2023 Volume 64 Issue 7 Pages 1551-1565

2023 Volume 64 Issue 7 Pages 1551-1565

High entropy alloys (HEAs) are a novel class of materials that have emerged as potential candidates for various industrial applications due to their excellent mechanical properties at cryogenic, ambient, elevated temperatures, and even under a hydrogen environment. The incorporation of nanocrystalline (nc) structure into HEAs has attracted significant attention for the further enhancement of their exceptional properties, as exceptional grain refinement usually results in enhanced strength without a large expense of ductility. High-pressure torsion (HPT) is often considered one of the most efficient methods for nanocrystallization, and this also holds true for HEAs. Recently, nanoindentation technique has been widely utilized to explore the relationship between HPT-induced grain refinement and mechanical behavior due to the inhomogeneous microstructure within the HPT disk. In this report, recent nanoindentation studies performed on HPT-processed HEAs are comprehensively reviewed with special emphasis on the nanomechanical behavior of nc HEAs.

High entropy alloys (HEAs) are a new member of structural materials introduced in 2004,1,2) which were defined originally as alloys consisting of at least five principal elements in (near-)equiatomic compositions. Recently, the concept of HEAs has been extended to an alloy with 2 to 4 principal elements, which is usually referred to as medium-entropy alloys (MEAs) having configurational entropy in the range of 0.69R–1.61R (where R is the molar gas constant).3–5) Due to the relatively high configurational entropy, M/HEAs often exhibit a simple solid solution phase having body-centered cubic (BCC),6,7) face-centered cubic (FCC)8,9) or hexagonal close-packed (HCP) structures.10,11) M/HEAs possess (1) an outstanding combination of strength and ductility,12–14) (2) high resistance to corrosion,15,16) hydrogen embrittlement,17,18) wear,19,20) and fatigue,21,22) and (3) excellent strength retention at cryogenic and elevated temperatures.9,23–25) These exceptional properties of M/HEAs could be further improved by tailoring the microstructure (e.g., introducing multiple phases,26,27) short-range ordering,28–30) or refined microstructure31–33)).

Since the grain boundaries (GBs) are a representative example of the defects controllable in an easy and obvious manner, grain refinement might be the most effective way to improve the mechanical strength according to the so-called Hall-Petch relation:34,35)

| \begin{equation} \sigma = \sigma_{0} + k_{\textit{HP}}d^{-0.5} \end{equation} | (1) |

At present, the application of severe plastic deformation (SPD) is known as the most effective ‘top-down’ strategy to achieve exceptional grain refinement in bulk coarse-grained (cg) materials.38–40) Although there are several conventional methods such as intensive rolling, fast forging, and shot peening for inducing high strain, the most known SPD processes that have received the most scientific and industrial attention include equal-channel angular pressing (ECAP),41) high-pressure torsion (HPT),42) and accumulative roll-bonding (ARB).43) This is primarily because the level of applied strain upon ECAP, HPT, and ARB can be continuously increased by repeating the procedure without considerably changing the overall dimensions of the workpieces. Compared with ECAP and ARB, HPT processing has the advantage of introducing higher accumulative strains and thus leading to an exceptional level of grain refinement.39,44–50) In fact, it was demonstrated that for several HEAs, the nc structure could be achieved from the very early stage of HPT, establishing the HPT processing as the most efficient way for exploiting the synergy between HEA and nc alloys.31,32,36,37) As a result, HPT processing has been used for improving the mechanical properties of several M/HEAs, such as CoCrFeMnNi,31,36) CoCrFeNi,51,52) Al0.3CoCrFeNi,32,53) Al0.5CoCrFeMnNi,54) AlCrFeCoNiNb,55) TiZrNbHfTa,37,56) AlFeCoNiCu,57) CrFe2NiMnV0.25,58) TiZrCrMnFeNi,59) AlTiFeCoNi,60) AlTiFeCoNi–C61) and CoCrFeMnNi–C.62) More recently, the application of HPT has been extended to nonmetallic high-entropy materials, including high-entropy hydride MgTiVCrFe–H,63) high-entropy oxide TiZrHfNbTaO11,64) and high-entropy oxynitride TiZrHfNbTaO6N365) for investigating their potential applications in hydrogen-related industries. It is noteworthy that the hardness value of AlCrFeCoNiNb HEA increases to ∼1030 HV (or ∼10.9 GPa) after HPT-processing,55) which represents the highest hardness value reported among the aforementioned HEAs.

