2018 Volume 59 Issue 7 Pages 1101-1105

2018 Volume 59 Issue 7 Pages 1101-1105

The traditional nano preparation method is costly and time-consuming, and contains hazardous chemical constituents, thus affecting the characteristics and applications of nanocolloid. The Electrical Spark Discharge Method (ESDM) used in this paper prepares Nano-Ag colloid in deionized water, which is characterized by low cost, continuous and rapid production, and is free of chemical substances. According to the UV-Vis analysis of Nano-Ag, it has a peak at about 392 nm. Based on Zetasizer analysis, the minimum size is distributed below 50 nm, and the zeta potential is about −35 mV which the value of pH is almost equal to 7, proving its good suspension stability. According to the results of SEM, Nano-Ag colloid prepared by ESDM has nanoscale particles, and the constituent is Ag only. As this method is free of any surfactants and chemical agent, the Nano-Ag is added in the human body by imitating agar, and coated with Niger, the Nano-Ag restrains the growth of Niger. The higher the concentration of Nano-Ag, the stronger the inhibitory effect on the growth of Niger.

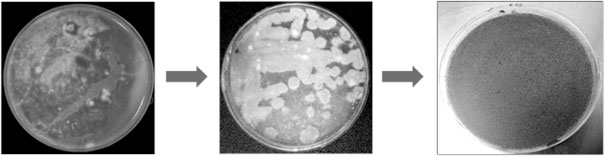

Fig. 7 1-Niger smeared on (a) 100%NanoAg-Agar (b) 10%NanoAg-Agar (c) 1%NanoAg-Agar.

The known materials are mostly composed of nano or finer atoms. The application of the small material is very extensively, and its characteristic is different from macroscopic. Nanotechnology has technical secondary classification in biological, physical, and chemical fields. The nanometer is a measurement unit of length, where one nanometer is one billionth of a meter1). In 1959, Physicist Feynman proposed the concept of nanotechnology in his famous lecture :There's Plenty of Room at the Bottom“ at the California Institute of Technology. The term nanometer did not exist at that time, and Feynman's address gave people a preliminary comprehension of nanotechnology2). Later, the invention of Scanning Tunneling Microscope (STM) enabled scientists to clearly observe nanoparticles. The invention of STM is regarded as an important milestone of nanotechnology.

Nanotechnology continues to advance, and involves complicated processes and applications3). At present, there are two kinds of nano preparation methods: chemical methods and physical methods4). The chemical methods include the vapor deposition process, the precipitation method, the electrochemical reduction method, etc5). The physical methods include thermal evaporation, the physical crushing method, magnetron sputtering, etc6,7). The chemical reduction method is the most extensive among the chemical methods. It uses a reducer for direct reduction or irradiation reduction of metals. Thermal evaporation is the most familiar among the physical methods, in which it directly heats the sample to gas, and gasified sample condenses on the outer layer of a swivel plate full of liquid nitrogen, thus, directly forming nanoparticles8). In terms of application, Nano-Ag-based applications are common. For example, the “invisible” effect of Ag because of the high reflection and low emission for far infrared ray, circuit board production, and the process of multilayer ceramic passive components9). Ag is a common and stable metal in daily life. In the distant past, people made Ag into Ag ornaments, wares, or currency. There are diversified Nano-Ag antibacterial products10–12), and opinions continue to differ on the antibacterial mechanism of Nano-Ag. It is generally agreed that Nano-Ag disturbs the synthesis of cell walls, damages cell membranes, and inhibits the synthesis of protein. Nano-Ag particles continuously release Ag+ in the solution, and these Ag+ are the major antibacterial factor. It is compared to “permanent germicide” for long-term antibacterial effect.

Electric Spark Discharge Method (ESDM) is characterized by low cost, continuous and rapid production, and is free of chemical substances. It is a physical methods to fabricate nanoparticles such as Au, Ag, Cu, etc13,14). And according to the analysis of the experimental apparatus, the particles are all nano-scaled. But it is seldom discuss the application of the “green” nanoparticles as in this paper. Ag can inhibit the growth of Niger but the Ag is prepared in chemical method. This study focuses on the first application of the ESDM fabricating the Ag colloid in the inhibiting the growth of Niger.

