2019 Volume 60 Issue 6 Pages 850-857

2019 Volume 60 Issue 6 Pages 850-857

Fatigue crack propagation rate of pressure-sintered Ag nanoparticles was investigated and prediction method of fatigue crack propagation using strain energy density computed by FEM was proposed. The fatigue crack propagation rate was lower than that of pressureless-sintered Ag nanoparticles around ambient temperature. At high temperature, multiple small cracks occurred ahead of a main crack and they were connected with one another and the propagation rate of the main crack increased, so that properties of fatigue crack propagation in the high temperature region were close to those of pressureless-sintered Ag nanoparticles.

As the inelastic strain energy density and the length of its acquisition area were inversely proportional, the prediction of fatigue crack propagation that do not depend on the size of the area was possible by the use of the proportional constant of the relationship. The behavior of thermal fatigue crack propagation of sintered joint structure that was predicted by the derived fatigue crack propagation law was mostly in agreement with experimental behavior.

Fig. 7 Relationships between fatigue crack propagation rate and ΔWin.

Next generation power devices that use wide-bandgap semiconductors are expected to operate at much higher temperatures than conventional devices. Using lead free solder alloys as die attach materials for power devices that operate at high temperatures is difficult in view of the mechanical reliability. In the circumstance, sinter joining with Ag nanoparticles is now considered as a potential alternative to conventional solder alloys.1,2) There have been, however, a few research reports released to the present on mechanical reliability of sintered Ag nanoparticles and there still remain many unclear points about the reliability. Recently, static characteristics of Ag nanoparticles are now being investigated through shearing tests of joint specimens3–5) or mechanical tests with the use of film type specimens.6–8)

As for investigations on characteristics of fatigue crack propagation and fatigue crack propagation law, there are no reports available yet except for the authors’ recent research. These are essential in studying the reliability of power semiconductor devices. The author et al. have investigated the rate of fatigue crack propagation of pressureless-sintered Ag nanoparticles with the use of cyclic J-integral ΔJ,9) a fracture mechanics parameter, and have demonstrated that fatigue properties of Ag nanoparticles are largely different from those of solder alloys.10) Given the prediction of the fatigue life of a power semiconductor device, it is not easy to calculate ΔJ in real device structure. A parameter alternative to ΔJ for assessing fatigue crack propagations is necessary. A method that do not use fracture mechanics parameters was proposed for BGA joints; in the method, FEM is used to calculate the inelastic strain energy density range ΔWin in the neighborhood of the fatigue crack tip region and the failure life is evaluated.11,12) Although there are points to note in the proposed method, such as its dependence of ΔWin on the mesh size of FEM model, the calculation of ΔWin is easier with the method than with ΔJ. In addition, considering the thermal fatigue analysis in die attach materials, a parameter applicable to the creep region is necessary. Since ΔWin can be applied not only to the fatigue analysis in elasto-plastic region but also to the analysis in creep region, ΔWin is suitable as the parameter for the thermal fatigue analysis of die attach materials. The author et al. have evaluated the fatigue crack propagation properties of pressureless-sintered Ag nanoparticles by the use of the inelastic strain energy density range and demonstrated its brittleness in the combination of the strain energy concentration present inside the pores of the sintered material with the low quality grain boundaries. For the future practical application of Ag nanoparticles to die attach materials, research of pressure-sintering that is deemed to have more ductile mechanical properties is required.

Therefore, in this study, fatigue crack propagation properties of pressure-sintered Ag nanoparticles that are expected to have more ductile was evaluated using strain energy density. And then, with the use of the derived fatigue crack propagation law, the thermal fatigue crack propagation life of a sintered joint specimen was predicted.

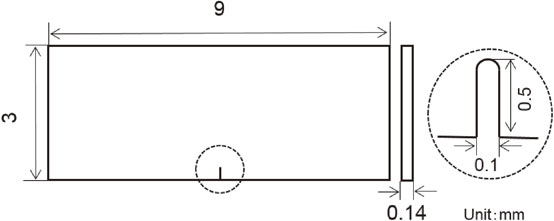

Ag nanoparticle paste with an average diameter of 100 nm was used. The paste was sintered at 523 K under a pressure of 5 MPa to create a strip-shaped plate material. The plate was then machined into a miniature sized flat plate specimen with a single notch (Single-Edge Notched) as in Fig. 1.10,13) The notch was introduced by a precision wire saw (50 µm in wire diameter).

Schematic illustration of single-edge notched (SEN) specimen.