The equivalent strain imposed by the HPT process is inhomogeneously distributed across the HPT disk (which has generally a diameter of 10 mm and a thickness of approximately 0.8 mm) according to the relation:49,66)

| \begin{equation} \varepsilon_{\textit{eq}} = \frac{1}{\sqrt{3}}\frac{2\pi Nr}{t_{D}} \end{equation} | (2) |

The primary objective of the nanoindentation test is to estimate the hardness, HN, which is also useful for analyzing the effect of rate and temperature on the deformation behavior of a material as discussed below. The HN is determined as

| \begin{equation} H_{N} = \frac{P_{\textit{max}}}{A_{c}} \end{equation} | (3) |

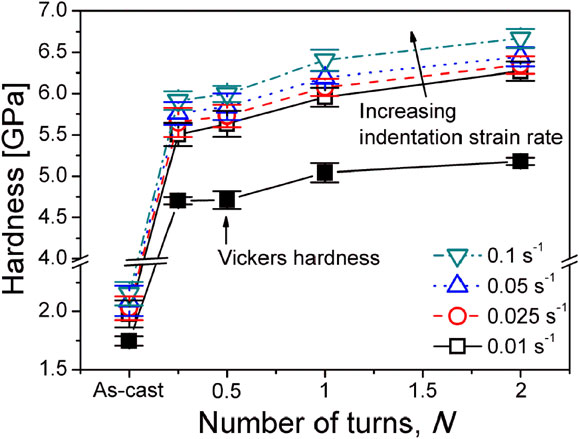

Figure 1 shows the variation in HN of CoCrFeMnNi HEA as a function of the number of HPT turns, N. Nanoindentation hardness remarkably increases in the early stages of the HPT process (N = 1/4 turn) and thereafter saturates toward the maximum values. Since HPT processing refined the grain size of CoCrFeMnNi HEA from an initial value of ∼40 µm to ∼40 nm without any phase transformation,31) HPT-induced hardening is mainly attributed to the grain refinement. It is also noteworthy that the tendency of the change in hardness is almost the same for the nanoindentation test and the microhardness test, but the higher values were recorded from nanoindentation tests compared with microhardness. This may be due to an indentation size effect (ISE) which is manifest as an increase in HN with decreasing h for a sharp indentation.71,72)

Variations in nanoindentation hardness (Pmax = 100 mN, Berkovich indenter) and microhardness (Pmax = 980 mN, Vickers indetner) of CoCrFeMnNi HEA as a function of N.31) Note that all hardness values were taken at the edge of HPT disks.

From nanoindentation tests, it is also possible to estimate the critical resolved shear stress required to operate plastic flow across the GB, τc, based on the dislocation pile-up model as:73)

| \begin{equation} k_{\textit{HP}} = 3M(\pi m_{s}\tau_{c}Gb/2\alpha)^{1/2} \end{equation} | (4) |

Change in nanohardness (Pmax = 100 mN, Berkovich indenter) of CoCrFeNi HEA as a function of d−1/2 under different $\dot{\varepsilon }_{i}$.52) Note that all hardness values were taken at the edge of HPT disks.

The significant GB strengthening in FCC M/HEAs is often attributed to the severe lattice distortion, which results in high Peierls stress.76) It is also noteworthy that the kHP values obtained from Fig. 2 are obviously higher than the kHP value (∼21.8 MP(mm)1/2) reported for the CoCrFeMnNi HEA of which grain size was controlled through heat treatments. This discrepancy could be due to the fact that the Hall-Petch plot in Fig. 2 was analyzed without taking into account the effect of dislocation hardening. During HPT processing, a large number of dislocations can accumulate and hence further contribute to HPT-induced hardening as followed by Taylor equation ($\sigma_{Taylor} = \alpha MGb\sqrt{\rho } $, where ρ is dislocation density).77–80) Therefore, it should be noted that the kHP values presented in Fig. 2 and Table 1 might be overestimated due to the lack of consideration of dislocation hardening.