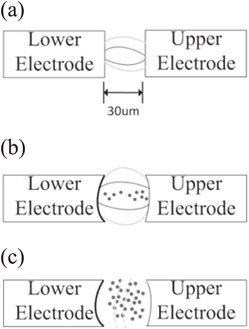

Figure 1 shows the structural representation of ESDM15). The nanometal preparation parameters can be adjusted on the control panel, such as the discharge pulse width, magnitude of the current, high/low voltage, and with/without capacitance. The discharge pulse width (including discharge time (TON) and off time (TOFF)) and magnitude of current Ip on the electrical discharge machine are controlled16). The electric spark is generated when the gap between the upper and lower metal electrodes is 30 um, and the high temperature electric spark melts the electrode surface to generate nanometal particles. There is a servo control system in the electrical discharge machine system, and when the electrodes are short circuited or open circuited, the upper and lower electrodes are separated or closed to each other, thus, the upper and lower electrodes are kept 30 um apart. The upper and lower electrodes are Ag in this paper. The beaker contains deionized water (DI water) and a magnet, and the magnetic stirrer stirs the magnet in the beaker to disperse the nanoparticles in the DI water17,18). As ESDM is dedicated to be a green method, there are only DI water, magnetic stirrer and electrodes in the beaker19). There is no other elements like reagent.

Structural representation of ESDM.

Figure 2 shows the principle of ESDM. The upper and lower electrodes are connected to tens to hundreds of V DC voltage. When the electric field intensity is higher than the insulating strength of the dielectric fluid (DI water in this paper), there is an electric spark between the electrodes, i.e. the arc, as shown in Fig. 2(a). The heat energy temperature is 5000~6000 K at the moment of discharge20), which melts the metal of the electrode surface, as shown in Fig. 2(b). The molten metal is cooled rapidly by the peripheral DI water at normal temperature, in order to form nano-scale fine particles, as shown in Fig. 2(c).

Principle of ESDM.

Aspergillus niger (Niger) is a type of filamentous fungus able to grow on various materials, such as air, soil, etc. Its growth area is very extensive, and it is the most abundant species in nature21,22). Niger is grown with a little nutrition and a great deal of oxygen. Niger infection can cause pulmonary disease, skin injury, and allergy. The secondary metabolite generated by Niger-ochratoxin A is carcinogenic. The Niger used in this paper is provided by the Bioresource Collection and Research Center (BCRC); the Niger of pure strain is to be cultured twice before using, and all experimental processes shall proceed on a sterile console23).

Malt Extract Agar (MEA) is a good habitat for Niger, and its preparation process is as followings. First, 33.6 g/L Malt Extract Agar, 0.1 g/L Chloramphenicol, and 1 L deionized water are weighed by microbalance and mixed in a beaker. Chloramphenicol is a bacterial inhibitor. The mixed culture medium is heated by heating magnetic stirrers to 90℃ and stirred continuously, in order to dissolve the MEA in liquid. The beaker is sterilized in an Autoclave. Finally, in the Aseptic Technique, the solution is poured in the culture dish, and the MEA is obtained when the yellow liquid turns into a colorless colloid. All the MEA should store in a refrigerator. A MEA needs to be placed in an incubator at constant temperature and humidity, and it needs to be observed for several days. If there are fungi, meaning this lot of MEA is contaminated, it needs to discard. As the MEA's pH < 5, it is adverse to the growth of bacteria, which is likely to be inhibited. While the fungi grow slowly, they are free from the effect of pH < 5. Several days later, the mature fungi successively secrete antibiotics, thus, bacteria cannot grow. Therefore, using MEA as a culture medium can reduce the interference of bacteria, rendering it suitable for cultivating fungi24).

When the MEA is prepared, the pure Niger, as provided by BCRC, is smeared on the MEA, which grows into the first offspring. As the first offspring strain may be pure genus, but not pure species, and affected by other microorganisms, it is not suitable for research. When the second offspring Niger is cultured, the Niger is washed off with 0.05% Tween80, and placed in the beaker. Tween80, also known as polysorbate, is a sort of non-ionic surfactant, which is soluble in water freely, and can be used as an emulsifier25). Its main function is to moisten spores in order that the spores are likely to be washed off. The DI water is mixed with Tween80 in this study to prepare 0.05% Tween80 as the Niger cleaning fluid. When the Niger grows, it is initially a white colony, then turns yellow, and finally, it becomes dark yellow and black spores, as shown in Fig. 3.

Niger growth process.

In order to test the bacteriostatic effect of Nano-Ag colloid at different concentrations made by ESDM, the Nano-Ag colloid prepared by ESDM is diluted into two concentrations: 10% and 1%. In terms of the dilution process, 10 g of the Nano-Ag colloid (100%) prepared by ESDM is placed in the beaker, and mixed with 90 g DI water to obtain 10% Nano-Ag colloid; the 1% Nano-Ag colloid is prepared in a like manner. The DI water for preparing MEA is replaced by 100%, 10%, and 1% Nano-Ag colloid, and the other materials and preparation methods are identical, in order to prepare Nano-Ag culture media (NanoAg-Agar) at different concentrations. The NanoAg-Agar concentrations are described, as follows:

All the NanoAg-Agar is sealed with parafilm and placed in the refrigerator. The NanoAg-Agar at each concentration is placed in the incubator at constant temperature and humidity, and whether there are fungi is observed several days later. If there are fungi, meaning this lot of NanoAg-Agar is contaminated by fungi, it is discarded. In order to avoid the colony counts growing too fast to be observed due to too high concentration of Niger, the solution, after the Niger is washed off with 0.05%Tween80, is regarded as 100%, and the 100%Niger is diluted to 10% and 1% solutions. The 100% Niger is abbreviated to 100-Niger; the 10% Niger is abbreviated to 10-Niger; the 1% Niger is abbreviated to 1-Niger.

In the preparation of Nano-Ag by ESDM, this study uses UV-Visible Spectroscopy (UV-Vis), Zetasizer, and Scanning Electron Microscope (SEM) to analyze the characteristics of Nano-Ag26,27). The analysis results of the precision instruments prove that the Nano-Ag prepared by ESDM is a nano-scale product, as shown in Fig. 4. The parameter settings for Nano-Ag preparation are shown in Table 1. At normal temperature and pressure, the processing time is set as 90 seconds, the voltage and current are 140 V and level 4, the discharge pulse width (TON-TOFF) is 50-50 us. The upper and lower electrodes are silver wire at purity of 99.99% and in diameter of 1 mm. The Nano-Ag is generated in 250 ml DI water as dielectric fluid.

Result of ESDM prepared Nano-Ag (a) UV-Vis (b) Size distribution (c) zeta potential (d) SEM.

Nano-Ag prepared by ESDM is analyzed by UV-VIS, and the analysis result is as shown in Fig. 4(a). It is observed that, there is a super high peak of about 0.058 when the wavelength is 392 nm. The size distribution and zeta potential of nanoparticles are measured by Zetasizer, as shown in Fig. 4(b) and Fig. 4(c). It is observed that, while the Nano-Ag has particles below 100 nm, the nanocolloid particles prepared by ESDM are in different sizes, thus, it is likely to generate large nanoparticles in the process of ESDM. The absolute peaks of zeta potential are greater than 30 mV, meaning the Nano-Ag prepared by ESDM has good suspension stability, and can suspended in DI water for the long-term28). Because the dielectric fluid is DI water so the value of pH is almost equal to 7. The zeta potential has different peaks. The reason is that experiment is conducted in DI water and analyzed right after the nano-Ag by ESDM is fabricated. This is more precise in this method. In this case, different sizes of the nanoparticles and the oxide cause the results. Finally, the SEM result shows the shape and size, as shown in Fig. 4(d). It is observed that the Nano-Ag particle size is less than 100 nm, is actually on the nano-scale, and the particle shape is circular29).

3.2 Nano-Ag inhibits NigerThe Nano-Ag prepared by ESDM is used for experiments of inhibiting Niger. The 100-Niger, 10-Niger, and 1-Niger are smeared on the NanoAg-Agar at different concentrations on the sterile console, respectively, sealed with parafilm, and cultured in a temperature control box. Several days later, the inhibition of Niger by Nano-Ag colloid is obtained, as shown in Figs. 5–7. Figure 5 shows the 100-Niger smeared on (a) 100%NanoAg-Agar; (b) 10%NanoAg-Agar; (c) 1%NanoAg-Agar. Figure 6 shows 10-Niger. Figure 7 shows 1-Niger. Figure 5(a), Fig. 5(b), and Fig. 5(c) are compared, and the colony counts are (a)>(b)>(c). In Fig. 6, the colony counts are (a)>(b)>(c). In Fig. 7, while the colony counts are approximately equivalent, the number of colony counts is reduced slightly in Fig. 7(a). According to the above colony counts comparison result, Nano-Ag colloid can inhibit the growth of Niger. The higher the Nano-Ag colloid concentration, the less the colony counts of Niger. In terms of the growth condition of Niger, only the white colony is grown out. There is no yellow or black spore, meaning the growth of Niger has been inhibited by Nano-Ag colloid.

100-Niger smeared on (a) 100%NanoAg-Agar (b) 10%NanoAg-Agar (c) 1%NanoAg-Agar.

10-Niger smeared on (a) 100%NanoAg-Agar (b) 10%NanoAg-Agar (c) 1%NanoAg-Agar.

1-Niger smeared on (a) 100%NanoAg-Agar (b) 10%NanoAg-Agar (c) 1%NanoAg-Agar.

This study used ESDM to successfully prepare Nano-Ag that is characterized by low cost, and is free of chemical substances. The Nano-Ag can restrain the Aspergillus Niger on the agar. This paper focuses on the first application of the ESDM fabricating the Nano-Ag colloid in the inhibiting the growth of Niger. The contributions of this study are detailed as follows:

The authors would like to thank the Ministry of Science and Technology (NSC 103-2221-E-027-070) for financial support of this research. The authors also claim that the contents of this paper have been neither copyrighted or published, nor submitted for publication elsewhere.