2019 Volume 60 Issue 1 Pages 93-98

2019 Volume 60 Issue 1 Pages 93-98

Micro-Vickers hardness and positron lifetime were measured after 1 MeV proton irradiation to a fluence of 3 × 1017 ions/cm2 at below 80°C and post-irradiation isochronal annealing to 650°C to investigate the effects of nickel (Ni), phosphorous (P) and sulfur (S) on the irradiation hardening of Fe–0.2 mass% C–0.3 mass% Cu model alloy. With increasing the Ni content to 0.6 mass%, irradiation hardening was increased, while a further increase to 1 mass% resulted in a small reduction. The addition of 0.05 mass% P increased the irradiation hardening of the model alloys irrespective of the addition of 0.6 mass% Ni, while the addition of 0.05 mass% S showed almost no effect on the hardening. Positron lifetime measurements revealed that the intensity of long-lifetime component, namely the number density of microvoids, increased and decreased for the alloy added with P and S, respectively. However, no significant effect of Ni content on the long-lifetime component was observed. Post-irradiation anneal-hardening was large and became a maximum at around 350–375°C in most of the alloys studied. The addition of 0.6 mass% Ni caused almost no effect on the annealing behavior, while further addition of 0.05 mass% P reduced the hardness change by the annealing to 400°C. During post-irradiation annealing to around 400°C, the long-lifetime component increased in the alloy with P, but it was so small in the alloy with S or manganese (Mn). These suggest that P enhances the growth of the microvoids but S as well as Mn suppress it.

Understanding radiation mechanism is essential to predict irradiation embrittlement of structural materials during long operation of light water reactors. For the research on radiation mechanism, model alloys were often irradiated with ions to investigate the effects of irradiation damages on hardening and microstructure. Meanwhile neutron-irradiation hardening behavior of reactor pressure vessel (RPV) steels have been investigated to estimate radiation embrittlement of the steels assuming that the reference temperature shift is proportional to the amount of irradiation hardening.1,2) Especially, the effects of alloying elements and impurities on the irradiation hardening were the main issues for the prediction of radiation embrittlement of different sorts of RPV steels with different alloy compositions and impurity levels. In many sorts of RPV steels, copper (Cu) as an impurity of the steel played a significant role in irradiation embrittlement and hardening, which led the temperature shift prediction to focusing on Cu contribution.3–9) The contents of Ni and P have been often involved in the prediction formula. In the previous works, we reported that irradiation hardening of the model alloys added with Cu has been attributed to some of contributors, such as, vacancy clusters or microvoids, interstitial dislocation loops and Cu precipitates.8,9) Although the hardening mechanisms for RPV steels have not been definitely established, understanding the irradiation hardening mechanisms in the model alloys are believed to assist understanding the mechanisms in RPV steels.

The effects of Ni on the irradiation hardening of Fe–Cu model alloys were investigated by many researchers, and we reported that Ni itself had a quite large potential for irradiation hardening of iron (Fe)-based model alloys without addition of Cu.10,11) According to the previous paper12) on the effect of Ni on radiation response of VVER RPV steel, the lower Ni content lead to the lower density of Ni-based radiation-induced precipitates under irradiation and hence to the lower contribution of the hardening and radiation embrittlement of these steels than steels with higher Ni content (1.16–1.34%) under accelerated neutron irradiation.

Although many efforts have been made for understanding Cu-clustering induced hardening, the number of research on the effects of impurities, such as P and S, is so limited because the embrittlement by such impurities was usually caused by grain boundary embrittlement. However, hardening effect is still an issue for the steel with impurities, since the grain boundary embrittlement was often accompanied by irradiation hardening. As for impurity P, it was reported that ductile-brittle transition temperature (DBTT) was increased by P doping for the alloy with Cu less than 0.01 mass%, but no shift was observed for the alloy with 0.3 mass% Cu.13) As for the effect of S, radiation embrittlement was increased with increasing S content in VVER-1000 RPV weld but no effect was observed in the base metal.14)

As for the estimation method of irradiation embrittlement, ΔDBTT, several empirical formulas were established by means of statistic analytical method for the impact test data of irradiated RPV steels. The effects of Cu, Ni, silicon (Si) and P were taken into account in the formulas but not for S and Mn. For more precise evaluation, researches on modeling irradiation embrittlement and hardening have been conducted.15–19)