Recently, there have been several attempts to fabricate nanocomposites by performing the HPT processing on dual-phase HEAs (such as Al0.7CoCrFeNi)81) or two disks of HEAs with different phases.82) For example, Taheriniya et al.82) produced an FCC CoCrFeMnNi and BCC HfNbTaTiZr nanocomposite via HPT processing (Fig. 3(a)–3(e)) and reported that the microhardness of the composite was found to be superior to the HPT deformed single-phase matrices after the same number of revolutions, i.e., the imposed ideal shear strains (Fig. 3(f)). To gain an insight on the hardness distribution within the constituent phases, high resolution-high speed nanoindentation mapping was employed for the nanocomposite and the results are displayed in Fig. 4.82) As shown in Fig. 4(a), two distinct phases are clearly identified by the cluster maps and, more importantly, the average values of hardness for Phase 1 (i.e., FCC phase) and Phase 2 (i.e., BCC phase) gradually increase with increasing numbers of HPT turns. In addition, the hardness intensity maps in Fig. 4(b) clearly revealed that a significant increase in hardness was observed in Phase 2 near the interphase boundary, in which deformation-induced dislocation accumulation and element migration occurred.82)

SEM images and the corresponding EDS elemental maps of CoCrFeMnNi and HfNbTaTiZr nanocomposites processed by HPT after (a) N = 5, (b) N = 10, and (c) N = 15 along with (d) enlarged image of (c), (e) EDS line scan across different phases occurring in N = 10 sample, (f) results of microhardness test (Pmax = 10 N, Vickers indenter). Note that the individual concentration profiles are shifted in (e) for better visibility.82)

Results of nanoindentation on the HPT-induced CoCrFeMnNi and HfNbTaTiZr nanocomposites: (a) Cluster maps with two distinct phases and the average hardness of Phase 1 and 2 plotted for each sample; (b) Hardness intensity maps.82)

Similarly, Gao et al.81) carried out nanoindentation on an HPT-processed dual-phase Al0.7CoCrFeNi HEA for exploring the contribution of constituent phases to its overall strength. Since the BCC/B2 phases (especially in HPT-processed samples) are too small to be directly indented, the authors suggested the protocol to estimate the hardness of only BCC/B2 phase from the hardness of FCC + BCC/B2 mixture, which is schematically illustrated in Fig. 5(a). As shown in the inset of Fig. 5(a), the indentation impressions produced at Pmax = 10 mN include both FCC and BCC/B2 phases. Therefore, the tests with Pmax = 5 mN were additionally performed on only the FCC phase. Since the HN obtained from FCC + BCC/B2 (i.e., HN at Pmax = 10 mN) cannot be directly compared with the HN obtained from the FCC phase (i.e., HN at Pmax = 5 mN) due to ISE, HN should be converted to the size-independent, mascroscopic hardness, H0 using the Nix-Gao model:71)

| \begin{equation} H_{N}^{2} = H_{0}^{2}\left(1 + \frac{h^{*}}{h} \right) \end{equation} | (5) |

| \begin{equation} H_{0,B} = \frac{H_{0,\textit{all}} - H_{0,F}X_{F}}{1 - {X_{F}}} \end{equation} | (6) |

| \begin{align} r_{p} &= h_{c}\,\mathit{cot}(90^{\circ} - \theta) \bigg\{ \frac{1}{6(1 - \nu)} \bigg[\frac{E}{\sigma_{y}}\tan (90^{\circ} - \theta) \\ &\quad + 4(1 - 2\nu) \bigg] \bigg\}^{1/3} \end{align} | (7) |

(a) Schematic diagram of ISE calculation process for the HPT-processed Al0.7CoCrFeNi HEA, the solid line is theoretical value of nanoindentation data, and the dashed line is the curve after ISE correction, (b) changes in H0 of uncharged and hydrogen-charged samples, and (c) hardening ratio by hydrogen charging and by HPT (inset) as a function of N.81)

