2020 Volume 68 Issue 6 Pages 516-519

2020 Volume 68 Issue 6 Pages 516-519

Mohs paste is useful for controlling exudates from wounds and infections and is used to treat patients with inoperable skin tumors. Unfortunately, Mohs paste is difficult to preserve because its viscosity and stickiness increase dramatically immediately after preparation, resulting in decreased usability. In this study, the combined use of cryopreservation and kneading was shown to improve long-term storage of Mohs paste. At 25°C, Mohs pastes solidified rapidly, and viscosity reached approximately 700 Pa·s 5 h after preparation. In contrast, cryopreservation at −20°C attenuated hardening of Mohs pastes, and kneading also decreased viscosity. The viscosity of Mohs pastes cotreated with cryopreservation and kneading after 7 months of storage was <70 Pa·s. In addition, tissue invasion with these stored pastes was similar to freshly prepared Mohs paste. Results suggest that the combination of cryopreservation and kneading permits Mohs paste to be stored over extended periods, which may increase the utility of the paste for clinical use.

Unresectable malignancies, such as advanced breast cancer, gradually become malodorous, hemorrhagic, and ulcerative and grow into disintegrated large tumors. These ancillary symptoms significantly reduce the QOL of patients. In recent years, the use of Mohs chemosurgery has become widespread, primarily to improve QOL by chemically fixing ulcerated tissues.1,2) In Japan, Mohs paste is often used to prevent such odor, hemorrhage, and exudate.2)

Mohs microscopic surgery is a method for tissue fixation developed by Mohs in the 1930s. The paste is based on zinc oxide starch powder (Mohs paste) and is widely used in Japan.3) Mohs paste is also used to decrease exudate from self-destructive wounds and to manage hemorrhage by fixing tissues for removal of inoperable superficial tumors.

Mohs paste action is due to zinc chloride, which is ionized in tissues and leads to protein agglutination and hardening of tumor cells. As a result, hemorrhage is reduced, and odors and exudates are controlled.4–6) Mohs paste is thus useful for controlling seepage from wounds and infections and for treatment of patients with inoperable skin tumors.

However, viscoelasticity and malleability of Mohs paste are dramatically increased and decreased, respectively, immediately after preparation, with a concomitant increase in stickiness. Greater viscosity and stickiness cause inflammation and pain through adhesion to normal tissues following the application of the paste.7) Hence, long-term storage of Mohs paste is difficult. To address this problem, alternative substrates for Mohs pastes were investigated in a previous study.8) Yamamoto et al. reported that physicochemical changes immediately after preparation were prevented by 4% D-sorbitol.8) Taguchi et al. similarly showed that a starch-free Mohs paste was subject to smaller changes in viscosity without reducing efficacy.9) Kawamata et al. found that the increase in viscosity was suppressed for 14 d by the addition of a simple zinc oxide ointment,10) and Sato et al. prepared several types of ointment bases, hydrophilic ointment, absorptive cream, and liquid paraffin that effectively suppressed the increase in viscosity.11) Thus, some information is available for improving long-term storage of Mohs paste. Novel techniques are still required to store Mohs paste for longer periods without loss of effectiveness. Further studies are necessary to assess clinical applications.9–11) In this study, changes in viscosity and efficacy (tissue invasion) of Mohs paste after storage at various temperatures and kneading are reported.

Zinc chloride was provided from FUJIFILM Wako Pure Chemical Corporation (Osaka, Japan), and zinc oxide starch powder and glycerin were purchased from Maruishi-Pharm (Osaka, Japan). All chemicals were special grades.

