2021 Volume 62 Issue 3 Pages 396-402

2021 Volume 62 Issue 3 Pages 396-402

The TiNbZr/HA (hydroxyapatite) composites evoked widespread concern in biomedical application. However, their properties were affected by processing parameters, such as milling time, sintering temperature and pressure, etc., during sintering process. The Ti35Nb7Zr/10HA (hydroxyapatite) composites were herein synthesized via spark plasma sintering (SPS) at a range of temperatures (800, 900, 1000, 1100 and 1250°C). Results show that the composites are mainly composed of β-Ti, α-Ti, a little of HA and ceramic interphases, like Ti2O, CaTiO3, CaZrO3, CaO and TixPy. With the increase of sintering temperature, the the compressive strength of the composites increases from 960 to 2279 MPa, and the elastic modulus from 45 to 61 GPa, due to the increase of ceramic interphases. The vitro tests reveal that the composite sintered at 1000°C possesses excellent ability to induce the formation of bone-like apatite and cell proliferation. Therefore, the composite prepared at 1000°C with low modulus (52 GPa) and obvious bioactivity exhibits immense potential for biomedical applications.

The Ti alloys with outstanding mechanical properties and biocompatibility usually appear bioinert.1–4) To improve the bioinert of Ti and Ti alloy, and shorten the bone-fixation term and the bone remodeling processes, HA (Ca10(PO4)6(OH)2), as a similar mineral constituent and crystal structure to apatite in the human skeletal system,5–7) was added into Ti and Ti alloys to enhance their bioactivity. These Ti based bioceramic composites have given rise to an interest in biomedical application. Despite Ti–HA,8,9) and Ti–6Al–4V–HA10,11) composites were prepared, the high elastic modulus of the metal matrix (80–120 GPa) or the toxic elements, e.g. Al and V, would be unfavorable factors, which could induce “stress shielding” or high release of proinflammatory and osteolytic mediators.12)

It is found that the Ti–Nb based composites with bio-ceramic (e.g. Ca3(PO4)2, Ca2P2O7, and Ca10(PO4)6(OH)2) prepared by sintering technology has been widely concerned as a potential biomedical implant and excluded toxic elements.13–15) However, the studies on effects of sintering processing parameters were scarce. Wang et al. found that the milling time affected hardness and relative density of the sintered Ti35Nb2.5Sn/10HA composites.16) Salman et al. illuminated that increasing the sintering temperature from 700 to 1000°C had significant effect on improving the hardness of HA/Ti6Al4V composite.17) During the sintering process, it was found that the bioceramic adding into the Ti alloy could be decomposed at certain temperature,18) which affected the microstructure and properties. Therefore, the study on the effect of sintering temperature as a vital parameter to control the properties of Ti based composites would be necessary.19)

Moreover, we have reported the effect of HA content on the properties of the Ti35Nb7Zr alloy in the previous study, and the results show that 10% ha has the best performance.20) Therefore, based on the above mentioned, the nontoxic Ti35Nb7Zr/10HA composites were sintered by spark plasma sintering (SPS) at a range of temperatures (800–1200°C). The effects of sintering temperature on the microstructure evolution, mechanical properties, and in vitro bioactivity were systemically investigated.

The pure initial Ti (purity ∼99.7%, average particle size ∼25 µm), Nb (purity ∼99.7%, average particle size ∼10.5 µm), Zr (purity ∼99.7%, average particle size ∼25 µm) and HA (Ca10(PO4)6(OH)2) powders (purity ∼99.9%, average particle size ∼100 nm) according to a mass ratio of 48:35:7:10 were mixed in a mill/mixer machine (XQM-4) with sealed stainless steel container at a speed of 300 rpm for 12 h. Before the mixing, the anhydrous alcohol was added into the container to avoid cold welding and pollution among the powders. The sintering process was performed by SPS system (SPS-515S, Syntex Inc, Japan) at different temperatures (800, 900, 1000, 1100, 1200 and 1250°C) and kept for 10 min. During the preparation process, the heating rate was set to 100°C min−1, the pressure was maintained at 40 MPa, and the vacuum degree of SPS chamber was maintained at 6–10 Pa. By contrast, the Ti–35Nb–7Zr alloy was prepared under the same conditions.

