2020 Volume 61 Issue 11 Pages 2236-2240

2020 Volume 61 Issue 11 Pages 2236-2240

Extrusion freeforming (EFF)-based 3D printing of ceramic materials is an additive manufacturing technology that builds 3D objects through layer-wise slurry deposition (LSP) of ceramics. This process offers advantages such as a high efficiency of formation, wide applicability, and low cost. The effect of solids content on the rheological behavior of Al2O3 ceramic slurry, and the effect of sintering temperature on microscopic morphologies and the precision of the parts fabricated by 3D printing, were investigated. Results show that the slurry viscosity gradually increases while the slurry flowability is reduced with an increasing solids content. Solids content should be high enough to prepare highly compact ceramic parts, however, an over-high solids content is likely to decrease the flowability of ceramic slurry. The optimal solids content was determined to be 50 vol%. As the sintering temperature increases, the green bodies become more compact and develop fewer cracks. However, the ceramic particles will be transformed to liquid phase at a high sintering temperature, which affects the shapes of sintered samples. The optimal sintering temperature was determined to be 1700°C. After being sintered at high temperature, the samples are found to be free from obvious surface defects or deformations and show slight uniform shrinkage, with a shrinkage rate of 20%. Surface roughness also decreases indicating that surface quality has improved. Finally, a set of sample ceramic structures were printed using optimized process parameters.

Fig. 1 Schematic diagram of the EFF method for fabricating Al2O3 ceramic parts.

Ceramic products and parts have inherent advantages including high resistance to temperature and corrosion, as well as high hardness and strength. These materials have been applied in numerous fields such as cultural creativity, aeronautics and astronautics, engineering machinery, electronics, and civilian uses.1–3) Traditionally, ceramic products are manufactured in three steps, i.e. raw material preparation, forming and sintering. During these steps, the process of forming is the most labor-intensive. There are many traditional forming processes for ceramic materials, including dry pressing, isostatic pressing, slip casting and injection molding.4) These methods use different forming principles and have associated advantages and disadvantages, most of these methods require the preparation of molds, and so can be classified as mold-dependent processes.5)

3D printing, also known as additive manufacturing, forms 3D objects by adding materials layer by layer and is a completely direct digital manufacturing technology.6) When applied to the forming of ceramic materials, it can avoid the occurrence of defects that are inevitable in traditional ceramic production and significantly expands the room and degrees of freedom for innovative ceramic products. The technology is applicable to the manufacturing of complex parts, and small-batch production of diverse types of products. At present, the additive manufacturing technologies used in ceramic production mainly include laminated object manufacturing (LOM),7) inkjet printing (IJP),8) fused deposition modeling (FDM),9) stereo lithography apparatus (SLA),10) selective laser sintering (SLS)11) and extrusion freeforming (EFF).12) Amongst these techniques, EEF allows the extrusion and forming of ceramic slurry by screw rotation and piston-like movements. The principles underpinning the technology are to place prepared ceramic slurry in the feeding mechanism, to deliver the slurry to the extrusion mechanism under the action of the feeding mechanism, and then to extrude the slurry by using a motor or screw onto the forming plane. This is followed by piling up and forming layer by layer.13) EFF is used for common clay, the material can only be used in some arts and crafts applications, and does not have the excellent properties of Al2O3 ceramics, so cannot be used in aerospace engineering situations.14) Other additive manufacturing technologies use expensive equipment, incur high production cost, and involve complex processes; this study provides a new idea for improving the preparation efficiency of Al2O3 ceramic parts.

The Al2O3 ceramic parts were prepared by the EFF method in this paper. The properties of Al2O3 ceramic slurry, the green and sintered samples were characterized.

The ceramic materials used were α-Al2O3 powders with an average particle size of 7 µm and purity of 99.9%. If the particles were too small, they were likely to be agglomerated and difficult to disperse. When the particles were too large, large gaps between them tended to occur and so the materials were difficult to be bonded. Proper amounts of dispersant (ammonium citrate), lubricant (glycerol) and binder (polyvinyl alcohol) were weighed to add to the deionized water. They were then stirred to allow complete dissolution when preparing the premixed solution. Then, the ground α-Al2O3 powders were added in the premixed solution, which were subjected to ball-milling in a GM-1L-2 ball mill to obtain a stable precursor. Appropriate amounts of hydrochloric acid or aqueous ammonia could be added in the precursor to adjust the pH. After stirring the slurry sufficiently in an AIR-1L vacuum mixer at 250 rpm for 1 h, the required experimental slurry was obtained. The viscosity of the ceramic slurry was determined using an NDJ-1 rotational viscometer at 6 rpm for 12 s. The process parameters are explored in terms of Al2O3 powder interaction with various additives used to change the colloidal properties of the ceramic paste, at the same time meet the standard required for EFF, and to ensure the shrinkage rate, density, strength, and other physical properties. Table 1 lists the salient experimental formula.