The fatigue crack propagation test was performed in displacement-controlled pulsating tensile-tensile mode.13) The control waveform was symmetric triangular wave. The total displacement range was 4 µm–15 µm (equivalent to the nominal strain range 0.13%–0.50%). Test temperatures were three levels of 298 K, 333 K, and 448 K. The strain rate was 1 × 10−3/sec. A fatigue crack propagation machine was a fatigue test machine equipped with a piezo actuator (Saginomiya: LMH-207-20) as in Fig. 2. For measuring displacements, a capacitive displacement sensor installed near the specimen fixing jig was used; the values measured by the sensor were used for actuator controlling. Specimen temperature was raised by the ceramic heater installed inside a specimen fixing jig and test temperatures were controlled by the thermocouple fixed to the specimen fixing jig with the allowable range of ±2 K. Fatigue crack lengths were measured by video images recorded at each prescribed cycles by a microscope (Leica Z16 APO) installed on the upper part of the test machine.

Fatigue crack propagation testing machine.

In the test conditions of the large scale yielding, like this study, it is ideal to evaluate of the fatigue crack propagation using path-independent cyclic J-integral ΔJ. However, as it is difficult to calculate ΔJ by general purpose FEM code, assessment with a scalar parameter alternative to ΔJ is required. The author et al. have so far made the evaluation of fatigue crack propagation of pressureless-sintered Ag nanoparticles by the use of the inelastic energy density range ΔWin around the crack tip calculated by FEM as a scalar parameter alternative to ΔJ.13) This method is based on the assumption that the average of inelastic strain energy densities near the crack tip is representative of the mechanical environment of the region where damage is progressing in front of the crack tip. The calculation of ΔWin was carried out at the element group contained in the region surrounding the crack tip of FEM model, elemental solutions of inelastic strain energy densities were averaged to calculate the quantity of variation per fatigue cycle. The equation to calculate the average of element solutions is shown in eq. (1).11)

| \begin{equation} \Delta W_{\text{in}} = \frac{\displaystyle\sum \Delta W_{\text{in}}^{\text{element}} \cdot V^{\text{element}} }{\displaystyle\sum V^{\text{element}}} \end{equation} | (1) |

| \begin{equation} \dot{x}_{\text{i}} = \frac{2}{3}\sum_{i = 1}^{n}A_{1} \dot{\varepsilon}_{\text{p}} - A_{2}x_{\text{i}}\dot{p} \end{equation} | (2) |

Geometry of Single Edge Notch (SEN) specimen.

Thermal fatigue crack propagation life in the joint structure was predicted by the fatigue crack propagation law gained from the SEN specimen. The specimen was a joint body of SiC and the Cu/CuCr clad that was pressure-sintered with Ag nanoparticles in the same condition as in the fatigue crack propagation testing. A schematic illustration of the joint specimen is shown in Fig. 4. The joint specimen was subjected to thermal cycle testing with the maximum temperature of 448 K and the minimum of 218 K at the temperature ramp rate of 23.0 K/min and with the dwelling time of 15 minutes for each of maximum and minimum temperature. The crack length on the diagonal surface was measured at the number of cycles prescribed by ultrasonic microscope.

Sintered joint specimen for thermal cycle test.

The elastic modulus, Poisson’s ratio, and CTE of each material used in FEM analysis are shown in Table 2. The property of Ag nanoparticles was defined as elasto-plastic creep body. For the elasto-plastic constitutive equation, Chaboche model was used and Norton’s law of eq. (3) was used for the creep constitutive equation. Material constants of constitutive equations were determined by the tensile test and stress relaxation test that were conducted separately. Determined material constants for Chaboche model of individual equations are shown in Table 3.

| \begin{equation} \frac{d\varepsilon}{dt} = 3.5\times 10^{-4}\sigma^{7.1}\exp\left(-\frac{92000}{8.31\cdot T}\right) \end{equation} | (3) |

The microstructure of the specimens were observed by a field emission scanning electron microscope (FE-SEM) following polishing by Ar ion sputter-etching.

The microstructure of the SEN specimen after sintering is shown in Fig. 5, where the porous structure specific to sintered Ag nanoparticles was observed. The porosity of the specimen in this study was about 8.3% and an average grain size was 247 nm. It is known that the porosity of sintered Ag nanoparticles is strongly dependent on sintering conditions, according to which the porosity varies from about 10% to 40%.15–18) In pressureless-sintering, numerous pores were observed in the neck area.10,17) In comparison with the porosity in pressureless-sintered body, the porosity in the specimen of this study was lower and there were a few of neck areas that were seen in the process of sintering. The microstructure of the specimen in this study was densified because the sintering was progressing by pressurization.