2.2 Microstructure and mechanical measurementThe phases of the specimens containing the powder mixtures and sintered composites were detected using X-Ray Diffraction (XRD) (D8 Advance, Bruker, Germany) with Cu Kα radiation within the range of 20–80°. The morphology of the Ti35Nb7Zr/10HA powders, HA powders and the sintered composites were observed using Tungsten Filament Scanning Electron Microscopy (SEM) (ZEISS, EVO 18, Germany) and Transmission Electron Microscope (TEM) (JEM-2100, Japanese Electronics Co. Ltd., Japan), Field Emission Scanning Electron Microscopy (FE-SEM) (FEI, Nova NaNOSEM-450, USA), respectively.

According to the standards of GB/T 7314-2005, the specimens with Φ 4 × 10 mm and Φ 2 × 10 mm were used to characterize compressive strength and elastic modulus by a universal testing machine (Shimadzu, AG-X 100 KN, Japan) at room temperature, respectively. The compression rate in the test was 1 mm/min.

2.3 In vitro mineralization evaluationThe specimens were immersed in simulated body fluid (SBF) to evaluate its potential in vivo bioactivity. The SBF solution was prepared according to the method of Kokubo.21) Every prepared specimen with size of 10 × 10 × 3 mm was lonely immersed in 100 mL of SBF solution in a jar which was kept at 37 ± 1°C for 7 days, without refreshing SBF solution. Finally, the immersion specimens were removed, and then washed in deionized water. Their surface morphologies and component analysis were probed by Scanning Electron Microscopy (FEI, Nova NaNOSEM-450, USA) and X-Ray photoelectron spectroscopy (XPS) (PHI5000 Versaprobe-II, Japan), respectively.

2.4 In vitro cell cultureROS1728 (osteoblasts of rats) was selected to assess the eventual cell behavior on the surface of Ti35Nb7Zr/10HA composites according to ISO 10993-5:1999 and GB/T 16886.5-2003. The cells were only cultured in Dulbecco’s modified Eagle’s medium (DMEM) at 37 ± 1°C in a humidified atmosphere with 5% CO2. The specimens with size of Φ 5 × 1 mm, after sterilized at 120°C for 1 h, were cultured with the cells in 96-well plates at an initial density of 5 × 103 cells per 100 µL culture medium. The composite specimens were acted as experimental groups, and the Ti–35Nb–7Zr alloy as control group. After the incubation for 1, 2 and 4 days, respectively, the specimens were further incubated for 4 h after adding 10 µL of the MTT solution into each well. Subsequently, 100 mL of formazan solution was added into each well, the optical density (OD) was measured by an enzyme-linked detector at 570 nm wavelength. Statistical analyses were achieved by the SPSS20.0 software package (IBM, USA). The quantitative data was expressed as mean standard deviation. The values of P < 0.05 were considered significant, and the values of P < 0.01 were considered highly significant.

The affinity between cells and specimens was evaluated by Fluorescence Microscope (NIKON, TE2000-U, Japan) after that the cells were dyed. To further show the state of the cell growth, Field Emission Scanning Electron Microscopy (FEI, Nova NaNOSEM-450, USA) was applied to characterize the cell morphology adhered on the surface of the specimens undergoing 48 h culture.

To elucidate the effects of ball milling on the raw powder, the microstructure and phase transformation of the powder mixtures were characterized via XRD, SEM and TEM. Figure 1 shows microstructure of the composite powder after ball milling for 12 h.

Microstructure and phase transformation of the Ti35Nb7Zr/10HA composite powder after ball milling for 12 h: (a) XRD pattern of the composite powder; (a′) SEM morphology of the composite powder; (b) TEM image of HA powders.

