic flow stress. The storage times were denoted as Day 0 (nonirradiated), Day 21, and Day 90. Each plot shows the average value, and the error bars indicate standard deviations. Asterisks are included in the upper or lower parts of an error bar in each plot to denote cases where a significant difference (p < 0.05) was found between the average values of the nonirradiated and irradiated specimens.

Plastic flow pressure vs. storage time of gamma and electron beam irradiated UHMWPE.

After gamma irradiation, the plastic flow stress did not change on Day 21 but significantly increased by 6.6% at 25 kGy and by 11% at 200 kGy on Day 90. However, after EB irradiation, an increasing trend was found at a lower dose of 25 kGy compared to a dose of 200 kGy for the gamma rays.

3.3 Change in ESR spectraFigure 8 shows the ESR spectra of the specimens treated by gamma irradiation at 25 kGy. Because no ESR signals were observed in sample (a), which was nonirradiated, it was inferred to not contain dangling bonds. However, ESR signals were observed in samples (b)–(f), which were treated by gamma irradiation. Hence, these samples were inferred to contain dangling bonds. In addition, the dangling bonds tended to increase over time.

ESR spectra on gamma irradiated UHMWPE: (a) untreated, (b) 7 days, (c) 21 days, (d) 90 days, (e) 130 days and (f) 180 days after irradiation, respectively.

Spectrum (b) on Day 7 shows the characteristics of allyl radicals, whereas spectra (c)–(f) after Day 7 show the characteristics of peroxy radicals12).

Figure 9 shows the ESR spectra of the specimens treated by EB irradiation at 25 kGy. A weak ESR signal was observed in sample (c) on Day 21 after irradiation treatment, suggesting the formation of dangling bonds.

ESR spectra on electron beam irradiated UHMWPE: (a) untreated, (b) 7 days and (c) 21 days after irradiation, respectively.

Polyethylene is classified into crosslinking polymers. The following facts about the radiation of polymeric materials are generally well known13,14).

Because of the cleavage of C–C and C–H bonds by irradiation, free radicals including allyl and peroxy radicals are generated. Reactions between the free radicals promote C–C and ester crosslinking and produce three-dimensional structures in which molecular chains are restrained and difficult to deform. As a result, the tensile strength and Young's modulus increase. However, reactions between free radicals and oxygen molecules produce aldehydes and ketones, which are not involved in crosslinking and lead to the deterioration of the materials. In this case, defects are produced by the cleavage of molecular chains and fractures originate from the defects. Therefore, the tensile strength decreases.

The extent of crosslinking increases with the dose. Lee et al.15) reported that the maximum EB irradiation that can promote crosslinking in amorphous regions is 250 kGy. Therefore, this study adopted doses of 25 kGy and 200 kGy, which were expected to enhance crosslinking.

It is assumed that Young's modulus and 0.2% proof stress increased significantly up to Day 21 after gamma irradiation because of the promotion of crosslinking. On Day 90, Young's modulus and 0.2% proof stress showed a decreasing trend at a dose of 25 kGy. This trend was attributed to the material becoming brittle because of the reactants produced by the reactions of free radicals that did not lead to crosslinking, as described above.

Because the intensity of the ESR signals attributable to the free radicals in the samples exposed to 200 kGy irradiation increased markedly compared to those in the samples exposed to 25 kGy irradiation, more free radicals were generated in the samples exposed to 200 kGy irradiation than the samples exposed to 25 kGy irradiation. It was supposed that oxidation products generated during long-term storage had little influence. Thus, almost no changes were found in Young's modulus and 0.2% proof stress, and the characteristic values were maintained because the promotion of crosslinking was significant.

In the case of EB irradiation, Young's modulus and 0.2% proof stress showed increasing trends. However, it was assumed that the number of free radicals generated in the EB-irradiated specimens was lower than that generated in the gamma-irradiated specimens because the EBs did not penetrate as deeply as the gamma rays and thus had less influence on the specimens. Therefore, the extent of crosslinking was lower, and the increase in the values of the dynamic properties was also smaller than that in the case of the gamma-irradiated specimens.

The plastic flow stress increased because of irradiation. In particular, the plastic flow stress of the samples treated by EB irradiation at 25 kGy increased markedly compared to the samples treated by gamma irradiation, although the region influenced by the EBs was small. It was assumed that approximately (230–360)-μm-thick EB-modified parts were formed at the surface of the test specimens. In other words, the increase in Young's modulus and strength in the vicinity of the surface of the test specimens because of crosslinking due to EB irradiation suppressed the plastic deformation of the amorphous regions.

Several studies have been conducted on the ESR of free radicals formed in UHMWPE by irradiation3,16,17). However, because the generation of radicals depends on the irradiation conditions and changes in a complicated manner over time, the identification of radical species and the determination of radical concentrations are difficult.

An allyl radical generated by irradiation and storage in air is assumed to be a relatively long-lived species that exhibits septuplet spectra. These spectra increase after relatively short-lived alkyl radicals (sextuplet) formed in the early days decrease over several weeks.

In this study, the identification of radical species and the determination of radical concentrations from ESR spectra were not performed because this study was primarily aimed at confirming the presence or absence of free radicals. However, the ESR spectra of the gamma-irradiated specimens were similar to those of the allyl and peroxy radicals generated by gamma irradiation in a tibial component of an artificial knee joint, as reported by Jahan et al.12) In addition, the results of studies on time-dependent changes in free radicals performed by Nakamura et al.16) and Zhao et al.17) indicated that the generation of allyl radicals was thought to begin on Day 7 after irradiation and that of peroxy radicals was thought to begin on or after Day 21.

In this study, UHMWPE used for medical purposes was treated by irradiation with gamma rays and EBs. During the irradiation, changes in Young's modulus and 0.2% proof stress were examined by a compression test and those in the plastic flow stress were examined by an indentation test because these properties were not sufficiently evaluated previously. The results indicated that the compressive properties of the gamma-irradiated specimens showed higher values than those of the nonirradiated ones.

The plastic flow stress of the EB-irradiated specimens exhibited higher values than that of the nonirradiated specimens. The increase in the plastic flow stress because of EB irradiation was assumed to be due to the suppression of the plastic deformation in amorphous parts by crosslinking. This result indicates the EB irradiation treatment is an effective method for strengthening the surface of medical UHMWPE.

Furthermore, ESR analysis was performed to confirm the presence of dangling bonds generated by irradiation. Because the irradiated samples exhibited ESR signals attributable to free radicals, dangling bonds were probably present in the UHMWPE specimens.

In the future, solid-state nuclear magnetic resonance analysis will be performed to clarify the relationship between the change in dynamic properties due to irradiation and the molecular structure of UHMWPE.

We would like to thank Mr. Ryo NOMURA and Mr. Arata YAGI of Nishi Laboratory, Department of Materials Science, Tokai University, for their assistance with electron-beam irradiation experiments.