2024 Volume 65 Issue 6 Pages 629-636

2024 Volume 65 Issue 6 Pages 629-636

This study investigates the effect of the line weld angle with respect to the load axis on the strength properties of cross-type LSW joints with four line welds. Static and fatigue tests, finite element method analysis, and three-dimensional crack observation were performed on joints with line welds at three different angles 30°, 45°, and 60°, respectively to investigate the effect of the line weld angle. As a result, the cross-type LSW joints showed superior strength properties compared with those of the Φ-type LSW joints regardless of the line welding angle. The fatigue strength was particularly superior in the region with a high test force amplitude. The amount of fatigue crack propagation in the thickness direction increases as the line welding angle increases. This trend is similar to that observed for the Φ-type joints reported by Sannomiya et al. It can be inferred that an increase in the amount of crack propagation in the thickness direction increases the crack propagation path length, and thus the crack propagation life. Furthermore, FEM analysis showed that the line weld angle does not significantly affect the fatigue crack initiation life. The results of three-dimensional observations showed that too large a line welding angle increased the number of crack initiation points and reduced the crack growth life relative to the total life, resulting in a significantly shorter crack growth life compared with the fracture life. These results indicate that the strength properties of LSW joints can be improved by increasing the number of line welds, and that further strength improvement can be expected by welding line welds at the appropriate angles with respect to the load axis. For the conditions considered in this study, the line welding angle that exhibits the highest fatigue strength is estimated to be between 45° and 60°.

Relationship between test force amplitude and Number of cycles to failure on fatigue test.

In recent years, the automotive industry has been required to reduce its CO2 emissions in response to climate change. Companies have thus reduced the weight of car bodies to improve fuel efficiency. However, to improve crash safety, thicker components, which tend to increase vehicle weight, are required. Therefore, there is growing demand for high-tensile steel sheets, which are stronger than mild steel, to achieve both car body weight reduction and crash safety [1, 2]. In general, welding is used to construct automotive structures. Resistance spot welding (RSW) is widely used for this task due to its high workability, low cost, and easy automation. RSW has been extensively studied since it is important to ensure the strength and reliability of welds, which are a source of stress concentration, in the design of car bodies [3–8]. The welding cycle time for RSW is long because many welding machines are required. Due to the shape and structure of the welding machine, the electrodes must be clamped on both sides of the member, which reduces the degree of freedom in structural design, and the arm of the welding machine must move from one welding point to the next.

Laser welding has attracted attention as an alternative technology to overcome these problems. Compared with conventional welding techniques such as RSW, laser welding has several advantages, including higher precision. Unlike RSW, laser welding can form welds from one side of the member, allowing for greater flexibility in structural design. The most distinctive advantage of laser welding is the ability to freely manipulate the shape of the weld [9]. However, the introduction of a new welding technique requires consideration of various factors that affect fatigue strength. Laser welding has thus been extensively studied [10–18].

Focusing on the flexibility of the weld shape with laser welding, Sannomiya et al. devised a Φ-type laser spot welding (LSW) joint by applying two-line welds to conventional LSW to improve fatigue strength by increasing the joint area. The fatigue properties of Φ-type LSW joints and the effect of the line welding angle with respect to the load axis on the fatigue properties were investigated. According to Sannomiya et al. the fatigue strength of Φ-type LSW joints is superior to that of conventional LSW joints regardless of the line welding angle. They also found that a joint with the line weld applied at 45° with respect to the load axis (referred to as Φ45) had the best fatigue strength. These results suggest that the fatigue strength of LSW can be improved by applying line welding and can be further increased by applying the line weld at an angle with respect to the load axis [19].

The joining method adopted in the present study enables the use of two additional welding lines compared with those for the Φ-type LSW joint described above. Here, a cross-type LSW joint with four line welding is using conventional LSW to further improve fatigue strength. The fatigue properties of cross-type LSW joints and the effect of the line welding angle on the fatigue properties of high-tensile steel are investigated.

