Featured articles

-

Volume 68 (2025) Issue 11 Pages 605-610Unraveling the Origin of Localized Surface Plasmon Resonance in Noble Metals and Its Integration with Surface Plasmon Polaritons Read more

-

Volume 68 (2025) Issue 10 Pages 548-553Kinetic Analysis and Operando Spectroscopy for Revealing Microscopic Reaction Mechanisms on Photocatalyst Surfaces Read more

-

Volume 68 (2025) Issue 9 Pages 510-515Features and Latest Trends of Electron Beam Additive Manufacturing System Read more

-

Volume 68 (2025) Issue 8 Pages 454-458Structure Analysis of H by Channeling 15N-NRA and Discovery of H-induced Jahn-Teller Effects Read more

-

Volume 68 (2025) Issue 7 Pages 407-412Direct Visualization of Metal–Insulator Transition Dynamics in VO2 Thin Films Read more

-

Volume 68 (2025) Issue 6 Pages 320-327Accelerating the Data Generation, Accumulation and Utilization via Machine Learning Read more

-

Volume 68 (2025) Issue 5 Pages 277-282Observation of Edge States in Te Using Synchrotron-based Micro-ARPES Read more

-

Volume 68 (2025) Issue 4 Pages 204-211Operando Observations for Catalysis with Soft-X-ray Surface Spectroscopy Read more

-

Volume 68 (2025) Issue 3 Pages 137-142Development of Superconducting Qubits Based on Nitride Superconductors Read more

-

Volume 68 (2025) Issue 2 Pages 71-76Autonomous Robotic Experiments for Powder X-ray Diffraction Read more

-

Volume 68 (2025) Issue 1 Pages 37-42International Standardization of Local Elastic Modulus Measurement by Atomic Force Microscopy and Its Application to Materials Industry Read more

-

Volume 67 (2024) Issue 12 Pages 586-592Latest Trends of Sealing Inspections and Leak Testing Read more

-

-

Volume 67 (2024) Issue 10 Pages 500-505Introduction for “EMPeaks”, High-throughput Spectrum Analysis Assisted by Machine Learning Read more

-

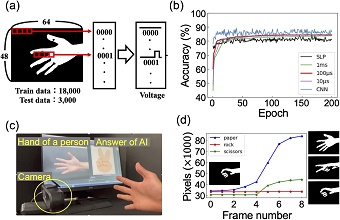

Volume 67 (2024) Issue 9 Pages 428-432Physical Reservoir Computing Devices Utilizing Nanomaterial Random Network and Its Sensing Application Read more

-

Volume 67 (2024) Issue 8 Pages 376-380Structural Analysis for the Oxide Surface of Nb(110) with Atomic Force Microscopy Read more

-

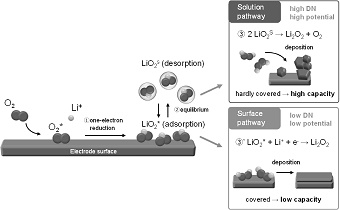

Volume 67 (2024) Issue 7 Pages 310-315The Reductive Formation and Oxidative Decomposition of Solid-State Discharge Products in Lithium–Oxygen Secondary Batteries Read more

-

Volume 67 (2024) Issue 6 Pages 261-266Direct Observation of Single Asperity Friction and Wear Studied by Transmission Electron Microscopy with Atomic Resolution Read more

-

Volume 67 (2024) Issue 5 Pages 206-211Electrochemical Imaging of Catalytically Active Site by Scanning Electrochemical Cell Microscopy Read more

-

Volume 67 (2024) Issue 4 Pages 186-191Dry Pumps in Accelerator—Usage at the Japan Proton Accelerator Research Complex (J-PARC)— Read more