After the milling process, the crystal structure of Ti was changed. Comparing with the standard card, the diffraction peaks of Ti were identified as two kinds of crystal structures (hexagonal close packed (α-Ti) and body-centered cubic lattice (β-Ti)) by XRD patterns. Therefore, the composite was mainly composed by β-Ti and α-Ti during the mechanical alloying (MA) process, shown in Fig. 1(a). The MA process can crush the raw powders, and amalgamate the Nb, Zr and HA particles into the Ti particles, shown from Fig. 1(a′). However, the HA powders have no sign of decomposing. The characteristic peaks of HA are depicted by the XRD patterns. Moreover, the microstructure of nano-scale HA powders with about 100 nm is characterized by TEM (Fig. 1(b)). It can be seen that the HA powders are easy to agglomerate together, which might induce chemical composition inhomogeneity in the following rapid sintering process. Moreover, due to the limited time of MA process, Nb and Zr can still be detected by XRD. Therefore, the sintering temperature would be an important factor to control the forming quality of specimens.

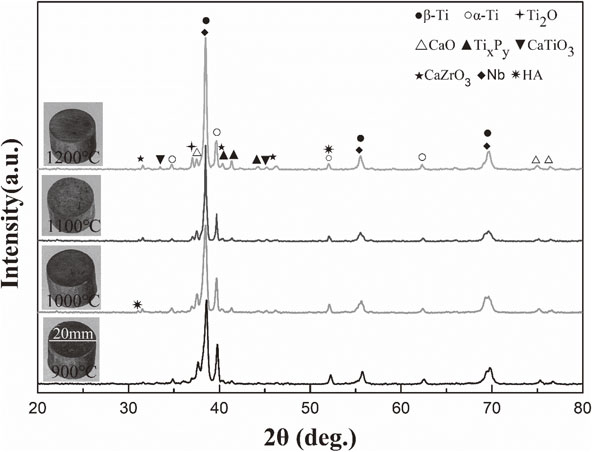

3.2 Microstructure of the sintered compositesBased on the previous experiments, sintering stress and holding time are confirmed as 40 MPa and 10 min, respectively. According to the plasma sintering mechanism of some literatures,22,23) the sintering temperature of conductive materials rises faster than that of non-conductive materials, mainly due to the direct current (DC) component in pulse current, current skin effect and eddy current in the die and blank, Joule’s heat generated by eddy current in grains, small heat capacity of the heated system and direct-contact heating for conductive materials, whereas lacking of eddy current for non-conductive materials. Therefore, the addition of non-conductive HA into the conductive Ti–35Nb–7Zr alloy would decrease the heating efficiency. Meanwhile, the die of sintered non-conductive materials would suffer a greater thermo shock than that of conductive materials during sintering process.24) Hence, the sintering temperature of Ti35Nb7Zr/10HA composites should be controlled to prevent burst of the graphite die due to temperature difference between material and inner surface of die. In brief, the sintering temperature for Ti35Nb7Zr/10HA composites must be fitted to prepare the specimens perfectly. Various sintering temperature, such as 800, 850, 900, 1000, 1100, 1200, and 1250°C, were implemented in the sintering process. It is found that the specimens still appear crack at low sintering temperature of 800 and 850°C, and obvious melted pits at high sintering temperature of 1250°C. It is well known that the powder sintered by SPS system should avoid melting, otherwise the sintering would induce the rupture of die and even the damage of equipment cavity.21) Finally, the sintering temperature were confirmed in a valid range of 900∼1200°C. The images of sintered specimens are showed in Fig. 2, which also reveals the XRD patterns of the Ti35Nb7Zr/10HA composites at different sintering temperatures.

XRD patterns of the sintered Ti35Nb7Zr/10HA composites at different sintering temperatures.

From Fig. 2, all of sintered specimens have good forming quality, and no obvious defects. Besides, it can be seen that the Ti35Nb7Zr/10HA composites at different sintering temperatures are mainly consisted of β-Ti, α-Ti, a little of HA and the ceramic interphases, like Ti2O, CaTiO3, CaZrO3, CaO and TixPy. With increasing sintering temperature, the peaks of β-Ti and some ceramic interphases (Ti2O, TixPy and CaZrO3) ascend, while the peaks of the α-Ti decrease.