Initial microstructure of Ag nanoparticles sintered under pressure of 5 MPa.

Figure 6 shows the relationship between fatigue crack length at each test temperature a and the number of cycles N. The relationship between fatigue crack length and the number of cycles became linear at any test temperature. This is because the fatigue crack propagation test in this study was conducted under the displacement controlling mode, in which only small changes took place in the driving forces (ΔWin) to growth the fatigue crack. Thus, the fatigue crack propagation rate was calculated by the linear approximation of the relationship between fatigue crack length a and the number of cycles N.

Fatigue crack propagation curves for each condition.

Figure 7 shows the relationship between fatigue crack propagation rate of pressure-sintered Ag nanoparticles and ΔWin. At any test temperature the fatigue crack propagation law of Paris type holds between fatigue crack propagation rate and ΔWin. Material constants at individual temperatures are shown in Table 4.

| \begin{equation} \frac{da}{dN} = C_{1}\Delta W_{\text{in}}{}^{C_{2}} \end{equation} | (4) |

Relationships between fatigue crack propagation rate and ΔWin.

Figure 8 shows the fatigue crack propagation path in representative test conditions of pressure-sintered Ag nanoparticles. At any test temperature, a fatigue crack propagated along a grain boundary (the sintered interface between Ag particles). In crystalline materials with a grain size of several hundred nanometers, deformation and fracture at grain boundary become dominant.23) Because of this, also in pressure-sintered Ag nanoparticles, grain boundary fracture became fatigue crack propagation mechanisms. Pores originally contained in sintered Ag particles become clumped/connected to each other after a long time of high temperature exposure and macroscopic pores grow large which causes for mechanical properties to decrease.18) The testing time in this study was relatively short for about several to several dozens of hours. However, compared to the initial microstructure, the size and the number of pores increased around a crack tip by stress-induced diffusion as well as temperature. Since the increased pores leads a brittle characteristic from the structural point of view, the fatigue crack propagates through a pore at any test condition.

SEM micrographs showing microstructures around fatigue crack tip after fatigue test.

When the microstructure after the testing was observed with a focus on changes in fracture mechanisms at 448 K and other temperatures, differences were seen in the damage near a crack tip. As shown in Fig. 8, a grown up crack was seen at 448 K ahead of the main crack (in the traveling direction of the crack). At lower temperatures, however, other cracks except for the main crack were not observed. Grain boundary diffusion became more active at 448 K than at ambient temperature and the pores easily became connected to one another. Connecting of the pores induces crack initiation and multiple small cracks occur ahead of the main crack. It is considered that by the main crack being connected to small cracks, brittle properties were derived and as a result, the fatigue crack propagation rate increased. Thus, C2 and the fatigue crack propagation rate increased at 448 K.

3.2 Prediction of fatigue crack propagation of sintered joint specimenThe inelastic strain energy density range of the crack tip calculated by FEM is dependent on the size of the area surrounding a crack and dependent on the size of an element in the area, unlike the case in which the path independent J was used. In considering the application of the foregoing to fatigue crack propagation analysis in real joint structures, the dependence of the area surrounding a crack and the dependence of the element size in the area need to be clarified. Therefore, these types of dependence having effects on Win were investigated by altering the size of the region to obtain inelastic strain energy Win and the size of the divided element. The FEM models was 1/2 symmetric with a notch introduced as in Fig. 3. Figure 9 shows the relationship between the side length of quadrate Larea to obtain Win, the element size in the square region Lelement and Win. As shown in Fig. 9, the gradient of the straight line was −1 and Win is inversely proportional to Larea. Furthermore, even if an alteration is made to Lelement, the effect of the element size is almost negligible because Win is calculated as an average in the quadrate region.

Relationship between Win and Larea for each element size (Lelement).