In this study, SPFC590 (JISG3135, thickness: 1 mm), a cold-rolled high-strength steel generally used in the automotive industry, was used. The chemical composition and mechanical properties of SPFC590 are shown in Tables 1 and 2, respectively. After the material was cut into 100 mm × 40 mm plates, two plates were overlapped by 50 mm and the center of the overlap was joined using LSW. Line welding was then applied to the specimens. The specimen dimensions and an overview of the welds are shown in Fig. 1. The joining conditions are shown in Table 3. For the LSW used in this study, a circular weld was formed by laser irradiation in a spiral shape from the center; then, immediately before the circular weld solidified, laser irradiation in a straight line to form a line weld by pouring molten metal from the circular weld into a groove created by the laser beam. Line welds were applied at three angles (30°, 45°, and 60°) to investigate the effect of the line weld angle with respect to the load axis. The joints fabricated with these three angles are denoted cross30, cross45, and cross60, respectively. For all three shapes, the diameter of the circular weld was 6 mm, and the length of the line weld was 5.5 mm. To investigate the fatigue characteristics of the cross-type LSW joints, these joints were compared with Φ45, which had the best fatigue strength of Φ-type joints.

Shape and dimensions of joints used in this study.

A servo-hydraulic pulser (Shimadzu, EHF-EV050k1-020-0A50kN) was used for the tests. Static tensile tests were performed at a loading speed of 100 N/s. Fatigue tests were performed with a load ratio of Rp = 0.1, and a test frequency of f = 10 to 20 Hz. Cyclic stress continued until the specimen broke or the number of cycles reached N = 1 × 107.

2.3 Geometrically non-linear finite element method analysisA three-dimensional elastic-plastic analysis was performed to investigate the stress state in the joints during the test. Marc Mentat 2017 (MSC Software) was used for the geometrically non-linear FEM analysis. Figure 2 shows the analysis model for cross45. The mesh was radially divided around the tip of the line weld so that the line welding angle would not affect the mesh division. As boundary conditions, the upper plate had fixed displacements along the X, Y, and Z axes, and the lower plate had displacements along the Y and Z axes and a load of 2.5 kN along the X axis. The plate spacing was set to 0.02 mm, an experimental value based on cross-sectional observation. The chucking area was 25 mm from both ends of the joint as in the actual test. The material properties are shown in Table 4. A stress-strain diagram is shown in Fig. 3. The base metal, circular welds, and line welds were all assumed to be elastoplastic. The yield stresses were set linearly to the average value of Vickers hardness in each region of base metal, circular welds, and line welds (base metal: 196 HV, circular welds: 349 HV, line welds: 425 HV). Detailed data on the Vickers hardness are described below.

FEM analysis model for cross45.

Stress-Strain curves.

To investigate the strength characteristics, such as crack initiation and growth life, of cross-type LSW joints in more detail, strain gauges (Kyowa Dengyo, KFGS-2-120-C1-11 L1M2R, gauge length: 2 mm) were attached to the joints to observe the strain behavior during the test. Figure 4 shows the location of the strain gauge attachments at cross45. Strain was obtained using the one-gauge method. To improve the accuracy of strain acquisition, the location of the strain gauge attachment was roughened with #200 emery paper, cleaned with acetone, and then coated with strain gauge-specific adhesive before the strain gauge was attached.

Strain gauge attachment position at cross45.

Three-dimensional observation of crack growth was conducted to investigate the amount and behavior of fatigue crack growth in the joints. The observation procedure was as follows.

Diagram of observation point cutout and observation direction.