The increasing temperature can finally induce the phase transition from α-Ti (hcp crystal structure) to β-Ti (bcc crystal structure). It is inferred that the β stabilizer Nb, which is more active at high temperature, promoting α-Ti to sustainable development of β-Ti. Although the phase transformation happened in the sintering process, the undecomposed HA remains in the sintered specimens, which also suggests that HA do not decompose completely during the sintering process. The decomposed HA could involve in the reaction between HA and metallic elements (e.g. Ti and Zr) during sintering process at high temperature. The sintering reaction could be expressed by eq. (1), eq. (2), and eq. (3).25)

| \begin{align} &\text{Ti} + \text{Ca$_{10}$(PO$_{4}$)$_{6}$(OH)$_{2}$}\\ &\quad \to \text{Ti$_{2}$O} + \text{CaO} + \text{CaTiO$_{3}$} + \text{Ti$_{x}$P$_{y}$} \end{align} | (1) |

| \begin{equation} \text{Zr} + \text{O}\to \text{ZrO$_{2}$} \end{equation} | (2) |

| \begin{equation} \text{ZrO$_{2}$} + \text{CaO}\to \text{CaZrO$_{3}$} \end{equation} | (3) |

The aforesaid reaction would affect the morphology of composites, which could also be one of the key factors for osseo-integration of implants.18,26,27) Therefore, the BSEM images of the Ti35Nb7Zr/10HA composites at different sintering temperatures ranging from 900 to 1200°C are exhibited by Fig. 3. With increasing sintering temperature, the white phases and deep gray phases reduce, while the light gray ones increase. At the low sintering temperature of 900°C, there are a lot of pores existing in the composites (Fig. 3(a)). Into these pores, many particles emerge along the inner wall of the pores (the inset of Fig. 3(a)). It is deduced that the low sintering temperature of 900°C cannot induce a perfect sintering for the Ti35Nb7Zr/10HA composite. When sintering temperature increases to 1000°C, it is exciting that the microstructure of the Ti35Nb7Zr/10HA composite presents homogeneous phase distribution (Fig. 3(b)) and connecting phases together without obvious attached particles onto the inner wall of the pores (yellow arrows in the inset of Fig. 3(b)), indicating an adequate sintering happened at this temperature. With the sintering temperature increased to 1100 or 1200°C, the white phases disappear, and the average crystal size decreases, there are obvious acicular shapes as a typical characteristic of α-Ti phases emerging in the bulk β-Ti matrix (Fig. 3(c) and 3(d)). It can be concluded that one can significantly decrease the grain size, and improve the microstructure uniformity of the composites by implementing high-temperature heating in the SPS process. The violent reaction occurs in the composites with the increase of sintering temperature, resulting in more pores and reaction products. During the cooling process, these pores and reaction products could consequently provide preferential nucleation sites for the gain growth of the composites. Therefore, the grain size would decrease with the increase of sintering temperature. This is consistent with the results of Fauzi A et al.28) Nevertheless, there are more pores appeared on the surface of the composites sintered at high temperature (Fig. 3(d)), which can be induced by some gases from the decomposed HA. Therefore, it is necessary to control the sintering temperature in a proper scale so as to prohibit the formation of more gases.

BSEM images of the sintered Ti35Nb7Zr/10HA composites at different sintering temperatures: (a) 900°C; (b) 1000°C; (c) 1100°C; (d) 1200°C.

The X-Ray mapping scanning result of the sintered composites is shown in Fig. 4. These images display obvious element differences: the gray phases and the white phases are mainly composed of Ti element and Nb element, respectively; the ceramic interphases mainly emerge into the pores. Intensity of reaction between the ceramic and metallic elements is governed by sintering temperature so that the ceramic interphases dominate the whole pores. In other words, the high sintering temperature causes more strong reaction, which could induce more uniform element distribution in the matrix and more pores on the surface of the composites, e.g. Fig. 3(d). Accordingly, a large number of ceramic interphases engendered in the pores would affect the mechanical properties of composites.

X-Ray mapping scanning result of the sintered Ti35Nb7Zr/10HA composites: (a) 900°C; (b) 1000°C.