In addition to the hardness, nanoindentation testing can be used to determine the elastic modulus from the P-h curve through the relation:68,69)

| \begin{equation} S = \beta \frac{2}{\sqrt{\pi}}E_{r}\sqrt{A_{c}} \end{equation} | (8) |

| \begin{equation} \frac{1}{E_{\textit{eff}}} = \frac{1 - \nu_{s}^{2}}{E_{s}} + \frac{1 - \nu_{i}^{2}}{E_{i}}. \end{equation} | (9) |

Nanoindentation results (hmax = 2500 nm, Berkovich indenter) on CoCrFeMnNi HEAs with millimeter-sized grain (CH), micrometer-sized grain (MG), and HPT-processed nanocrystalline (NC) structure: (a) Hardness and (b) elastic modulus measured at room temperature after 1 h isochronal heat treatments at different annealing temperatures.85)

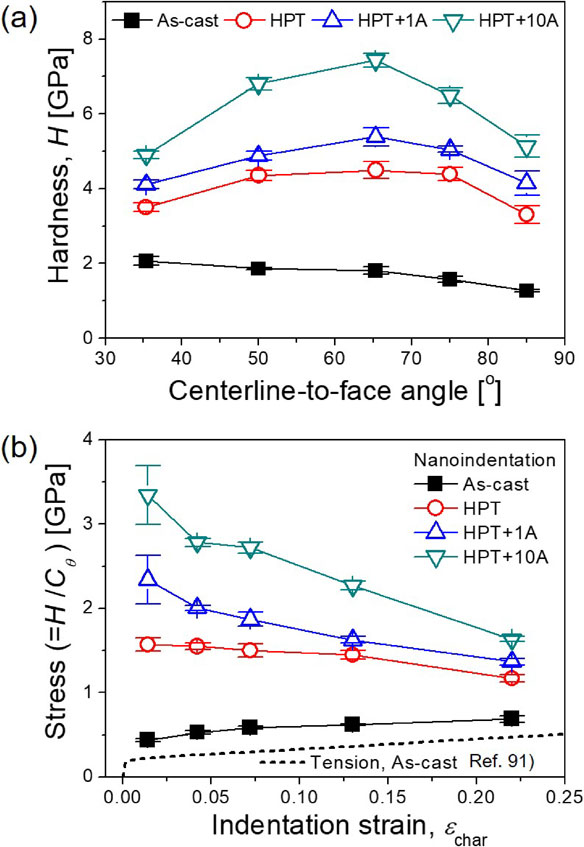

Since a sharper indenter induces a larger elasto-plastic strain in the material,86,87) a series of nanoindentation tests with numerous triangular pyramidal indenters having different “sharpness” that can be determined by centerline-to-face angle, ψ, makes it possible to estimate the constitutive stress-strain behavior of a local region within HPT-processed HEAs. This allows for systematic analysis of the effects of grain size on the stress–strain response and thus the constitutive behavior of HPT-processed HEAs. Such an example can be found in Lee et al.88) that explored the effect of annealing treatment on plastic flow in HPT-processed CoCrFeMnNi HEA. Figure 7 shows the variations in hardness (H) as a function of ψ (i.e., the sharpness of pyramidal indenter) for the HPT-processed CoCrFeMnNi HEA before (HPT) and after annealing treatment at 723 K for 1 h (HPT+1A) and 10 h (HPT+10A). For comparison purposes, the corresponding H versus ψ plot for the as-cast sample is also displayed in Fig. 7. As mentioned earlier, the indentations made with different ψ lead to different levels of plastic strain (so-called as characteristic strain, εchar) which can be described as89)

| \begin{equation} \varepsilon_{\textit{char}} = 0.2\sqrt{\frac{\pi}{3\sqrt{3}}}\cot \psi \end{equation} | (10) |

| \begin{equation} \sigma_{f} = \frac{H}{C_{\psi}} \end{equation} | (11) |

| \begin{equation} C_{\psi} = \frac{2}{3}\left[2 + \mathit{ln}\left(\frac{1}{3}\frac{E}{\sigma_{y}}\sqrt{\frac{\pi}{3\sqrt{3}}} \cot \psi \right) \right] \end{equation} | (12) |

(a) Variations in nanohardness (Pmax = 100 mN) as a function of indetner angle and (b) the estimated stress-strain curves for as-cast CoCrFeMnNi HEA and HPT-processed nc CoCrFeMnNi HEA with or without isothermal annealing.88) The tensile test data for the as-cast HEA91) is also shown for comparison purposes.