Figure 1 shows a schematic diagram of the EFF method for fabricating Al2O3 ceramic parts. The EFF device (Huachuang Intelligent Manufacturing Technology Co., Ltd) is mainly composed of four modules: a slurry preparing module, a 3D movable module, a screw extruding module and a controlling module. The slurry preparing module is used for premixed solution and slurry preparation. The 3D movable module is used for carrying the screw extruding module to move in three dimensions. The screw extruding module is used for extruding the slurry from a nozzle. The controlling module is used for controlling the movement and extrusion of ceramic slurry by a computer. At the start of the printing, 3D models are designed and sliced into the printing code. Secondly, the Al2O3 slurry is added into the barrel for printing. 3D models are designed and sliced into the printing code. The nozzle continuously prints ceramic parts by controlling the reasonable printing parameters.

Schematic diagram of the EFF method for fabricating Al2O3 ceramic parts.

Previous research has shown that the extrusion parameters of the extrusion mechanism including the screw rotation speed, thread depth, thread width, and nozzle diameter are key factors influencing the printing quality. For example, the precision of products prepared by the EFF process is related to the diameter of the nozzle with a smaller nozzle diameter corresponding to a higher accuracy of the products, however, a smaller nozzle diameter requires high-performance slurry.

The optimized printing parameters (the screw rotational speed of 60 r/min, a thread depth of 4 mm, a thread width of 17 mm and a nozzle diameter of 1 mm) for manufacturing Al2O3 ceramic parts with higher accuracy using the EFF process were obtained.

2.3 Sintering processing and characterizationSintering is an important step in the 3D printing of ceramic materials and can directly affect the performance of ceramic parts. A WZDS-20 vacuum sintering furnace produced by Beijing Research Institute of Mechanical & Electrical Technology was used as the sintering equipment. The sintering process curve is illustrated in Fig. 2. To avoid damage to the samples after debonding, the debonding and sintering processes were combined. Thermal debonding was conducted at a temperature lower than 550°C, and then the samples were heated to 800°C to completely remove the binder. This was followed by heating the samples to 1500°C, 1600°C, 1700°C, and 1800°C for sintering. Afterwards, the samples were then preserved for 120 min and cooled inside the furnace.

Sintering process curve.

The surface morphology was characterized by a scanning electron microscope (SEM, JSM-6390LA), and the surface roughness of the samples was measured by using a surface roughness tester (SRT6210).

In the EEF-based 3D printing of ceramic slurry, rheological behavior is the key performance that should be guaranteed when preparing the slurry and significantly influences properties such as the density of green bodies and forming accuracy. The rheological behavior of ceramic slurry was affected by numerous factors, e.g. solids content, dispersant content, pH value, and ball-milling time. Of these factors, the influence of solids content on the rheological behavior of the ceramic slurry was mainly elucidated. An important index for measuring the rheological behavior is viscosity, as an over-high viscosity is likely to result in solid-liquid separation and blocking of extrusion heads during the forming. Also, when viscosity is too low, the forming effect is poor and so the strength of the fabricated parts is reduced which causes cracks during sintering. Therefore, ceramic slurry with optimized viscosity should be prepared.

Figure 3 illustrates the effect of different solids contents on the flowability of ceramic slurry. It was found that with increasing solids content, the viscosity of the slurry gradually increases whilst the flowability decreases. This is because the organic content in the ceramic slurry decreases with increasing solids content, so that the Al2O3 particles have a higher probability of being in contact with each other, which enlarges the internal friction during the flow of ceramic slurry. The binder in the slurry enables the Al2O3 particles to form flocculent structures directly, which can resist certain external forces. As a result, Al2O3 particles are difficult to move, resulting in increased viscosity of the ceramic slurry. If the slurry contains less solid phase, it becomes less viscous and more flowable. Therefore, in order to prepare highly compact ceramic parts, the solids content should be relatively high. However, if solids content is too high, the flowability of the slurry is worsened. The optimized solids content used in the experiments is 50 vol%.

