- |<

- <

- 1

- >

- >|

-

2023 年 63 巻 5 号 p. Cover-

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセスPDF形式でダウンロード (406K) -

2023 年 63 巻 5 号 p. Editorial-

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセスPDF形式でダウンロード (824K) -

2023 年 63 巻 5 号 p. Contents-

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセスPDF形式でダウンロード (205K)

-

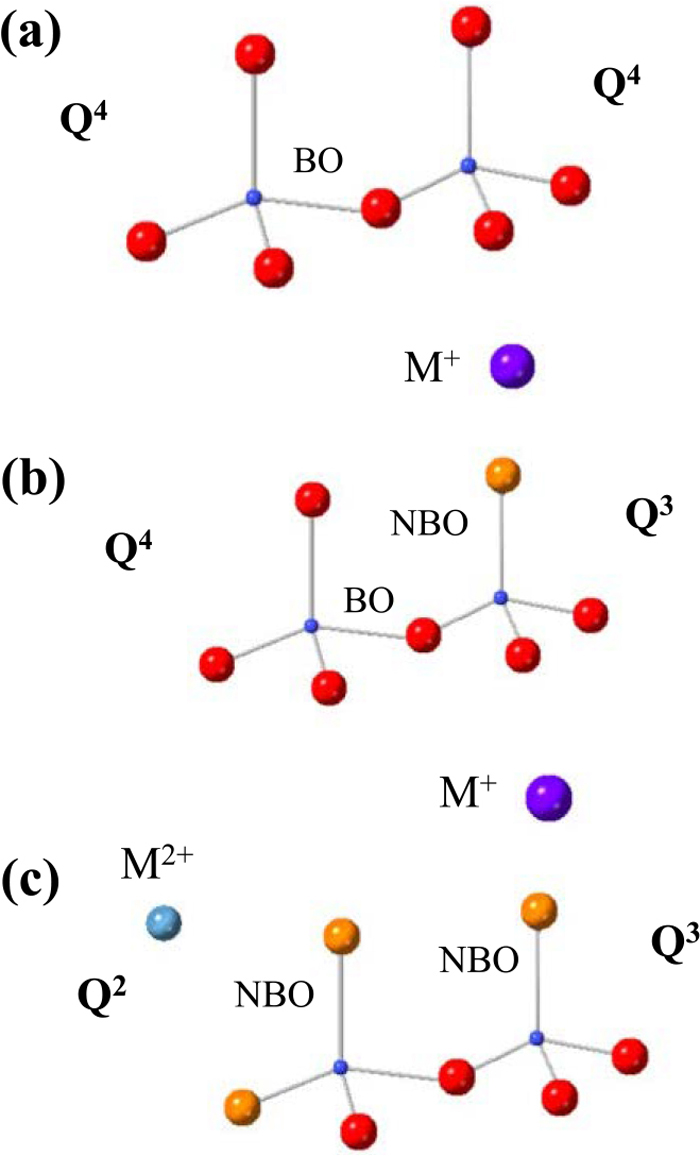

Shigeru Suzuki, Sohei Sukenaga, Tsuyoshi Nishi, Kozo Shinoda, Hiroyuki ...原稿種別: Review

2023 年 63 巻 5 号 p. 767-778

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLRecent structural-analysis research was reviewed for characterizing multicomponent melts and glasses processed at high temperatures. Multicomponent melts and glasses are often formed in slags during pyrometallurgical processing and the vitrification of highly radioactive wastes from nuclear power plants. Melt and glass physical properties were interpreted based on structural analyses using different methods. For example, the viscosities of different molten-silicate compositions were explained based on Raman and magic-angle-spinning magnetic resonance (MAS NMR) spectra. In addition, the thermal conductivities of multicomponent vitrified glasses were examined based on the structures elucidated using MAS NMR spectroscopy. X-ray absorption spectroscopy, which provides information about element chemical states, is used to analyze the local structure around specific elements in both melts and glasses. These studies show that structural analysis methods provide important information for designing and controlling melts and glasses processed at high temperatures. The structures characterized using different analysis methods were presented to elucidate the physical properties of multicomponent melts and glasses processed at high temperatures and propose prospects and directions for further research of process-oriented methods.

