2021 Volume 62 Issue 7 Pages 1009-1012

2021 Volume 62 Issue 7 Pages 1009-1012

The alignment and angular dependences of the coercivity of (Sm, Ce)2(Co, Fe, Cu, Zr)17 magnets were investigated. The coercivity of an aligned magnet is slightly larger than that of the isotropically aligned magnet. This result differs from those of Nd–Fe–B sintered magnets and ferrite magnets. In regard to the angular dependence, the coercivity of (Sm, Ce)2(Co, Fe, Cu, Zr)17 magnets decreases from 0° to 40° and increases thereafter. The trend is similar to that observed in Ga-doped Nd–Fe–B sintered magnets and ferrite magnets and reproduces those expected from a Stoner–Wohlfarth model or a coherent rotation of magnetization, even though the magnetization reversals for these magnets proceed through the motion of magnetic domain walls. The angular dependence of the coercivity of isotropically aligned magnets agrees well with the calculation results for angles up to 50° obtained under the assumption that the magnetization of every grain reverses independently through the motion of magnetic domain walls. These results support strongly the conclusion that the coercivity of Ga-doped Nd–Fe–B sintered magnets and ferrite magnets, both which have an angular dependence similar to (Sm, Ce)2(Co, Fe, Cu, Zr)17 magnets, is determined by the motion of magnetic domain walls.

Fig. 3 Angular dependence of the coercivity of aligned Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnets.

SmCo magnets such as SmCo5-type magnets and Sm2(Co, Fe, Cu, Zr)17-type magnets are still important in various applications, especially applications used in high temperature environments of over 200°C and applications requiring high stability. These magnets are also attractive for their composition, being free of any heavy rare-earth element.

Magnetization reversal in Sm2(Co, Fe, Cu, Zr)17 magnets is governed by the motion of the magnetic domain walls. The demagnetization of these magnets proceeds with the pinning and de-pinning of these walls and is principally driven through the difference in anisotropy energies of the Sm(Co, Cu)5 and Sm2(Co, Fe)17 phases inherent in the cellular structures formed in the aging process.1–3) In their manufacture, these magnets receive different heat treatments after sintering, specifically, a solution treatment after which the coercivity (HcJ) of a magnet is very low.4) The cellular structures formed inside Sm(Co, Fe, Cu)7 grains during the solution treatment moreover grow with the aging heat treatment; HcJ for these magnets then increases. The behavior is quite different from those of Nd–Fe–B sintered magnets and ferrite magnets. The HcJ for Nd–Fe–B magnets and ferrite magnets already emerges after sintering. The influence of aging temperature on the HcJ is small compared with that for Sm2(Co, Fe, Cu, Zr)17 magnets. The microstructures of as-sintered and as-aged Nd–Fe–B sintered magnets were reported by H. Sepehri-Amin et al.5) For Nd–Fe–B sintered magnets, every Nd2Fe14B grain is a single crystal. These grains are surrounded by the Nd-rich phase, called the grain boundary phase, and there are no pinning sites inside the Nd2Fe14B grains.6) Ferrite magnets have a similar structure as Nd–Fe–B sintered magnets; they are also reported to have a grain boundary phase.7) Moreover, the HcJ for Nd–Fe–B sintered and ferrite magnets exhibits a grain-size dependence,8–11) whereas there are few reports showing that HcJ of Sm2(Co, Fe, Cu, Zr)17 magnets depend on their grain size. Hence, it seems that HcJ of Sm2(Co, Fe, Cu, Zr)17 magnets does not depend on their grain size because their coercivity is determined by microstructures present inside grains.

From the differences in magnetic properties of the initial magnetization curves, Sm2(Co, Fe, Cu, Zr)17 magnets are classed as pinning-type, which means their coercivity is governed by the pinning and de-pinning of the magnetic domain walls. In contrast, Nd–Fe–B sintered magnets belong to the nucleation-type class, meaning the coercivity of these magnets is determined either by the coherent rotation of the magnetization caused by nucleation of the reverse magnetization in a defect for which weak anisotropy exists in the grain boundary or by the motion of a magnetic domain wall nucleating from an activation volume arising from thermal fluctuation.12,13)

In verifying which mechanism governed the coercivity in Nd–Fe–B sintered magnets, the angular dependence of coercivity (ANDC) was analyzed, although establishing which was difficult. For Sm–Co magnets, the ANDC was reported for SmCo5 magnets,14–16) which have similar initial magnetization curves as Nd–Fe–B sintered magnets.