Preparation of Mohs PasteZinc chloride (25 g) was dissolved in 12.5-g aliquots of purified water at 25°C and cooled to room temperature (zinc chloride solution). Zinc oxide starch powder (25 g) was then gradually added to the zinc chloride solution and was mixed using a pestle. Glycerin (5.7 g) was added to optimize viscosity. The composition of the paste is shown in Table 1. The paste was stored at −80°C in an ACF-205C freezer (YOSHII ELECTRIC CO., Ltd., Gunma, Japan), at −20°C in an ACF-205R freezer (YOSHII ELECTRIC CO., Ltd.), at 4°C in a 09VQ refrigerator (NIKKEI PANEL SYSTEM, Tokyo, Japan), or at 25°C in an HB-80 incubator (IKEDARIKA, Tokyo, Japan).

| Composition | Weight |

|---|---|

| Zinc chloride | 25 g |

| Zinc oxide starch powder | 25 g |

| Glycerin | 5.7 g |

| Purified water | 12.5 g |

Changes in weight, viscosity, and tissue invasion were evaluated after storage at different temperatures. Paste was kneaded 60 times by a glass rod and returned to room temperature (5 min) before measurement. Viscosity was determined using a Brookfield digital viscometer (Brookfield Engineering Laboratories, Inc., Middleboro, MA, U.S.A.). Viscosity was compared with and without kneading. Medicinal effects were evaluated by applying 1.0-g samples to chicken breast meat for 2 h. Subsequently, a circle of skin (diameter, 1.5 cm) to which paste had been applied was cut and photographed with a digital camera. Depths and areas of skin invasion were analyzed using ImageJ software.

Statistical AnalysisDifferences were identified using Dunnett’s multiple comparison test with JMP (SAS Institute Inc., Cary, NC, U.S.A.) software and were considered significant for p < 0.05.

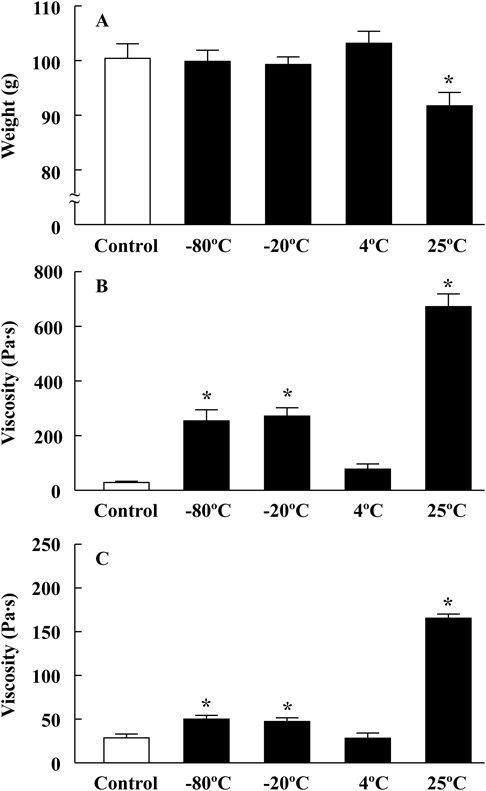

Figure 1 shows changes in viscosity of Mohs paste 0–2 d after preparation and subsequent storage at 25°C. Weights of Mohs paste samples decreased with time approximately 90% after 2 d (Fig. 1B). Viscosity significantly increased at 5 h and at 2 d after preparation did not change notably between these time points (Fig. 1C). Figures 2A and B show changes in weights and viscosities of Mohs paste after storage at various temperatures. No decreases in weight were observed after refrigeration (4°C) or cryopreservation (−80 and −20°C) for 2 d. Increases in viscosity were attenuated by both refrigeration and cryopreservation, with final viscosity similar to that immediately after preparation. Figure 2C shows the effects of kneading on the viscosity of Mohs paste after storage at various temperatures.

Data are presented as means ± standard error (S.E.) of three to five experiments; * p < 0.05 vs. 0 h for each category. Mohs paste samples were solidified within 5 h of preparation, with a viscosity of approximately 700 Pa·s.

Mohs paste samples were stored at −80, −20, 4, or 25°C for 2 d. (A) Changes in weights of Mohs paste samples; changes in viscosity of Mohs paste without (B) and with (C) kneading; control, Mohs paste immediately after preparation; data are presented as means ± S.E. of three to five experiments; * p < 0.05 vs. control for each category. Refrigeration and cryopreservation prevented hardening of Mohs paste. Kneading decreased the viscosity of paste samples.

Changes in viscosity of Mohs paste were attenuated by storage at lower temperatures, in contrast to the significant increase after storage at 25°C. Viscosity was <50 Pa·s in all refrigerated and cryopreserved paste samples. Prior to assessments of efficacy on chicken breast meat (Fig. 3), Mohs paste was stored for 2 d and was kneaded before application. After storage under ambient, refrigeration, and cryopreservation conditions, depths and areas of tissue invasion did not differ significantly from controls that used paste immediately after preparation.

Mohs paste samples were stored at −20, 4, or 25°C for 2 d and were kneaded before application. Digital image (A), depth (B), and area (C) of invasion of skin treated with Mohs paste for 2 h; control, Mohs paste immediately after preparation. Data are presented as means ± S.E. of three experiments. Tissue invasion efficacy of Mohs paste samples were similar after storage at −20, 4, or 25°C, as in controls.

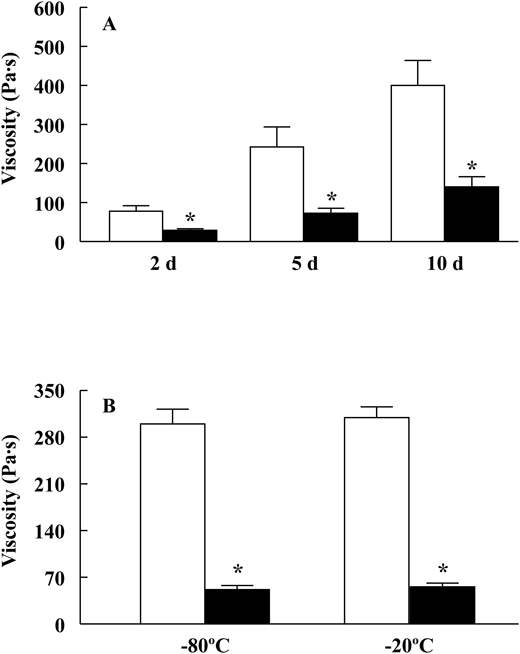

Changes in viscosity (Fig. 4) and tissue invasion (Fig. 5) of Mohs paste were measured after long-term storage under refrigeration and cryopreservation conditions and kneading. After refrigeration and kneading, the viscosity of Mohs pastes gradually increased with time, exceeding 100 Pa·s 10 d after preparation (Fig. 4A). In contrast, the viscosity of Mohs pastes remained at approximately 50 Pa·s after refrigeration for 7 months (Fig. 4B). Tissue invasion by Mohs paste did not correlate with viscosity and did not differ significantly between control pastes and pastes stored at −20, 4, and 25°C (Fig. 5).

(A) Changes in viscosity of Mohs paste after storage at 4°C for 2–10 d; (B) changes in viscosity of Mohs paste after storage at −80 and −20°C for 7 months; open column, Mohs paste without kneading (non-kneaded Mohs paste); closed column, Mohs paste with kneading; data are presented as means ± S.E. of three to five experiments; * p < 0.05 vs. non-kneaded Mohs paste in each storage category. Solidification of Mohs paste during long-term storage was attenuated when stored at −80 and −20°C. After storage under these temperature conditions for 7 months, viscosity of Mohs paste remained <70 Pa·s.

Mohs paste samples were stored at −20, 4, and 25°C for 7 months and kneaded before the application. Digital image (A), depth (B), and area (C) of skin tissues treated with Mohs paste for 2 h; control, Mohs paste immediately after preparation. Data are presented as means ± S.E. of three experiments. Assessments of tissue invasion show no significant differences between control samples and those stored at −20, 4, or 25°C.

Mohs paste is useful for controlling exudates from wounds and infections and is used to treat inoperable skin tumors. Long-term storage of Mohs paste that retains a suitable viscosity is expected to be of immediate use to patients; however, viscoelasticity and malleability of Mohs paste change rapidly after preparation. Using the current standard procedure, the paste is kneaded prior to use, though this technique using paste stored at room temperature does not restore viscosity to that immediately after preparation. Long-term storage is thus hindered, and, in response to concerns of Japanese clinicians, studies aimed at extending storage times for Mohs paste without loss of utility have been undertaken.8,10,11) In this study, the effects of different storage temperatures and kneading on the viscosity and efficacy of Mohs paste are reported. Data indicate that storage using a combination of cryopreservation and kneading preserves the usability and efficacy of paste for controlling exudates.

Tissue fixation using Mohs microscopic surgery was developed by Mohs, yet the formulation was not popular in Japan because some components were difficult to obtain. Instead, zinc oxide starch powder is adopted, and this modified formulation is termed Mohs paste.3,6) Accordingly, Mohs paste was prepared using zinc oxide starch powder (Table 1). Changes in properties of this paste were evaluated over time. Initially, changes in weight and viscosity were addressed. Mohs paste solidified within 5 h of preparation, with a viscosity of approximately 700 Pa·s (Fig. 1). This hardening was attenuated by refrigeration and cryopreservation (Fig. 2).

Zinc chloride forms 1.5 and 2.5 hydrates at 26 and 13°C, respectively, and trihydrates and tetrahydrates at 7 and −30°C, respectively.12) After storage at −20°C, the viscosity of Mohs paste was significantly lower than that after storage at 25°C, suggesting a correlation between hydration number and viscosity. Hence, low storage temperatures likely prevent hardening of Mohs paste through an increase in hydration of zinc oxide, although further study is required to elucidate the relationship between hydration and viscosity.

Glycerin is often used to optimize the viscosity of Mohs paste prior to clinical application. However, in the absence of indicators of viscosity, this method requires experience and skill. Hence, an easier method for controlling the viscosity of Mohs paste is awaited by clinicians.10)

Fluid characteristics are broadly classified as Newtonian and non-Newtonian, and non-Newtonian fluids are classified as plastic, quasi-plastic, quasi-viscous, and dilatant. Herein, viscosity of Mohs paste is reported under low shear stress. However, shear velocity increased along with shear stress and viscosity of Mohs paste also decreased with such stress (Fig. 2). Hence, Mohs paste can be classified as a quasi-plastic fluid, for which viscosity can be decreased by physical manipulation, such as kneading.

Given the observed changes to physical properties of Mohs paste, viscosity of Mohs paste can be preserved after long-term storage using the combination of temperature control and kneading. Data show that viscosity was approximately 50 Pa·s after 7 months of cold storage and kneading (Fig. 4). Viscosity and handling of such pastes are the same as these properties in pastes immediately after preparation. A combination of temperature control and kneading can, thus, make long-term storage of Mohs paste feasible.

In clinical use, the amount of tissue invasion by Mohs paste is central to its therapeutic usefulness. Specifically, blood vessels under tissue are damaged by deep tissue, yet weak tissue invasion fails to produce the desired effects. Therefore, tissue invasion after long-term cryopreservation and kneading was assessed. The selection of an appropriate model for evaluating tissue invasion is important. In a previous study, Sato et al. evaluated the therapeutic effect of Mohs paste by using chicken breast meat.13) Thus, Mohs paste was stored for 7 months, kneaded, and then applied to chicken breast meat as described by Sato et al.13) Tissue invasion of Mohs paste did not differ significantly between control pastes used immediately after preparation and pastes stored at −20, 4, or 25°C for 7 months (Fig. 5). Reportedly, tissue invasion of Mohs paste follows after ionization of zinc chloride by moisture in tumor tissues. Zn ions then lead to protein aggregation and hardening of the tissues (tissue invasion).14) Thus, Mohs paste can be used after long-term storage. Further, no relationship exists between viscosity and the ionization state of zinc chloride. Further study is necessary to confirm therapeutic efficacy in multiple cancer patients.

In conclusion, cryopreservation and kneading can alleviate problems of long-term storage of Mohs paste. This study provides important information for clinicians for long-term storage and usability of Mohs paste.

The authors declare no conflict of interest.