抄録全体を表示PDF形式でダウンロード (1200K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1200K) HTML形式で全画面表示

-

Ji Zhang, Lifeng Zhang, Qiang Ren, Jinzhen Hu原稿種別: Regular Article

2023 年 63 巻 5 号 p. 779-790

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLLaboratory experiments were performed to study the pitting process induced by different kinds of inclusions in stainless steels with and without cerium. When the content of total cerium in the stainless steel increased from 0 to 430 ppm, the evolution path of inclusions in the stainless steel was Al2O3–SiO2–MnO(–CaO)–MnS → Ce–Al–Si–Ca–O–S → homogeneous Ce–O–S → heterogeneous Ce–O–S. Immersion test was performed and morphologies of pits induced by different types of inclusions were observed. The dissolution sequence was Ce–O phase in heterogeneous Ce–O–S and MnS → homogeneous Ce–O–S, Ce–S phase in heterogeneous Ce–O–S and steel matrix → Ce–Al–Si–Ca–O–S → Al2O3–SiO2–MnO(–CaO). A corrosion index was defined to compare the corrosion resistance of the steel matrix around inclusions. Besides, first-principles calculations of related inclusions were performed to clarify the mechanism of pitting corrosion induced by different kinds of inclusions in the stainless steel.

抄録全体を表示PDF形式でダウンロード (4236K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (4236K) HTML形式で全画面表示 -

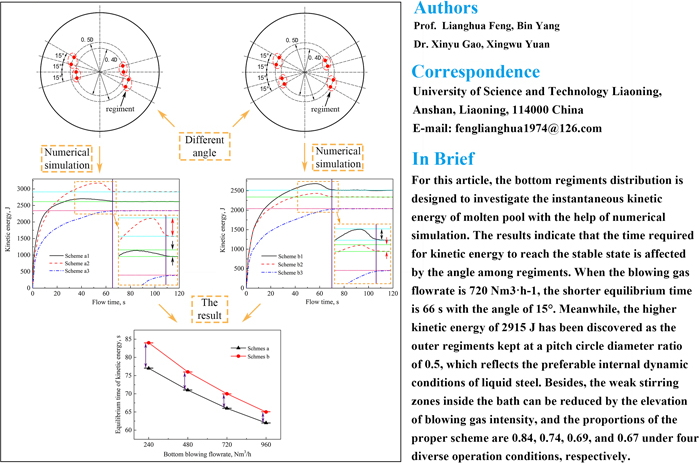

Xinyu Gao, Lianghua Feng, Xingwu Yuan, Bin Yang原稿種別: Regular Article

2023 年 63 巻 5 号 p. 791-798

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLFor this article, the bottom regiments distribution is designed to investigate the instantaneous kinetic energy of molten pool with the help of numerical simulation. The results indicate that the time required for kinetic energy to reach the stable state is affected by the angle among regiments. When the blowing gas flowrate is 720 Nm3·h−1, the shorter equilibrium time is 66 s with the angle of 15°. Meanwhile, the higher kinetic energy of 2915 J has been discovered as the outer regiments kept at a pitch circle diameter ratio of 0.5, which reflects the preferable internal dynamic conditions of liquid steel. While the molten pool can get enough stirring force, and the outer cluster should not be arranged closely to the furnace wall to avoid unnecessary energy dissipation. Besides, the weak stirring zones inside the bath can be reduced by the elevation of blowing gas intensity, and the proportions of the proper scheme are 0.84, 0.74, 0.69, and 0.67 under four diverse operation conditions, respectively.

抄録全体を表示PDF形式でダウンロード (1534K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1534K) HTML形式で全画面表示 -

Takayuki Iwama, Ryo Inoue, Kenji Nakase, Shigeru Ueda原稿種別: Regular Article

2023 年 63 巻 5 号 p. 799-809

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLIt is expected that phosphorus-concentrated slag produced by using the pyro-reaction between high phosphorus hot metal, which was prepared by the reduction of usual steelmaking slag with a small amount of hot metal, and oxidizing slag can become an important phosphorus resource instead of phosphate rock. For separating phosphorus from the phosphorus-concentrated slag, the citric acid leaching method has been reported to be available. In this study, the effects of cooling condition and oxidation treatment of phosphorus-concentrated slag on the dissolution behaviors of phosphorus and other elements were discussed. Compared to slow-cooled slag, CO2 blowing-quenched slag did not affect dissolution of phosphorus but decreased dissolution of iron. Oxidation treatment increased the dissolution ratio of phosphorus by about twice and decreased that of iron by one-sixth. It was confirmed by the microscopic analysis of the mineral phases in these slags that the concentration of SiO2 and FeO solid-solved in 3CaO·P2O5 (C3P) phase increased by slow cooling, and they precipitated as fine Fe2O3–SiO2 compound in C3P phase by oxidation. Furthermore, the dissolution behavior of SiO2 and FeO solid-solved in C3P phase was investigated. Experimental results showed that the C3P–2CaO·SiO2 dissolved easily and the C3P–3FeO·P2O5 dissolved hardly. From those experimental findings, it was presumed that the change in dissolution behavior due to slag cooling conditions and oxidation treatment were attributed to the concentration of SiO2 and FeO in C3P phase.