Kolluri et al. reported the results of surveillance tests of thermal aged VVER-440, which contained 0.01–0.025 mass% of P and 0.015–0.025 mass% S, for 27 years (∼200,000 h) at 290°C in a surveillance channel of Armenian nuclear power plant, and showed that no age hardening and embrittlement was detected because of adequate compositions of the impurities under unirradiated condition.15) Kuleshova et al. also investigated the effects of neutron irradiation on VVER-1000 RPV base metal, and reported that the accelerated neutron irradiation at 300°C caused the formation of radiation-induced precipitates and dislocation loops, as well as some increase in P grain boundary segregation, which resulted in acting the hardening and non-hardening mechanisms of radiation embrittlement.16) Terentyev et al. performed an atomistic study to investigate the interaction of dislocation loops with moving dislocations and specifically addressed the effect of solute segregation on the loop’s barrier strength and interaction mechanism, focusing in particular on Mn. And it was found that the enrichment of Mn in the core of dislocation loops caused a significant increase of the unpinning stress, especially for small or invisible ones.17) Lambrecht et al. discussed on the basis of positron annihilation spectroscopy analyses and suggested that the main obstacles causing hardening in Cu-free alloys were most probably self-interstitial clusters decorated with Mn. Furthermore, they also suggested that in low-Cu RPV steels and in Fe–CuMnNi alloys, the main effect was still due to Cu-rich precipitates at low doses, but the role of Mn-related features became predominant at higher doses.18) Jiang et al. investigated the microstructural evolution of RPV steels induced by proton and heavy ion irradiation at low temperature (∼373 K), and suggested that ion irradiation produced many point defects and vacancy cluster defects, which induced the formation of dislocation loops and the increase of nanoindentation hardness.19)

However, the development of more substantial models which are based on the accumulated experimental data without hypotheses would be necessary. Annealing behavior of irradiation hardening is considered to be due to the evolution of irradiation-induced microstructures during annealing, where the mobility of vacancies change remarkably. For understanding the bases of irradiation hardening of iron base alloys and steels, the observations of hardness change and evolution of vacancy type defects during post-irradiation annealing are effective.

The objective of this work is to investigate the effects of Ni, P and S on the annealing behavior of irradiation hardening of Fe–0.2 mass% C–0.3 mass% Cu alloy in order to understand the role of these alloying or impurity elements playing in the irradiation hardening in model alloys.