Our previous papers reported on the relationship between the alignment dependence of coercivities (ALDC) and ANDC for various Nd–Fe–B sintered magnets and ferrite magnets.17–28) From the ALDC, we concluded that the HcJ of each magnet is determined by the motion of the magnetic domain walls associated with the crust of the grains and not related to a single grain. We also reported the ANDC of SrO·6Fe2O3 and Ga-doped magnets and confirmed that their coercivities are also determined from the motion of the magnetic domain walls even though the ANDC manifests as a coherent rotation.25,28) In determining their coercivity mechanism, we remarked that the ANDC does not suffice; both ALDC and ANDC need to be examined for this determination.

We also reported magnetization reversals in (Sm, Ce)2(Co, Fe, Cu, Zr)17 magnets obtained using soft X-ray magnetic circular dichroism microscopy (XMCD). We confirmed that the HcJ of these magnets is determined by the motion of the magnetic domain walls.29)

However, there is no clarity regarding the ALDC and ANDC of Sm2(Co, Fe, Cu, Zr)17 magnets. Below, we focus on this aspect for (Sm, Ce)2(Co, Fe, Cu, Zr)17 magnets.

Isotropically aligned and highly aligned Sm2Co17-type magnets, with the same composition Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 reported in our previous paper,29) were used in this experiment. The magnets, provided by Shin-Etsu Chemical Co., Ltd., were cut and ground to 7 × 7 × 7 mm3 cubes for measurements of their magnetic properties for the ALDC. For the ANDC, cylindrical magnets, each of 4 mm diameter and 4 mm length, were used. The easy magnetization direction of each was transverse to the cylinder’s axis. The magnetic properties of the ALDC were measured with a pulse field magnetometer (TMP-2-08S25VT-C, Toei Industry Co., Ltd., Tokyo, Japan) with an 8 T (6.4 MA/m) magnetic field. For the ANDC measurements, the 8 T magnetic field was applied along with the easy magnetization direction for full magnetization. The magnetic properties were measured at various angles from 0° to 80° using a vibrating sample magnetometer (VSM-5, Toei Industry, Tokyo, Japan) with a 1.8 T magnetic field.

Figure 1 shows the alignment dependence of the magnetization for Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2. The alignments used in this experiment were determined from α = Br/Js, (Br denoting the residual magnetization and Js the saturation magnetization); the alignments of isotropically aligned and highly aligned magnets were 0.51, 0.96 and 1.0 respectively, where Js is used for the magnetization of α = 1.0. The magnetization of isotropically aligned magnets is almost half the saturation magnetization.

Alignment dependence of the magnetization of Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnets.

Figure 2 shows the demagnetization curves of our isotropically aligned and aligned magnets, their magnetic properties being respectively Br = 0.551 T, HcJ = 1149 kA/m with α = 0.51 and Br = 1.036 T, HcJ = 1175 kA/m with α = 0.96. In addition, the HcJ for isotropically aligned magnets is slightly lower than that of aligned magnets. As we mentioned in our previous papers of Nd–Fe–B sintered magnets,20,21) we expect their coercivities to decrease as the alignment improves when the motion of the magnetic domain wall determines the coercivity; by contrast, their coercivities should increase when the coherent rotation of magnetization determines HcJ. However, the coercivity of the Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnet is determined by the magnetic domain wall motion. Moreover, XMCD observations support this conclusion.29) We do not find the same relation observed in Nd–Fe–B sintered magnets including Ga-doped Nd–Fe–B sintered magnets and ferrite magnets. The HcJ of these magnets always decreases as the alignment improves. This difference may arise from the difference in the origin of HcJ.

Demagnetization curves for the aligned and isotropically aligned Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnets.

After sintering and a solution treatment, the HcJ of Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 is very low, being similar to those of Sm2(Co, Fe, Cu, Zr)17 magnets. High HcJ emerges after the aging treatment.4) However, Nd–Fe–B sintered magnets and ferrite magnets have high HcJ after sintering.30,31) Even though the HcJ of Nd–Fe–B sintered magnets and ferrite magnets exhibits a grain-size dependence,8–11) there are few reports on the grain size dependence of coercivity for Sm2(Co, Fe, Cu, Zr)17-type magnets. These differences might be due to the different ALDC between Nd–Fe–B sintered magnets and ferrite magnets.