抄録全体を表示PDF形式でダウンロード (2648K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (2648K) HTML形式で全画面表示 -

Venkat Arunchaitanya Gadi, Govind Sharan Gupta原稿種別: Regular Article

2023 年 63 巻 5 号 p. 810-821

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLIn many systems, the liquid flows in discrete rivulet/droplet form rather than continuous in non-wetting or low liquid flow rate conditions. A discrete liquid flow (DLF) theory has been used by a few researchers to describe these systems such as Ironmaking blast furnace. A few investigators have applied the discrete flow of liquid in structured packing where the particles are arranged in a particular pattern where void size and shape are fixed. However, in the real world, the packing system is random, for which the DLF theory has not been extended/verified. Also, DLF theory has not been verified for 2D structural packing in the absence of gas flow rigorously. In this article, this theory is not only validated for structural packing in the absence of gas flow but also extended and validated for 2D random packing. Random packing has been created using the Discrete Element Method. The void size and shape are determined using a novel graph-based algorithm in the random 2D bed to study the liquid flow. The liquid flow behaviour has been studied in various conditions, like changing the packing size and bed height. This study confirms that the bed topology plays an important role in dictating the liquid flow behavior in a randomly packed bed.

抄録全体を表示PDF形式でダウンロード (1547K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1547K) HTML形式で全画面表示 -

Kosuke Awaya, Domu Mitsuyama, Kazushi Tamaki, Keijiro Saito, Yoshiaki ...原稿種別: Regular Article

2023 年 63 巻 5 号 p. 822-827

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLThe knowledge of sulfide capacities of FeO-containing slags is necessary for better understanding the resulfurization reaction in hot metal pre-treatments. In this study, copper-iron-sulfur liquid alloy was equilibrated with CaO–SiO2–FeO ternary slag to measure sulfide capacities and FeO activities simultaneously at temperature below the melting point of pure iron. The experimental result that the sulfide capacity increased with increasing FeO content could be explained by the fact that FeO was a basic oxide, and the sulfide capacity of the CaO–SiO2–FeO ternary system was significantly larger than those of the CaO–SiO2–MgO, CaO–SiO2–AlO1.5 and CaO–SiO2–CaF2 ternary systems. Although the FeO activity and oxygen potential were raised by the FeO addition, the calculated value for sulfur distribution ratio between CaO–SiO2–FeO slag and hot metal increased with an increase in FeO content.

抄録全体を表示PDF形式でダウンロード (745K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (745K) HTML形式で全画面表示

-

Yong Deng, Ran Liu, Dequan Wang, Kexin Jiao, Yanjun Liu, Ziyu Guo, Sai ...原稿種別: Regular Article

2023 年 63 巻 5 号 p. 828-834

発行日: 2023/05/15

公開日: 2023/05/16

[早期公開] 公開日: 2022/10/31ジャーナル オープンアクセス HTMLThe state of deadman in hearth is important for the long campaign life of blast furnace (BF). In order to clarify the influence of deadman on sidewall erosion, the corresponding relationship between the shape of deadman and sidewall erosion was studied, the fundamental reason for the difference of sidewall erosion was analyzed, the influence mechanism of slag-coke interface and iron-coke interface on the coke in deadman was explored based on the phase distribution in deadman. The results show that: The shape of circumferential bulge at the root of deadman is a common feature of BFs, this feature is the main reason for the serious erosion of sidewall, and the serious erosion area of sidewall corresponds to the root position of deadman. The deadman shows a dynamic evolution law of sinking and floating under the action of force in the smelting process of BF, the depth of slag and iron level in hearth has the greatest influence on the deadman. The difference of central voidage of deadman is the fundamental reason for the difference of sidewall erosion for BFs in which the deadman is in the same floating state. Slag-coke interface and iron-coke interface commonly exist in hearth. The dissolution reaction at iron-coke interface makes carbon in coke continuously migrate into molten iron, which makes the graphitization degree of coke increase, the coke is easy to pulverize, this is the main mechanism of coke deterioration and renewal in deadman. The enrichment of harmful element K at slag-coke interface makes the coke expand and crack, the coke matrix is easier to peel off, which accelerates the deterioration process of coke.

抄録全体を表示PDF形式でダウンロード (1310K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1310K) HTML形式で全画面表示 -

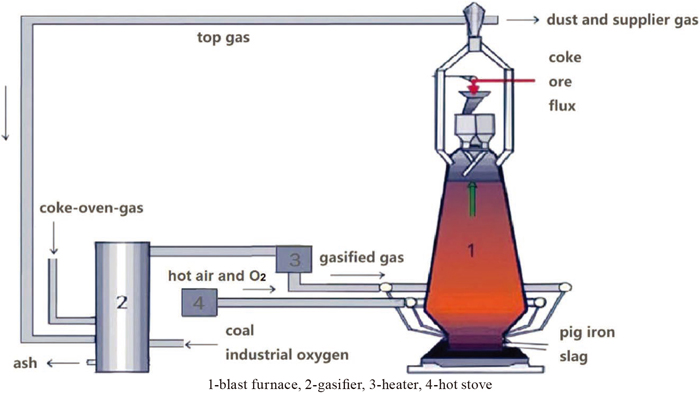

Jianpeng Li, Xiaojie Liu, Xin Li, Qing Lyu, Yana Qie原稿種別: Regular Article

2023 年 63 巻 5 号 p. 835-845

発行日: 2023/05/15

公開日: 2023/05/16

[早期公開] 公開日: 2023/02/13ジャーナル オープンアクセス HTMLFor the blast furnace iron-making process which depends on the coke seriously and is the largest CO2 emission source in iron and steel industry, a novel technology integrated the blast furnace process and co-gasification of coal-COG-BF top gas is investigated and examined its potential of energy conservation and CO2 emission reduction. The mathematical model of the whole integrated process is established based on mass and heat balance principles. And typical operation analyses for the integrated process are demonstrated by this model. The results indicate that it takes about 4 times for the unsteady process caused by the recycling of BF top gas to reach steady. Compared with conventional blast furnace process, the coke ratios in two integrated process cases selected decrease by 33.5 kg/tHM and 81.3 kg/tHM obviously, and the fuel ratios decrease 1.1% and 8.2% due to the increase of coal ratios by 27.9 kg/tHM and 39.1 kg/tHM. The energy consumption decreases by 8.3% and 10.8%. And the CO2 emission decreases by 37.0% and 42.9%.

抄録全体を表示PDF形式でダウンロード (1699K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1699K) HTML形式で全画面表示

-

Wenliang Dong, Anjun Xu, Changliang Zhao, Chenxi Ji, Haibo Li, Ning Ha ...原稿種別: Regular Article

2023 年 63 巻 5 号 p. 846-853

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLIn the current study, the reaction behavior between bottom blowing CO2 and the molten steel at different converter stages was studied by the thermodynamic calculation. At the initial stage, CO2 reacts with [C] before the turning point and then reacts with [C] and [Si] simultaneously after that. CO2 completely reacts with [C] and twice volume of CO generates at the middle stage. The reaction ratio of CO2 and [C] gradually decreases at the final stage due to the ratio of CO2 reacting with [Fe] and the residual unreacted CO2 increases. Then the effect of the bottom blowing gas type and intensity on the [C]·[O] value and T.Fe content in the slag were studied by industrial trials in a 300 t converter. When Ar is blown at the final stage, the CO partial pressure decreases with the increasing of the bottom blowing intensity, while the opposite result is obtained when blowing with CO2. The CO2 bottom blowing into the converter should be switched with Ar, and the blowing time of CO2 should be controlled in the early 12 minutes to avoid increasing the [C]·[O] value and the T.Fe content in the slag. In order to improve the reaction rate of CO2 and [C], it is necessary for the CO2 to be blown during the high-speed decarburization period when the [C] content is between 0.7 mass% and 3.3 mass% and the bottom blowing time is between 5 and 12 minutes.

抄録全体を表示PDF形式でダウンロード (1198K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1198K) HTML形式で全画面表示

-

Guangda Bao, Ting Wu, Jianghua Qi, Wen Yang, Haichuan Wang原稿種別: Regular Article

2023 年 63 巻 5 号 p. 854-861

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLTo obtain aluminate-based mold fluxes with appropriate performances for continuous casting of high-aluminum steel, the effects of Na2O and K2O contents on the structure and properties of aluminate slag with various CaO/Al2O3 (C/A) were investigated using Fourier transform infrared and Raman spectroscopy, hemispheric melting point instrument, rotational viscometer and X-ray diffraction. It is concluded that with Na2O and K2O addition, the polymerization degree, viscosity at 1300°C and break temperature of aluminate slag first declined and then grew at C/A ratio of 1.1 since Al2O3 changed from a basic oxide to an acidic oxide, and the transition points corresponding to Na2O and K2O contents were 6 wt% and 2 wt%, respectively, while they reduced continuously at C/A=1.3 due to Na+ and K+ augment evolved the complex anionic group into a simple structure with Al2O3 acting as an acidic oxide. Combing the melting temperature and structural evolution, it demonstrated that the structure polymerization plays a predominant role in effecting the viscosity at 1300°C. The crystallization ratio increased with Na2O and K2O enhancement, especially when their contents exceed 6 wt% at C/A=1.1 and 4 wt% at C/A=1.3, because of peak intensities of crystals CaF2 and Ca2Al2SiO7 increased and new phase of Na(AlSi3O8) and K(AlSi3O8) precipitated.

抄録全体を表示PDF形式でダウンロード (5644K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (5644K) HTML形式で全画面表示 -

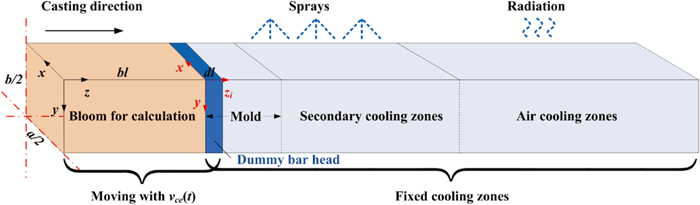

Jian Yang, Zhi Xie, Hongji Meng, Zhenwei Hu, Wenhong Liu, Zhenping Ji原稿種別: Regular Article

2023 年 63 巻 5 号 p. 862-869

発行日: 2023/05/15

公開日: 2023/05/16

[早期公開] 公開日: 2023/02/13ジャーナル オープンアクセス HTMLIn this paper, a specially designed three dimensional transient heat transfer model has been developed for initial stage of steel continuous casting process. Firstly, a general three dimensional heat transfer model for continuous casting process has been established, and it is discretized by finite volume method and solved by alternative direction implicit method. For transient simulation of initial stage, the fixed-length moving bloom with dummy bar at its bottom experiences time-variant boundary conditions, while the filling process is also equivalent to moving process. Secondly, the transient model has been calibrated by surface temperature measurements by pyrometer and shell-thickness measurements by nail-shooting. Online temperature measurement for verification indicates the calibrated model is reliable as the maximum error between calculations and measurements are within ±28°C, and soon in less than 80 s the error will be reduced to within ±5°C. Thirdly, uncertainty caused by dummy bar’s length and thermo-physical properties has been studied, and the results indicate that the uncertainty is quite small and acceptable. Finally, the model has been applied to optimizing the secondary cooling water flows and cut length of strand head.

抄録全体を表示PDF形式でダウンロード (1809K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1809K) HTML形式で全画面表示 -

Qiang Gu, Hongxia Li, Guoqi Liu, Weikui Ma, Feixiang Ma原稿種別: Regular Article

2023 年 63 巻 5 号 p. 870-879

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLNegative pressure inside submerged entry nozzle (SEN) during continuous casting process will cause the external air to enter the SEN to cause the secondary oxidation of the molten steel and accelerate the SEN clogging. Based on it, this paper innovatively designed an Al2O3 clogging experimental method under near working conditions, and verified its feasibility. Compared with the existing experimental methods, this new experiment method stimulates the working conditions, ensures the stable source, content, and size of Al2O3 inclusions around specimens. The new test method is used to determine that that the calcium stabilized ZrO2 lining had the better anti-clogging effect.

抄録全体を表示PDF形式でダウンロード (2433K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (2433K) HTML形式で全画面表示

-

Chunyang Shi, Shiyu Guo, Jin Chen, Ruxin Zhong, Baoshuai Wang, Peng Su ...原稿種別: Regular Article

2023 年 63 巻 5 号 p. 880-888

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLBreakout is one of the hazardous industrial accidents in continuous casting production, which has adverse effects on operational stability, product quality, personal safety and equipment life. Therefore, the study of the breakout prediction model is of great significance. A hybrid intelligent algorithm is proposed based on twin support vector machine of improved whale optimization (LWOA-TSVR) by introducing the Levy flight algorithm. It uses the LWOA algorithm to solve the optimization problem of the objective function in the TSVR algorithm, so as to obtain a new breakout prediction model. The simulation and industrial trials results show that the model has higher recognition accuracy than the traditional detection method, and can predict all the breakout signals accurately and timely. Five advanced algorithms are compared to further verify the performance of the model. The results prove that LWOA-TSVR has the advantages of fast convergence speed and high prediction accuracy compared with the other four algorithms. The model is applied to the practical production of a steel mill. Finally, the reported ratio of the model is 100% and the prediction accuracy is 98.2%, which is found to be more effective than the practical application system used in continuous casting production. Hence, this model provides a theoretical basis for breakout detection technology.

抄録全体を表示PDF形式でダウンロード (1402K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1402K) HTML形式で全画面表示

-

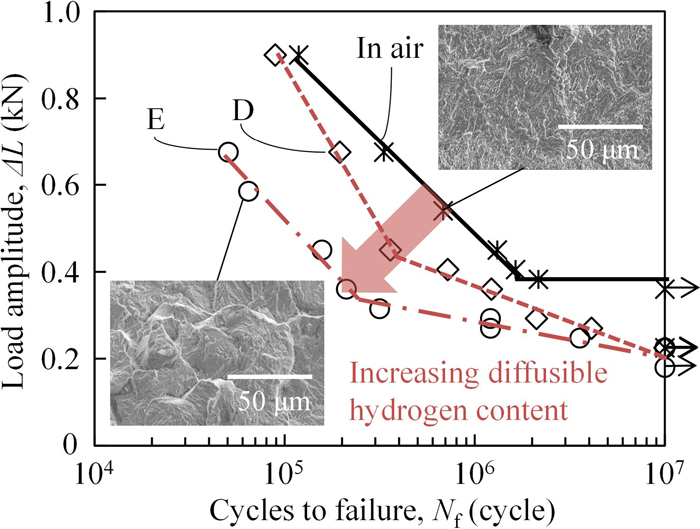

Gaku Kitahara, Takashi Asada, Hideaki Matsuoka原稿種別: Regular Article

2023 年 63 巻 5 号 p. 889-898

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLSpot-welded advanced high-strength steel (AHSS) sheets are used to decrease car body weight and enhance crashworthiness simultaneously. Such welds are susceptible to hydrogen embrittlement, but research in this area is limited. We have evaluated the hydrogen embrittlement properties of spot welds fabricated with AHSS sheets and clarified the dependence of diffusible hydrogen content and tensile rate on tensile shear strength. However, the performance of spot welds must be evaluated not only by static testing such as tensile shear tests but also by dynamic fatigue testing. Herein, we investigated the effects of diffusible hydrogen on their fatigue life via tensile–shear fatigue tests under cathodic hydrogen charging. The number of cycles to failure and the endurance limit decreased with diffusible hydrogen content. The number of cycles to failure decreased as the constant amplitude-loading frequency declined. The intergranular cracking is more likely to occurs as the amount of diffusible hydrogen increases and as the frequency decreases. These results are explained by hydrogen accumulation and crack growth behavior caused by mechanism for hydrogen-enhanced local plasticity and hydrogen enhancement of the strain-induced generation of vacancies mechanism. Furthermore, the correlation between static testing and dynamic fatigue testing was investigated, and the relationship between fatigue strength and the amount of diffusible hydrogen was in good agreement with the diffusible hydrogen dependence of tensile shear strength obtained from slow rate tensile shear tests under hydrogen charging.

抄録全体を表示PDF形式でダウンロード (3596K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (3596K) HTML形式で全画面表示

-

Naoki Maruyama, Miyuki Yamamoto, Shinichiro Tabata原稿種別: Regular Article

2023 年 63 巻 5 号 p. 899-909

発行日: 2023/05/15

公開日: 2023/05/16

[早期公開] 公開日: 2023/02/20ジャーナル オープンアクセス HTMLTo elucidate the mechanisms of deformation and a state of plastic stability at the front of Lüders bands during a tensile test, metastable austenitic transformation-induced plasticity (TRIP) steels with different dislocation densities and ferritic steels were characterized via macroscopic-DIC-based stress–strain investigations and scanning electron microscopy (SEM). A direct correlation between stress–strain curves and measured strain distributions in the tensile specimen indicated that the Lüders front represents a transition region from a state of plastic instability to one of stability, whereby a general rule relating the Lüders strain (

) and increments in the true stress in the Lüders band (

) and increments in the true stress in the Lüders band ( ) to a lower yield stress (

) to a lower yield stress ( ) can be described as

) can be described as  irrespective of the amount of deformation-induced martensite in the band or crystal structure of the steel. The inclination angle of the Lüders front with respect to the tensile direction changed from 55° to 90° with a reduction in the measured strain ratio (−εyy/εxx) in the Lüders band, and the change agreed with the tendency calculated by the plasticity model, assuming the pure shear occurs under the minimum shear strain criterion. SEM observations of the sheet surface and the front cross-section in the TRIP steel showed the formation of multiple inclined ~20 µm-wide shear deformation zones that accompanied a reduction in thickness. All the observed geometrical characteristics of the Lüders front were qualitatively described by a mechanism involving minimizing the misalignment from the fixed tensile axis caused by ‘shear’ deformation.

irrespective of the amount of deformation-induced martensite in the band or crystal structure of the steel. The inclination angle of the Lüders front with respect to the tensile direction changed from 55° to 90° with a reduction in the measured strain ratio (−εyy/εxx) in the Lüders band, and the change agreed with the tendency calculated by the plasticity model, assuming the pure shear occurs under the minimum shear strain criterion. SEM observations of the sheet surface and the front cross-section in the TRIP steel showed the formation of multiple inclined ~20 µm-wide shear deformation zones that accompanied a reduction in thickness. All the observed geometrical characteristics of the Lüders front were qualitatively described by a mechanism involving minimizing the misalignment from the fixed tensile axis caused by ‘shear’ deformation. 抄録全体を表示PDF形式でダウンロード (1890K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1890K) HTML形式で全画面表示 -

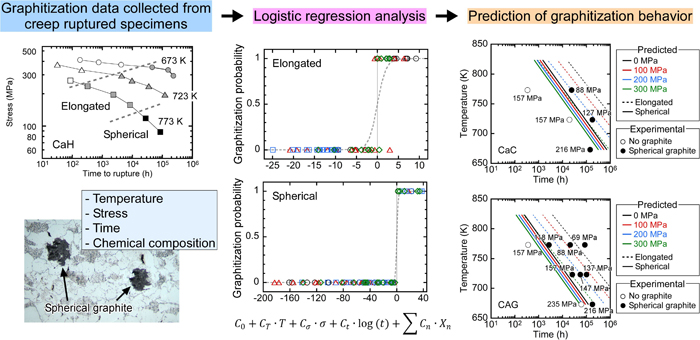

Tomotaka Hatakeyama, Kaoru Sekido, Kota Sawada原稿種別: Regular Article

2023 年 63 巻 5 号 p. 910-918

発行日: 2023/05/15

公開日: 2023/05/16

[早期公開] 公開日: 2023/02/13ジャーナル オープンアクセス HTMLCarbon steels with ferrite and pearlite microstructures suffer from graphitization by the decomposition of cementite when exposed to elevated temperatures for long periods. Graphitization degrades the mechanical properties of the steels and increases its risk of failure. Therefore, by considering the extended life span of a thermal power plant, where carbon steels are used at elevated temperatures, evaluation of graphitization risk is necessary. This study evaluates the effect of temperature, stress, time, and chemical composition for both elongated and spherical graphitization using logistic regression of previously reported graphitization conditions in long-term creep ruptured specimens and establishes a prediction formula for graphitization occurrence. In addition, the accuracy of the prediction formula was validated by investigating the graphitization behavior of other carbon steels.

抄録全体を表示PDF形式でダウンロード (1649K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1649K) HTML形式で全画面表示 -

Kohichi Isobe, Yuga Kumagai, Takumi Satou原稿種別: Regular Article

2023 年 63 巻 5 号 p. 919-929

発行日: 2023/05/15

公開日: 2023/05/16

[早期公開] 公開日: 2023/02/13ジャーナル オープンアクセス HTMLTo optimize reverse transformation treatment, which is effective in preventing hot rolling cracking in the CC-HCR (Continuous Casting - Hot Charge Rolling) process, three-dimensional metallo-thermo-mechanical analyses were performed. The metallo-thermo-mechanics and a CCT (Continuous Cooling Transformation) diagram estimation method using JMatPro were used to obtain the required cooling time for reverse transformation in immersion cooling with water jet and to elucidate the effects of nonuniform cooling and γ grain size on thermal deformation and stress generation behaviors during cooling and the mechanisms of these events.

These analyses clarified the following. When diffusion-controlled transformation occurs during cooling, the required cooling time increases as Dγ (Diameter of γ grain) increases, and becomes substantially constant when only martensitic transformation occurs. In addition, the difference of Dγ causes a difference in the type of transformation that occurs during cooling and the temperature range where transformation occurs during cooling, and these differences produce differences in the amount of transformation expansion, which greatly affects the bloom deformation behavior during cooling. Furthermore, there is a difference in the level of the maximum generated stress during cooling depending on whether the transformation that occurs near the bloom surface layer during cooling is diffusion-controlled transformation or martensitic transformation. In addition, this difference in transformation behavior also causes a difference in the mechanism of maximum stress generation.

抄録全体を表示PDF形式でダウンロード (1597K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1597K) HTML形式で全画面表示

-

Vinit Kumar Singh, Radhakanta Rana, Shiv Brat Singh, Amrita Kundu原稿種別: Regular Article

2023 年 63 巻 5 号 p. 930-940

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLThe microstructural modification and the effect of cold/warm rolling and annealing on tensile properties of ferritic low density steels containing different amounts of carbon (0.0035 mass%, Steel 1 and 0.04 mass%, Steel 2) and aluminium (6.8 mass%, Steel 1 and 9.7 mass%, Steel 2) were investigated with respect to amount of ferrite, grain size and formation of Fe3Al intermetallic. The Steel 1 was deformed by cold rolling at room temperature and Steel 2 was deformed through warm rolling at 250°C to avoid prior cracks formation. After rolling, samples of Steels 1 and 2 were annealed at 900°C for 5 minutes. The yield strength, ultimate tensile strength and ductility increase while yield ratio decreases with annealing. This is due to formation of Fe3Al intermetallic and reduction of ferrite grain size. Due to high interstitial Carbon in Steel 2, yield point phenomenon was observed which may reduce the formability of the steel. The cracks started during tensile test at the ferrite grains and ferrite grain boundaries and the fracture took place in the quasi cleavage mode in Steels 1 and 2. The grain refinement and the microstructural features due to rolling and annealing are accountable for the good combination of strength and ductility of the both steels.

抄録全体を表示PDF形式でダウンロード (1916K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1916K) HTML形式で全画面表示 -

Takashi Matsuno, Nanami Kinoshita, Tomoko Matsuda, Yoshiaki Honda, Tak ...原稿種別: Regular Article

2023 年 63 巻 5 号 p. 941-949

発行日: 2023/05/15

公開日: 2023/05/16

ジャーナル オープンアクセス HTMLOne of the objectives for the development of high-strength dual-phase (DP) steel is improving the stretch-flangeability. Large-strained sheared edges are deformed and frequently cracked during stretch-flange formation. Considering shearing as the first deformation, the stretch-flange deformation may be regarded as a secondary deformation. To improve the stretch-flangeability of the DP steels, many researchers have analyzed the microvoid formation. However, in these analyses, the shearing process was not considered. With this background, ex-situ mini-bending tests combined with scanning electron microscopy (SEM) monitoring of microvoid formation were conducted during the secondary deformation. Prior to the secondary deformation, several microvoids were observed on the sheared surface and fine subgrains formed in the ferrite. During secondary deformation, the preliminary microvoids present at the ferrite-martensite interface propagated into the ferrite phase. In contrast, this behavior was not observed for the reamed surface deformation, which was formed without preliminary deformation. Furthermore, microvoids were initiated on ferrite grains that were not present at the ferrite-martensite interface, and martensite islands were not cracked during secondary deformation. This result is noteworthy because martensite cracking was the main factor involved in microvoid initiation, in the absence of shearing. Electron backscattering diffraction analysis revealed that the work hardening of ferrite, prior to the secondary deformation, caused a deviation in the strain concentration sites from those found in the reamed surface deformation. Therefore, this study elucidated microvoid formation on preliminary deformed surfaces via shearing and provided insights for material development considering deformations on the sheared surfaces of materials.

抄録全体を表示PDF形式でダウンロード (4237K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (4237K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|