Effect of solids content on flowability of ceramic slurry.

Figure 4 shows the 3D-printed ceramic green bodies and cross-sections of the samples sintered at different temperatures. As can be seen from Fig. 4(a) of the ceramic green bodies, different sized ceramic particles are uniformly distributed and have large gaps, indicative of low compactness. With increasing sintering temperature, the compactness of the green bodies gradually is improved while the number of cracks is reduced. When sintered at 1700°C, ceramic particles are burnt together and the gaps disappear, suggesting high compactness: the cross-sectional morphology of the sintered body shows small porosity and produces the desired shape of sintered part. However, when the sintering temperature is 1800°C, although the porosity is lower and the density is higher, when a liquid phase forms in the body, the shape of the parts also changes, therefore, from the comprehensive analysis of the density, shrinkage rate, and shape of the sintered parts, the optimal sintering temperature is 1700°C.

The 3D-printed ceramic green bodies and cross-sections of the samples sintered at different temperatures. (a) green body, (b) 1500°C, (c) 1600°C, (d) 1700°C, (e) 1800°C.

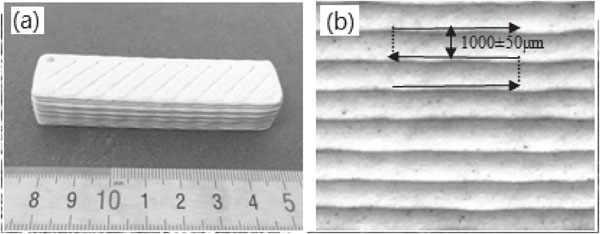

Figure 5 illustrates the physical structure and surface morphologies of a cuboid ceramic green body printed using the optimized extrusion parameters. No defects or deformations are observed from Fig. 5(a), which indicates that the ceramic slurry prepared is suitable for 3D printing. The printed lines can be found from Fig. 5(b). The distance between two adjacent peaks or troughs is 1,200 µm, which conforms to the parameters set in the 3D printing slicing software. The surface roughness Ra was determined to be 160 µm. The sintered cuboid sample and its surface morphologies are displayed in Fig. 6. As shown in Fig. 6(a), no obvious defects or deformations are found on the surface of the sample, suggesting uniform shrinkage of the printed samples during sintering. It can be seen from Fig. 6(b) that two adjacent printed lines show a narrowed distance of 1,000 µm compared to that before sintering, with a shrinkage rate of 20% around. The surface roughness Ra is also decreased to 134 µm, indicating that the surface quality has improved. These results show that shrinkage during sintering of the printed samples is beneficial towards improving the surface quality of the sample.

The printed cuboid sample. (a) the green body, (b) the surface morphology.

The sintered cuboid sample. (a) the sintered sample, (b) the surface morphology.

Figure 7 illustrates other Al2O3 ceramic parts prepared by the EFF process. These data show that the EFF process can be used to prepare ceramic parts. The aforementioned results reveal that the dimensional accuracy and the surface quality of the printed ceramic samples can be improved further. This is mainly because the ceramic slurry is extruded and formed by screw rotation and piston-like movements. Due to the complex extrusion and deposition process of the ceramic slurry, it is difficult to control the precise slurry extrusion of an extrusion device. The extrusion and forming processes warrant future research efforts and the optimization of the control parameters of the device during the forming process is of great significance for improving the quality of printed products.

The Al2O3 ceramic parts prepared by the EFF process.

The Al2O3 ceramic parts were successfully printed using the EFF process which bestows the advantages of a simple structure and more efficient use of raw materials. This study breaks through the material limitation of traditional EFF technology and investigates the manufacture of Al2O3 ceramic parts, providing a new method for further research into the manufacturing techniques available to make ceramic parts for the aerospace, and other industries. The following conclusions can be drawn:

The work described in this paper was supported National Natural Science Foundation of China (No. 51675272) and Jiangsu Science and technology plan project (No. BE2019002-2) and Science and technology plan project of Lianyungang high tech Zone (ZD201909) and Jiangsu blue and green engineering project.