Figure 3 shows the ANDC of highly aligned magnets (α = 0.96). The HcJ of these magnets decreases from 0° to 40° and increases thereafter, the trend being similar to that of ferrite magnets and Ga-doped Nd–Fe–B sintered magnets.25,28) The ANDC of these magnets appears similar to that obtained from the Stoner–Wohlfarth model. We explained the ANDC of ferrite magnets and Ga-doped Nd–Fe–B magnets as arising from the motion of magnetic domain walls if the results from the ALDC of these magnets are used.25,28) For Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnets, the ANDC and the ALDC do not exhibit the correlation observed in Nd–Fe–B magnets and ferrite magnets and, at first glance, the ANDC appears identical to that from the Stoner–Wohlfarth model. Nevertheless, without doubt, the HcJ of Sm2Co17-type magnets is determined by this domain wall motion.

Angular dependence of the coercivity of aligned Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnets.

Furthermore, the ANDC of the Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnet supports strongly our hypothesis that the HcJ of ferrite magnets and Ga-doped Nd–Fe–B sintered magnets is determined also by the motion of magnetic domain walls.

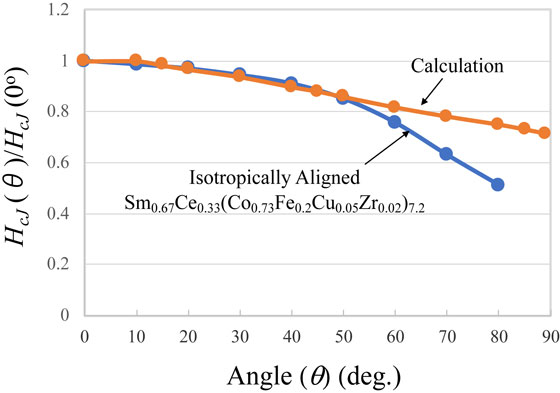

Figure 4 shows the ANDC of the isotropically aligned magnet of Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 in a comparison with related calculations of a previous paper.26) The ANDC of these magnets agrees well with these calculations, which are obtained assuming that each grain undergoes an independent magnetic reversal through the motion of the magnetic domain walls for angles up to 50° and is similar to those of Nd–Fe–B sintered magnets, Ga-doped Nd–Fe–B sintered magnets, and ferrite magnets.25,26,28)

Angular dependence of the coercivity of isotropically aligned Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnets.

The ANDC of isotropically oriented magnets also suggests that the motion of the magnetic domain wall determines the coercivity.

We found the ALDC of the Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnet to be different from those of Nd–Fe–B sintered magnets, Ga-doped Nd–Fe–B sintered magnets, and ferrite magnets. The HcJ of aligned magnets is slightly larger in value than that of isotropically aligned magnets. We did not find the same ALDC relation observed in Nd–Fe–B sintered magnets and ferrite magnets.

The coercivity of the Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnet decreases from 0° to 40°, then increase at 50°, the trend being similar to that of Ga-doped Nd–Fe–B sintered magnets and ferrite magnets. At a glance, the ANDC of Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnet is similar to that obtained from the Stoner–Wohlfarth model and the coherent rotation model of magnetization. However, from the XMCD results, magnetization reversals of this magnet proceed through the motion of the magnetic domain wall. We previously noted that the ANDC of Ga-doped magnets and ferrite magnets accounts for the magnetic domain wall motion even though their ANDC is similar to that of the Stoner–Wohlfarth model. These results support our claim that the discussion based only on the ANDC does is not insufficient for the explanation of coercivities, and both ALDC and ANDC are necessary, especially for Nd–Fe–B sintered magnets including Ga-doped Nd–Fe–B sintered magnets and for ferrite magnets. The ANDC of the Sm0.67Ce0.33(Co0.73Fe0.2Cu0.05Zr0.02)7.2 magnet only appears similar to the magnetization behavior obtained from the Stoner–Wohlfarth or the coherent rotation model, to which the behavior of Ga-doped Nd–Fe–B sintered magnets and SrO·6Fe2O3 is also similar.25,28)

Finally, for angles up to 50°, the ANDC of isotropically aligned magnets agrees well with the calculation results. This result holds for Nd–Fe–B sintered magnets, Ga-doped Nd–Fe–B sintered magnets, and ferrite magnets.

This work was supported by the Japan Science and Technology Agency (JST), in part by the Collaborative Research Based on Industrial Demand under Grant JPMJSK 1617, and in part by the Japan Society for the Promotion of Sciences (JSPS) Grant-Aid for Scientific Research (KAKENHI) under Grant 17K06781. We thank Shin-Etsu Chemical Co., Ltd. for providing magnet samples.