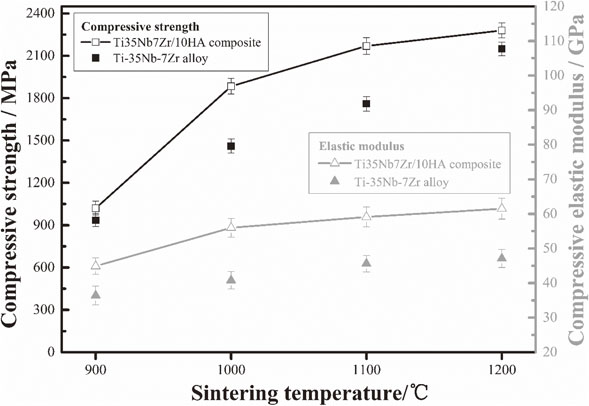

To elucidate the effects of sintering temperature on mechanical properties of the composites, the compressive test was applied to characterize the mechanical properties, e.g. compressive strength and elastic modulus, and their results are exhibited in Fig. 5. As shown in these curves, the compressive strength and elastic modulus increase with the increase of sintering temperature. But the displayed values of the composites are higher than those of Ti–35Nb–7Zr alloy under the same preparation conditions. In other words, the composite matrix could be enhanced by the HA, which also causes an increase of the elastic modulus.

Elastic modulus and compressive strength of the sintered Ti35Nb7Zr/10HA composites and Ti–35Nb–7Zr alloy prepared at different sintering temperatures.

The mechanical properties of the composites are governed by sintering temperature. At 900°C, the compressive strength of composites is about 1020 MPa, which is considerably lower than the other composites. When the sintering temperature is achieved at 1000°C, the compressive strength and elastic modulus are 1884 MPa and 52 GPa, respectively. After the sintering experiment implemented at 1100 and 1200°C, the compressive strength of composites is greater than 2000 MPa, and the elastic moduli are greater than 60 GPa. However, as implant materials, the elastic modulus is desired to approach the values of human bones (10–30 GPa). It is clearly that the composites sintered at 1000°C has a much higher compressive strength than that of nature bones (89–295 MPa),29) and a lower elastic modulus than those composites sintered at 1100 and 1200°C, which can satisfy the design requirement of implant materials.

With the increase of sintering temperature, the more uniform microstructure and finer grain of composites promote an increase of the compressive strength. It is well known that β phases would decrease the elastic modulus.30) The high sintering temperature induces more content of β phases (Fig. 2). But, the ceramic interphases with high elastic modules31) also increased due to the high sintering temperature. Hence, given that the sintering temperature is controlled in proper scale as so to govern the microstructure, the composite would possess good mechanical properties.

3.4 In vitro bioactivity evaluationThe formation ability of apatite in SBF was extensively applied to evaluate the bioactivity of implant materials and prove their applicative potential for clinical practice. The immersion surfaces of the composites are detected by XPS and SEM, and their results are depicted in Fig. 6. It is clarified that HA addition and applicable sintering temperature (above 900°C) in this experiment can obviously induce the formation of containing Ca compound after 7 days’ immersion in SBF solution, indicated by Fig. 6(a). The fitted curves of the sintered composite at 1000°C, as shown in Fig. 6(b), confirm that the containing Ca compounds could be Ca(OH)2, CaO, HA, CaCO3, etc. Therefore, it can be deduced that there is bone-like apatite formed on the composite surface. In addition, the surface of composites sintered at 1000°C is covered by amounts of apatite particles (Fig. 6(c)), and even exists partial apatite stack layer (Fig. 6(d)), which indicates an excellent bioactivity of the composites.

XPS spectra and SEM micrograph of Ti35Nb7Zr/10HA composites after immersion in SBF for 7 days: (a) the XPS spectra of Ca 2p core level for the composites prepared at different sintering temperature; (b) the fitted XPS spectra Ca 2p core level for the composites prepared at 1000°C; (c) FESEM images of the composites prepared at 1000°C; (d) FESEM magnified region of the pink rectangle of Fig. 6(c).

