2022 Volume 63 Issue 7 Pages 1097-1100

2022 Volume 63 Issue 7 Pages 1097-1100

CeFe11Ti melt-spun ribbon with the ThMn12 phase was produced by annealing of the rapidly quenched specimen, but the resultant specimen contained some α-Fe phase and showed a coercivity of less than 0.1 MAm−1, below the expected coercivity value for permanent magnets. The coercivity of the CeFe11Ti melt-spun ribbon was improved by Sm substitution. The optimally annealed (Ce,Sm)Fe11Ti melt-spun ribbons exhibited a relatively high coercivity, although these specimens contained α-Fe phase together with the ThMn12 phase. The coercivity and Curie temperature of the annealed (Ce,Sm)Fe11Ti melt-spun ribbons increased with increasing the Sm content. The optimally annealed SmFe11Ti melt-spun ribbon showed a high coercivity of 0.40 MAm−1 when annealed at 1073 K.

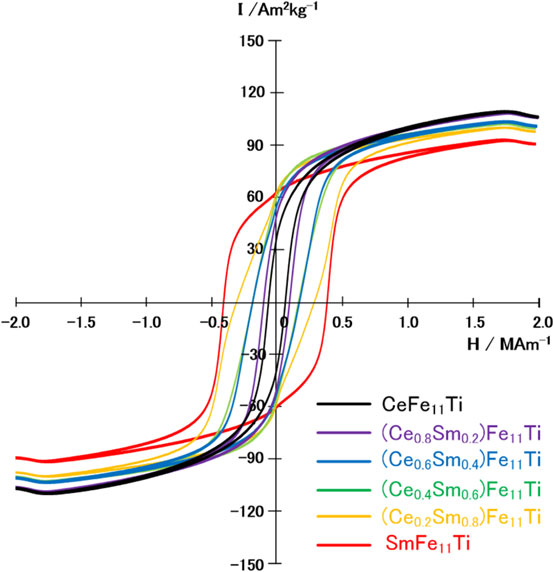

Fig. 4 Hysteresis curves of the Ce1−xSmxFe11Ti (x = 0–1) specimens annealed at 1073 K.

With the increasing concern about environmental issues, it is essential to reduce greenhouse gas emissions from factories and power plants as well as automobiles and other forms of transportation. In this regard, increased use of electric vehicles is essential for a sustainable future. Nd–Fe–B rare-earth permanent magnets, which are extensively applied in electric vehicles, have consequently become key materials in the modern world.1–3)

The supply of rare-earth elements, which are considered to be critical resources for high technology, is currently a focus of concern.4–6) The rare-earth elements are not particularly uncommon; some rare-earth elements are much more abundant than many widely used elements such as lead. The problem of the rare-earth elements is the balance of supply and demand.7–9) The rare-earth elements consist of a group of 17 elements, which are refined in accordance with the constituents of rare-earth ores. Some rare-earth elements are consequently produced in larger amounts than required, and these elements are simply stockpiled. For example, although neodymium (Nd) is necessary for Nd–Fe–B rare-earth permanent magnets, it is impossible to refine only this particular rare-earth element from the rare-earth ore. Therefore, the balance between the demand for the various rare-earth elements and the natural abundances of each type is a major problem for rare-earth industries.

There is an enormous surplus of Cerium (Ce), which is the predominant rare-earth element in ores such as bastnesite and monazite in the current rare-earth market.10) Thus, the use of Ce in rare-earth permanent magnets is desirable. In recent years, the search for new permanent magnet materials has focused on the RFe12 (R = rare earth) intermetallic compounds.11–13) The RFe12 intermetallic compounds possess the tetragonal ThMn12-type structure.14,15) Because the binary RFe12 compound is metastable, the formation of the RFe12 phase is rather difficult. However, it has been found that the small substitution of T (T = Cr, Mo, V, Ti) for Fe in the RFe12 compound results in the formation of the R(Fe,T)12 compound.16–19) The ThMn12-type rare-earth permanent magnets possess high saturation magnetization and a large anisotropy field comparable to those of Nd–Fe–B rare-earth permanent magnets. Thus, Ce-based magnets with the ThMn12-type intermetallic compound would be ideal candidates for new-rare earth permanent magnets.20) Theoretical investigations have shown that Ce might be a possible stabilizer of the ThMn12-type intermetallic compound.21,22) The coercivity values of Ce-based ThMn12-type intermetallic compounds have been reported as 0.048 MAm−1 for CeFe10.5Mo10.5 alloy and 0.06 MAm−1 for CeFe11Ti alloy.23,24) It has also been reported that the substitutions of Sm for Ce, Co for Fe, and V for Ti resulted in an increase in coercivity.25–27) It has been reported that the magnetic properties of the ThMn12-type intermetallic compounds are deeply dependent on the processing conditions.28) The purpose of this work was to investigate the magnetic properties of CeFe11Ti and (Ce,Sm)Fe11Ti magnets produced by melt-spinning and subsequent heat treatment.

Rapidly quenched Ce1−xSmxFe11Ti (x = 0–1) specimens were obtained by melt-spinning onto a chromium-plated copper wheel rotating at a surface velocity of 50 ms−1 in an argon atmosphere. The resultant melt-spun ribbons were obtained as fragmented pieces (thickness 10–20 µm; width 1–2 mm). Heat treatments of the as-quenched specimens was performed in an argon atmosphere for 1 hour at different temperatures of 873–1173 K. The details of the processing conditions have been reported elsewhere.28) The crystal structure of the specimens was determined by X-ray diffraction (XRD) with Cu-Kα radiation. The magnetic properties of the specimens were evaluated using a vibrating sample magnetometer (VSM).

First, the hysteresis curves of the as-quenched CeFe11Ti melt-spun ribbon and the annealed specimens were evaluated (Fig. 1). The as-quenched specimen displayed a narrow hysteresis curve with a saturation magnetization of 65 Am2kg−1 and a coercivity of 0.04 MAm−1. The annealed specimens exhibited slightly wide hysteresis curves with a saturation magnetization of 85–95 Am2kg−1 and a coercivity of 0.048–0.064 MAm−1 depending on the annealing temperature. Please note that the saturation magnetization here is not the true intrinsic value. Instead, a maximum magnetization value measured at the maximum applied field of 2.0 MAm−1 was adopted for convenience sake. Although it was confirmed that annealing of the rapidly quenched CeFe11Ti melt-spun ribbons enhanced their magnetic properties, their coercivity values were less than 0.1 MAm−1, below the expected coercivity value for permanent magnets.

Hysteresis curves of the as-quenched CeFe11Ti melt-spun ribbon and the annealed specimens.

Since it is known that SmFe11Ti melt-spun ribbons exhibit relatively high coercivity,28) rapidly quenched Ce1−xSmxFe11Ti (x = 0–1) melt-spun ribbons were prepared with the aim of improving the magnetic properties of CeFe11Ti melt-spun ribbon. Figure 2 shows the XRD patterns obtained from the rapidly quenched Ce1−xSmxFe11Ti (x = 0–1) melt-spun ribbons. The diffraction peaks of the ThMn12 and α-Fe phases were found in the XRD pattern of the as-quenched CeFe11Ti specimen. The diffraction peaks of these phases gradually became weaker as the Sm content increased. A broad peak was seen in the XRD pattern of the SmFe11Ti specimen. This indicates that the Sm substitution resulted in an increase in glass formability.

XRD patterns obtained from the rapidly quenched Ce1−xSmxFe11Ti (x = 0–1) melt-spun ribbons.

Figure 3 shows the coercivity of the Ce1−xSmxFe11Ti (x = 0–1) melt-spun ribbons plotted as a function of the annealing temperature. The coercivity of the CeFe11Ti specimen exhibited little change as the annealing temperature increased, while that of the Sm-containing specimens became higher as the Sm content and annealing temperature increased up to a temperature of 1073 K. The maximum coercivity was obtained by the SmFe11Ti specimen when annealed at 1073 K. Thus, 1073 K was determined to be the optimal annealing temperature.

Coercivity of the annealed Ce1−xSmxFe11Ti (x = 0–1) specimens as a function of the annealing temperature.

The hysteresis curves of the optimally annealed Ce1−xSmxFe11Ti (x = 0–1) specimens are shown in Fig. 4. Both the remanence and coercivity of the specimens increased, from 36.8 Am2kg−1 for the CeFe11Ti specimen to 63.7 Am2kg−1 for the SmFe11Ti specimen and from 0.064 MAm−1 for the CeFe11Ti specimen to 0.40 MAm−1 for the SmFe11Ti specimen. This indicates that the Sm substitution in the rapidly quenched CeFe11Ti melt-spun ribbons significantly improved their magnetic properties.

Hysteresis curves of the Ce1−xSmxFe11Ti (x = 0–1) specimens annealed at 1073 K.

Figure 5 shows the XRD patterns of the optimally annealed Ce1−xSmxFe11Ti (x = 0–1) specimen. After annealing, the Ce1−xSmxFe11Ti (x = 0–1) specimens consisted of the ThMn12 phase together with the α-Fe phase. The α-Fe phase remained in the annealed specimens even though the amorphous specimens were annealed. There have been many reports on the existence of the α-Fe phase in ThMn12-type magnets.27,28) Although the existence of the soft magnetic α-Fe phase deteriorates the hard magnetic properties of the ThMn12-type magnets, it is difficult to produce these magnets without the α-Fe phase.

XRD patterns obtained from the Ce1−xSmxFe11Ti (x = 0–1) specimens annealed at 1073 K.

The thermomagnetic studies were carried out to clarify the magnetic phases in the optimally annealed Ce1−xSmxFe11Ti (x = 0–1) specimens. The results, shown in Fig. 6, confirmed that the Ce1−xSmxFe11Ti (x = 0–1) specimens consisted of the α-Fe and ThMn12 phases. The Curie temperature of the CeFe11Ti specimen was 475 K. It was also found that the Curie temperature of the ThMn12 phase increased with the increasing Sm content. The remanence, coercivity, and Curie temperature of the optimally annealed Ce1−xSmxFe11Ti (x = 0–1) specimens were summarized in the Table 1. This indicates that the Sm substitution resulted in an increase in the Curie temperature as well as in the coercivity.

Thermomagnetic curves of the Ce1−xSmxFe11Ti (x = 0–1) specimens annealed at 1073 K.

This paper describes the results of a study on the structures and magnetic properties of CeFe11Ti and (Ce,Sm)Fe11Ti melt-spun ribbons. The as-quenched CeFe11Ti melt-spun ribbon and annealed specimens exhibited a coercivity of less than 0.1 MAm−1, below the expected coercivity value for permanent magnets. On the other hand, the coercivity of the (Ce,Sm)Fe11Ti melt-spun ribbons was increased by the heat treatment. X-ray and thermomagnetic studies revealed that the annealed (Ce,Sm)Fe11Ti melt-spun ribbons contained some α-Fe phase together with the ThMn12 phase. It was found that the coercivity and Curie temperature of the annealed (Ce,Sm)Fe11Ti melt-spun ribbons increased as the Sm content increased.

This research was supported by a grant from the Takahashi Industrial and Economic Research Foundation.