If Larea is replaced with the distance from the crack tip, the relationship between Larea and Win obeys HRR singularity.24,25) In the HRR singularity field, stress and strain can be found as in eq. (5) and eq. (6).

| \begin{equation} \sigma_{ij} = k_{1}\left(\frac{J}{r}\right)^{\frac{1}{n + 1}}{} \cdot \tilde{\sigma}_{ij}(\theta) \end{equation} | (5) |

| \begin{equation} \varepsilon_{ij} = k_{2}\left(\frac{J}{r}\right)^{\frac{n}{n+1}} {}\cdot \tilde{\varepsilon}_{ij}(\theta) \end{equation} | (6) |

| \begin{equation} W_{\text{in}} = \frac{W_{\text{in-c}}}{L_{\text{area}}} \end{equation} | (7) |

| \begin{equation} \frac{da}{dN} = C_{3}\Delta W_{\text{in-c}}{}^{C_{2}} \end{equation} | (8) |

The ΔWin-c in the sintered joint during temperature cycling was calculated with a two-dimensional FEM model having the reproduced diagonal cross section of the specimen as shown in Fig. 10. The element type was eight-node axisymmetric element. A FEM model was created for each predetermined crack length. Contact elements were set to the fatigue crack surfaces and the fatigue crack propagation path was determined based on the observations made after the thermal cycle test. A SAT (Scanning Acoustic Tomograph) image of and a SEM image of a cross section observed after testing are shown in Fig. 11. The fatigue crack started to develop from the joint interface at the corner on the chip side and propagated near the joint interface adjacent to the clad material. In the FEM, an initial crack of 20 µm was created and the fatigue crack propagation path was set to the joint interface on the side of the clad material. Assuming that the driving force for fatigue crack propagation is dominated by the energy on the side of the sintered layer, ΔWin was calculated in the area of 10 µm × 20 µm on the side of Ag nanoparticles near a fatigue crack. Assuming in-phase type thermal fatigue, the reference temperature was set to be 298 K. The life of thermal fatigue crack propagation of the joint specimen was calculated by the use of eq. (9) as below.

| \begin{equation} N = \int_{a_{0}}^{a_{\text{f}}}\frac{da}{C_{3}\Delta W_{\text{in-c}}(a)^{C_{2}}} \end{equation} | (9) |

FEM model of sintered joint specimen for thermal cycle analysis.

SAT image and SEM micrograph showing crack propagation path of sintered joint specimen after thermal cycle test.

Figure 12 shows the relationship between crack length and ΔWin-c obtained from the FEM analysis of the thermal cycle test. ΔWin-c increased as crack length increased, which relationship can be approximated by a quadratic polynomial. By inputting this relational expression in eq. (9), the number of fatigue cycles were obtained at the point where the crack length grew from the initial length to 2.2 mm.

ΔWin-c as a function of fatigue crack length for thermal cycle analysis.

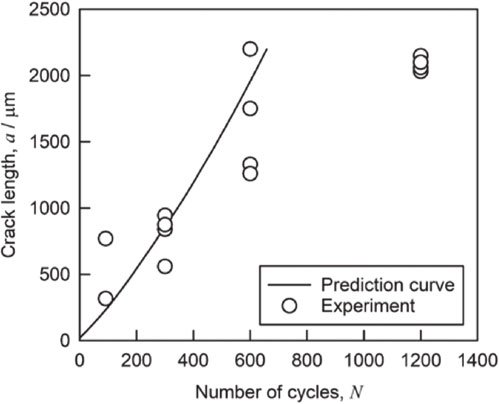

Figure 13 shows a comparison between the calculated number of cycles to thermal fatigue crack propagation and results of thermal cycle test. White circles are the test results and the curved line is the calculated value. The prediction results of fatigue crack propagation by the method of the study are roughly consistent with the fatigue crack propagation in the thermal cycle test. However, according to the prediction results, the fatigue crack propagation rate increased with an increase in fatigue crack length, whereas the test results showed that the fatigue crack propagation rate decreased with an increase in fatigue crack length. This may have occurred due to a possible reason that the axisymmetrical model used in the FEM analysis did not precisely reproduce the joint specimen. In the two-dimensional model with axisymmetrical elements, the length of crack front decreases with increasing fatigue crack propagation. Therefore, the load to be subjected to per unit length of the crack front become larger along with crack propagation, resulting in an increase in the fatigue crack propagation rate. On the other hands, the actual structure of the joint body was quadrate. In the case, the crack initiated at the joint corner propagated and the crack length increased along with the advancement of crack propagation. Therefore, the load per unit length of the crack front decreased with a decrease in the fatigue crack propagation rate. It is considered that more precise crack propagation behavior can be reproduced with the use of a three-dimensional FEM model.

Prediction result of thermal fatigue crack propagation for sintered joint specimen.

This research was conducted with the support of the Grants-in-Aid of New Energy and Industrial Technology Development Organization (NEDO).