According to ISO 10993-5:1999 and GB/T 16886.5-2003, the cell proliferation was measured using the MTT assay as an account of the reductase activity in mitochondria of living cells. Therefore, the in vitro bioactivity cell culture of the Ti35N7Zr–10HA composites, including cytotoxicity assay (MTT), cell proliferation, was tested by using ROS1728 (osteoblasts of rats) (Fig. 7). For the MTT results in Fig. 7(a), the cell viability exhibits the increasing tendency with the increasing culture time. When compared with the Ti–35Nb–7Zr alloy, the composites show higher OD values at 570 nm. The OD values of the composites with sintering temperature exceeding 900°C are higher than those of the composite sintered at 900°C. It indicates that the Ti35Nb7Zr/10HA composites (above 900°C) can promote cell proliferation in the MTT assay. Because all the cell proliferation rates according to the formula (4) for the composites (above 900°C) are higher than 100%, and therefore evaluated as the Grade 0–1 relative growth rate values according to ISO 10993-5-2009.

| \begin{equation} P = \mathrm{OD}_{\textit{exp}}/\mathrm{OD}_{\textit{con}} \end{equation} | (4) |

(a) MTT results of ROS1728 osteoblasts cultured in Ti35Nb7Zr/10HA specimens extracts for different days (Vs with control, *: p < 0.05; **: p < 0.01; number of samples: n = 3); (b) and (c) show cytotoxicity assay (Fluorescent microscopy) using ROS1728 osteoblasts cultured in the Ti–35Nb–7Zr specimen and the Ti35Nb7Zr/10HA composite (1000°C) specimen extracts after 48 h of culture, respectively; (d) and (e) show cell morphology of the Ti–35Nb–7Zr alloy and the Ti35Nb7Zr/10HA composite (1000°C) specimens for 48 h of culture by SEM, respectively.

The morphology of ROS1728 osteoblasts cultured in the specimen extracts after 48 h is characterized by Fluorescent microscopy, as shown in Fig. 7(b) and 7(c). The cell morphological characteristics of ROS1728 in the composite extracts show spindle shapes, and the filopodia can be found clearly around the specimen. But there is no obvious growth in the control group.

The cell morphologies on the surface of specimens after 48 h of culture were further presented in Fig. 7(d) and 7(e). For both of specimens, the cells are observed to adhere to their surfaces. However, the surface cell growth of Ti–35Nb–7Zr alloy is less pronounced, and the limited establishment of cell spreading is shown after 48 h of culture (Fig. 7(d)). Even so, the entire composite surface is almost covered by cells, which are flat and well spread with numerous filopodia extensions after 48 h of culture, as shown in Fig. 7(e). It is deduced that HA addition into Ti–35Nb–7Zr alloy at 1000°C can be beneficial to cell adhesion and growth between the material and osteoblast.

Therefore, the foregoing discussion obtains the conclusion that, considering the favorable morphology, mechanical properties and bioactivity, the Ti35Nb7Zr/10HA composites sintered at 1000°C via SPS process would be promising candidates for biomedical applications in biological hard tissue replacement or repair.

The as-sintered composites were prepared via mechanical alloying (MA) process and spark plasma sintering (SPS) process at 900–1200°C. The MA process can promote the phase transition from α-Ti to β-Ti, but no obvious decompose of HA. After SPS process at different temperature, the Ti35Nb7Zr/10HA composites are mainly consist of β-Ti, α-Ti, a little of HA and the ceramic interphases, like Ti2O, CaTiO3, CaZrO3, CaO and TixPy. The SEM micrograph of composites verifies the presence of some element enrichment regions and porosity. With sintering temperature increasing, the element enrichment regions of the composites are reduced, whereas the porosity is enlarged, and all mechanical properties (compressive strength, yield strength, and elastic modulus) of the composites increase. When the sintering process is implemented at 1000°C, the composite possesses superior compressive strength of 1884 MPa and low elastic modulus of 52 GPa. In vitro mineralization test evidences the formation of a bone-like apatite on the composite (1000°C) surface in the presence of SBF, revealing that the composite has in vitro apatite-forming activity. The cell (ROS1728 osteoblast) cytotoxicity assay (MTT) and cell adhesion assay confirm that the composite (1000°C), compared with Ti–35Nb–7Zr alloy, exhibits a high cell proliferation rates above 100%, and obviously promotes the cells to grow and spread along the surface in the form of flat appearance and filopodia extensions after 48 h of culture.

This work was jointly supported by the National Natural Science Foundation of China (31660262), the Applied Basic Research Foundation of Yunnan (2018EF001(-059)), the Introduction of talent research start-up fund of Kunming University of Science and Technology (KKSY201751010), and the Key Research and Development Project of Yunnan (2018BA064).