With eq. (10)–(12) and Table 2, H vs. ψ data in Fig. 7(a) can be successfully converted into stress vs. strain plots as shown in Fig. 7(b), where the tensile stress-strain curve for the as-cast HEA is also shown. Except for a slight discrepancy in stress, which may be due to the ISE, the derived the trend of stress change with respect to strain (or strain-hardening behavior) of the as-cast HEA sample agrees well with tensile results.91) It is interesting to find that the CoCrFeMnNi exhibits a transition from strain-hardening to strain-softening as grain size reduces from ∼40 µm (i.e., as-cast sample) to ∼40 nm (HPT sample). Similar to conventional nc metals and alloys, an extensive dynamic recovery, dynamic recrystallization, and the existence of residual internal stress in GBs could be considered as the possible mechanisms for the strain-softening phenomena in nc CoCrFeMnNi HEA. Figure 7(b) also revealed that the quantity of strain-softening increases with the annealing time, indicating that an additional mechanism may be activated for the annealed HPT samples. Considering that the fractions of annealing-induced second phases (especially for the intermetallic NiMn and FeCo phases) were reduced with increasing εchar, the deformation-assisted dissolution of the intermetallic phases could be the reason for the severe strain-softening behavior in the annealed HPT samples. The deformation-assisted destabilization of the second phases can be explained by taking into account the increase in the interface energy resulting from the dislocation accumulation and friction at the site.

The rate-dependent plasticity such as strain-rate sensitivity and activation volume permits a better understanding of thermally-activated plastic deformation mechanisms. Nanoindentation testing offers the advantage of being able to analyze the rate-dependent plasticity with reliability, since it can quickly generate a large amount of data and hence statistical analysis is feasible. Strain-rate sensitivity (m) and activation volume (V*) can be estimated by nanoindentation tests in two different methods: multiple constant strain-rate (CSR) tests and single strain-rate jump (SRJ) tests. With the empirical relation between the uniaxial strain rate $\dot{\varepsilon }$ and the indentation strain rate $\dot{\varepsilon }_{i}$ (i.e., $\dot{\varepsilon } \approx \beta \dot{\varepsilon }_{i}$, where β is constant92,93)), m and V* values can be expressed at a given strain, ε, and temperature, T, by

| \begin{equation} m = \left( \frac{\partial\,\mathit{ln}\,\sigma_{f}}{\partial\,\mathit{ln}\,\dot{\varepsilon}} \right)_{\varepsilon,T} {}= \left(\frac{\partial\,\mathit{ln}(H/C_{\psi})}{\partial\,\mathit{ln}(\beta \dot{\varepsilon}_{i})} \right)_{\varepsilon,T} \end{equation} | (13) |

| \begin{equation} V^{*} = \sqrt{3} kT \left(\frac{\partial\,\mathit{ln}\,\dot{\varepsilon}}{\partial \sigma_{f}} \right)_{\varepsilon,T}{}\approx \sqrt{3}kT \left(\frac{\partial\,\ln (\beta \dot{\varepsilon}_{i})}{\partial (H/C_{\psi})} \right)_{\varepsilon,T}, \end{equation} | (14) |

Variations in (a) strain-rate sensitivity and (b) activation volume of HPT-processed CoCrFeMnNi HEA with increasing N. Stress versus strain rate and logarithmic strain rate versus linear stress plots are provided in the insets of (a) and (b), reespectively.31) Note that nanohardness values were obtained under Pmax of 100 mN with Berkovich indenter.