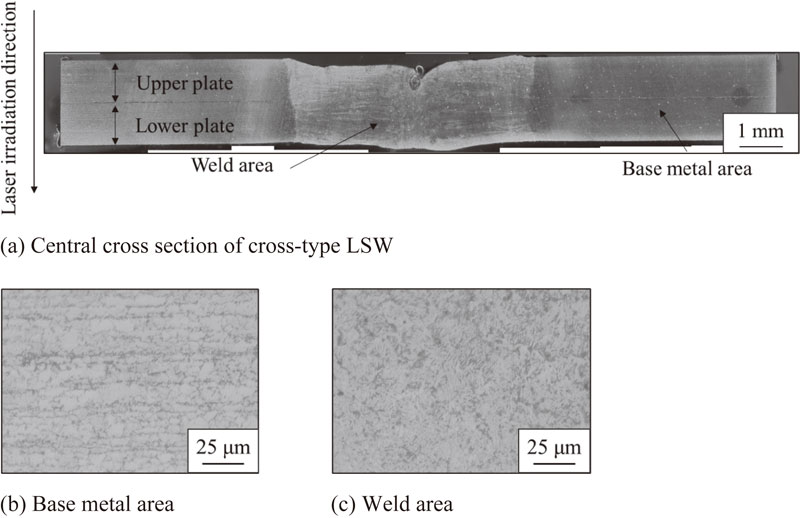

Microstructural observation of the central cross section of the cross-type LSW joints fabricated in this study was performed using scanning electron microscopy (SEM). Figure 6 shows the results of the observation. Figure 6(a) shows that the amount of molten metal in the lower plate is smaller than that in the upper plate. Since the laser irradiation and welding were performed from one side of the upper plate, the heat input to the upper plate was higher, which is thought to have resulted in an increase in the amount of molten metal on the upper plate side. The dent at the top of Fig. 6(a) is caused by the welding process. Since the line welds are welded by flowing molten metal from the circular weld, the material in the circular weld is reduced and the dent is formed as shown in the figure. Furthermore, Fig. 6(b) and (c) show that the joints were composed of needle-like grain, which was due to the formation of martensite by the heat of melting. The measured diameter of the molten pool was approximately 6 mm.

Images of central cross section of cross-type LSW.

The results of Vickers hardness tests conducted on cross-type LSW joints are shown in Fig. 7. The Vickers hardness was 280–340 HV, for the circular welds, 340–490 HV for the line welds, and 160–200 HV for the base metal, indicating that the hardness of the welds was higher than that of the base metal. This is due to the formation of martensite, which is harder than the base metal. In addition, it was confirmed that the hardness increased with distance away from the center of the weld in the weld zone. This is presumably because the cooling rate is higher in the region closer to the base metal than in the center of the weld.

Vickers hardness test results.

The static tensile test results are shown in Fig. 8. In this study, two joints were tested for each shape. The average of the test results was used as the tensile strength. The average tensile strength was 14.6, 14.6, 13.2, and 12.9 kN for cross30, cross45, cross60, and Φ45, respectively.

Static tensile test results.

A comparison of the cross and Φ-type joints confirmed that the tensile strength of the cross-type joints was higher. In other words, increasing the number of line welds increased the tensile strength. The tensile strength of cross60 is lower than that of cross30 and cross45, suggesting that the tensile strength decreases as the line welding angle increases beyond a certain value.

3.3 Fatigue test resultsThe fatigue test results are shown in Fig. 9. The plots can distinguish the fracture modes since two different macroscopic fracture modes were observed in this study, as shown in Fig. 10. The macroscopic fracture modes of cross45 at test force amplitudes of 1.0 kN and 2.5 kN, respectively, are shown in Fig. 10(a) and (b) as representative examples. Weld area fracture is a fracture mode in which a fatigue crack propagates in the weld zone and the upper and lower plates separate, as shown in Fig. 10(a). Base metal fracture is a fracture mode in which a fatigue crack propagates mainly in the base metal in the direction perpendicular to the load axis, resulting in the fracture of the steel plate on one side, as shown in Fig. 10(b).

Force amplitude versus number of cycles to failure.

Macroscopic fracture form of cross45.

Figure 9 shows that the cross-type LSW joint has a very low fatigue limit compared with the tensile strength given in the previous section. In other words, cross-type LSW joints have low fatigue resistance. Differences in the fatigue life of the various joints were observed in the region with a high test force amplitude where weld fracture was observed. In contrast, there was no difference in the region with a low test force amplitude region where base material failure occurred. This is because the cracks that lead to base metal failure propagate mainly in the base metal and are less affected by weld geometry. This tendency is also true for the Φ-type joints reported by Sannomiya et al. [19]. In the region with a high test force amplitude, where the fatigue life difference was observed, all the cross-type joints had longer fatigue lives than those of Φ-type joints with two line welds, indicating the superiority of the cross-type joint with four line welds. The Φ-type joint has two fewer line welds than the cross-type joint, resulting in a smaller joint area and therefore inferior joint rigidity, which is the main reason for the inferior fatigue strength of the Φ-type joint. Furthermore, focusing on the line welding angle of the cross-type joint, it was confirmed that cross45 had the best fatigue properties, followed by cross30 and cross60.