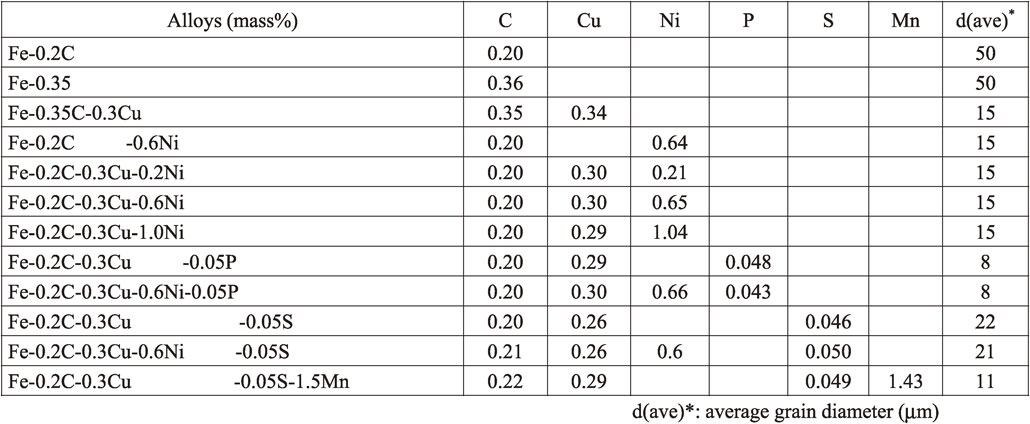

A variety of iron based model alloys were produced by plasma-arc melting method by alloying each elemental metal with the mother alloys of Fe–5 mass% Cu and/or Fe–4 mass% C which were also produced by the method in advance. The chemical compositions of the produced alloys are shown in Table 1. The alloy buttons were cold-rolled to a sheet and the specimens were punched out into disks of 5 mm in diameter. The specimens were sealed in an evacuated quartz tube and solution-heat treated at 880°C for 7.5 h and quenched into iced water followed by tempering at 670°C for 2.2 h. The specimens were annealed at 620°C for 22.5 h and finally furnace-cooled to simulate the post-weld heat treatment in the practical fabrication processes of RPV steels. The grain size of each alloy is shown in Table 1. The alloys were irradiated with 1 MeV protons up to a fluence of 3 × 1017 ions/cm2 at below 80°C using a tandetron accelerator. At this temperature, single vacancies are mobile in the locallized area to form tiney vacancy clusters or microvoids. After the proton irradiation, positron lifetime measurements and micro Vickers hardness tests were carried out. Isochronal annealing was conducted for unirradiated and proton irradiated alloys for 30 min from 100°C to 650°C with increasing temperature by 25°C step to investigate recovery behavior of irradiation hardening and defect structures.

The 1 MeV proton injection range in these alloys was about 7 µm, while indent diagonal depth by Vickers micro-hardness test with a load of 25 g is over 10 µm. As a result, the hardness measured in this study is an average of the irradiated region, peak damage region and underlying unirradiated region. The average of 18 data excluding the minimum and maximum values from the measured 20 data was obtained. The averaged error in the hardness (HV) is ±12. Positron annihilation lifetime measurements were performed at room temperature. The spectra of positron annihilation were decomposed into two components following the PATFIT-88 program,20) that is, the matrix component (τ1, I1) and the microvoid component (τ2, I2), where τ and I are the lifetime and intensity, respectively.

Figure 1 shows the dependence of micro-Vickers hardness of the alloys on Ni content before and after irradiation as well as the amount of irradiation hardening, ΔHV. Before irradiation, the hardness was not significantly influenced by Ni content. As for the irradiation hardening, ΔHv increased with increasing Ni concentration in all the alloys up to 0.6 mass% Ni but a small reduction was observed in 1 mass% Ni. It is clear that the addition of 0.05 mass% P to Fe–C–Cu–(Ni) alloy resulted in a significant increase in the irradiation hardening, while the addition of 0.05 mass% S had almost no effect on the hardening of the alloy. It is noted that the alloy with 1.5 mass% Mn addition results in the highest hardness after irradiation among the alloys.

The dependence of micro-Vickers hardness of the alloys on Ni content before and after irradiation as well as the amount of irradiation hardening, ΔHV.

After irradiation, a longer lifetime (>∼200 ps) component, τ2, which was considered to be the positron lifetime at microvoid, appeared in all the alloys, while τ1 of the most of alloys was around 110 psec that is generally indicating the lifetime in the Fe matrix (bulk). Figure 2 shows the Ni content dependence of the lifetime of long lifetime component and its intensity, I2. This indicates that microvoids with rather high number density were formed by the irradiation at below 80°C. It can be said that the positron lifetime (τ2) and intensity (I2) was not greatly affected by the Ni content.

The Ni content dependence of the lifetime of long lifetime component and its intensity, I2.

The effect of 0.05 mass% P on the positron spectrum was observed: τ2 reduced from 313 psec (Fe–0.2 mass% C–0.3 mass% Cu) to 272 psec. The intensity was higher to around 29% in comparison to the alloy without P.

Addition of S to Fe–C–Cu alloys caused a decrease in the number density of microvoids. Especially, in the alloy with both Mn and S, the number density of microvoids decreased.

3.2 Annealing behavior 3.2.1 Hardness changeIsochronal annealing behavior of the hardness of unirradiated alloys are shown in Fig. 3(a) for Fe–C–Cu alloys and Fig. 3(b) for Fe–C–Cu–Ni alloys. Irrespective of Ni addition, a remarkable anneal hardening was observed above 500°C. Another anneal hardening was observed in Ni or P added alloys in the annealing temperature range between 100°C and around 200°C.

Isochronal annealing behavior of the hardness of unirradiated alloys: (a) Fe–C–Cu alloys and (b) Fe–C–Cu–Ni alloys.

Figure 4 shows the annealing behavior of ΔHV of each alloy where the ΔHV is calculated to be a subtraction of the hardness of unirradiated alloy after a given annealing from the hardness of the post-irradiation annealed alloy. Figure 4 describes the effect of addition of P and S on the annealing behavior in Fe–C–Cu alloy (Fig. 4(a)) and Fe–C–Cu–Ni alloy (Fig. 4(b)). In general, irradiation hardening, ΔHV, appears to decrease with annealing temperature up to around 200°C more or less, then increase up to 350°C. Above 400°C, ΔHV decreases and keep the hardening to 550°C and finally disappears at around 600°C–650°C. The characteristic features of the effects of Ni, P and S are as follows:

Annealing behavior of ΔHV of each alloy where the ΔHV is estimated to be a subtraction of the hardness of unirradiated alloy after a given annealing from the hardness of the post-irradiation annealed alloy: (a) Fe–C–Cu alloy and (b) Fe–C–Cu–Ni alloy.

In the Fe–C–Cu alloys with and without P addition, the lifetime, τ2, increased up to around 200°C and then decreased or saturated with increasing annealing temperature up to around 350°C, as shown in Fig. 5(a) and the similar behavior was observed in Fe–C–Cu–Ni alloys (Fig. 5(b)). According to the previous research,21) the lifetime observed here (>250 ps) is corresponding to microvoids. The increase in the lifetime in this study suggests that microvoids grew during annealing to 200°C and decreased or kept the size to 300°C, then increased again up to 350–400°C. The annealing to 450°C resulted in the disappearance of the microvoids. It can be said that the P addition suppressed the reduction of the size of the microvoids. The addition of S to the Fe–C–Cu alloy caused a monotonic reduction of the microvoid size by the annealing above 200°C. Mn addition caused a significant acceleration of disappearance of microvoids by the annealing to 200°C, although the hardening was still observed. Figure 5(b) shows the similar experimental results with Fig. 5(a) but the alloys contained Ni as an alloy element. The effects of P and S on the annealing behavior of microvoid size in the Ni added alloys is very similar to the alloys without Ni addition: the addition of P kept the microvoid size continuing to increase up to 400°C, while the addition of S caused the reduction of the void size above 300°C.

Long-lifetime component, τ2, and its intensity, I2, of (a) Fe–C–Cu and (b) Fe–C–Cu–Ni alloys during post-irradiation annealing to 450°C.

Based on the superimposed-atom model calculation,21) it is considered that microvoids, which consist of 5–15 vacancies and resultantly their average radius is estimated to be 0.25–0.32 nm, are formed by the irradiation at below 80°C. I2 was about 21–25%. From the calculation of specific trapping rate and experience, the number density of microvoid is estimated to be 1023∼1024/m3 in the order of magnitude. However, our previous study8–11) showed that microvoids are not the main factor controlling irradiation hardening of iron-based model alloys. And, finally, it was concluded that interstitial-type dislocation loops (I-loops) and copper clusters are the main hardener of the alloys. Although microvoids are not directly related to the hardening, they play an important role in the formation of I-loops through the recombination of vacancies and interstitial atoms.

4.2 Nickel effectsIrradiation hardening of the Fe–0.2C–0.3Cu–(Ni) alloy was not remarkably affected by the addition of Ni up to 1 mass%, although ΔHV increased with increasing Ni content up to 0.6 mass% but a small reduction was observed in 1 mass% Ni. Finally, the difference in the ΔHV in the range of Ni content between 0.2 and 1 mass% is 15% at most, and irradiation effect was reverse below and above 0.6 mass% Ni. It is considered that there is no significant interaction between Ni atom and vacancy. Also, microvoid formation behavior was not affected by Ni content in the Fe–C–Cu–(Ni) alloy. The addition of Ni affected the anneal hardening from 100°C to 200°C in unirradiated alloys as shown in Fig. 3(b), in which Ni may enhance the precipitation of ε-carbides. Since irradiated alloys showed no significant change in the hardness, the subtraction, ΔHV, showed a decrease as indicated in Fig. 4(b). As for the Ni effect on the dislocation loop formation, it is unclear from this experiment, although the present study suggests that the formation of dislocation loops are not remarkably influenced by Ni content at this irradiation and post-irradiation annealing conditions.

4.3 Phosphorous effectsIrradiation hardening of the Fe–0.2C–0.3Cu alloy with and without Ni addition was remarkably increased by the addition of 0.05 mass% P. Positron lifetime measurement revealed that τ2 reduced to 272 psec: the average size of microvoids decreased, which corresponded to 5 vacancies cluster. Its number density increased to 29%, which means the number density was higher than 1024 n/m3 by the addition of P. This fine dispersion of smaller microvoids is considered to be due to interaction of vacancies with P. Based on TEM observation that interstitial-type dislocation loops became smaller by the addition of P and Ni,10) it is considered that they interact with both interstitial-type defects and vacancy-type defect clusters in Fe-based alloys regardless of atomic size factor. It was also reported9,10) that the under-sized atoms in BCC Fe matrix trap interstitial atoms to provide I-loops, and enhances irradiation hardening. Since P is considered to be an under-sized solute in Fe, it is expected that the similar effect is brought about for the alloy with P. Thus, the enhanced hardening by P addition can be interpreted in terms of interstitial atoms trapping mechanism that works to increase the number density of I-loops. When interstitial atoms are trapped by P atoms, the mobility of interstitial atoms is apparently reduced. This may suppress the recombination of interstitial atoms and vacancies, and total number density of defects, I-loops and microvoids increases.

4.4 Sulfur and manganese effectsThe effect of S on the hardness was not so large as that of P. The effect appears to become large with the addition of Ni. For the Fe–C–Cu–Ni alloy, the addition of S caused a decrease in ΔHv. As for the effect on positron lifetime, it is considered that the addition of S increased the size of microvoids and decreased its number density. Mn is presumed to form MnS to stabilize S. Since the Mn concentration is much higher than S, the rest of Mn plays another important role as trapping sites for vacancies.

4.5 Recovery processAs shown in Fig. 3, some alloys showed the reduction of the hardening by annealing to 200°C. Since the positron data indicated that microvoids were formed by the irradiation at below 80°C, they were generated as a result of cascade damage formation. As mentioned in section 4.2, the addition of Ni affected the anneal hardening from 100°C to 200°C in unirradiated alloys as shown in Fig. 3(b). It can be interpreted in terms of the enhancement of the precipitation of ε-carbides. Since irradiated alloys showed no significant change in the hardness at 100°C∼200°C, the subtraction, ΔHV, showed a decrease as indicated in Fig. 4(a) and/or (b). Thus, the reduction of ΔHV in this annealing temperature range in Fig. 4 might not be due to irradiation effects. However, the growth of the microvoids by the post-irradiation annealing suggests that some vacancies, which were trapped at alloy elements such as Cu, Ni, P and S, de-trapped from the elements with rather low binding energy. Those de-trapped vacancies contributed to growing microvoids and also shrinking I-type dislocation loops that might cause hardening.

Above 200°C, it is considered that carbon-vacancy (C-V) pairs were decomposed and Cu clustering occurred during annealing, resultantly post-irradiation anneal-hardening was observed for the alloys with Cu addition. The previous our study suggested that fine carbide precipitation was also enhanced the proton irradiation hardening.9) The increase in the hardening by the annealing above 200°C is considered to be due to the precipitation hardening of Cu clusters and/or carbides, although the I-type dislocation loops were still the main contributor of the hardening. Annealing above 400°C causes the decomposition of microvoids, which caused the mutual annihilation between I-type dislocations. The remaining hardness after the annealing to 450°C is due to Cu clusters which was also observed in unirradiated alloys with Cu.

Above 450°C, the residual ΔHV is smaller in the alloys with P. This suggests that the amount of Cu clusters is reduced by P, which is consistent with the explanation of a large contribution of I-loops to the hardening. In all model alloys irrespective of Ni addition, a remarkable anneal hardening was observed above 500°C, which is due to Cu precipitation and formation of Cu clusters by thermal aging. It should be noted that Cu clusters are still remaining even after the post-irradiation annealing to 650°C.

The effects of Ni, P and S on the irradiation hardening of Fe–Cu based model alloys were investigated after 1 MeV proton irradiation to a fluence of 3 × 1017 ions/cm2 at below 80°C. Post-irradiation annealing behavior of the hardening was also investigated. The obtained main results are:

We would like to thank Associate Professor Shinji Nagata, Institute for Materials Research, Tohoku University and Associate Professor Katsumi Takahiro, Kyoto Institute of Technology, for their assistance for proton irradiation. Authors also thank Mr. Sanko Takahashi, Institute for Materials Research, Tohoku University for his contribution to produce model alloys. Finally, authors appreciate our thanks to Professor Sadae Yamaguchi, Chiba Institute of Technology, for his support of this research.