As shown in Fig. 8(a), the HPT process has a substantial effect on these rate-sensitive parameters, suggesting that the predominant deformation process in the HEA could be transformed by grain refinement. To better understand the effect of grain refinement on the deformation mechanism of HEAs, the m and V* values of HEAs from the literature31,52,94–104) are plotted as a function of grain size, d, in Fig. 9. For comparison purposes, the literature data for pure Ni and binary Ni alloys105–113) are also present in Fig. 9. The m and V* for those alloys are summarized in Table 3. Note that only the results for FCC HEAs are included in Fig. 9, since the variation in m value with d in BCC and HCP HEAs has not been extensively examined. For example, González-Masís et al.56) investigated the rate-dependent plasticity in the HPT-processed Ti–Nb–Zr–Ta–Hf system through nanoindentation technique. However, the effect of element addition rather than the effect of grain size on strain-rate sensitivity was mainly focused in their work; m value tends to decrease with increasing the number of elements (m ∼ 0.011 for TiNb and m ∼ 0.006 for TiNbZrTaHf).56)

For clarity, all the data in Fig. 9 are grouped into two separate ranges of d, i.e., ∼5–100 nm (nc range) and ∼4–200 µm (cg range). In the nc regime, the m values for FCC HEAs (∼0.016–0.07) are comparable to that for pure Ni (∼0.010–0.055), whereas in the cg regime, the m values show a significant discrepancy (∼0.007–0.06 for HEAs vs. ∼0.002–0.005 for Ni). These results indicate that the deformation mechanisms in nc HEAs and nc Ni are similar, whereas the deformation mechanism in cg HEA is considerably distinct from that in cg Ni. A similar conclusion can also be drawn from V* versus d plots in Fig. 9(c) and 9(d). The V* values for the conventional cg FCC metals and alloys are typically in the range of ∼100–1000 b3, corresponding to the dislocation forest cutting mechanism,114,115) as shown in Fig. 9(d). On the other hand, cg FCC HEAs exhibit significantly lower V* values (usually in the range of ∼10–100 b3), indicating that the short-range of barriers, which are responsible for thermal-activated deformation,105,114) are predominant. This might be due to the fact that HEAs have high lattice friction stress and hence the Peierls barrier to dislocation motion is much stronger than conventional FCC metals.97,116) In addition, the existence of chemical short-range ordering in the HEAs, which has been confirmed theoretically and/or experimentally,29–31) may also be responsible for its high friction stress and thus contribute to the low V* values in the cg HEAs.97,102,116) By contrast, the V* values for nc fcc HEAs and nc fcc metals are around ∼10 b3, suggesting that the deformation mechanism in the nc fcc HEAs is GB-mediated dislocation activity (e.g., dislocation nucleation and/or dislocation depinning at GBs105,106)) as in the conventional nc FCC metals. Thus, it is concluded that the rate-limiting deformation mechanism in FCC HEAs transforms from lattice atoms-dislocation interaction to GB-mediated plasticity as the d is reduced to nc regime.

Since all mechanical properties such as H, m, and V* are highly dependent on testing temperature, nanoindentation tests at various temperatures can provide crucial information for high-temperature (HT) applications of HEAs. Figure 10 shows the HT nanoindentation results obtained from CoCrFeMnNi HEAs with cg and HPT-processed nc structures.117) As expected, HN of both nc and cg HEAs decreases with increasing T, but the slope of the ln(HN) versus 1/T plot is significantly changed at ∼473 K only for nc HEA (Fig. 10(a)). A similar transition can also be captured in the variation in m as a function of T (Fig. 10(b)); the value of m remains nearly constant (∼0.015) up to 423 K, then increases abruptly from 473 K onwards with T. Although sudden changes in HN and m values at ∼473 K indicate a possible transition in the deformation mechanism of nc HEA, it is challenging to confirm this mechanistic transition due to the lack of any substantial change in V* across the whole examined T range (Fig. 10(c)). These tendencies are in a good agreement with the data reported by Maier-Kiener et al.,98) despite a slight discrepancy in absolute values. Therefore, an investigation of the apparent activation energy, Q, is essential for a complete understanding of the thermally-activated deformation process. According to the Boltzmann-type constitutive law for temperature-dependent plastic strain rate, $\dot{\varepsilon } = \dot{\varepsilon }_{0} \textit{exp}( - \frac{Q}{kT})$, where $\dot{\varepsilon }_{0}$ is a pre-exponential constant and the barrier Q is described as the stress-dependent Gibbs free energy $\Delta \mathcal{G}$ for the activation of deformation. Considering that the entropy for deformation tends to be ignored due to its extremely small value, $\Delta \mathcal{G}$ is often assumed to be equal to the apparent activation enthalpy, $\Delta \mathcal{H}$.115,118) Then, $\Delta \mathcal{H}$ can be expressed as:115,118)

| \begin{equation} \Delta \mathcal{H} = \frac{HV^{*}}{\sqrt{3}C_{\psi}}\frac{\partial (\mathit{ln}\,H)}{\partial (1/T)} \end{equation} | (15) |