3.4 Fracture surface observationFracture surface observation was conducted at a test force amplitude of 2.5 kN, at which weld fracture occurred. Figure 11 shows the fracture surface observation results for cross30. Based on the observation of the fracture surface and the report by Sannomiya et al. [19], it is inferred that the cracks occurred at two points at the tips of the line welds on the load-bearing side. Figure 11(c) shows the results of the three-dimensional observation of the fracture surface of the line weld. The figure shows that the fracture surface is relatively flat. This indicates that fatigue cracks propagating in the line weld propagate near the interface between the upper and lower plates.

SEM fracture surface observation of cross30 (Pa = 2.5 kN).

Figure 12 shows the results of the fracture surface observation of cross60. The fracture surface of the line weld shown in Fig. 12(b) is not flat, as seen for cross30, but had a bump in the direction of the plate thickness. In other words, when the line welding angle with respect to the load axis is small, the fatigue crack propagates near the interface between the upper and lower plates. The amount of propagation in the thickness direction increases as the line welding angle increases. This trend is similar to that observed for the Φ-type joints reported by Sannomiya et al. [19]. It can be inferred that an increase in the amount of crack propagation in the thickness direction increases the crack propagation path length, and thus the crack propagation life.

SEM fracture surface observation of cross60 (Pa = 2.5 kN).

The above results suggest that the crack growth life can be extended by increasing the line welding angle. However, this is inconsistent with the fatigue test results shown in Fig. 9. A stress analysis using FEM was thus performed, as described in the next section.

3.5 Geometrically non-linear finite element method analysisThe stress concentration at the tip of the line weld, which is the crack initiation point, was calculated using FEM analysis. The results of the analysis are shown in Fig. 13. The figure shows that the von Mises stress at the tip of the line weld decreases as the line welding angle increases. This is due to the increase in the area available for load sharing with increasing line welding angle. It is known that higher stresses generally lead to earlier crack initiation; however, a comparison of the von Mises stresses for all cross-type joints shows relatively close values (834–878 MPa). It is unclear whether this difference in stress concentration at the tip of the line weld affects the crack initiation life of each joint. Therefore, an estimation of the crack initiation life was conducted by investigating the strain behavior. The results are shown in Fig. 14. The figure shows that the strain increases immediately after the start of the test in all cross-type joints, indicating that the cross-type joints crack very early regardless of the line welding angle, and that the difference in stress concentration at the tip of the line weld, which was confirmed by FEM analysis, does not significantly affect the fatigue crack initiation life.

FEM analysis results of von Mises stress (Pmax = 2.5 kN).

Maximum strain behavior.

The results of our experiments reveal the following.

The results of three-dimensional observations of fatigue cracks are shown in Fig. 15. As can be seen, the cracks in cross30 and cross45 started and propagated from the tip of the line weld on the load-bearing side. There was no significant difference in the amount of crack propagation. In contrast, in cross60, the cracks originated from the circular welds in addition to the two tips of the line welds. The FEM analysis results shown in Fig. 13 indicate that in cross60, high stresses are generated not only at the two tips of the line welds but also at the circular welds. This is because when the line welding angle is increased, as in Cross 60, the horizontal distance of the load axis from the tip of the line weld to the circular weld, where stress is concentrated, becomes shorter, and the load is shared at three points, including the circular weld, not just at the two line welds. In addition, the shorter horizontal joint area of the load axis compared to other shapes of joints is one of the reasons for the inferior rigidity and higher bending stresses. Fatigue cracks usually initiate at two points at the tip of the line weld on the load-bearing side for a cross-type joint; however, when the line welding angle is increased to 60°, fatigue cracks also initiate at the circular weld (i.e., there are three crack initiation points), resulting in a significantly shorter crack growth life compared with the fracture life.

Results of three-dimensional crack observation (Pa = 2.5 kN).

In this study, cross-type LSW joints were fabricated by welding four line welds at three different line welding angles with respect to the load axis. Static and fatigue tests and a FEM analysis were used to investigate the fatigue properties of cross-type LSW joints and the effect of the line welding angle on strength properties. The following conclusions were obtained.