Results of the HT nanoindentation experiments on HPT-processed nc CoCrFeMnNi HEA: (a) the variation in nanohardness (hmax = 1700 nm, Berkovich indenter) as a function of 1/T; (b) the changes in strain-rate sensitivity, (c) activation volume, and (d) apparent activation enthalpy as a function of T.117)

Due to the large fraction of non-equilibrium GBs in the HPT-processed HEAs, the diffusion-related process such as creep deformation could be enhanced in the alloys even at relatively low temperatures such as RT.70,103) Therefore, the research of creep behavior at RT is crucial for evaluating the mechanical robustness of HPT-processed HEAs in a continuous mechanical load environment. Among various nanoindentation creep testing methods, the most popular by far is the constant-load method; the sample is quasi-statically loaded to a predetermined peak load, then the load is held constant, and the increase in h with holding time, thold, is recorded. This popularity is simply due to its close resemblance of the procedure to that in the conventional uniaxial creep test. From the change in h with t data, the variation in σf (converted from H using eq. (11)) as a function of t can be obtained. To determine $\dot{\varepsilon }_{i} = (dh/dt)/h$ for the creep regime, the displacement rate (dh/dt) is often calculated by fitting the h versus thold plot with an empirical equation:122,123)

| \begin{equation} h(t_{\textit{hold}}) = h_{0} + At_{\textit{hold}}^{\kappa} + Bt_{\textit{hold}} \end{equation} | (16) |

Although a sharp indenter like a three-sided pyramidal Berkovich indenter is widely used for nanoindentation creep test, some critical differences in data between indentation creep and uniaxial creep have been reported not only for conventional metals and alloys,123,124) but also for HEAs.70,103) For example, Yu et al.103) examined the creep resistance of HPT-processed Al0.1CoCrFeNi HEA by nanoindentation equipped with a Berkovich indenter. Figure 11(a) shows the h versus thold plots obtained at the points of different distances from the disk center (r = 0 mm, 3 mm, and 5 mm). The h versus thold curves are somewhat analogous to the early stages of the typical high-temperature creep curves, including both transient and steady-state creep regimes. The amount of creep displacement increases from 4.12 nm to 12.08 nm from the center (r = 0 mm) to the edge (r = 5 mm), implying that the creep deformation of the HEA is indeed enhanced by grain refinement. As shown in Fig. 11(b), however, the estimated n values (n ∼ 83 for r = 0 mm, n ∼ 41 for r = 3 mm, n ∼ 29 for r = 5 mm) are unreasonably high, so that it is difficult to identify the underlying mechanism of creep deformation. This implausible creep behavior might arise from some critical issues related to the sharp tip geometry. Detailed explanations for these issues are introduced elsewhere.124)

Results of nanoindentation creep tests with Berkovich indenter on HPT-processed Al0.1CoCrFeNi HEA: (a) Creep displacement versus time; (b) double logarithimic plot between nanoindentation hardness and time.103)

To solve the issues related to sharp tip geometry, Lee et al.70) employed a spherical indenter to explore the creep behavior of the HPT-processed CoCrFeMnNi HEA. In spherical indentation, εchar in eq. (10) can be quantified as $0.2\sqrt{2hR - h^{2}} /R$ where R is the radius of the spherical indenter. As demonstrated in the inset of Fig. 12(a) and 12(b), creep deformation occurs even at RT in both cg and nc HEAs and, more importantly, the amount of creep strain (εcreep = ε − ε0, where ε0 is the strain at the onset of creep) clearly increases as Pmax increases. To estimate the $\dot{\varepsilon }_{i}$ for the spherical indentation, εcreep versus thold curves were fitted according to Garofalo’s mathematical fitting equation,125)

| \begin{equation} \varepsilon_{\textit{creep}} = I(1 - e^{-\Phi t_{\textit{hold}}}) + \chi t_{\textit{hold}} \end{equation} | (17) |

Results of nanoindentation creep tests with spherical indenter on CoCrFeMnNi HEAs: Strain rate versus holding time (with the inset showing creep strain versus holding time) for (a) HPT-processed nc HEA and (b) as-cast cg HEA.70)

Relations between quasi-steady state (QSS) creep strain rate and stress for HPT-processed nc CoCrFeMnNi HEA.70)

For practical applications of nc HEAs developed with the aid of HPT, it is crucial to demonstrate that their prominent mechanical performance is preserved even under a harsh environment such as a hydrogen atmosphere. Since the susceptibility of materials to hydrogen embrittlement (HE) is strongly correlated with their microstructure, the large fraction of GBs in nc HEAs may lead to significantly different HE behavior compared to cg HEAs. To shed light on this, Zhao et al.126) investigated the hydrogen absorption and its effect on the hardness of two nc HEAs (i.e., CoCrFeNi and CoCrFeMnNi) and compared the results with those obtained from cg counterparts. As shown in Fig. 14(a), a clear increase in HN upon hydrogen charging is observed in all cases. Importantly, the percentage increase in HN is much smaller in both nc HEAs (∼7%) whereas it is substantial in cg samples (∼57% for CoCrFeMnNi and ∼29% for CoCrFeNi). On the basis of these results, it is reasonable to speculate that the effect of hydrogen on ductility/toughness may be weaker in nc HEA than in cg HEA. Insights into the possible reasons can be gained by analyzing the deformation mechanisms inferred through the V* values. For the uncharged samples, V* values in the nc HEAs are in the range of ∼11–18 b3, whereas V* of the cg samples varies between ∼22 and 70 b3 (Fig. 14(b)), which is consistent with the literature data in Fig. 9(c) and Table 3. On the other hand, V* values obtained on hydrogen-charged samples are always lower than those of the uncharged ones, implying that the absorbed hydrogen increases the lattice friction stress for dislocation motion. Such an enhancement in the friction stress inhibits dislocation mobility, leading to an increase in hardness with a reduction in V*, which might eventually enhance the alloy susceptibility to HE. Such a contribution, however, would be negligible in nc HEAs, since the deformation in nc HEAs is mainly dominated by GB-mediated plasticity rather than by lattice atoms-dislocation interaction, as deduced from the above analysis on V*. As noted from Fig. 5(b) and 5(c), a similar trend also could be observed in dual-phase Al0.7CoCrFeNi HEA; hydrogen-induced hardening is significantly reduced after HPT processing for both FCC and BCC/B2 phases. Interestingly, the FCC phase shows much stronger hydrogen-induced hardening than the BCC/B2 phase. This is because the FCC phase absorbs much more interstitial hydrogen than BCC/B2.127) In addition, the FCC phase is relatively softer than the BCC/B2 phase, making it more amenable to hydrogen-induced solid solution strengthening.87,128)

(a) Changes in hardness due to hydrogen charging in CoCrFeNi and CoCrFeMnNi HEAs. (b) Activation volume (V*) in both uncharged and hydrogen-charged HEAs.126)

Due to the extremely high straining, HPT processing can achieve exceptional grain refinement from cg to nc in various HEAs. To gain insights into the relationship between refined microstructure and mechanical behavior of HPT-processed HEAs, the nanoindentation technique has been widely employed under a variety of strain-rate and temperature conditions, allowing for exploring various mechanical properties of the local regions within an HPT disk. This review mainly focused on the results of nanoindentation research on HPT-processed HEAs with the following aspects:

The work at Chungnam National University was supported in part by research fund of Chungnam National University, and in part by the National Research Foundation (NRF) grant funded by the Korean government (MSIT) (No. 2021R1A4A1031494). The work at Hanyang University was supported by the NRF grant funded by the MSIT (No. 2022R1A5A1030054). This study at Oregon State University was supported by the National Science Foundation of the United States under Grant No. CMMI-2051205. The work at the University of Southampton was supported by the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS.